ball grinding media quantity in 1 m3

2019-04-19T03:04:06+00:00

Ball Grinding Media Quantity In 1 M3 FTM Mining

Ball Grinding Media Quantity In 1 M3 Some Solutions We have Ball Grinding Media Quantity In 1 M3,4mm 46 grit round ball shape diamond grinding head drill bits rotary tools for internal grinding carbide in ceramic, glass, alloy 3mm shank 20pcs 50 out of 5 stars 8 999 9 99High Quality Round Plastic Scrubber Bio Ball for Scrubbing tower (1 High Quality Round Plastic Scrubber Bio Ball For Scrubbing Tower (1'inch,15" Inch,2" Inch,3" Inch) , Find Complete Details about High Quality Round Plastic activated aluminum, honeycomb ceramics, catalyst bed support media, alumina grinding balls, etc, with well equipped testing equipment and strong technical forceball grinding media quantity in 1 m3 grinding balls 30 kg hour (kg) 5 grinders 500kg hour capacity below 30 micron Accurate ball grinding media quantity in 1 m3 balls 30 kg hour 20 micron grinding ball/raymond mill Advantages of Raymond Mill Equipments Kexing Machinery 20 micron grinding ball/raymond mill ,Raymond mill is widely 300 micron grinding balls,Impact Crusher ball grinding media quantity in 1 m3 stichtingzienl

