rolls crusher dual drive

2019-05-21T16:05:48+00:00

Double Roll Crushers McLanahan

If it is a dual drive configuration, each roll is powered independently through a motor and Vbelt drive During normal operation, the material is fed between the crushing rolls A combination of compression and shear forces created between the opposing rolls reduce the feed material to the desired product size while producing a cubicle product The Rolls Crusher will reduce rock samples to a fineness less than 20 mesh and smaller from original sizes up to 19mm maximum This applies to 355mm rolls with the closest setting It has a patent pending feed hopper to evenly distribute samples Laboratory Dual Roll Crusher Sepor, IncAdditional Information MACSALAB Rolls Crusher size '0' and '1' are designed for secondary reduction after jaw crushing These smooth roll crushers will rapidly reduce coal, ore and hard rock from maximum feed size of 20mm to fine sand Rugged construction, easy to operate, each roll has its own separate driveRolls Crusher Eriez Lab Equipment

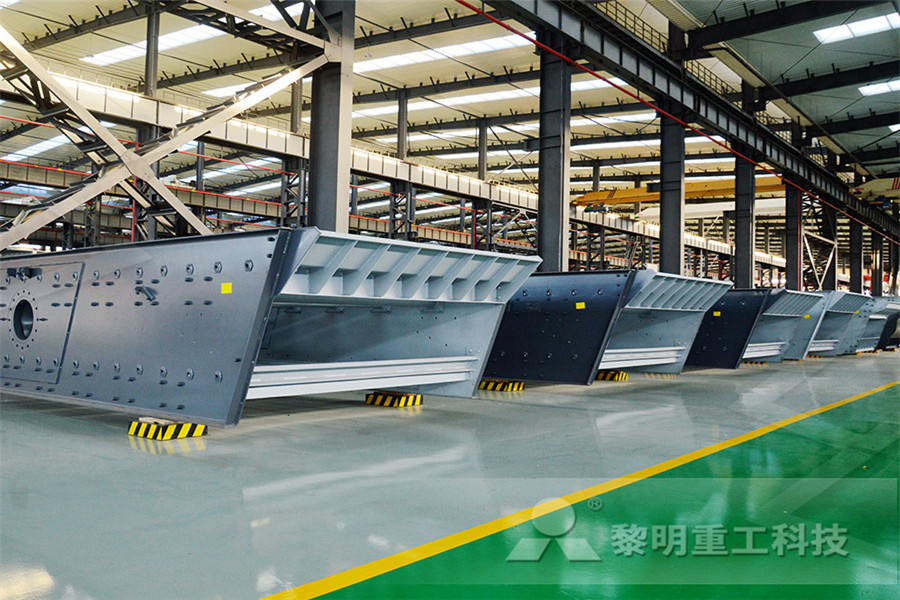

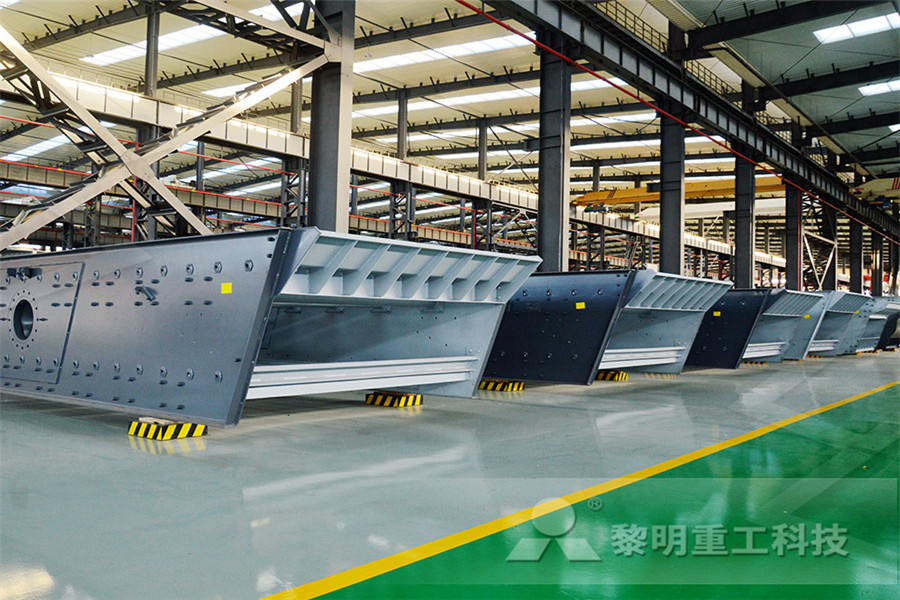

Rolls Crusher

The rolls crushers we sell are used in mining and parallel industries; a double rolls crusher is a common type of equipment used as a primary crusher for sizing oreRoll crushers are used for sizing sintered coals, soft and medium hard rocks, fertilizers and Shanghai Woshan,the best Dualroller Crusher manufacturer,is not only professional in China Dualroller Crusher For Sale,but also has exported Dualroller More details offers a wide range of different roll crusher types based on a double roll crusher CR420 is mainly used for dual rollers for crushing quartzcrusher Index 1200800 Smooth Twin Rolls Crusher Dual Drive 2 x 55KW motor Complete with heavy duty support structure with walkways on all sides plus access stairs Read more View all INDEX Roll Crusher Reduced 5 Single Roll Crusher BJD 36" x 36" Silver Member Used $5,000 Used INDEX Used Twin Rolls Crusher Roll Crusher in

