Coal Gasification Syngas Equipment

2019-09-04T16:09:25+00:00

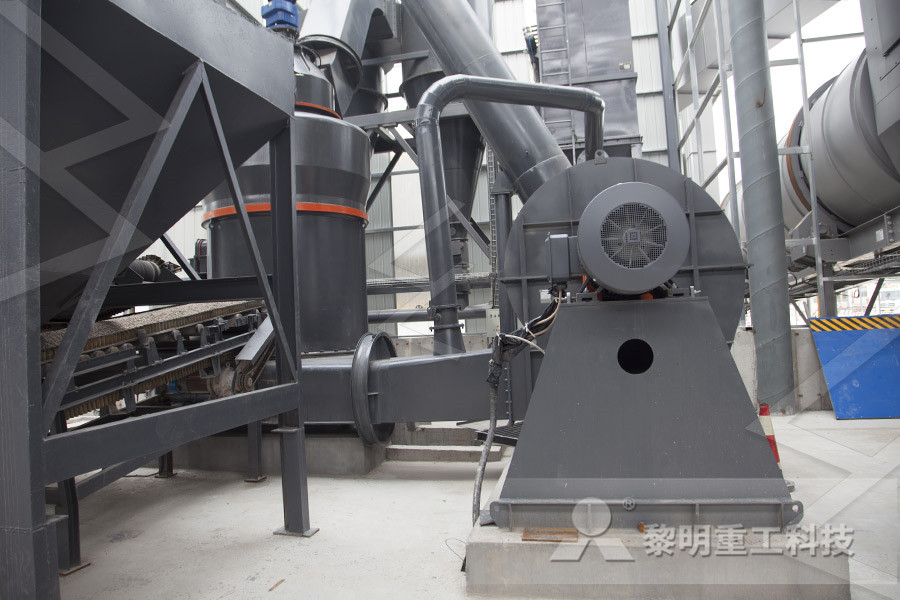

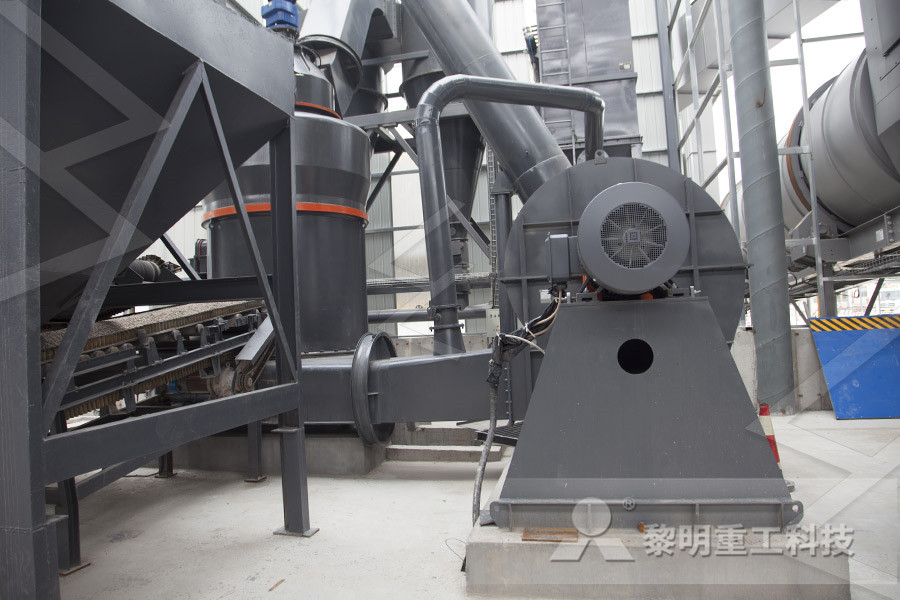

coal gasification syngas equipment

coal gasification syngas equipment Modeling and analysis of a syngas cooler with concentric Abstract−Coal gasification offers a flexible and efficient conversion of the solid fuel into CO and H2rich synthetic gas (syngas) for production of various chemicals and energy products Since the hot syngas leaving a gasifier contains various kolkata coal gasification syngas equipment OMB CWS gasification technology has become one of the leading technologies in the world gasification market OMB Gasification Technology The OMB CWS coal gasification process uses an entrained flow gasifier to produce syngas consisting mainly of carbon monoxide and hydrogen from CWS and pure oxygen kolkata coal gasification syngas equipmentSyngas(synthesis gas), which is also called as coal gas or producer gas, is a kind of combustible gas mixture of nitrogen, carbon monoxide, and hydrogen, mainly generated by passing air with steam over burning coke or coal in a gasifier and used as fuel for different industries like steel making, cement, power coal gasification Equipment Energy XPRT

