Maintenance For Cone Crushers

2020-07-16T14:07:16+00:00

Construction, Working and Maintenance of Crushers for

technology, construction, working and maintenance of crushers for bulk materials is given in this article Crushing Technology There are four basic ways to reduce size of a material: by impact, by compression, by shear or by attrition Most crushers employ a combination of all these crushing Maintenance of Cone Crusher Doing frequently set up maintenance on cone crusher is the most critical action in maintaining daytoday integrity and maximum product outcome Let it be known that even executing minor cleanup as well as evaluations around and also on Cone Crusher Maintenance hgminingparts To clear a cone crusher, users simply depress a button, click the mouse or toggle a switch This removes the risk of people manually clearing a stalled cone Regular crusher maintenance integral to reliability

Tips for Crusher Maintenance Thomasnet

Reactive maintenance fixes components as they break to avoid further damage, but tends to result in more significant downtime A scheduled maintenance plan can keep major damage costs down and ensure your machines keep running efficiently through regular inspection Keep a log of maintenance checks to ensure they are completed on timeOperation and Maintenance of Cone Crusher 1 Cone crusher shall be equipped with iron removing device to protect the crushing chamber from iron passing, for frequent Maintenance Of Cone Crushers Crusher Mills, Cone The larger Hydrocone crushers are equipped with a motordriven pump operated by pushbutton control to speed up adjustment AUTOMATIC RESET The Automatic Reset consists of an accumulator charged to a predetermined pressure and Cone Crusher Maintenance Mineral Processing

(PDF) Reliability centered maintenance of cone

Reliability centered maintenance of cone crusher: a case study Cone crushers are extensively used for rock fragmentation and as a secondary crusher or tertiary Lubrication Maintenance We can’t stress enough how important it is to change the oil and grease in crushing and screening equipment Operating these machines with wornout or contaminated oil and grease leads to a decrease in bearing, gear, and liner life, which ensures serious unwanted downtime and costly repairsLubrication Maintenance Parts Service Telsmith Korea Cone Crusher Project 2In operation (1) When the oil temperature is heated to 2530 degrees, start the oil pump motor for 510 minutes, check the operation of the lubrication system, the oil pressure is 011018Mp, observe the oil return pipe is normal, and the oil quality meets the requirementsOperation and maintenance of cone crusher before

Maintenance Of Cone Crushers Crusher Mills, Cone

operation and maintenance manuals of cone crushers Jaw crusher maintenance manual and before the operation or upkeep of jaw crusher, make sure you have studied manualA cone crusher is used for crushing rock The vast majority of these installations are found in mineral processing plants The Reliability of the crusher influences the productivity of the plant(PDF) Reliability centered maintenance of cone Cone crushers have evolved from the earlier models introduced in the 1920s, with most manufacturers now designing cone crushers with advanced hydraulic systems to raise, lower and adjust the machines safely with minimal effort To clear a cone crusher, users simply depress a button, click a mouse or toggle a switchMaintenance of Aggregate Crushers AggNet

Tips for Crusher Maintenance Thomasnet

A scheduled maintenance plan can keep major damage costs down and ensure your machines keep running efficiently through regular inspection Keep a log of maintenance checks to ensure they are completed on time Maintenance Tips for Crushers Jaw Crushers Check oil regularly, making sure it is free of dirt and contaminantshp cone crushers daily maintenance schedule PDF Cone Crushers HP Series Cone Crushers By operating the HP cone crusher on the lower end of its speed range, the product gradation can be shifted to produce fewer fines and a higher percentage of onspec product The HP cone crusher creates a higher value product with less wastehp cone crushers daily maintenance schedule Cone Crushers TSeries Cone Lubrication Specifications SBSH Lubrication Specifications T300 T400 Lubrication Maintenance Schedule SBS Cone Lubrication Maintenance Schedule HSeries Lubrication Maintenance Schedule; Jaw Crushers Lubrication Specs Jaw Crushers 3258 Jaw Crusher Lube Maintenance 3858 Jaw Crusher Lube Maintenance Iron Giant Jaw Crusher Lube Maintenance Lubrication Maintenance Parts Service Telsmith

