manganese ore processing high grade

2020-04-27T10:04:58+00:00

Manganese Ore Processing Mineral Processing

The problem involved in Manganese Ore Processing deals with the production of acceptable specification grades of manganese concentrates at a maximum recovery of the total manganese from ores having variable characteristics The The survey testes and processing results demonstrate that HEM is a costeffective method for exploration of podiform, high grade manganese ore bodies, as along as the host rocks are comparatively HoistEM data processing for discovery of high grade The HoistEM surveydesign tests and processing results demonstrate that HoistEM is a costeffective method for exploration of podiform, highgrade manganese ore bodies, as long as the host rocks are comparatively resistive, and a flight line spacing of 80 m or less is usedHoistEM Data Processing for Discovery of HighGrade

A Case Study ofthe Production ofHighgrade Manganese

manganese ore at the cost of ferromanganese alloys2 This, however, has not yet been realized, mostly owing to the high costs involved in the ORP Increasing transport costs, coupled with an international demand for highgrade ore, are encouraging producers to investigate means ofbenefici ating manganese ores Australia and Brazil are both exam manganese ore, power plays an important role in the production of ese alloy There are basically two mangan processes for the manufacturing of the alloy using either one of high, medium or low grade ore, viz; Blast furnace and submerged electric arc furnace [SEAF] When manganese ore is converted into manganese alloy, thereHydrometallurgical Processing of Manganese Ores: A F2 grade with its high manganese silicon content has been designed for production of SilicoManganese (SiMn) This high grade and highly reactive ore is an excellent product to improve process performances (less waste, lower energy consumption), particularly though the production of HIGH GRADE ORE Eramet

Classification of manganese oresMetalpedia

①High grade manganese ore (more than 44%48% Mn) ②Medium grade manganese ore (35%44% Mn) ③Low grade manganese ore (25%35% Mn) Classification according to chemical constituents; Manganese is found in more than 100 minerals including various sulphides, oxides, carbonates, silicates, phosphates and borates The most commonly occurring PHYSICOCHEMICAL PROCESSING OF LOW GRADE MANGANESE ORE 197 Effect of temperature and time The experiments were carried out to study the progress of the reaction with time at different temperatures The plots of frac{ion reacted, R, versus time, t, at five different temperatures 323, 333, 343, 353 and 363 K are presented in Fig 1Physicochemical processing of low grade manganese The HoistEM surveydesign tests and processing results demonstrate that HoistEM is a costeffective method for exploration of podiform, highgrade manganese ore bodies, as long as the host rocks are comparatively resistive, and a flight line spacing of 80 m or less is usedHoistEM Data Processing for Discovery of HighGrade

HoistEM data processing for discovery of high grade

The survey testes and processing results demonstrate that HEM is a costeffective method for exploration of podiform, high grade manganese ore bodies, as along as the host rocks are comparatively Manganese minerals have a fineness less than micron, which is not easily dissociated, and hard to be separated into a higher concentrate grade 02 Manganese processing technology As for the fine and micro embedded manganese ores, and there are an amount of high phosphate ore, high iron ore and co (concomitant) beneficial metalsGuide of Manganese Ore Processing Method Xinhai manganese ore processing Spectral analysis elements chemical analysis to fix the chemical composition of Manganese ore And the grade of the Mn elements is around 1999% will be sent to the wet concentration ore stock pile g The talings from the high gradient magnetic separator will be dewatered in the settling pond and it willThe brief introduction of manganese ore mineral

Manganese processing Britannica

Manganese processing, preparation of the ore for use in various products Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F) Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities such The CDI results were further refined by calibration to borehole conductivity results The survey testes and processing results demonstrate that HEM is a costeffective method for exploration of podiform, high grade manganese ore bodies, as along as the host rocks are comparatively resistive and flight line spacing of 80m or less is usedHoistEM data processing for discovery of high grade The beginning of the Manganese ore processing involves a multistage crushing workflow From there, the production of ferromanganese, the manganese ore is mixed with iron ore and carbon and then reduced either in a blast furnace or in an electric arc furnace The resulting ferromanganese has a Manganese content of 30% to 80%Manganese Mining and Processing for Investors,

