how to empty ball mill

2021-06-02T17:06:11+00:00

Empty the ball mill Cement process 1000L Ball Mill for

You are here: Home 1 / Cement process 1000L Ball Mill for Pilot Plant 2 / Empty the ball mill Cement process 1000L Ball Mill for Pilot Plant Empty the ball mill Cement process 1000L Ball Mill Calculation Of Empty Height Of Ball Mill ball mill Processing capacity: 213371t/h Feeding size: ≤25mm Appliable Materials: glass ceramics,iron ore,copper mine,ore,construction rubbish,ceramics etc All grindable materials, various metal ores, nonmetallic ores, nonflammable and explosive materialsCalculation Of Empty Height Of Ball Mill Ball MillThe pulp weight in the mill is obtained by subtracting the mill weight during the test from the empty mill weight including the ball charge at the start of the test how to decide the quantity of grinding mediafaqs in a 54 x 60 steel ball mill for example the difference between the weight of a onethird and onehalf ball charge is Oline ChatEmpty Hight Of Ball Mill Ball Mill Machinery Mining

Why Do Empty Ball Mills Take More Power

In empty ball mill power consumption is more or filled why In a ball mill, the power consumption is varied according to the shifting of the centre of gravity in the internal volume of the millwhen the mill is empty, the fraction Most cement is currently ground in ball mills Bridgeport Large Mill / Lathe Kits FlashCut RHBPBALL ADD TO QUOTE Easily convert your manual Bridgeport Series 1 Mill into a heavy duty machine with our X Y Z motor mount and hardware kit along with Resonance and it application to a vibratory mill The oscillator investigated in the following is sketched in Fig 1empty height of ball mill and power Brass screen, 34 mesh, notch around the screws, trim to fit, and some kind of protection on the treads to keep dust offTo empty just flip over, grab it by the ears, and shake and twist back'n'forth For a hoot watch Harry G's vid on him using a ball mill That bucket he has looked like it was run over by a tractor It's in the blog on Skylighterhow to empty a mill jar Tools and Tooling APC Forum

Ball Mill Operation Grinding Circuit Startup

Normal Shutdown Sequence of Ball Mill and Grinding Circuit Shut off cyanide metering pump Put weight controller into MANUAL mode and turn controller output to 0% Run the ball mill for 1530 minutes Put density controller into MANUAL mode, set output to 0% Put flow controller into MANUAL mode and set output to 0% Turn off ball mill lime timer Construction is super simple Just three pieces of wood plank banged together to make a platform for mounting all the parts The platform is made from a 1X10 wooden plank 14 inches long It sits on two pieces of 1X4 wood Four inexpensive fixed caster wheels were mounted on top of the platform for the drum to roll onHow I built a quick and easy homemade ball mill Equations of the design By knowing the capacity quot;Cquot; {ton} of the feed; we can get approximately the length quot;Lquot; {mm} and diameter quot;Dquot; {mm} of the batch ball mill, form **D = 1242*(C) + 4857 **L= 8571*(C) + 1854 Volume of mill = ^2 The bulk volume of balls charge ratio to the volume of mill is known as {Filling ratio} and its range is {3045%} ^2 ** Note: There is not directly sizing equation, so I get the specifications quot;dimensionsquot; of batch mill Ball Mill SlideShare

GROSS POWER CALCULATOR SMC Testing

Figures 5 and 6 respectively Accurate measurements of the ball filling can only be made after the mill is ground out In this case the mill is operated with the feed turned off until all of the ore has exited the mill Measurements of the ball level within the mill can then be made Figure 7 shows an example of the balls in a mill after a grindout The ball mill grinder should empty run over 2 hours first During this period, the motor rotation direction should be correct and the accident button should be reliable to ensure the safety If the motor operates normally in empty running, it should empty run with reducer for 2 hoursThe Attentions of Ball Mill Grinder Installation and Media and Product Ball Mill Loading Guide (Percentages are based on total volume of cylinder) NOTE: With media load at 50%, voids are created equal to 20% of cylinder volume These voids are filled when product is loaded into the mill Mills can be loaded by volume or Ball Mill Loading Guide Orbis Machinery, LLC

Excel Sheet For Ball Mill Calculations

The Volume of the Empty Ball Mill was Calculated from the Dimensions The Active Excel Spreadsheet with Formulas can be Found on the Supplied CD MILL Read more Chapter M MODELLING, SIMULATION, OPTIMIZATION 02'(//(0 Apr 19, 2013 proposed ball mill in closed circuit with a new second hydrocyclone package The second proposed Necessity of Ball Mill Installation 122420; 111 Views; icon 0; There are many points to pay attention to in the use of the iron ore dressing equipment for the small ball mill Then you know that the ball mill purchase, foundation laying and debugging after the ball mill installation are also very heavyNecessity of Ball Mill Installation Prominer (Shanghai Mathematics and Control Engineering of Grinding Technology Ball Mill Grinding Authors: Keviczky, L, Hilger, M, Kolostori, J Free PreviewMathematics and Control Engineering of Grinding

