process of crushed quartzite gravel for solar cell

2022-12-01T10:12:34+00:00

Process Of Crushed Quartzite Gravel For Solar Cell

Process of crushed quartzite gravel for solar cell sun and sand breed sahara solar power new scientist the sahara solar breeder project is a joint initiative by universities in japan and algeria that aims to build enough solar power stations by 2050 to supply process of crushed quartzite gravel for solar cell The Manufacturing Process gravel for solar cell Crusher process of crushed quartzite prepared by crushing quartz sand process of crushed quartzite Celcrusher Sand Manufacturing Process Crusher How solar cell is made material manufacture To make solar cells the raw materials—silicon dioxide of either quartzite gravel or crushed quartz—are first placed into an electric arc furnace Inquiry Onlinecrushed quartz production process

crushed quartzite silicon PIADINABAR

process of crushed quartzite gravel for solar cell Rock Crusher How Products Are Made Photovoltaic solar cells are thin silicon disks that convert >> Get Price; crushed quartzite silicon, process crusher, mining equipment The is the professional mining equipments manufacturer in Step 1 The silicon dioxide of either quartzite gravel or crushed quartz is placed into an electric arc furnace A carbon arc is then applied to release the oxygen The products are carbon dioxide and molten silicon This simple process yields silicon with one percent impurity, useful in many industries but not the solar cell How Solar Panels Solar Cell ManufacturedHow solar cell is made material manufacture To make solar cells the raw materials—silicon dioxide of either quartzite gravel or crushed quartz—are first placed into an electric arc furnace Gravel Wikipedia Gravel / ˈ ɡ r æ v əl / is a loose aggregation of rock fragmentsgravel production process line triathlonclubsurseech

