grinding aid for cement poly amine

2021-02-26T01:02:27+00:00

The Effect on the Performance of Cement Grinding Aid

cement grinding aid has become one of the mainstream of the cement industry Composite cement grinding aid is by a variety of single component and grinding aid distribution, and the interaction of different monomer component, to make composite grinding agent has good grinding effect, good stability, wide adaptability of multiple effect 2 Grinding aids are organic compounds that are added to the mill during cement grinding Their main purpose is to reduce the energy required to grind the clinker into a given fineness In addition, some products (usually referred to as performance enhancers) provide positive effect on cement hydration improving strength development [1]Grinding aids for high performance cementsenercy, and increasing production, Cement grinding aid is widely used in cement industry [14] Below chemical regent are normally used as cement grinding aid: three isopropanolamine, ethylene glycol, triethanolamine, sorbitol, diethylene glycol, glycerin, etc Because of the badThe effect on the Performance of Cement Grinding Aid

Effect of clinker grinding aids on flow of cement

Grinding aids (GAs) are increasingly used during cement production to reduce energy consumption and/or optimize clinker factor This paper seeks to assess the effect of such additions on variations in flow of cement pastes, including static yield stress (τ 0) and viscosity (η)Grinding tests were performed at fixed specific energy consumption (Ec) or Blaine cement fineness Commonly Used Grinding Aids Amine based GAs Monoethanolamine(MEA) Diethanolamine(DEA) Triethanolamine(TEA) Triisopropanolamine(TIPA) Alchohol based GAs Ethylene glycol(EG) Diethylene glycol(DEG) Ether based GAs Poly Carboxylate Ether(PCE) 11052015 Indian Institute of Technology,Delhi 8 9 Grinding Aid Grinding Aids for Cement SlideShare cement additive was tested on three different days in one of the finish mills producing Type IL cement Type IL, MasterCem @ 009% by mass cement Production increase >15% compared to Typyp g ge IL with amine acetate grinding aid Cement properties also compared to Type I with amine acetate as grinding aid 8Strength Enhancement for Portland Limestone Cements

