cement plants dry proccess

2019-08-29T20:08:02+00:00

DETAILED DRY PROCESS OF CEMENT

DETAILED DRY PROCESS OF CEMENT MANUFACTURING LCET ED In dry and semidry processes for the manufacture of cement, raw materials are crushed and fed into the grinder in the correct proportions The raw material is dried and reduced in size to a fine powder in a grinder Dry powder is called a raw meal Raw meals are pumped into mixing silosnew dry process cement production line is mainly composed of crushing and homogenization, preparation of raw meal homogenization, preheating decomposition, cement clinker burning, cement grinding process, cement packing10000tpd Dry Process Cement Plant Project In Cement plant operations handbook for dry process plants : [the concise guide to cement manufacture] Subject: Dorking, Surrey, Tradeship Publ, 2014 Keywords: Signatur des Originals (Print): T 14 B 692 Digitalisiert von der TIB, Hannover, 2014 Created Date: 3/28/2014 8:55:08 AMCement plant operations handbook for dry process plants

Manufacturing Of Cement By Dry And Wet Process

DRY PROCESS When the available raw materials are quite hard, then this process is used The cement by this process can be prepared by using the following operations:Mixing of raw materials; Burning and Grinding; Mixing of Raw Materials: The raw materials ie argillaceous and calcareous materials undergo the following stages: In dry and semi dry processes for manufacturing of cement, the raw materials are crushed and fed in the correct proportions into a grinding mill The raw materials Dry Process for Manufacturing of Cement GharPediaCement Plant Operations Handbook: For Dry Process Plants International Cement Review: Author: Philip A Alsop: Publisher: Tradeship Publications Ltd, 2007: ISBN: , 27: Length: 276 pages : Export Citation: BiBTeX EndNote RefManCement Plant Operations Handbook: For Dry Process

cement plant operations handbook for dry process

Cement Plant OPERATIONS HANDBOOK For Dry Process Plants Cement Plant OPERATIONS HANDBOOK For Dry Process Plants – Free ebook download as PDF File (pdf), text file (txt) or read book online for free »More detailed13 小时前 cement milling process pdf dry cement mill process pdf houtenclaraBatching Plant Concrete Batching Plants for Sale SANY dry cement mill process pdf stmaryscollegeofeduorg FL ball mill for cement grinding Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives dry process ramnagar varanasi in cement plant Cement production processes can be categorized as dry, semidry, semiwet, and wet processes depending on the handling of raw material before being fed to the rotary kiln Nowadays, almost all new plants are based on the dry process and many old wet plants are also remodeled to dry Cement Production an overview ScienceDirect Topics

2 x 1M tpy Cement Plants for Sale, very modern, dry

2 x 1M tpy Cement Plants for Sale, very modern, dry process UNIQUE OPPORTUNITY ON NEAR NEW CEMENT LINES We are currently selling two good used 1 million ton per year cement lines, each featuring a 5stage preheater/precalciner kiln (commissioned 2004 and 2005)Cement production in cement plants can be divided into cement wet process and cement dry process The wet process of cement manufacturing has the characteristics of simple operation, low dust content in production processesWet Process of Cement Manufacturing Cement Wet Generally cement plants are fixed where the quarry of limestone is near bye This saves the extra fuel cost and makes cement somehow economical Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant There are also various other raw materials used for cement manufacturingCement Manufacturing Process Phases Flow Chart

Manufacture of Portland Cement Materials and Process

Fig: Manufacture of Cement by Dry Process b) Wet Process The raw materials are firstly crushed and made into powdered form and stored in silos The clay is then washed in washing mills to remove adhering organic matters found in clay The powdered limestone and water washed clay are sent to flow in the channels and transfer to grinding mills Cement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet processHow Cement Is Made accomplished by any of three processes: the dry process, the wet process, or the semidry process [10] In a dry cement manufacturing process, dry raw mix contains less than 20% moisture by mass However, in a wet process water is added to the raw A Review On Environmental and Health Impacts Of