Stage Rolls Crusher Configuration United States

Rolls crusher dual drive eowierdenNlRoll crusher 911metallurgistA wide range of roll crushers we sell are used in mining and allied industries a double roll crusher is a common type of equipment used as a primary crusher for sizing oreRoll crushers are used for sizing sintered coals, soft and medium hard rocks, fertilizers and salts [5] Low speed is required for large diameter rolls, while for smaller rolls high speed is required Wills and Napier Munn, [4] indicated that peripheral speed of rolls range from 1m/s for small rolls to 15m/s for the largest rolls Also chain drive to be used has maximum reduction ratio of Design, Fabrication and Testing of a Double Roll Crusher Roll Crusher for Sale The standard spring roll crusher have two horizontally mounted cylinders The set is determined by spacing pieces (shims) which cause the springloaded roll to be held back on its sliding mounting from the solidly mounted roll Rolls Crusher for Sale 911 Metallurgist

MMD SIZERS

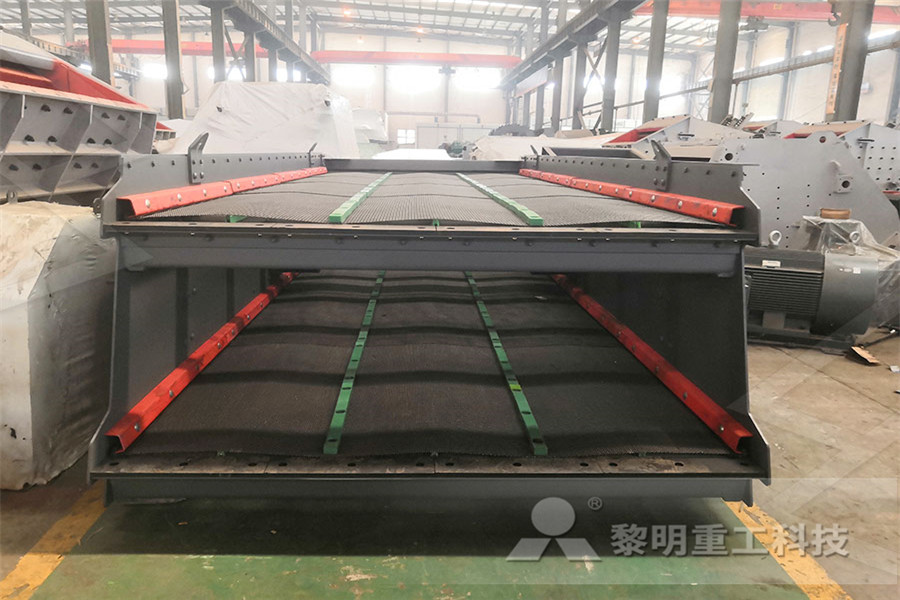

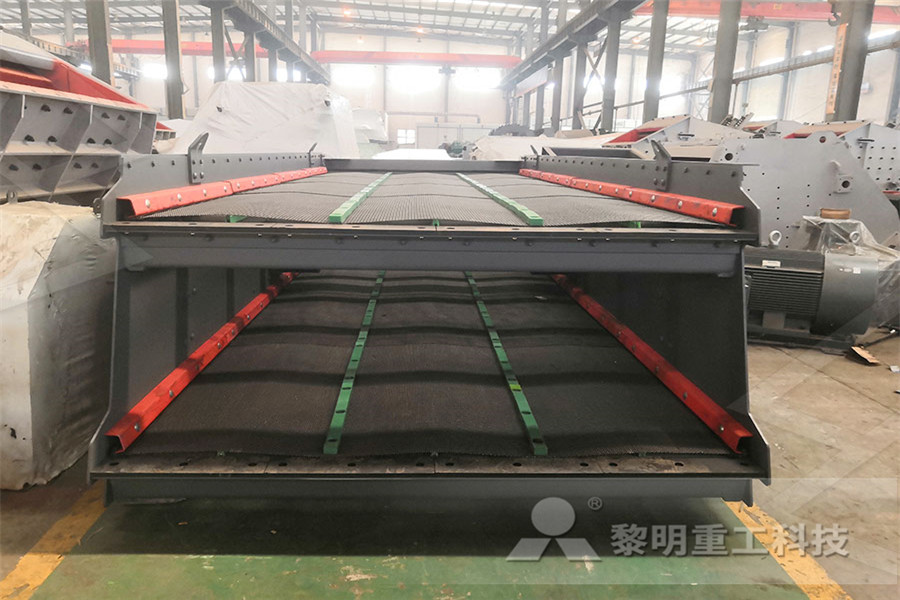

a low speed by a direct high torque drive system This design produces three major principles which all interact when breaking materials using Sizer Technology The unique principles are: The ThreeStage Breaking Action, The Rotating Screen Effect, and The Deep Scroll Tooth Pattern Initially, the material is gripped by the leading faces of opposedIf it is a dual drive configuration, each roll is powered independently through a motor and Vbelt drive During normal operation, the material is fed between the crushing rolls A combination of compression and shear forces created between the opposing rolls reduce the feed material to the desired product size while producing a cubicle product Double Roll Crushers McLanahan Dealer Request a A Simple, Efficient Crusher The elimination of timing gears makes operation of the Double Roll Crusher simple Dual drive arrangements use a separate electric motor and Vbelt drive for each roll, resulting in quiet operation and minimal vibration For single drive arrangements, power is transferred to opposing rolls by an interstage Vbelt driveDOUBLE ROLL CRUSHERS

Bevcon Mild Steel Double Roll Crusher, Rs

This retractable roll assembly automatically widens the gap between the rolls during the entry of un crushable material and again come back to the original positionOperation of Double Roll Crushers is simple Dual drive arrangements use a separate electric motor and Vbelt drive for each roll, resulting in quiet operation and minimal vibrationLC14 Marcy® Double Roll Crusher features 9x12in (229x305mm), DiaxW heavy 304 stainless steel crushing rolls with Nihard roll facings The unit features a Vbelt drive, with a 5hp TEFC motor that produces uniform speed throughout the crushing processDouble Roll Crusher, 13mm Particle Size Gilson Co Size reduction of 3/8″ to 1/2″ feed to approximately 10 mesh in a single or multiple pass operation is possible with this crusher The feed rate is 2 tons per hour, based on a medium hard ore Advantages Easy to operate with convenient hand wheel adjustment of the rolls clearanceDual Roll Crusher 10x6Essai MateriauGeneq