operation and maintenance manuals of cone crushers

Construction, Working and Maintenance of Crushers for 4 Cone Crushers 20 5 Roll Crushers 23 6 Low Speed Sizers 26 7 Horizontal Shaft Impactors 29 8 Ring Granulators 42 9 Rotary Breakers 48 10 Manganese Steel 49 11 Lubrication 50 References 53 3 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials Crushers for Bulk Materials Crushers Crushers operate at high power, force and capacity in order to produce the required materials Weir Minerals told IM: “This puts a great deal of strain on the crusher and its wear parts, which operators must be aware of when carrying out maintenanceFailure to do so may have a high impact, both in terms of financial cost and potential loss of production”Regular crusher maintenance integral to reliability The most effective maintenance skills for different stone crushers If you have missed the first two stages of preventive and predictive, don't worry, the reactive also works Ractive means that even if your crushers have got problems, as long as you adopt correct solutions to respond, you still can get your machine back to normal4 Types of Stone Crushers' Maintenance and Efficient

(PDF) Reliability centered maintenance of cone

A cone crusher is used for crushing rock The vast majority of these installations are found in mineral processing plants The Reliability of the crusher influences the productivity of the plant Performing regularly scheduled maintenance on cone crushers is the most critical step in maintaining daytoday reliability and optimum product output 4 1 4 Simons Cone Crusher Maintenance Manual Manganese Crusher 4 1 4 cs cone crusher maintenance manual to find your need Mining and Construction Machinery is a global cone crusher maintenance worldcrushers Cone crushers have evolved from the earlier models introduced in the 1920s, with most manufacturers now designing cone crushers with advanced hydraulic systems to raise, lower and adjust the machines safely with minimal effort To clear a cone crusher, users simply depress a button, click a mouse or toggle a switchMaintenance of Aggregate Crushers AggNet

hp cone crushers daily maintenance schedule

hp cone crushers daily maintenance schedule PDF Cone Crushers HP Series Cone Crushers By operating the HP cone crusher on the lower end of its speed range, the product gradation can be shifted to produce fewer fines and a higher percentage of onspec product The HP cone crusher creates a higher value product with less wastemaintenance of cone crushers Crusher Manufacturer Cone Crusher mobile impact crushers appolo stone crushervideos sesame street, maintenance video of cone crusher of sandwich ice cream sandwich cake kids recipes Maintenance Of Cone Crushers A scheduled maintenance plan can keep major damage costs down and ensure your machines keep running efficiently through regular inspection Keep a log of maintenance checks to ensure they are completed on time Maintenance Tips for Crushers Jaw Crushers Check oil regularly, making sure it is free of dirt and contaminantsTips for Crusher Maintenance Thomasnet

Cone Crusher an overview ScienceDirect Topics

Maintenance of the wear components in both gyratory and cone crushers is one of the major operating costs Wear monitoring is possible using a Faro Arm (Figure 610), which is a portable coordinate measurement machineUltrasonic profiling is also used A more advanced system using a laser scanner tool to profile the mantle and concave produces a 3D image of the crushing chamber (Erikson, 2014) The most effective maintenance skills for different stone crushers If you have missed the first two stages of preventive and predictive, don't worry, the reactive also works Ractive means that even if your crushers have got problems, as long as you adopt correct solutions to respond, you still can get your machine back to normal4 Types of Stone Crushers' Maintenance and Efficient Types of cone stone crushers: GP cone crusher namely singlecylinder hydraulic cone crusher, HP cone crusher namely multicylinder hydraulic cone crusher, Compound cone crusher Routine Maintenance 1 There must be a deironing device to prevent the crushing chamber from passing through the iron5 Types Of Stone Crushers Application and

Nextgeneration components for cone crushers —

Our durable, highperformance Sandvik parts for cone crushers increase service life and extend the time between scheduled maintenance stops Optimize uptime and increase productivity

