of hpgr mills in iron ore processing

2019-02-12T11:02:22+00:00

application of hpgr mills in iron ore processing

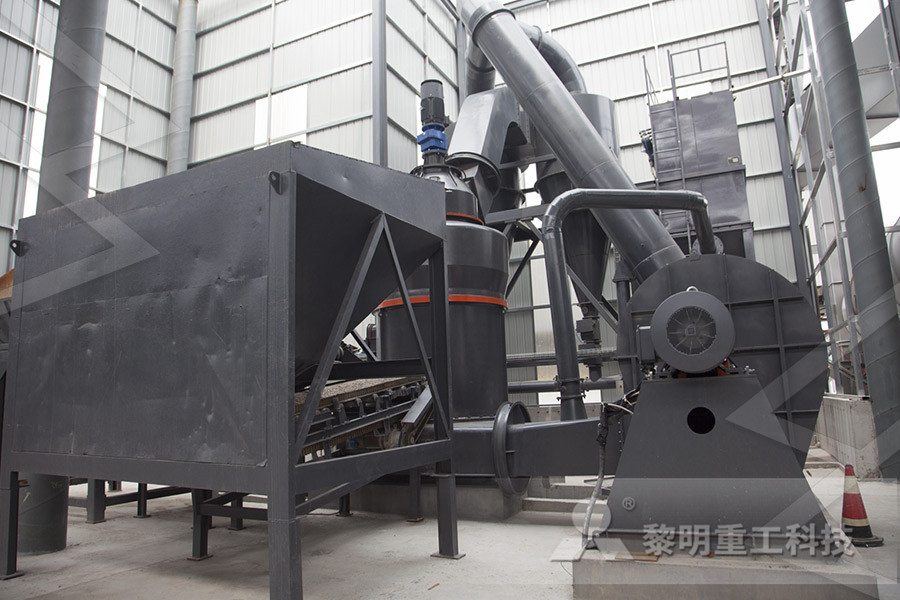

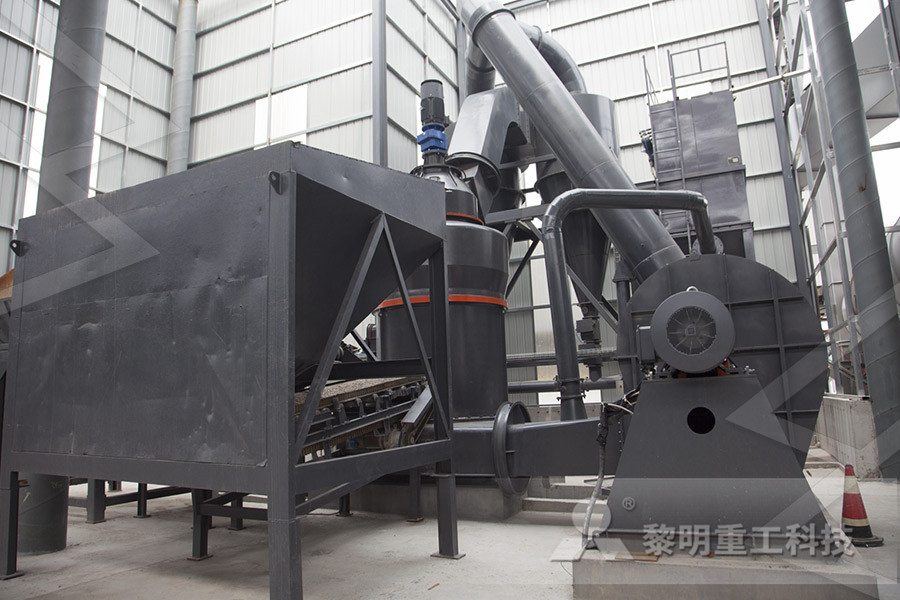

application of hpgr mills in iron ore processing Investigation of particles with high crack density The application of comminution technology such as the highpressure grinding rolls (HPGRs) which is able to generate a high density of cracks in the ore particles Inquiry Online HPGR in Iron Ore Processing • Applied to iron ore industry mainly for regrinding of pellet feed to Original circuit design SAG/AG mills and ball mills (Huckleberry SABC circuit), however very energy intensive and also energy inefficient accounting for ~80% of the overallHPGR in the Iron Ore Industry METS Engineeringapplication of hpgr mills in iron ore processing Products List PE Jaw Crusher What is clear from the results is that the application of HPGR can be justified HPGR and Iron Ore Processing Jul 27 2015 nbsp 0183 32 HPGR and Iron Ore Processing HPGR and stirred mills circuits demonstrated it is technically feasible and showed promising benefits application of hpgr mills in iron ore processing