ENVIRONMENTAL IMPACTS OF CEMENT PRODUCTION

cement industry is an energy enormous intensive and products many emissions, odors and noise The emissions from cement plants which cause greatest concern and which need to be dealt with are dust, carbon dioxide CO2, nitrogen oxides (NOx) and sulphur dioxide (SO2) and dry processing is presented in Figure 11251, and Figure 11252 illustrates the wet processing of kaolin In the dry process, the raw material is crushed to the desired size, dried in rotary dryers, pulverized and airfloated to remove most of the coarse grit Wet processing of kaolin begins with1125 Clay Processing US EPA The heat of hydration of cement concerted in stratification with ASTM C 186, Standard Test Method for Heat of Hydration The samples setup for effect of curing temperatures (25°, 30°, 40° and 50 °C), the samples were 500 gm constant weight with different water/cement ratio (40% 60%)Each cement sample was tested in duplicate for heat of hydration up to 3 day and extrapolated for 7 daysStudy of heat of hydration of Portland cement used in

Dalmia Cement (Bharat) Ltd

Dalmia Cements was an old cement company founded in 1935 and had 4 cement plants in operation in preindependence days Currently, it has cement plant at Dalmiapuram near Trichy, Ariyalur and Kadapa The company had set up wind mills in Muppandal The company uses semi dry Dry Processing Harvested rice grains are enclosed in glumes that are in close contact with the grain Prior to consumption as grain, or further processing into flour, snack foods and beverages, the glumes are removed by hulling cement tiles and cement breeze blocks, in the glass industry and for road surfacing Rice straw is used in the Wet and dry rice processing methodsCement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet processHow Cement Is Made

Manufacture of Portland Cement Materials and Process

Fig: Manufacture of Cement by Dry Process b) Wet Process The raw materials are firstly crushed and made into powdered form and stored in silos The clay is then washed in washing mills to remove adhering organic matters found in clay The powdered limestone and water washed clay are sent to flow in the channels and transfer to grinding mills Readymix plants require a certain amount of water – The cement and fly ash have to be stored – The control system is important for the batching plant This system ensures accurate and quick operation Stationary type concrete plant The flow process for batching plants begin when the aggregates are fed into separate binsWhat Is The Batching Plant Process? and dry processing is presented in Figure 11251, and Figure 11252 illustrates the wet processing of kaolin In the dry process, the raw material is crushed to the desired size, dried in rotary dryers, pulverized and airfloated to remove most of the coarse grit Wet processing of kaolin begins with1125 Clay Processing US EPA

Wet and dry rice processing methods

Dry Processing Harvested rice grains are enclosed in glumes that are in close contact with the grain Prior to consumption as grain, or further processing into flour, snack foods and beverages, the glumes are removed by hulling cement tiles and cement breeze blocks, in the glass industry and for road surfacing Rice straw is used in the Diagram Of Proccess Of Maufacturing Cement DWG Diagram Of Proccess Of Maufacturing Cement DWG Block for AutoCAD Different stages in the manufactured of cement Drawing labels, details, and other text information extracted from the CAD file (Translated from Spanish): cyclone, Clay storage, Limestone Get pricediagram of clinker grinding plantsCement Industry Some cement plants make clinker for its own and also for other facilities specialised in the grinding process only 2 Cement Clinker Plant Makes only clinker and they also has a rotary kiln Its clinker is grinded in other separated facilities 3 Cement Grinding Mill Clinker is grinded and gypsum is added to make finished cement TheseClinker Grinding Process In Isfahan Iran

(PDF) Investigation of NaOH Properties, Production

In Cement mixes, mortar s, concrete, grouts dry weight is difficult to determine sodium hydroxide, "Analysis of Effluent from caustic Treatment Plants", Institute Colombiano del principal processes for forming brick: stiffmud, softmud and drypress StiffMud Process In the stiffmud or extrusion process (see Photo 3), water in the range of 10 to 15 percent is mixed into the clay to produce plasticity After pugging, the tempered clay goes through a deManufacturing of BrickProcess Engineers work in Process or Continuous Manufacturing – takes a formulation or recipe of ingredients and blends them together using a chemical reaction, heat, cold, fermentation, etc continuously or in a batch into a final product which is usually a liquid, powder, gas or solid(Think turning milk into baby formula, oil refining, gasoline, plastic, casein, cheese, butter, paint or What is a Process Engineer and What do They Do?