COMPLEX PROCESSING OF IRONMANGANESE ORE OF

degree of manganese and silicon has amounted, correspondingly: 8385% and 5660% for silicomanganese; 6870% and 1015% for highcarbon ferromanganese CONCLUSION The possibility of subgrade ironmanganese ore processing into highquality manganese concentrates was demonstratedBnB works in partnership with BRL to finance production expansion and expand processing capacity to meet the growing international market demand for the high quality of the manganese ore produced by BRL Premium Commodities Grade Manganese High Content Manganese Concentrate 50% 55% Mn Low GradeBRL MANGANESE MINING BR LITHIUM Manganese ore is a weak magnetic mineral [Specific magnetization coefficient X=10×10^6~600×10^6cm3/g] Under the magnetic separator with magnetic field intensity Ho=800~1600 kA/m (10000~20000oe), it can be recycled to increase the manganese grade by 4% to 10%The 7 Most Useful Manganese Ore Beneficiation

Manganese Mining and Processing for Investors in

High grade, highpurity Manganese is the primary cathode material to build the battery's energystoring capacity by increasing its energy density The main purpose of processing Manganese ore This method is suitable for processing lowgrade, inlaid finegrained manganese oxide ores The above are common manganese ore beneficiation methods In actual production, most of the manganese carbonate ore beneficiation methods use strong magnetic separation, heavy medium beneficiation method and flotation methodManganese Mining Solution Mineral Processing degree of manganese and silicon has amounted, correspondingly: 8385% and 5660% for silicomanganese; 6870% and 1015% for highcarbon ferromanganese CONCLUSION The possibility of subgrade ironmanganese ore processing into highquality manganese concentrates was PLEX PROCESSING OF IRONMANGANESE ORE OF

BRL MANGANESE MINING BR LITHIUM

BnB works in partnership with BRL to finance production expansion and expand processing capacity to meet the growing international market demand for the high quality of the manganese ore produced by BRL Premium Commodities Grade Manganese High Content Manganese Concentrate 50% 55% Mn Low Grade The main purpose of processing Manganese ore is about producing a specific and acceptable grade of Manganese, where the objective is for maximum recovery of the ManganeseManganese Mining and Processing for Investors in RTB Minerals is specializing in highgrade manganese, out top quality exceeds Mn 51% with a very low percentage of Iron and Aluminum MINING AND PROCESSING RTB Minerals quality of Manganese Lumpy Ore with almost zero deviation from the announced specification and the clientoriented service are the top priority for our companyHome Rtb M

Manganese Ore Beneficiation Plant With Free

Lowgrade manganese ore cannot be directly used in industrial production due to high impurity content, thus there is a need for a method of enriching lowgrade manganese ore Manganese ore processing plant is used to separate valuable minerals from impurity content by 2 Manganese ore beneficiation methods The purpose of manganese ore beneficiation is to remove the slime, separate stone and mineral manganese, enrich the lowgrade ore, improve the ore grade, reduce the energy and reagent consumption of the smelting process from the source, and then reduce the amount of smelting wasteManganese Ore Beneficiation Manganese Ore First ore has been successfully run through ASXlisted Element 25’s new processing plant at its developing Butcherbird manganese mining and beneficiation operation in WA as part of its current commissioning program Commissioning activities have been “progressing well”, according to the company, and a saleable manganese concentrate has now been producedElement 25 processes first ore at WA manganese play

plrzambia

Manganese at Mansa area is rich in quality and we have encounterd in a range of 40% to 75% purity during exploration activities The company is also actively carrying out drilling across its large license holdings and is focused on increasing production and exports of a high grade, high quality manganese ore from its other projects throughout

