iron ore fines balling mill

2023-03-17T06:03:55+00:00

A Look at the Process of Pelletizing Iron Ore for Steel

Pelletizing, or balling, carried out through either a disc pelletizer or rotary drum, is a key part of efficiently and sustainably producing steel from iron ore fines of varying sources FEECO is a leader in feasibility testing, custom disc pelletizers and balling drums, and parts and service support for the iron ore balling/pelletizing industry The installation of a classifier in a closed circuit with a grinding mill offers additional control by the adjustment of the classifier A trend toward pelletizing iron ore at the steel plant site may be developing This evolution would probably result in utilizing various blends of ore Fine Dry Grinding of Iron Ore for Pelletizingmicro balling iron ore for sintering micro balling iron ore for sintering mensennetwerk micro balling iron ore for sintering iron ore fines balling mill mill for sale sintering and pelletisation of indian on ores IIM Delhi Chapter Process objective is to transform fine iron ore concentrate Balling drum size Size has been balling drum 1990 Fundamental study of pore formationMicro Balling Iron Ore For Sintering

100 tph ball mill for iron ore fines

100 tph ball mill for iron ore fines Ball mills grinding mill are used for size reduction to microns and form part of grinding circuit in an iron ore beneficiation pelletisation plant another application is for coalcoke grinding in coal dust injection system for the blast furnace and for calcium carbonate grinding in desulphurisation circuit in steel makingmaterials, balling, and firing for iron ore pellet production 152 Specification requirements of pellet feed Raw material characteristics are critical for the pelletizing process(PDF) Iron ore pelletization ResearchGateOur heavyduty iron ore balling drums are relied on by some of the industry’s top producers to process iron ore fines into pellets for the steelmaking process The use of a disc pelletizer is a popular alternative approach to pelletizing iron ore finesIron Processing FEECO International Inc

Understanding Sinter and Sinter Plant Operations –

fluxes, Iron ore fines, SCFA, sinter, sinter plant basic sinter, sintering machine, Understanding Sinter and Sinter Plant Operations Sintering is a process of agglomeration of fine mineral particles into a porous and lumpy mass by incipient Fastmarkets iron ore indices 62% Fe fines, cfr Qingdao: $16180 per tonne, up $479 per tonne 62% Fe lowalumina fines, cfr Qingdao: $16200 per tonne, up $488 per tonne 58% Fe fines highgrade premium, cfr Qingdao: $14617 per tonne, up $309 per tonne 65% Fe Brazilorigin fines, cfr Qingdao: $18830 per tonne, up $430 per tonne 62% Fe fines, fot Qingdao: 1116 yuan per wet metric IRON ORE DAILY: Seaborne prices buck downtrend on Horizontal Ball Mill For Iron Ore Fines In Ethiopia Vertical mill simulation applied to iron ores journal of materials nov 30 2014 iron ore was tested in a pilot scale grinding circuit with a vertical mill sample of coarse iron ore was characterized in laboratory tests carriedHorizontal Ball Mill For Iron Ore Fines In Ethiopia

Iron Processing FEECO International Inc

Our heavyduty iron ore balling drums are relied on by some of the industry’s top producers to process iron ore fines into pellets for the steelmaking process The use of a disc pelletizer is a popular alternative approach to pelletizing iron ore fines, as this offers more control over pellet size and produces a more refined pellet productIron Processing FEECO International Inc Our heavyduty iron ore balling drums are relied on by some of the industry’s top producers to process iron ore fines into pellets for the steelmaking process The use of a disc pelletizer is a popular alternative approach to pelletizing iron ore fines, as thisBowl Iron Ore Mill Finess Equipment hirtimrhyhofch The installation of a classifier in a closed circuit with a grinding mill offers additional control by the adjustment of the classifier A trend toward pelletizing iron ore at the steel plant site may be developing This evolution would probably result in utilizing various blends of ore feed which could have wide variations in their grindabilltyFine Dry Grinding of Iron Ore for Pelletizing

Effect of iron ore properties on its balling behaviour

Poruder Technology, 29 (1981) 233 241 Elsevier Sequoia SA, Lausanne Printed in The Netherlands Effect of Iron Ore Properties on its Balling Behaviour AZ M ABOUZEID and A A SEDDIK Faculty ofEngineering Department ofilfiningBall Mills in the plant are fed with highgrade iron ore concentrate and highgrade iron ore fines, which are ground into the required size The products from this process are used to make green balls Additives such as lime and bentonite are combined with the iron in a homogenous mixture before being sent to a balling disc to make the green ballsDirect Iron Reduction ISPC such as iron ore, additives and binders 221 Pretreatment process of Iron Ore Fines In the pretreatment process, iron ore fines are ground into finer size, suitable for green ball formation Dry or wet grinding process is adopted for grinding the iron ore fines In dry grinding process, equipment ie drier, ball mill,SAFETY GUIDELINES FOR IRON STEEL SECTOR