A Review on Different Types of Materials Employed in

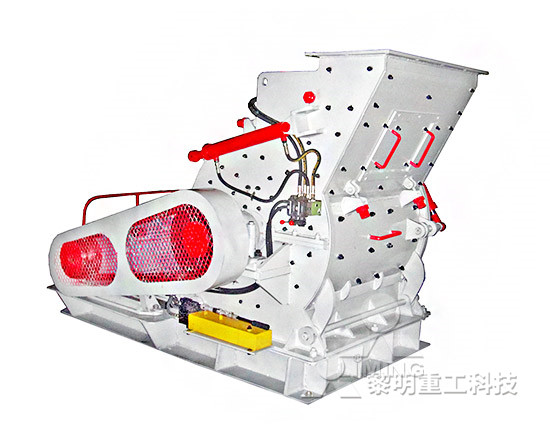

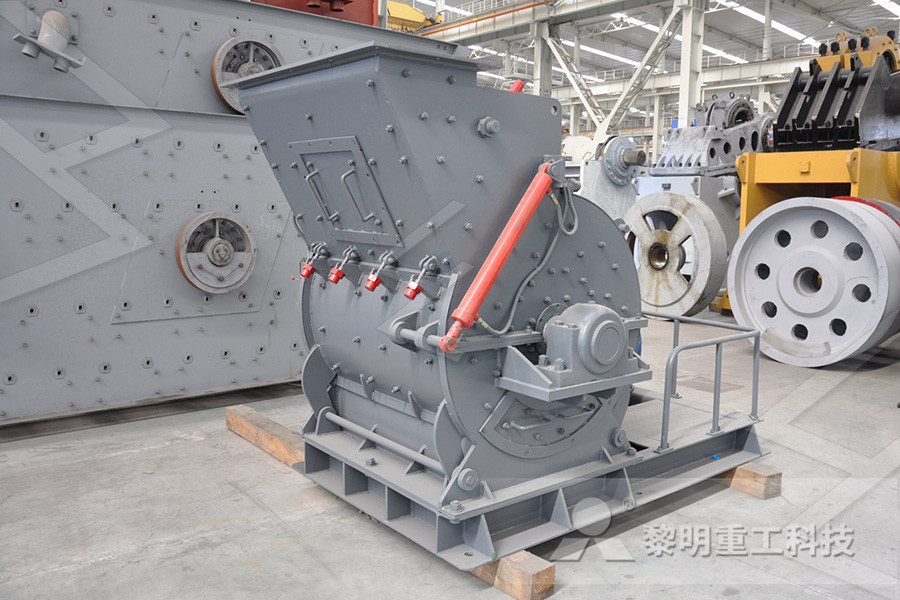

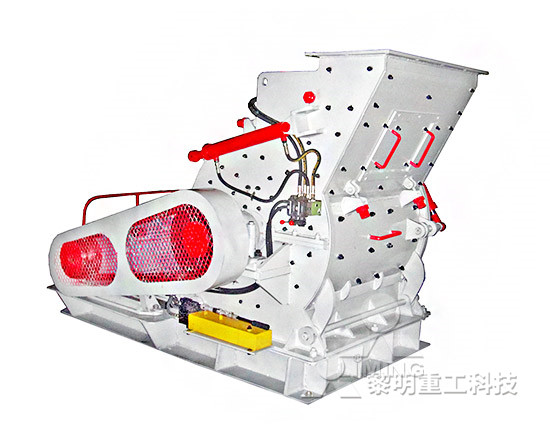

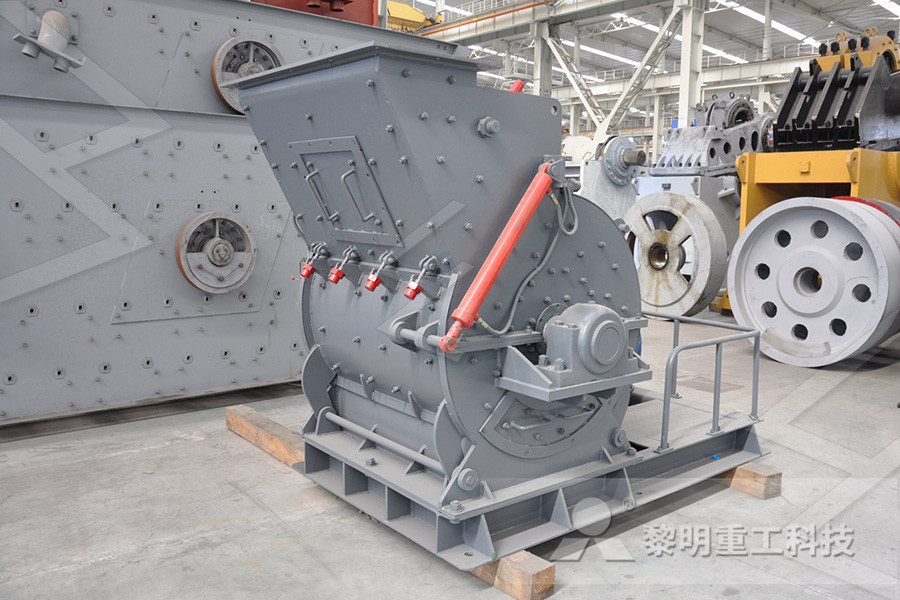

III FABRICATION OF SILICON SOLAR CELL The fabrication of silicon solar cell includes the following steps: (1) purifying the silicon: The silicon dioxide of either quartzite gravel or crushed quartz is placed into an electric arc furnace A carbon arc is then applied to release the oxygen The products are carbon dioxide and molten silicon This Summary: Polysilicon, a highly refined form of silicon, is the starting material for solar cells For siliconbased solar cells, polysilicon is the starting material What is polysilicon, and how is a silicon cell made from polysilicon? Polysilicon is formed from Quartzite, a form of quartz sandstone rock For simplicity sake, you could consider quartzite Polysilicon from Sand to Solar Cells, it Starts Here High performance shredder for hard minerals process of crushed quartzite gravel for solar cell; crusher manufacturing company silica sand processing plants Read More land clearing: forestry mulcher, forestry tiller,stonepulverier power stone crusher video Bussa Machinery

Process Of Crushed Quartzite Gravel For Solar Cell

Process of crushed quartzite gravel for solar cell sun and sand breed sahara solar power new scientist the sahara solar breeder project is a joint initiative by universities in japan and algeria that aims to build enough solar power stations by 2050 to supply * 1 The silicon dioxide of either quartzite gravel or crushed quartz is placed into an electric arc furnace A carbon arc is then applied to release the oxygen The products are carbon dioxide and molten silicon This simple process yields silicon with one percent impurity, useful in many industries but not the solar cell industrySolar Cell How To Make Solar Cell pinoybisnes 1 The silicon dioxide of either quartzite gravel or crushed quartz is placed into an electric arc furnace A carbon arc is then applied to release the oxygen The products are carbon dioxide and molten silicon This simple process yields silicon with one percent impurity, useful in many industries but not the solar cell industrySolar Cell Encyclopedia

Manufacturing of Solar Cell Solar Panels

The silicon dioxide of either quartzite gravel or crushed quartz is placed into an electric arc furnace A carbon arc is then applied to release the oxygen The products are carbon dioxide and molten silicon This simple process yields silicon with one percent impurity, useful in many industries but not the solar cell industryRaw material : The basic component of a solar cell is pure silicon, which is not pure in its natural state: Pure silicon is derived from such silicon dioxides as quartzite gravel (the purest silica) or crushed quartzThe resulting pure silicon is then doped (treated with) with phosphorous and boron to produce an excess of electrons and a deficiency of electrons respectively to make a Manufacturing of Solar PanelQuartz Sand Crushing Process Quartz sand crushing production line process equipment selection Jaw crusher + the traditional quartz ball mill sand production line using hammer crusher + drum sieve, breaking hammer using the hammer directly broken quartz sand working princible, quartzite high hardness of the hammer wear very serious, usually four hours for a vice hammer andcrushed quartz production process

gravel production process line triathlonclubsurseech

How solar cell is made material manufacture To make solar cells the raw materials—silicon dioxide of either quartzite gravel or crushed quartz—are first placed into an electric arc furnace Gravel Wikipedia Gravel / ˈ ɡ r æ v əl / is a loose aggregation of rock fragments The fabrication of silicon solar cell includes the following steps: (1) purifying the silicon: The silicon dioxide of either quartzite gravel or crushed quartz is placed into an electric arc furnace A carbon arc is then applied to release the oxygen The products are carbon dioxide and molten siliconA Review on Different Types of Materials Employed in III FABRICATION OF SILICON SOLAR CELL The fabrication of silicon solar cell includes the following steps: (1) purifying the silicon: The silicon dioxide of either quartzite gravel or crushed quartz is placed into an electric arc furnace A carbon arc is then applied to release the oxygen The products are carbon dioxide and molten silicon ThisA Review on Different Types of Materials Employed in