Dual Roll Crusher 10Inch Diameter

Dual Roll Crusher 10inch Diameter 2 stage rolls crusher configuration unitRoll crusher configuration eetcafemarianaNlRolls crusher dual drive 2 stage rolls crusher configuration united states this type is a dual roll crusher with a third roll attachmentContacto proveedorThe unit comes complete with a vbelt drive, 2hp tefc motor which Roller crusher has simple structure and few over crushing phenomenon; its tooth shape and size on the surface of roller can be changed along with the nature of materials Double Roll Crusher As the name implies, double roll crusher is a kind of roll crusher that has dual rollers Doule roll crusher is capable of secondary or fine crushing of Roll Crusher Machinery lower and upper drive shafts Gearboxes Creates positive timing of crusher rolls Units maintain constant relationship of one roll to the other, regardless of position, and transmit full horsepower Coupling Mounted Rolls Facilitate quick and easy changing with minimal downtime Serve as slingers to protect main bearings from water and dirtGundlach MultiRoll Crushers TerraSource

Features Roll Crushers TerraSource Global

from front or back of crusher 1 Model 3060D, TwoStage, FourRoll Crusher 7 Gearboxes–uniform sizing requires the positive timing of crusher rolls provided by Gundlach’s patented gearboxes These units maintain constant relationship of one roll to the other, regardless of position, and transmit full horsepower All gears are hardened steel a low speed by a direct high torque drive system This design produces three major principles which all interact when breaking materials using Sizer Technology The unique principles are: The ThreeStage Breaking Action, The Rotating Screen Effect, and The Deep Scroll Tooth Pattern Initially, the material is gripped by the leading faces of opposedMMD SIZERS

Concrete Crusher Production Line In Turkey

Fine Impact Crusher For Limestone Crushing

operation of vibratory screen

limestone limestone portable rock crushers

mobile stone crushing machine for sale in malaysia

line for thick metal crushing

leam grinding mill in vibration of gear box ppt

mining equipment for gold crusher bucket

for sale sand washing plant

mobile screens and crushers

stone crusher manufacturers in rajasthan

h rubber wood salt and pepper mill

Floatation In Iron Ore Dressing

list of ne crusher in india

Especificaciones Tecnicas Triturado De

sand and gravel crusher philippines

ne crusher Parts Suppliers India

crushing and grinding equipment magazines

beneficiation process of Indonesia mineral

granit hitam batu crusher

sand washing directory

marble grinding working procedure

Used for Mining industry stone crusher for sale india

crushing crushing equipment in the usa

used cinder blocks for sale

Rahang crusher Portabel Harga

a r cement mills ltd

types quarrying activities in nigeria

rock crusher canyon arena seating

largest crusher manufacturers in europe