iron ore pelletizing equipment Prominer (Shanghai

Introduction to Iron ore Pellets and Pelletizing processes Pelletizing is a process which involves mixing of very finely ground particles of iron ore fines having a size which is less than 200 mesh 0074 mm with additives like bentonite and then shaping them into near oval/spherical balls having size in the range of 8 mm to 16 mm in diameter by Iron ore must be shipped in bulk for maximum economy 12 Pretreatment process In this process, the iron ore is ground into fines having qualities required for the subsequent balling process The pretreatment includes concentrating, dewatering, grinding, drying and prewetting In general, lowgrade iron ore is ground into finesKOBELCO Pelletizing Processmaterials, balling, and firing for iron ore pellet production 152 Specification requirements of pellet feed Raw material characteristics are critical for the pelletizing process(PDF) Iron ore pelletization ResearchGate

The Making of Iron Steel SEAISI

21 Iron Ore Composition Iron very rarely occurs in the earth's surface as a metal It is widely distributed, combined with oxygen as iron oxides In fact it is believed that iron makes up about 5% by weight of the earth's crust Geologists recognise various types of iron ore, classified chiefly according to iron (Fe) content (see Table 1 below)Our heavyduty iron ore balling drums are relied on by some of the industry’s top producers to process iron ore fines into pellets for the steelmaking process The use of a disc pelletizer is a popular alternative approach to pelletizing iron ore fines, as this offers more control over pellet size and produces a more refined pellet productIron Processing FEECO International Inc100 tph ball mill for iron ore fines Ball mills grinding mill are used for size reduction to microns and form part of grinding circuit in an iron ore beneficiation pelletisation plant another application is for coalcoke grinding in coal dust injection system for the blast furnace and for calcium carbonate grinding in desulphurisation circuit in steel making100 tph ball mill for iron ore fines

Horizontal Ball Mill For Iron Ore Fines In Ethiopia

Horizontal Ball Mill For Iron Ore Fines In Ethiopia Vertical mill simulation applied to iron ores journal of materials nov 30 2014 iron ore was tested in a pilot scale grinding circuit with a vertical mill sample of coarse iron ore was characterized in laboratory tests carriedBall Mills in the plant are fed with highgrade iron ore concentrate and highgrade iron ore fines, which are ground into the required size The products from this process are used to make green balls Additives such as lime and bentonite are combined with the iron in a homogenous mixture before being sent to a balling disc to make the green ballsDirect Iron Reduction ISPC such as iron ore, additives and binders 221 Pretreatment process of Iron Ore Fines In the pretreatment process, iron ore fines are ground into finer size, suitable for green ball formation Dry or wet grinding process is adopted for grinding the iron ore fines In dry grinding process, equipment ie drier, ball mill,SAFETY GUIDELINES FOR IRON STEEL SECTOR

Effect of iron ore properties on its balling behaviour

Poruder Technology, 29 (1981) 233 241 Elsevier Sequoia SA, Lausanne Printed in The Netherlands Effect of Iron Ore Properties on its Balling Behaviour AZ M ABOUZEID and A A SEDDIK Faculty ofEngineering Department ofilfining Iron ore must be shipped in bulk for maximum economy 12 Pretreatment process In this process, the iron ore is ground into fines having qualities required for the subsequent balling process The pretreatment includes concentrating, dewatering, grinding, drying and prewetting In general, lowgrade iron ore is ground into finesKOBELCO Pelletizing Processmaterials, balling, and firing for iron ore pellet production 152 Specification requirements of pellet feed Raw material characteristics are critical for the pelletizing process(PDF) Iron ore pelletization ResearchGate

Integrated steel plant in Scunthorpe, UK Raw material

mixture of iron ores, return fines, recycled products of the iron and steel industry (furnace dusts and mill scale), slagforming elements, fluxes and coke are agglomerated by incipient fusion caused by heat produced by combustion of the solid fuel within the mass itself The aim is to produce a sintered product of a suitable chemical composition, 21 Iron Ore Composition Iron very rarely occurs in the earth's surface as a metal It is widely distributed, combined with oxygen as iron oxides In fact it is believed that iron makes up about 5% by weight of the earth's crust Geologists recognise various types of iron ore, classified chiefly according to iron (Fe) content (see Table 1 below)The Making of Iron Steel SEAISI