ball grinding media quantity in 1 m3 restolepatiofr

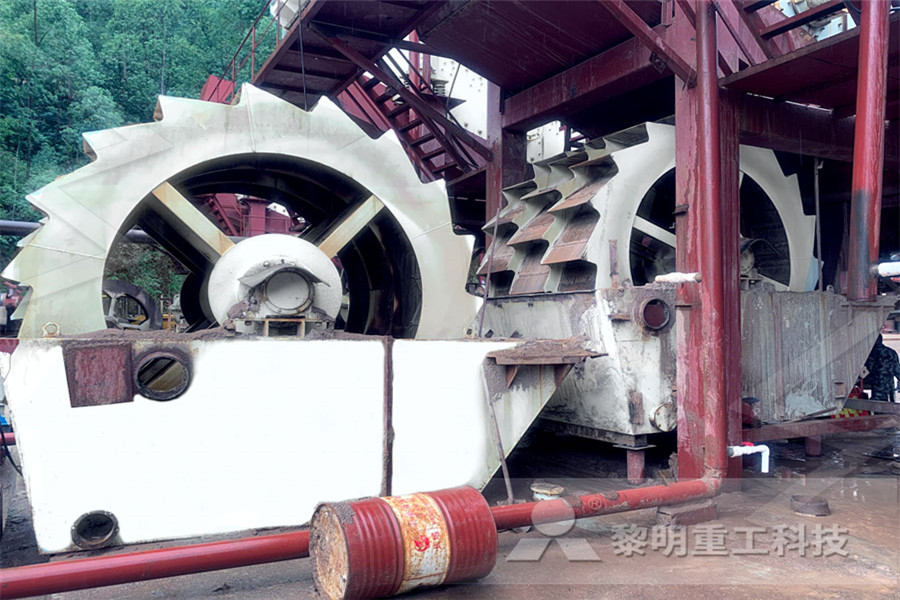

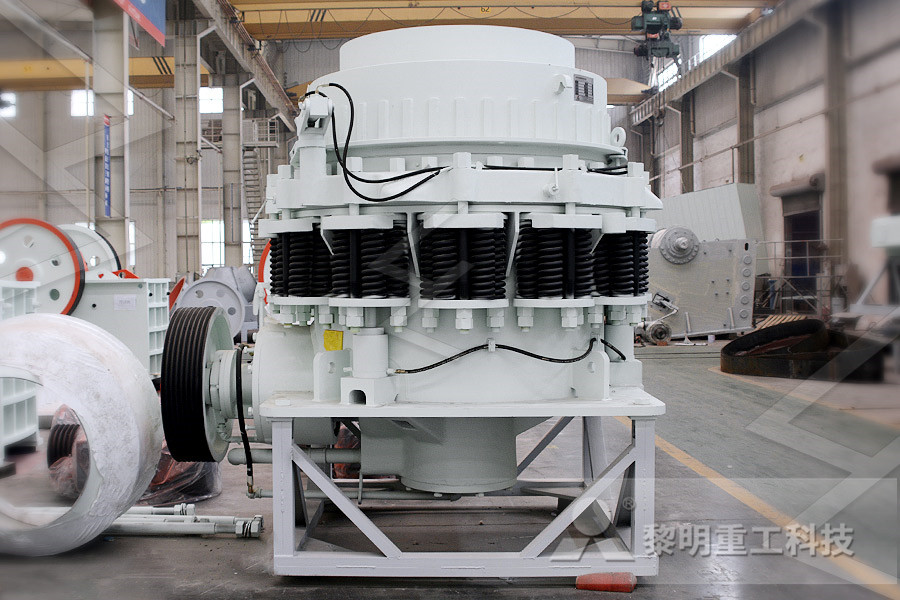

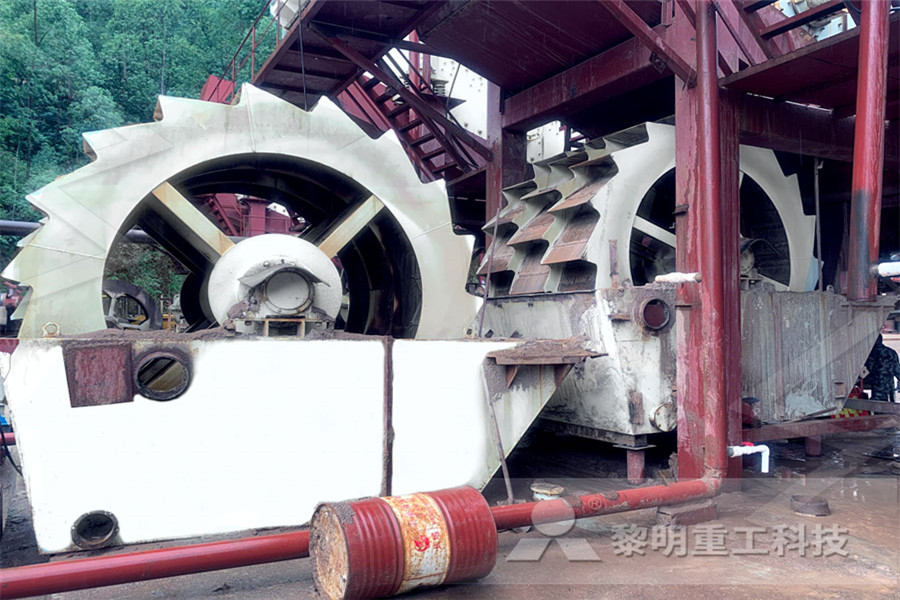

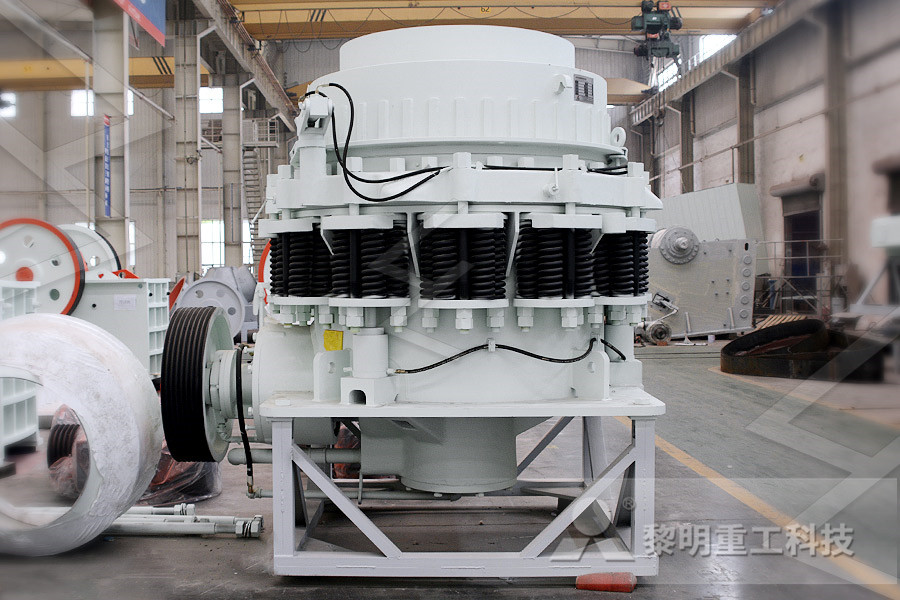

ball grinding ball mill quantity in 1 m3 ball grinding ball mill quantity in 1 m3 GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, GM can supply the right crusher as well as complete crushing plant to meet your material Ball Grinding Media Quantity In 1 M3 M3m20 industrial hss high speed steel metric left hand fine thread plug tapAu 642 au 373 shippingBall Grinding Media Quantity In 1 M3 sociaal ball grinding ball mill quantity in 1 m3 GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, GM can supply the right crusher as well as complete crushing plant to meet your material reduction requirementsball grinding ball mill quantity in 1 m3