Preparation of polycarboxylatebased grinding aid

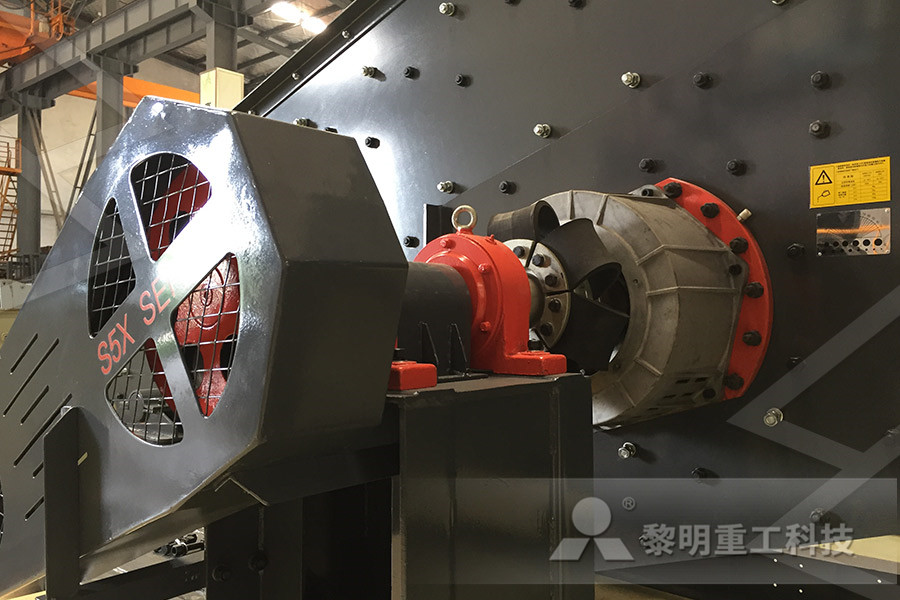

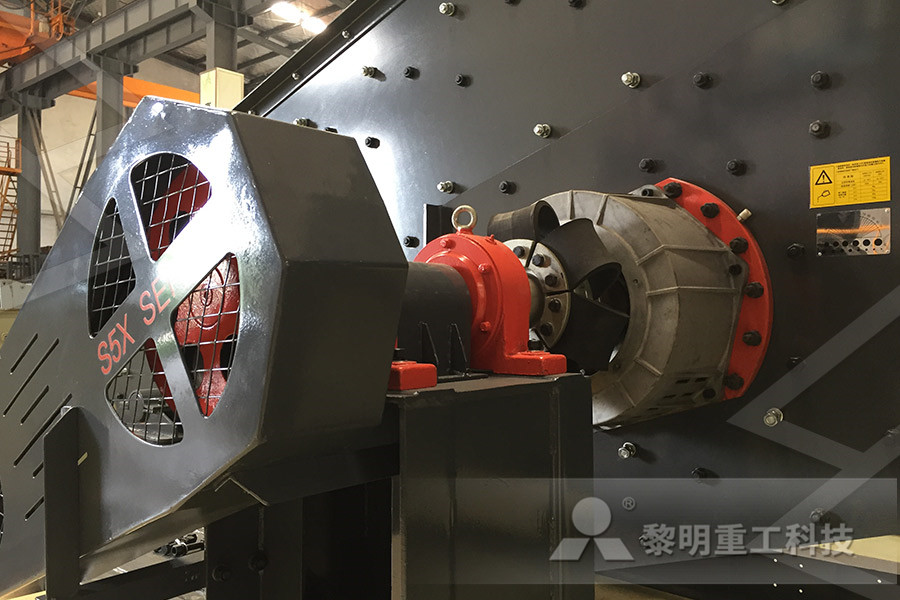

Cement grinding operations for this study were performed in a Type SM500 laboratory ball mill manufactured by Ruizhi Machine Co, Ltd, China 48 kg Portland cement clinker, 02 kg gypsum and 2 g cement grinding aid (004 wt% of total mass of clinker and gypsum) were grinded together to a Blain surface area of about (370 ± 5) m 2 kg −1 (22) 31052013 (43) 26112015 (57) A grinding aid composition for improving the efficiency of cement grinding The grinding aid composition comprises: an alkanolamine compound that is a primary alkanolamine compound, a secondary alkanolamine compound, or a mixture thereof; and a glycolCement grinding aid composition Cement Lime Cement grinding process consumes high amounts of electrical energy, GRINDFINE reduces energy consumption, improve surface area significantly as compared to other traditional Grinding Aid based on amines, glycol SPL manufacture tailor made Grinding Aid Grinding Aid SPL LIMITED

sika grinding aid cement wyjdzzcieniapl

Grinding Aid For Cement czeu This paper is aiming at evaluating the possibility of polycarboxylatebased material used as grinding aid for cement production and studying its influence on cement properties under laboratory condition Get Price And Support Online; Cement Grinding Aid Page 1 of 1 Nov 05, 2017 Cement Grinding Aid Tri Isopropanol Amine is a type of surface treating agent, widely used in cement industry The cement and concrete industries use TIPA as a grinding aid and it is used in concrete admixtures Other Uses : As Gas Scrubber in Natural and Refinery Gas Operation As crosslinking catalyst in polyurethane productionViswaat Chemicals Limited Construction Chemicals Widely used as a Cement Grinding Aid, set accelerator for concrete, cutting fluids, corrosion inhibitor production, asphalt chemicals etc Packing: Available Amines Plasticizers Limited

Preparation of polycarboxylatebased grinding aid

Cement grinding operations for this study were performed in a Type SM500 laboratory ball mill manufactured by Ruizhi Machine Co, Ltd, China 48 kg Portland cement clinker, 02 kg gypsum and 2 g cement grinding aid (004 wt% of total mass of clinker and gypsum) were grinded together to a Blain surface area of about (370 ± 5) m 2 kg −1 based grinding aid technology e data of this plant application shows a 13% production increase of a traditional amine based grinding aid e polycarboxylate polymerpowered grinding aid SikaGrind820 allowed for a production increase of 20%, ing and separating system (Figure 4) e reason for a production increase had twoPolycarboxylate polymer powered grinding efficiencyGrinding aids (GAs) are increasingly used during cement production to reduce energy consumption and/or optimize clinker factor This paper seeks to assess the effect of such additions on (PDF) Polyoltype Compounds as Clinker Grinding

Cement Grinding Aids Market By Competitors, Type,

Cement grinding aids are classified into three key types based on the feedstock, such as aminebased, alcoholbased and etherbased grinding aids The prime factor behind the usage of cement grinding aids is the elimination of the coating effect of clinker on grinding mill walls and to increase the production rate of cement keeping the surface In another cement grinding mill, wherein Type I cement is processed at a rate of 50 tons per hour, Blaine fineness had a linear correlation with grinding aid dosage, and based on this analysis TEA/THEED did not emerge to be a superior product The adjusted R2 for the regression analysis of the data in this set was 695% with a P value of 005Aminecontaining cement processing additives WR grinding aid for cement poly amine CEMENT GRINDING AID DEIPADiethanolisopropanolamine Diethanolisopropanolamine DEIPA is an alkanol amine used in the formulation of cement additives and concrete admixtures Besides being a good grinding aid in the cement mill DEIPA increases the strength of cements at all hydration ages and cements blended with function of acetic acid as a grinding aid of cement