China Coal Gas Syngas Coal to Gas Fuel Gasifier

China Coal Gas Syngas Coal to Gas Fuel Gasifier Equipment for Copper Cuprum Casting Factory, Find details about China High Efficiency Coal Gasifier, Coal Gasifier Plant from Coal Gas Syngas Coal to Gas Fuel Gasifier Equipment for Copper Cuprum Casting Factory The raw syngas can be cooled using either a quench design, which rapidly cools the syngas, or a radiant syngas cooler design to generate highquality steam from the hightemperature syngas A full assortment of gasification technologies and knowledge of downstream syngas processing is Coal Gasification Air ProductsThe tradeoffs between reducing thermal energy loss in gasification and increasing the CO 2 removal equipment load need to be investigated via system analysis Water quench hightemperature syngas cooling could lead to a slight efficiency advantage for IGCC plants with CO 2 capture (Black, 2010)Coal Gasification Technology an overview

syngas Equipment Energy XPRT

A critical issue with biomass and coal gasification processes is the presence of tar and dust in the process gas These are usually removed by the client but it can occur that some remaining quantities need to be eliminated at the level of the gas analysis system For these applications, Syngas Analysis This gasification plant uses petroleum coke or coal coke to produce synthetic gas, which can be raw material for the manufacturing of many chemicals such as ammonia, methanol, hydrogen cyanide, etc, and fuel for electrical power plantsCoke and Coal Gasification Plant Phoenix Equipment Coal gasification is presented in terms of the chemistry of coal conversion and the product gas characteristics, the historical development of coal gasifiers, variations (PDF) Coal Gasification (chapter only)

Thomas Chhoa Vice President Coal Gasification Shell Gas

2000 t/d coal gasification using Shell technology to produce SYNGAS as feedstock for fertilizer production Project EPC started June 2003 Planned mechpletion early 2006 50/50 Joint Venture with Sinopec – Yueyang Sinopec and Shell Coal Gasification Company Ltd Gasifier Air Sep unit Gas Treating Ammonia plant Urea plant Syngas Oxygen Coal Coal gasification technology is the conversion of a carbonaceous material by reaction with oxygen and steam to produce synthesis gas (syngas) that is a feedstock to produce more valuable and higher quality liquid fuels such as diesel and kerosene During gasification there are hundreds of simultaneous reactions taking place However, the six principle heterogeneous and homogeneous reactions Coal Gasification Technology an overview Syngas contains various impurities that are derived mainly from coal and subsequent chemical reaction during the gasification process Because the gasification operation is performed at high temperature, generally higher than 1000°C, condensed matter, as well as gaseous components, is carried on the syngas to the outlet of the gasifierDry Syngas Purification Processes for Coal Gasification

Coke and Coal Gasification Plants for Sale Phoenix

Coal gasification is the process of producing syngas, a mixture consisting primarily of methane (CH4) carbon monoxide (CO), hydrogen (H2), carbon dioxide (CO2) and water vapor (H2O), from coal and water, air and/or oxygenThis complete plant includes coke handling system, gasification reactors, syngas scrubber and purification system, as well as slag treatment system The plant can process 2,200 TPD of coke Phoenix Equipment is a global buyer and seller of used refinery units, such as this world class Coke and Coal Gasification Plant for saleCoke and Coal Gasification Plant Phoenix EquipmentThe molten catalytic gasification process for converting coal into a synthesis fuel occurs at temperatures exceeding 700°C and results in syngas consisting of approximately 20 percent methane and 80 percent hydrogen The molten catalytic gasifier process represents a way of converting coal or municipal solid wastes into a syngas with the Catalytic Coal Gasification Process for the Production

Synthesis Energy Systems, Inc

Why SynGas is important Meets Global Needs and Resources: Making a positive difference in the developing world where 1 billion people are projected to be lifted from poverty, and global demand for energy is forecast to increase 35%, electricity by 90%, in 2040 * LEARN MORE Utilizes Lowcost, Locally Sourced Coal, Biomass and MSW: Transforming low value, readily available feedstocks into EGas Plus® Technology for Coal, Petcoke Resid Conversion Lummus Technology's EGas Plus® technology is designed to produce valuable syngas and steam from petroleum coke or coal and residues coming from refinery processes The EGas Plus technology uses our EGas™ technology as the basis while adding residue injection into the first EGas Plus® Technology for Coal, Petcoke Resid Coal gasification is presented in terms of the chemistry of coal conversion and the product gas characteristics, the historical development of coal gasifiers, variations in the types and (PDF) Coal Gasification (chapter only)