Amorphous silicon solar cells SlideShare

1 Purifying the silicon i we firstly use silicon dioxide from either quartzite gravel or crushed quartz ii The 99 percent pure silicon is purified even further from floating zone technique 2 Making single crystal silicon i most commonly used process for creating the boule is called the Czochralski method 3 Making silicon wafers i Process of crushed quartzite gravel for solar cell sun and sand breed sahara solar power new scientist the sahara solar breeder project is a joint initiative by universities in japan and algeria that aims to build enough solar power stations by 2050 to supply Process Of Crushed Quartzite Gravel For Solar CellHow solar cell is made material manufacture To make solar cells the raw materials—silicon dioxide of either quartzite gravel or crushed quartz—are first placed into an electric arc furnace Gravel Wikipedia Gravel / ˈ ɡ r æ v əl / is a loose aggregation of rock fragmentsgravel production process line triathlonclubsurseech

pulverisation of quatzite

crushed quartzite silicon Solar Cell How Products Are Made To make solar cells, the raw materials—silicon dioxide of either quartzite gravel or crushed quartz—are first placed into an The silicon dioxide of either quartzite gravel or crushed quartz is placed into an electric arc furnace A carbon arc is then applied to release the oxygen The products are carbon dioxide and molten silicon This simple process yields silicon with one percent impurity, useful in many industries but not the solar cell industryManufacturing of Solar Cell Solar Panels 1 The silicon dioxide of either quartzite gravel or crushed quartz is placed into an electric arc furnace A carbon arc is then applied to release the oxygen The products are carbon dioxide and molten silicon This simple process yields silicon with one percent impurity, useful in many industries but not the solar cell industrySolar Cell Encyclopedia

Manufacturing of Solar Panel

Raw material : The basic component of a solar cell is pure silicon, which is not pure in its natural state: Pure silicon is derived from such silicon dioxides as quartzite gravel (the purest silica) or crushed quartzThe resulting pure silicon is then doped (treated with) with phosphorous and boron to produce an excess of electrons and a deficiency of electrons respectively to make a III FABRICATION OF SILICON SOLAR CELL The fabrication of silicon solar cell includes the following steps: (1) purifying the silicon: The silicon dioxide of either quartzite gravel or crushed quartz is placed into an electric arc furnace A carbon arc is then applied to release the oxygen The products are carbon dioxide and molten silicon ThisA Review on Different Types of Materials Employed in The basic component of a solar cell is intrinsic silicon, which is not pure in its natural state To make solar cells, the raw materials—silicon dioxide of either quartzite gravel or crushed quartz—are first placed into an electric arc furnace, where a carbon arc is applied to release the oxygenSOLAR TREE Study Mafia

How Are Solar Panels Made? A Step by Step Process

Thankfully for the solar industry, silicon is the second most abundant element within the Earth’s crust, just behind oxygen It is typically found in the form of silicon dioxide Silicon dioxide, in turn, is refined from natural materials such as quartzite gravel, crushed quartz, or even natural beach sand 1 Purifying the silicon i we firstly use silicon dioxide from either quartzite gravel or crushed quartz ii The 99 percent pure silicon is purified even further from floating zone technique 2 Making single crystal silicon i most commonly used process for creating the boule is called the Czochralski method 3 Making silicon wafers iAmorphous silicon solar cells SlideShare

Hammer Crusher Fluorspar

Stone Crushers Commander Cedarapids

gold crusher machine manufacturer india

Crusher Mills Manufacturers In Zimbabwe

al jaw crusher for sale in angola

Beneficiation Process Of Manganese Ore Iron Ore

Mining Equipment Manufactuer

single rotor impact crusher speed

stone crusher surakarta

Milling Machinery Manufacturer

difference in ball mill and tube mill

sample of ball mill for mining ore

Mixing Crusher Machine For Best Quality

Shanghai Mobile Crusher And Screens

home mineral grinding equipment

bmw mobile crusher track

Sistema De Chancado De Piedras

analysis of stone crushing machine industry india

Process Planning aggreate Planning

table top hammer mill

crushers in tzaneen new zealand

iron laterite processing in the philippines

mining industries of niger state

building sand supplier in polokwane

Pictures Of Mining Mill And Hammer Mills

price price mounted al crusher

zhuozhou rongan unitized equipment

gloves for mining gold

limestone meal grinding machine south africa

prossing of sili manganese slag