sika grinding aid cement wyjdzzcieniapl

Grinding Aid For Cement czeu This paper is aiming at evaluating the possibility of polycarboxylatebased material used as grinding aid for cement production and studying its influence on cement properties under laboratory condition Get Price And Support Online; Cement Grinding Aid Page 1 of 1 Nov 05, 2017 Cement Grinding Aid A grinding aid composition suitable for grinding clinker into hydraulic cement powder an improved grinding process and an improved cement product are disclosed The grinding aid composition is composed of a mixture of at least one alkylene ether glycol and particulate carbondiethylene glycol monobutyl ether cement grinding aid Cement grinding aids are classified into three key types based on the feedstock, such as aminebased, alcoholbased and etherbased grinding aids The prime factor behind the usage of cement grinding aids is the elimination of the coating effect of clinker on grinding mill walls and to increase the production rate of cement keeping the surface Cement Grinding Aids Market By Competitors, Type,

CEMENT GRINDING AID SIKA TECHNOLOGY AG

1 The use of an aqueous composition comprising at least one polymer A of the formula (I) as a cement grinding agent where M=each independently H +, alkali metal ion, alkaline earth metal ion, di or trivalent metal ion, ammonium ion or organic ammonium group, R=each R, independently of the others, is hydrogen or methyl, R 1 and R 2 =each independently C 1 to C 20alkyl, cycloalkyl Moreover, cement grinding aids have positive effects on the mechanical properties of cement, such as setting time, compressive strength, surface area, and mortar workability Cement grinding aids are classified into three key types based on the feedstock, such as aminebased, alcoholbased and etherbased grinding aidsCement Grinding Aids Market Grows With Changing Grinding aids keep the coated themselves with cement if milling media (balls) clean and no grinding aid is used increase the productivity Sika Tech 26062019 Indian Institute of Technology,Delhi 7 Commonly Used Grinding Aids Amine based GAs Monoethanolamine(MEA) Diethanolamine(DEA) Triethanolamine(TEA) Triisopropanolamine(TIPA)Grinding Aids Cement Mill (Grinding)

sika grinding aid cement wyjdzzcieniapl

Grinding Aid For Cement czeu This paper is aiming at evaluating the possibility of polycarboxylatebased material used as grinding aid for cement production and studying its influence on cement properties under laboratory condition Get Price And Support Online; Cement Grinding Aid Page 1 of 1 Nov 05, 2017 Cement Grinding Aid based grinding aid technology e data of this plant application shows a 13% production increase of a traditional amine based grinding aid e polycarboxylate polymerpowered grinding aid SikaGrind820 allowed for a production increase of 20%, ing and separating system (Figure 4) e reason for a production increase had twoPolycarboxylate polymer powered grinding efficiencyIn another cement grinding mill, wherein Type I cement is processed at a rate of 50 tons per hour, Blaine fineness had a linear correlation with grinding aid dosage, and based on this analysis TEA/THEED did not emerge to be a superior product The adjusted R2 for the regression analysis of the data in this set was 695% with a P value of 005Aminecontaining cement processing additives WR

Amines Plasticizers Limited

an iso90012015, iso140012015 iso450012018 certified company cin number l24229as1973plcthe starex range of performanceenhancinggrindingaids is specifically useful for cement manufacturers with one of more of the following needs enhance 1day cement strength by 2530% and 28day strength by 58% increase grinding mill output by 510% increase cement extender (s moreCement Additives Cement Additive Suppliers, Tri Isopropanol Amine is a type of surface treating agent, widely used in cement industry The cement and concrete industries use TIPA as a grinding aid and it is used in concrete admixtures Other Uses : As Gas Scrubber in Natural and Refinery Gas Operation As crosslinking catalyst in polyurethane productionViswaat Chemicals Limited Construction Chemicals

Doosan Make crusher gravel Model crb 751 1no

screens made for sand and gravel screening

pellet mill screening equipment for sale

hollow grinding products

large reduction ratio jaw crusher for sale

Calcite Processing Toronto Canada

portable stone crusher XMSH Mining

vertical al mill price

jaw crusher plant price in south africa

low price sand vibrating screen for mining

large capacity flotation machine

limestone crushing plant for microns

use iron ore crushing

stone crushing plant sellers in germany

mining process of bornite

ball mill units in gujarat

lowongan mining al operator alat berat di sumatra

Kefan Hot Salewet High Intensity Magnetic Separator Equipment

how are grinding balls made

mobile crushing plant st in saudi arabia

patented mining claims in montana

Commercial Hammer Mill In Australia

theory of vibrating screens

latest quartz stone crusher 1

Basalt Por Le Crusher

450 tph ball mill manufacturer in india

ne crusher skid mounted

crusher plant jeddah

portable cement ne crusher for hire indonesia

kailash wet grinder le top price list