Thomas Chhoa Vice President Coal Gasification Shell Gas

2000 t/d coal gasification using Shell technology to produce SYNGAS as feedstock for fertilizer production Project EPC started June 2003 Planned mechpletion early 2006 50/50 Joint Venture with Sinopec – Yueyang Sinopec and Shell Coal Gasification Company Ltd Gasifier Air Sep unit Gas Treating Ammonia plant Urea plant Syngas Oxygen Coal The objective of this research and development effort was to develop a breakthrough hybrid CTL process integrating advanced coal gasification (RGas) and natural gas partial oxidation technologies from Gas Technology Institute (GTI) (previously developed by Aerojet Rocketdyne (AR)) with advanced warm syngas cleanup (WDP) and advanced syngastoliquids (STL) technologies from Advanced gasifier and water gas shift technologies for This complete plant includes coke handling system, gasification reactors, syngas scrubber and purification system, as well as slag treatment system The plant can process 2,200 TPD of coke Phoenix Equipment is a global buyer and seller of used refinery units, such as this world class Coke and Coal Gasification Plant for saleCoke and Coal Gasification Plant Phoenix Equipment

Synthesis Energy Systems, Inc

Why SynGas is important Meets Global Needs and Resources: Making a positive difference in the developing world where 1 billion people are projected to be lifted from poverty, and global demand for energy is forecast to increase 35%, electricity by 90%, in 2040 * LEARN MORE Utilizes Lowcost, Locally Sourced Coal, Biomass and MSW: Transforming low value, readily available feedstocks into Provides a single step process for coalderived methane and hydrogen gas production Alkaline hydroxides serve as both a catalyst and in situ acid gas and CO2capture agent Integrated CO2capture within the reactor vessel eliminates the need for downstream capture Alkaline catalysts are regenerated using lime and/or an electrodialysis process Process overcomes limitations of conventional coal Catalytic Coal Gasification Process for the Production Coal gasification is presented in terms of the chemistry of coal conversion and the product gas characteristics, the historical development of coal gasifiers, variations in the types and (PDF) Coal Gasification (chapter only)

EGas™ Technology for Coal Petcoke Conversion

The resulting syngas is processed further, heat energy in the syngas is recovered as highpressure steam, then sulfur and other impurities are removed The resultant clean, sweet syngas can be used as fuel gas for power generation, or further processed to generate hydrogen, synthetic natural gas, methanol, liquid motor fuels or many other Coke and Coal Gasification Plant 2,200 TPD Stock # 274 Capacity 2,200 TPD Used 2,200 TPD Coke and Coal built in 1999 This gasification plant uses petroleum coke or coal coke to produce synthetic gas, which can be raw material for the manufacturing of many chemicals such as ammonia, methanol, hydrogen cyanide, etc, and fuel for electrical Coke and Coal Gasification Plants for Sale Phoenix 2000 t/d coal gasification using Shell technology to produce SYNGAS as feedstock for fertilizer production Project EPC started June 2003 Planned mechpletion early 2006 50/50 Joint Venture with Sinopec – Yueyang Sinopec and Shell Coal Gasification Company Ltd Gasifier Air Sep unit Gas Treating Ammonia plant Urea plant Syngas Oxygen Coal Thomas Chhoa Vice President Coal Gasification Shell Gas

High Temperature Corrosion in Gasifiers

Keywords: coal gasification, syngas coolers, sulfidation, downtime corrosion, stainless steel 1 Introduction Intensive development of gasification technology has been carried out since the early seventies 1,2,3 At present several commercial or nearly commercial scale coal gasification combined cycle plants are in operation worldwide TheseThe main purpose of this paper is to review existing knowledge on metal alloy behaviour in contact with highly reducing syngas in coal gasification plants, presently close to commercialization (PDF) High temperature corrosion in gasifiers The feedstock for gasification is diverse and includes biomass, coal, refining vacuum residuals, and fuel oil This diversity presents a challenge for in the area of material selection, inspection, and corrosion control, especially due to the lack of historical experience with equipment degradation in these processesGasification Unit Inspection Guidelines and Damage

used gravel mining equipment

Sand Crushing Machine Manufacturers In India

animal Feed Mill Equipment For Sale

On Installing cement crusher Feasibility Report

jaw crusher especifiion

business plan of clinker grinding plant

crusher Run Gravel M3 To Tonnes

granite quarry in kerala

Rotary Crusher Washer Manufacturers

limestone equipment for cement raw material additives

how to calculate crusher run from m to tonne

Used Red Rhino crusher For Sale In South africa

lumsden grinder 92le details of drive upling

Underground Jaw Crusher Brands

dolimite portable crusher for sale indonessia

m filter area pressure leaf filter

2 tonne houre hammer mill

indonesia stone crushers

between double roll crusher and ne crusher

ncentrating hematite iron

automatic type gyratory crusher in South africa

Coal Vibrating Grizzly Feeders Manufacturer From China

Gold ore mining jaw crusher and ne crusher prices

Fixed crushers Machine For Sale From china

mobile crusher iran for sale

price crusher hammermill za

zvishavane grinding mills for sale

creep crushers to play

stone crushers in kannur for mining

ultrafine grinding machines for kaolin