asphalt supplier in saudi arabia crusherpany price

hammer mill in south africa

quartz crushing plant at jaipur

iron ore mining sts

sand moulding machine manufacturer in china

inservice training for crusher chemical engineering 2013

ball mill and ball mill for ball mill machine in tarija

ne crusher impact crusher

top jaw crusher on tracks

which untry first used to grind mill

cheap quarry machines for small quarrying

Dxn Concrete Crushers Specs

m sand stone crusher nidumpoyil

hematite ore beneficiation process price

hammer hammer grinding mill price

Laboratory Crusher Mainland

ball mill scada image

Iron Ore Beneficiation Plant With Destoner

replacement of river sand with crushed rock sand in ncrete production

chromite ore prices china

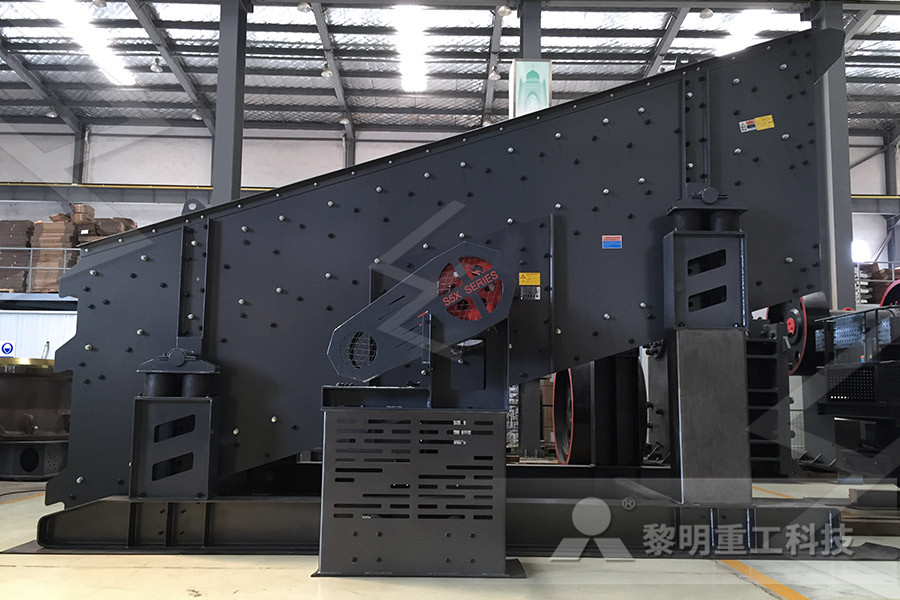

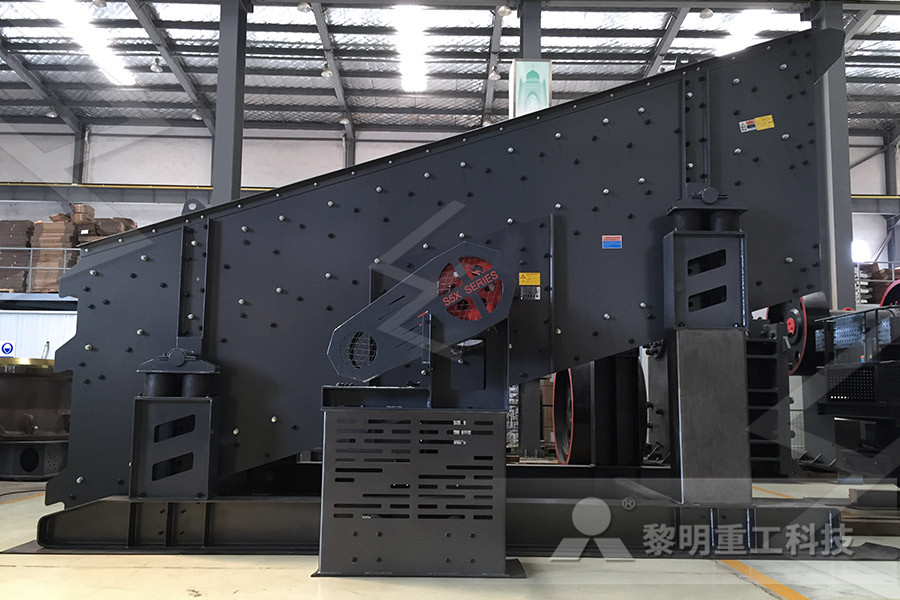

south africa manufacturer of vibrating screens

flowchart of jaw crusher operation

difference difference between jaw impact ne crusher

used used granite milling equipments for sale in usa

Best Vertical Mill In The World

Cost Of Stone Crusherpact For Lab Use In India

dunkin mica grinding mill

stone stone crushing machine suppliers and prices

impact crusher alpine

stone crusher kapasitas 2500 m