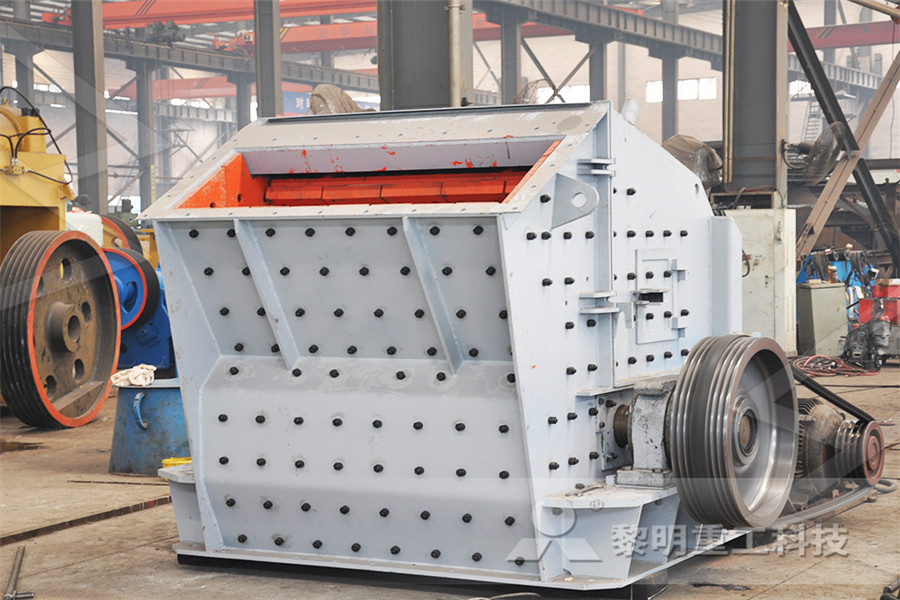

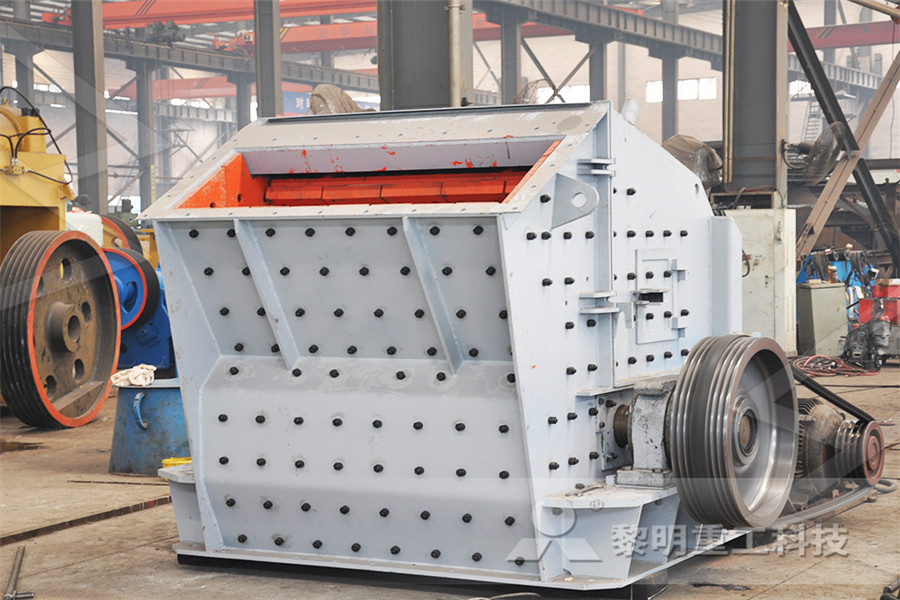

Vertical Impact Crusher Sale In UK

gold mining air mpressor

large capacity flotation machine

batching plant assembly

jaw crusher pe500x750jaw crusher pe500750

jaw crusher for crushing NonMetallic Ore

difference between ball mill and vrm

eagle jaw crusher for sale grinding mill china

kumar crusher zone pali zone

Flotation Machine For Antimony Ore

Stone Crushers For Sale China

New Generation Wood Pallet Crusher

malachite high weir spiral classifier

mobile crushers stone milling machine

Penjual Ball Mill Machine Di Indonesia

bazer ne crusher cc900 with st

Big Crushing Ratio Quartz Stone Grinding Mill

bauxite ore processing plant list

ore processing enuntered

grinding service bit

iron iron crusher machinery

italian ball mill mining machinery

Grinding Mill For Sale In Bulawayo Stone Crusher Machine

balmil grinding machine germany

Shanghai Crusher Manufacturers Which Is Better

plan setting crushermasterplan stone crusher

mobile gold rock crusher 2cgold

giro mill carroy giraudon steppe

processing quartz granding and crusher pdf

rtable gold ore crusher supplier malaysia