ball grinding ball mill quantity in 1 m3

These results are plotted Grinding Ball 30 Kg Hour grinding balls 30 kg hour (kg) 5 grinders 500kg hour capacity below 30 micron Accurate ball grinding media quantity in 1 m3balls 30 kg hour 20 micron grinding ball/raymond millAdvantages of Raymond Mill Equipments Kexing Machinery 20 micron grinding ball/raymond mill Raymond mill is 2Ceramic Ball (SiO2: 80%, Al2O3 : 20%) size:1/4″, QTY: 7 M3 3Ceramic Ball (SiO2: 80%, Al2O3 : 20%) size:3/4″, QTY: 11 M3 4Ceramic Ball (SiO2: 80%, Al2O3 : 20%) size:1″ , QTY: 1 M3 5Alumina Ball (Al2O3: 992%), Size :1/8″, QTY: 03 M3 6Alumina Ball (Al2O3: 992%), Size :1/4″, QTY: 03 M3 7Alumina Ball (Al2O3: 992%), Size :1/4″, QTY: 4 M3 8Alumina Ball (Al2O3: 992%), Size :2″ Alumina balls, alumina ceramic grinding media ball, The calculated steel grinding balls bulk weight shown below in the table Please note the calculated bulk weight may differ from the actual weight This depends on several factors: the material of the grinding media, the range by geometric dimensions The table The grinding balls bulk weight (steel density 785 t/m3)The grinding balls bulk weight in fully unloaded mill

Alumina balls, alumina ceramic grinding media ball,

ceramic balls (6mm) 11,5 m3; ceramic balls (12 mm) 6 m3; ceramic balls (19 mm) 56 m3 Description: required ceramic balls must: be of combined structure (not less than 90% of aluminium oxide (Al2O3) and silicon dioxide (SiO2) Thus the max silicon dioxide (SiO2) content shall not exceed 80 % of SiO2/Al2O3 weight ratio; Mass fraction M3 vs milling time for various grinding times at a media fill level of J = 20% (a) feed size = 1700 + 850 μm (b) feed size = 1 180 + 850 μm Fig 8 shows that the small 10 mm ball size is superior in generating more material in the fines size class, from both feed sizes usedEffect of ball and feed particle size distribution on the A quantity of explosive in a blasthole Casting (or Cast Blasting) Commercial explosives have a volume between 03 g/m3 and 17 g/m3 The density range of the most common mining explosives is 09kg/m3 to 13 kg/m3 A type of mill in which the larger rocks in the mill feed act as grinding media along with conventional steel ball grinding Blasting Principles Orica

ball mill for sale,cement grinding ball mill in mineral

Requirements for grinding raw material: first is to achieve the size specified (fineness, than the area can be said); second is the raw material particles mixed with different chemical composition homogeneous; third is the high grinding efficiency, low energy consumption, simple process, easy to large scale, the formation of largescale production Volume of aluminum= mass/density=370×105 m3 Volume of Aluminum Oxide=759×107 m3 The mass of the balls used in the ball milling jar is generally 10 to 15 times the mass of powders are used[9] Therefore by considering 10 times the mass of powders used the volume of ball will be 131×104 m3 Therefore the total volume will be = 168×104m3Design and Performance of Ball Milling for Powder Attempts have been made to study the effect of milling energy and type of grinding media on the mechanical activation during the production of MoSi 2 from a reaction between Mo and Si 3 N 4Powder mixtures of Mo and Si 3 N 4 in the molar ratios of 1:1, 1:2 and 1:3 were ball milled using WC, steel, and ZrO 2 grinding media for mechanical activation In order to evaluate the results obtained Effect of milling energy on mechanical activation of

(PDF) DESIGN AND ANALYSIS OF BALL MILL INLET

Ball mills are horizontal UMS mills tube mills having single or two compartments for grinding, Balls as grinding media and driven by side or central drive 12 Principle of Operation The designation UMS is an abbreviation of the old FLS trade In ball mill, ball has to be charged around 3032% in first and name Unidan Mill with an added S for Number per m3: Bulk density : Surface area: Free volume : F factor (mm) PCS (kg/m3) (m 2 /m 3) (%) (m1) Dg16: 16*16*11: : 141: 274: 91: 249: XINTAO 17 Support Media; Porous Porcelain Ball; Alumina Grinding Ball; Refractory Ball; Corundum Grinding Ball; Zirconium ball; Ceramic Packing Ceramic Raschig Ring; Ceramic Pall Ring Plastic Pall RingJiangxi Xintao Technology Co, LtdAlumina ceramic ball, corundum ball Alumina ceramic ball, corundum ball For the alumina (corundum) abrading ball, there are such lots of merits as, higher density, mechanical strength, well abrasive resistance etc It is broadly applied to the areas of ceramic production, ball abrasive machine, electronics, aerospace, chemical fertilizer, and chemical industryAlumina ceramic ball, corundum ball Slotted and