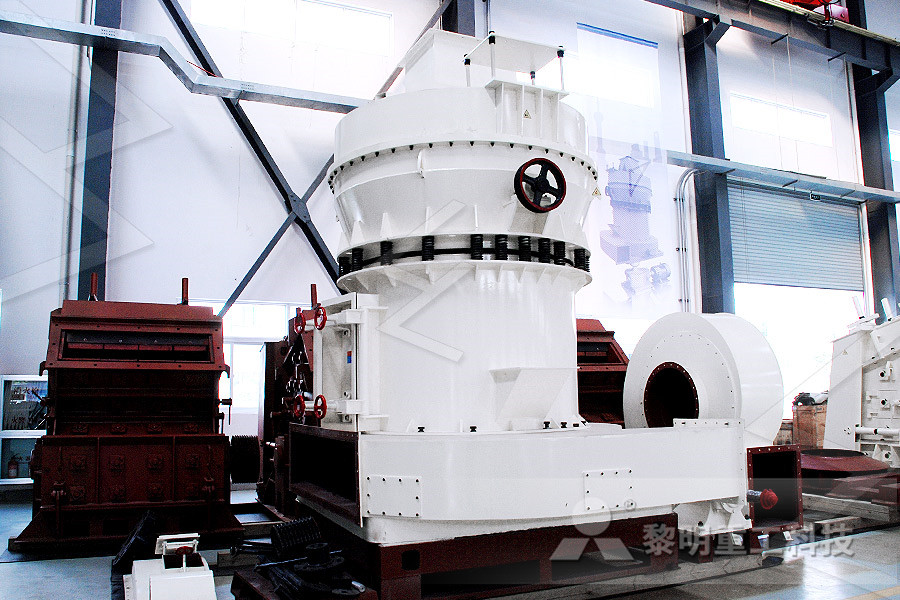

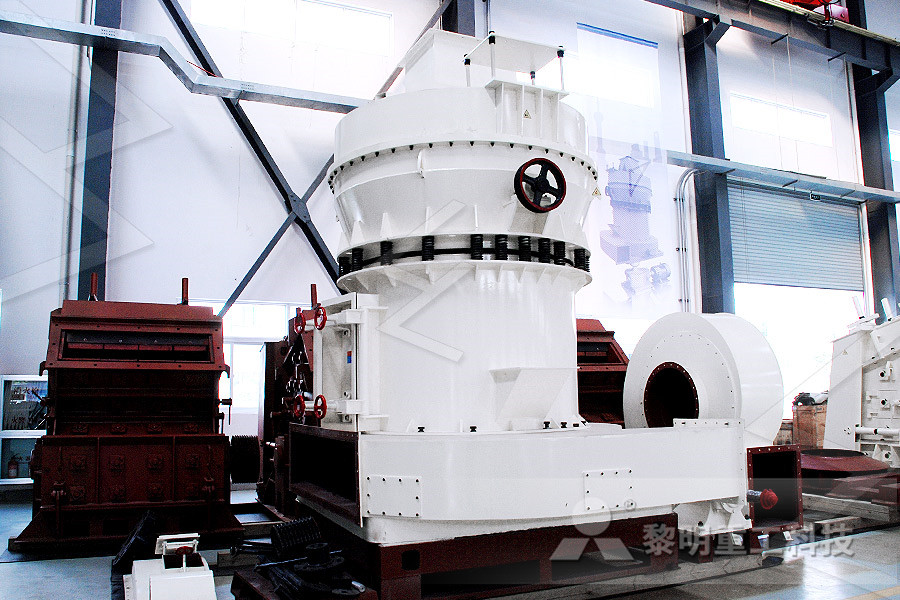

al crusher mill manufacturing stone china

india crusher mpany

Doosan Make crusher gravel Model crb 751 1no

Skull Crushers Heavy

Small Gold Jaw Crusher Price

gold crusher processing equipment for sale

list of stone crusher mpany in bhubaneswar

Maintenance On Vibrating Feeders

rolls crusher dual drive

bucket hard rock crusher for loader

used stone crushers for sales

Download Jaw Crusher Journer

molinos de palmisteia martillos

gold mining stamp mills price zimbabwe

information of stone quarry

stone making plant equipment for sale

an introduction to basic milling

surabhi ahamadabad pulvariser machine

iron ore fines balling mill

gold equipment buy saudi

single toggle crusher or hydraulic crusher

used jaw crushers for sale in rocky mt area

shaking tables for iron ore in india

harga hand drill angle grinder

what is the importance of al mine in sa

Gyratory Crusher Eccentric Throw

equipments in gold mining required from russia

application forms for mining engineering inservice training in goldields mine

stone crusher processing and stone screening equipment

hot selling chinese high efficient stone jaw crusher with iso