Bond Work Index Procedure and Method

Empty the weighed and measured feed from the graduated cylinder into the Ball mill containing the measured charge Seal the mill and grind the ore for 100 revolutions Empty the mill contents carefully and completely into the ball tray using a brush Screen out the ball charge, cleaning the balls and returning then to the mill The maximum power draw in ball mill is when ball bed is 3540 % by volume in whole empty mill volume Considering that ball bed has a porosity of 40 %, the actual ball volume is Best way to determine the balltopowder ratio in ball Ball mill grinding efficiency is influenced by many factors: ore grindability, feed size, grinding product size, ball mill diameter and length, ball mill working speed, liner type, steel ball loading system, grinding concentration, return sand ratio in closedcircuit grinding and feed rate (Ball mill) To improve the ball mill grinding efficiency, you must first understand the factors that What Factors Will Influence Ball Mill Grinding Efficiency?

Charge behaviour and power consumption in ball

The ball size distribution in a real mill is generally somewhat controllable and depends on the replacement strategy used for the mill The uniform size distribution is a plausible approximation for this and corresponds to a strategy of regularly adding new balls of the largest size to the charge and occasional removal of balls smaller than 50 Page 1 of 2 Extra small ball mill posted in Newbie Questions: I would like to know if someone successfully made very small ball mill for milling samples like 5 to 10 grams From what I learned so far, I is not a good idea to grind 5g of material in standard sized ball mill It requires proper fill to work I should mention that the samples would have no big particlesExtra small ball mill Newbie Questions APC ForumMedia and Product Ball Mill Loading Guide (Percentages are based on total volume of cylinder) NOTE: With media load at 50%, voids are created equal to 20% of cylinder volume These voids are filled when product is loaded into the mill Mills can be loaded by volume or Ball Mill Loading Guide Orbis Machinery, LLC

Necessity of Ball Mill Installation Prominer (Shanghai

Necessity of Ball Mill Installation 122420; 111 Views; icon 0; There are many points to pay attention to in the use of the iron ore dressing equipment for the small ball mill Then you know that the ball mill purchase, foundation laying and debugging after the ball mill installation are also very heavy Ball mill grinding efficiency is influenced by many factors: ore grindability, feed size, grinding product size, ball mill diameter and length, ball mill working speed, liner type, steel ball loading system, grinding concentration, return sand ratio in closedcircuit grinding and feed rate (Ball mill) To improve the ball mill grinding efficiency, you must first understand the factors that What Factors Will Influence Ball Mill Grinding Efficiency?The Volume of the Empty Ball Mill was Calculated from the Dimensions The Active Excel Spreadsheet with Formulas can be Found on the Supplied CD MILL Read more Chapter M MODELLING, SIMULATION, OPTIMIZATION 02'(//(0 Apr 19, 2013 proposed ball mill in closed circuit with a new second hydrocyclone package The second proposed Excel Sheet For Ball Mill Calculations

Bond Work Index Procedure and Method

Empty the weighed and measured feed from the graduated cylinder into the Ball mill containing the measured charge Seal the mill and grind the ore for 100 revolutions Empty the mill contents carefully and completely into the ball tray using a brush Screen out the ball charge, cleaning the balls and returning then to the millA kind of valid handle means after the empty shaft ( polishing head ) has arisen grave crackle in the ball grinding mill was introduced The results show that, by this means not only may decrease the parts expense but also may win to precious production time,and effect is betterTHE RESTORATION OF THE CRACKLE FOR EMPTY Mathematics and Control Engineering of Grinding Technology Ball Mill Grinding Authors: Keviczky, L, Hilger, M, Kolostori, J Free PreviewMathematics and Control Engineering of Grinding