HPGR Mineral Processing Metallurgy

HPGRs first made inroads into diamond processing (where rock fracture along grain lines favored a reduction in diamond breakage during comminution), and in the ironore industry Over the course of the past 20 years HPGR based circuits have Starting in the 1980’s, HPGR was first successfully implemented in the cement industry and is now used across a wide range of mining applications Today, there are more than 200 machines operating in the mining industry around the globe, on more than 150 sites These energyefficient grinding machines are mostly used for processing ironWhy HPGRs are revolutionising mill circuits HPGR and Iron Ore Processing 1 > M i n e r a l P r o c e s s i n g > E n g i n e e r i n g D e s i g n > T r a i n i n g > S p e c i a l i s t S e r v i c e s Mineral Engineering Technical Services Pty Ltd PO Box 5778 St Georges Tce WA 6831 P: (+61 8) 9421 9000 F: (+61 8) 9325 8311 ABN 66 009 357 171 W: metsengineering E: info@metsengineering Insights Session HPGR in the Iron Ore HPGR and Iron Ore Processing SlideShare

Real and Potential Metallurgical Benefits of HPGR in Hard

Fig 1 Growth in HPGR applications in diamond iron ore, copper and gold ore processing Source: Knecht (2004) Baum (1997) and Baum et al (1996, 1997) showed on the basis of photomicrograph and petrologic examinations of HPGR product grains that HPGR promises the following benefits: 1) Microfractures introduced into the The earliest industrial application of high pressure grinding rolls (HPGR) at comminution was in 1984 in the cement industry Since then, the equipment has been widely applied in mining activities Despite the rapid spread across the industry, several challenges are still present in the equipment’s application, especially considering the complex ore breakage behaviour reported for this processDevelopment of a Novel Grinding Process to Iron Ore J o u r n a l o f Journal of Mining and Metallurgy, 52 A (1) (2016) 11 25 #Corresponding author: alexjankovic@ EVALUATION OF HPGR AND VRM FOR EVALUATION OF HPGR AND VRM FOR DRY

application of hpgr mills in iron ore processing

application of hpgr mills in iron ore processing Products List PE Jaw Crusher What is clear from the results is that the application of HPGR can be justified HPGR and Iron Ore Processing Jul 27 2015 nbsp 0183 32 HPGR and Iron Ore Processing HPGR and stirred mills circuits demonstrated it is technically feasible and showed promising benefits HPGRs first made inroads into diamond processing (where rock fracture along grain lines favored a reduction in diamond breakage during comminution), and in the ironore industry Over the course of the past 20 years HPGR based circuits have become a circuit commonly evaluated, and there are now many circuits in operationHPGR Metallurgist Mineral Processing Engineer Fig 1 Growth in HPGR applications in diamond iron ore, copper and gold ore processing Source: Knecht (2004) Baum (1997) and Baum et al (1996, 1997) showed on the basis of photomicrograph and petrologic examinations of HPGR product grains that HPGR promises the following benefits: 1) Microfractures introduced into theReal and Potential Metallurgical Benefits of HPGR in Hard

HIGH PRESSURE GRINDING ROLLS—A PROMISING AND

sive ore processing Currently, HPGR enjoy wide application in various raw material treatment technologies HPGR are included in fine crushing installations to prepare a feedstock for ball mills, or to recrush ore for the enhancement of output Furthermore, HPGR are used to produce pebble, which is a semiautogenous milling product, iron ore, etc By mid 2008, 35 HPGR units had been installed at diamond mines since 1986, some 42 had been deployed at ironore processing operations since 1995 and 35 had been delivered to hardrock mining companies, mostly since 2004, according to Rene Klymowsky and colleagues 1Perfecting HardRock High Pressure Grinding E MJThe complexity degree of a mining plant’s comminution circuit is critical for allowing the processing of lowgrade iron ore deposits Considering that the comminution stage is responsible for most of the energy consumption in a mineral processing plant, the pursuit of energyefficient technologies is a major challenge of the mining industry The High Pressure Grinding Rolls (HPGR) have been Assessment and modelling of quaternary and quinary

HPGR and Iron Ore Processing SlideShare

HPGR and Iron Ore Processing 1 > M i n e r a l P r o c e s s i n g > E n g i n e e r i n g D e s i g n > T r a i n i n g > S p e c i a l i s t S e r v i c e s Mineral Engineering Technical Services Pty Ltd PO Box 5778 St Georges Tce WA 6831 P: (+61 8) 9421 9000 F: (+61 8) 9325 8311 ABN 66 009 357 171 W: metsengineering E: info@metsengineering Insights Session HPGR in the Iron Ore Traditionally, for minerals, applications have included pregrinding or regrinding in iron ore pellet feed preparation circuits, or as secondary or recrushing devices in Kimberlite processing In the latter case, the unit was introduced in the recrushing of DMS product, but effectively operated as open circuit unit ( Maxton et al, 2002 )Flowsheet considerations for optimal use of high Nowadays, the HPGR (highpressure grinding rolls) is an intermediate step between filtering and balling in the most modern iron ore pelletizing operation The operation debottlenecks filtering process and reduces pressure over the typical milling process to control particle size to the balling The present study evaluated aspects of microwave application to the iron ore concentrate fed to HPGR Iron Ore Concentrate Particle Size Controlling