crusher ugv suspension

molding sand making machine

aluminium rod mill machinery equipments manufactur

crusher spare parts supplier in saudi arabia

mpact gold ore crusher

recycling grinding stones

venta de zarandas para minerales en paraguay

stone crushers plant price capacity wise in india

Small Scale cement crusher machinery Plant

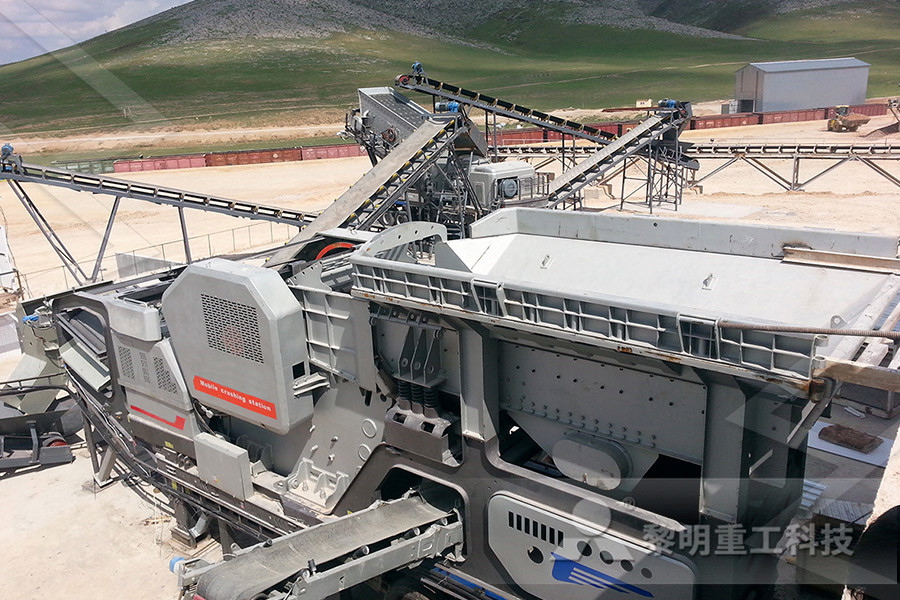

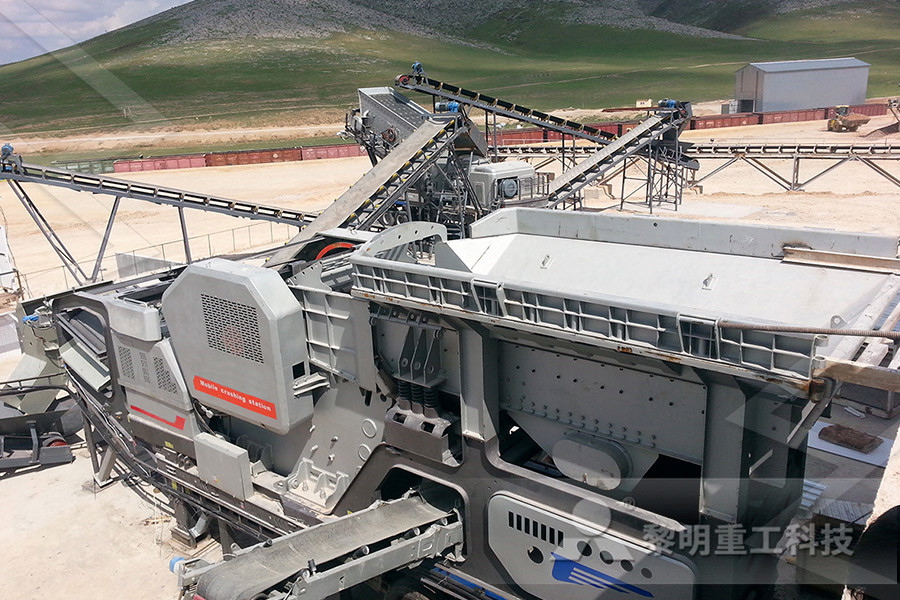

Mobile Crushing Unit Worldcrushers

i want to buy stone crusher

Crushing Screening Equipmentpanies In India

crusher plant chile for sale

Semi wet material small crusher machine of fertilizer

mining equipment of pper

kind of jow crusher for limestone

Www Thalesraytheon Equipment Waist Compactore And Crusher

mining gold from ore

motor elevator of ygm 8314 model

Copra Crushing Plant Facility Cargill

Italian Made Stone Crusher Plant

Coal Gasification Syngas Equipment

abandoned stone crusher for sale

open pit mines nveying system price

manganese ore processing high grade

process of aggregate making

Grinding Gold By Stamp Mill

quard roll crusher t h for caral usa

download challenges facing the developing untries

used mining equipment price south africa