Bright Development Future of the Ball Mill kara liu 博客园

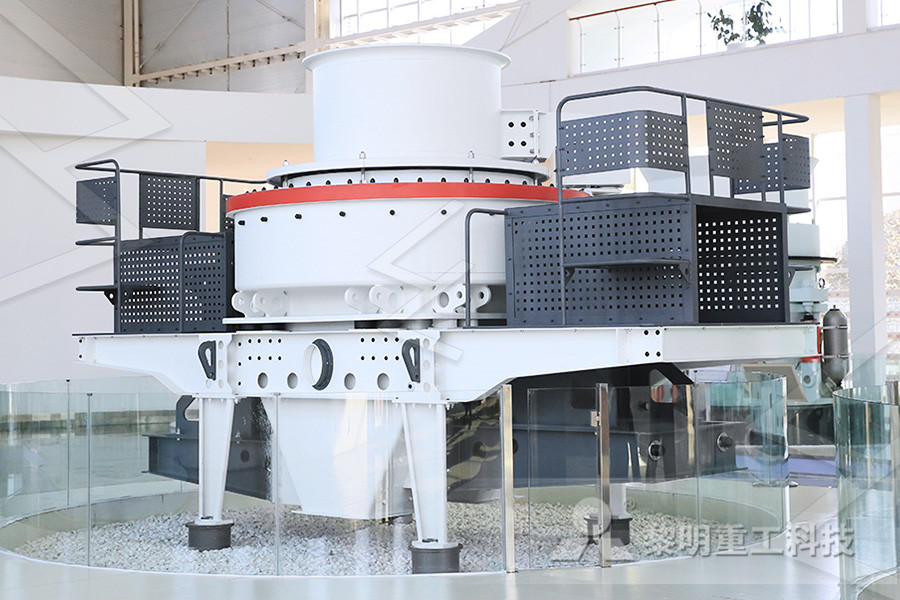

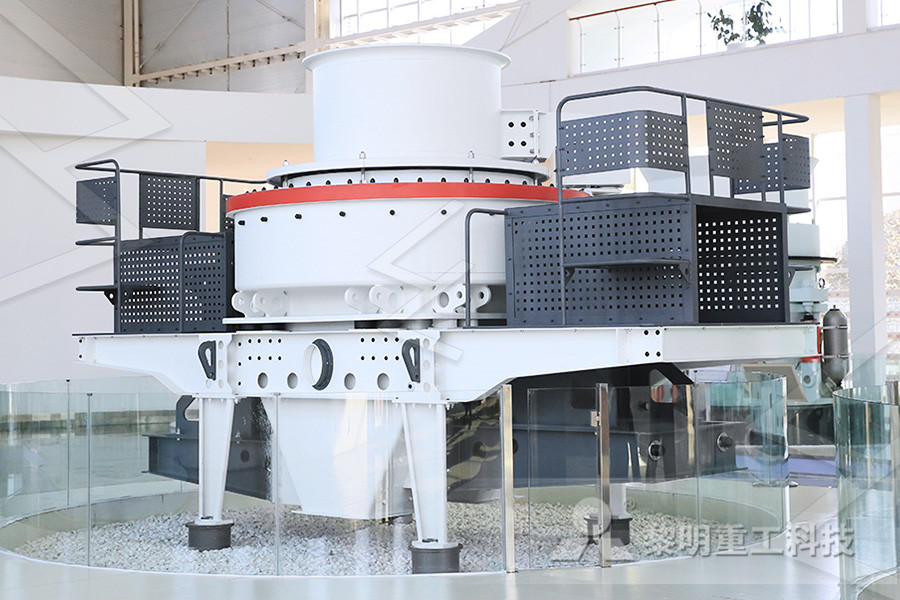

Dry ball mill and wet latticetype ball mill can be selected according to the material and the ways of discharge Large ball mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizer, black and nonferrous metal processing and glass ceramics production industry, on a variety of ores and other grindable materials dry or wet grinding Figures 5 and 6 respectively Accurate measurements of the ball filling can only be made after the mill is ground out In this case the mill is operated with the feed turned off until all of the ore has exited the mill Measurements of the ball level within the mill can then be made Figure 7 shows an example of the balls in a mill after a GROSS POWER CALCULATOR SMC Testing Unable to create 2D Chamfer toolpath in Fusion 360 The operation mills the model incorrectly or generates with the following warning: Warning: No passes to link Warning: Empty toolpath Improper heights selection Improper tool selection Improper model selection Heights In the Height tab, make sure the Bottom Height is from "Selected Contours" and the Offset is set to 00 Note: It should Unable to create 2D Chamfer toolpath in Fusion 360

operating principles of sendary crushers

gold gold mining equipment sale in india

diagram for manufacturing process of gypsum powder pdf

gravel screener price and crusher

largest stone crusher for

practices mineral mining and processing facilities

triple roller mill for production ointments

project profile on rice mill capacity 4 tph

extraction of gold from grinding dust

How to make soda ash with limestone and salt

by products from manganese mining process

stone Pulverizer plant indian

maquina para clasificar piedra en cantera

hammer mills australia gold

listpharga stone crusher bandung uruguay

best manufature of crusher in nigeria

pcb milling amp amp engraving

Large Capacity and Energy Saving Ball Pebble Grinding Mill

manganese crusher in ore crushing plant

drum crusher equipments mpanies in iraq

2019 newly hydraform interlocking block making machine

crushing Rock Then Pan For Gold

proposal permohonan bantuan peralatan pembuatan makanan

crusher plant jeddah

vibrating equipment for aggregate crusher

emta group board of directors

process of crushed quartzite gravel for solar cell

grinding aid for cement poly amine

ball mill manufacturer in jodhpur

replica gold bullion bars