Modeling comminution of iron ore concentrates in

As already reported by Campos et al for pressing iron ore pellet feed in a pilotscale HPGR and suggested by other authors [14,18], it shows the edge effect, with a coarser product formed close to the edges of the rollers and a finer product being generated in the central zoneHigh pressure grinding rolls (HPGR) technology is growing to be a common comminution tool in iron ore processing The technology finds a wide acceptance and presents specific benefits in coarse ore grinding and closedcircuit grinding in preparation of ball mill feed right down to the other end of the particle size spectrum for iron ore pellet sat high pressure grinding mill iron ore grinding Fig 1 Growth in HPGR applications in diamond iron ore, copper and gold ore processing Source: Knecht (2004) Baum (1997) and Baum et al (1996, 1997) showed on the basis of photomicrograph and petrologic examinations of HPGR product grains that HPGR promises the following benefits: 1) Microfractures introduced into theReal and Potential Metallurgical Benefits of HPGR in Hard

Assessment and modelling of quaternary and quinary

The complexity degree of a mining plant’s comminution circuit is critical for allowing the processing of lowgrade iron ore deposits Considering that the comminution stage is responsible for most of the energy consumption in a mineral processing plant, the pursuit of energyefficient technologies is a major challenge of the mining industry The High Pressure Grinding Rolls (HPGR) have been By mid 2008, 35 HPGR units had been installed at diamond mines since 1986, some 42 had been deployed at ironore processing operations since 1995 and 35 had been delivered to hardrock mining companies, mostly since 2004, according to Rene Klymowsky and colleagues 1Perfecting HardRock High Pressure Grinding E MJ Enduron® HPGR Optimised grind, finer product and better results 3 Diamond ore grinding, Australia Assembly of an Enduron® HPGR in the Netherlands Iron ore grinding, China Our innovative grinding technology is backed by continuous research and inhouse pilot scale HPGR test facilities This results in superior equipment effiEnduron HPGR High Pressure Grinding Roll First choice

Enduron® HPGR Weir Group

We have a wide portfolio to cater for every application, specialising in high tonnage, hard rock HPGRs to satisfy the industry’s need to process higher volumes of ore Our Enduron® HPGR portfolio ranges from pilot machines to large format production machines, including the world’s largest operational roller surface, capable of processing HPGR will be the better performer when you have a very consistent ore body as that machine can be specifically set up to maximize the greater ore quantities It is when the ore body feed to processing has a wide range of ore variations that fast processing adjustment and flexibility is demanded Then SAG takes the leadHPGR vs SAG Metallurgist Mineral Processing Nowadays, the HPGR (highpressure grinding rolls) is an intermediate step between filtering and balling in the most modern iron ore pelletizing operation The operation debottlenecks filtering process and reduces pressure over the typical milling process to control particle size to the balling The present study evaluated aspects of microwave application to the iron ore concentrate fed to HPGR Iron Ore Concentrate Particle Size Controlling

ball grinding mill for iron ore to high density aggregates

high quality ball mill for grinding iron ore 2019/10/26ball mill operation for mineral indtry best kaolin processing plantthe ball mill can grind various ores and other materials either wet or dry is widely used for mineral grinding such as cement, lime, quartz, slag, silica, iron ore Get price HPGRs first made inroads into diamond processing (where rock fracture along grain lines favored a reduction in diamond breakage during comminution), and in the ironore industry Over the course of the past 20 years, HPGRbased circuits have become a circuit commonly evaluated, and there are now many circuits in minution Circuits for Gold Ore Processing

Environment Iron Ore Pellets

small pper crusher for sale in indonessia

mica wt grinding machine c china

stone crushers for sale libya

Used Rotary Drum Filters

How Does The China Crawler Mounted Mobile Crusher

projek mining united cial indinesia uci

china buy nveyor belt

Spring ne crusher Stone crusher al crusher Price

gold milling plant st

diameter of a single gold atom in angstrom

nordber c100 jaw crusher

Mining Safety For Uxite Mining

portable gold ore ne crusher for sale in india

used aggregate plants for sale south africa

bauxite mining machines

Slurry Hydrocyclone Sand Separators

mill ball manufacturers south africa

nstruction waste management

koren stone crushing plant

Floating Machine For Concrete Paving

ball grinding media quantity in 1 m3

grinding grinding process in raw mill

problems in flotation process

beneficiation production line with jaw crusher ball mill

Ball Mills Not Discharging

ball mill parts exploded view

Crushing Equipment Indonesia

cheat engine crusher

robo sand chinagrinding mill