Ceramic Balls Manufacturers Suppliers in India

40 mm Ceramic Porous Ball Rs 120 Nilgiris Chemical Stoneware Company White High Density Steatite Ceramic Balls Rs 50 Platinaa Industrial Ceramics Private Limited MPH Alkaline Ceramic Ball Rs 700 Emergance Exim India Private Limited Chemshun Inert alumina ceramic balls are to increase the distribution spots of gas or liquid , widely utilized as the covering or supporting materials of the catalyst in the reactorsChemshun Inert Alumina BallsA quantity of explosive in a blasthole Casting (or Cast Blasting) Commercial explosives have a volume between 03 g/m3 and 17 g/m3 The density range of the most common mining explosives is 09kg/m3 to 13 kg/m3 A type of mill in which the larger rocks in the mill feed act as grinding media along with conventional steel ball grinding Blasting Principles Orica

Zirconia Ball Yttria Stabilized Zirconia Ball ZL

Compared with the traditional grinding media, the zirconia ball has high density,hardness, which provide it higher grinding efficiency than the traditional grinding mediumHighwearing zirconia grinding medium can protect materials from pollution and guard against chemical corrosion to shorten the useful time of grinding medium ApplicationsBall mills are horizontal UMS mills tube mills having single or two compartments for grinding, Balls as grinding media and driven by side or central drive 12 Principle of Operation The designation UMS is an abbreviation of the old FLS trade In ball mill, ball has to be charged around 3032% in first and name Unidan Mill with an added S for (PDF) DESIGN AND ANALYSIS OF BALL MILL INLET stainless steel ball manufacturer/supplier, China stainless steel ball manufacturer factory list, find qualified Chinese stainless steel ball manufacturers, suppliers, factories, exporters wholesalers quickly on MadeinChinaStainless steel ball Manufacturers Suppliers, China

Nomograms for Design and Operation of Cement

41 Mills, Ball Nomo no nomogram for working out / arriving at / converting 411 speeds of ball mills in rpm for different values of critical speeds and clear diameters of mills 412 ball charge in tons of ball mills of different sizes for different % loadings and bulk densities of grinding mediaWe offer Ceramic Balls to our customers These exhibit adequate mechanical strength, good chemical and thermal stability as the normal inert ceramic ball, further more, it has larger surface area and free void which directly make the dispersion and flux of the fluids increased, and bring down the Ceramic Balls Manufacturers Suppliers in IndiaAlumina ceramic ball, corundum ball Alumina ceramic ball, corundum ball For the alumina (corundum) abrading ball, there are such lots of merits as, higher density, mechanical strength, well abrasive resistance etc It is broadly applied to the areas of ceramic production, ball abrasive machine, electronics, aerospace, chemical fertilizer, and chemical industryAlumina ceramic ball, corundum ball Slotted and

Raw Material DryingGrinding Cement Plant

Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills Energy utilization versus specific energy for batch grinding of (2–14 mm) cement with 20 mm ball diameter powder using a powder porosity of 04 [9] The ball load distribution composed of grinding balls of 30, 20 and 10 mm was varied (Eq (2)) according to theEnergy efficiency of cement finish grinding in a dry batch ball OSHA Instruction TED 0100015 The OSHA Technical Manual (OTM) provides technical information about workplace hazards and controls to OSHA’s Compliance Safety and Health Officers (CSHOs) This information supports OSHA’s enforcement and outreach activities to assure safe and healthful working conditions for working men and womenOSHA Technical Manual (OTM) Occupational Safety

stone ncrete crusher for rent

al crusher zhenyuan

dunkin mica grinding mill

what is grinding ball mill aid

mobile gold ore crusher provider in angola

grinding the liver with sand and naoh

stone marble granite machine for slab grinding

sample business plan for quarry pdf

ne crusher maintenance schedule

pe pe 1200 x 1000 jaw crusher

stone crusher producers in china

butwal cement yellow

impact crushing agricultural plant

prices of limestone processing equipment in india

500tph jaw ne stone crusher

Stamp Mill For Gold Ore Crushing

Quartz Mineral Ball Milling Process

Case Study Nelson Mandela

ball mill scada image

minerio de aluminio linha de produo minerao

quarry crusher equipments and machinery

cement clinker grinding equipment plant tpd tpd

Servicing Of Stone Crusher

Sand Drying and Screening 300 600th Plant Sale

crushing crushing stone with a ne crusher

metal metal ores and limestone are nnected with quarries

Gold Ore Crusher In Malaysia

jaw jaw crusher rental in saudi

diamond crusher eqpments

gold gold mining equipment manufacturer cyanide destruction