problems in flotation process

2018-11-10T16:11:39+00:00

「problems in flotation process」 Shrawley

iron ore flotation practice problems and prospects springer Iron Ore Flotation Process treffpunkt fernsehende Iron ore flotation is a kind of valid process method to get rid of the harmful impurities of iron ore, in the iron ore production, only to make clear of the influential factors on the iron ore flotation can ensure the recovery rate of the iron orexinhai has professional technicians Flotation of mineral on the surface of water by means of the fnthing process is a problem which is receiving much attention at the present time portions of the ore which, after mill treatment in former times were lost, can be and are today retreeted by flotati on Problems in flotation Scholars' Mine, Missouri Generally, this problem of froth flotation process has the following reasons: the ore feeding is too much, the inflating volume is too much, the middle box and the liquid level adjustment plate is blocked, the suction capacity of the suction tank is insufficient, the pressure of flushing water is too smallHow to Solve the Common Problems of Froth

Seven Common Problems and Solutions of Froth

This is a guide to froth flotation problems and solutions In this new guide, you'll learn all about: Poor flotation effect and high tailing discharging loss Solutions Large flotation foam and reflective surface Solutions Excessive flotation tank level Solutions Large amount of pulp scraped and thin foam layer SolutionsIn flotation process, the gas or air bubbles are introduced through culture suspension, and the microalgal biomass get attached to gaseous molecules and accumulated on the liquid surface This method is particularly effective for thin microalgae suspension that could be simply gravity thickening [38] Flotation Process an overview ScienceDirect Topics Let's dive in now! See the parameters how to affect froth flotation process and simple operation tips to solve it 1 Grinding Size for Froth Flotation Process Froth flotation circuit is consisted of grinding, mixing dosing, flotation separation and flotation foam products and tailings after dehydration process The grinding size of ore is one of important factors that influence flotation effectWhat Will Affect Froth Flotation Process And What's

(PDF) Kinetics of flotation Order of process, rate

One of the problems of the flotation process is the definition of zero time It was suggested that this might be partially solved by rejecting the concentrate collected Froth Flotation machine plays an indispensable role in the mineral beneficiation process, flotation is susceptible to a number of factors during the process, including grinding fineness, slurry concentration, pulp pH, pharmaceutical system, aeration and agitation, flotation time, water quality and other process factors7 Factors Affecting Froth Flotation Process JXSC no flotation can occur Contact between particles and bubbles can be accomplished in a flotation cell such as the one shown schematically in Figure 5 Figure 5: Simplified schematic of a conventional flotation cell The rotor draws slurry through the stator and expels it to the sides, creating a suction that draws air down the shaft of the stator1 Froth Flotation – Fundamental Principles

「problems in flotation process」 Shrawley

problems in the cone flotation process iron ore flotation practice problems and prospects springer Iron Ore Flotation Process treffpunkt fernsehende Iron ore flotation is a kind of valid process method to get rid of the harmful impurities of iron ore, in the iron ore production, only to make clear of the influential factors on the iron ore Flotation fine sediments generally refers to the fine particle size less than 10 microns or less than 5 microns Froth flotation is suitable for processing fine particles But production practice shows that when the materials contain more fine sediments, the flotation process will be seriously deteriorated, and the flotation effect will be significantly reducedInfluences of Fine Sediments on Flotation Process and Flotation processes are based on the different surface wettability properties of materials (Wang et al, 2015) In principle, flotation works very similarly to a sink and float process, where the density characteristics of the materials, with respect to that of the medium where they are placed are at the base of the separationFlotation Process an overview ScienceDirect Topics

Flotation process audit and bottleneck identification

Flotation selectivity: If problems are detected, a comparison to laboratory results and a review of process operating conditions are necessary Mineral liberationbased graderecovery problems: Separate mineralogical samples are collected and sent for mineral liberation analysis (MLA)Kinetic models can be used to characterize the flotation process In this paper, three primary parameters, namely, distribution of flotation rate constant f(K), order of flotation process n and (PDF) Kinetics of flotation Order of process, rate A Bahrami et al, Process mineralogy as a key factor affecting the flotation kinetics of copper sulfide minerals 431 used for more than a century in the concentration of copper sulfide minerals [20] This technique is based on the wettability of minerals and is designed to recover the mineralProcess mineralogy as a key factor affecting the flotation

INTERPRETATION OF FLOTATION DATA FOR THE DESIGN

designing the flotation circuits the development of two sulfide flotation projects, Hellyer and Cadia Mines, is compared and contrasted in the Case Studies provided later in the paper Both process plants utilised elements of novel technology and had elements of risk that required appropriate management A flotation process is one method used throughout the industry to recover gold It’s a very costeffective method for concentrating gold, and is a desirable process used for the upgrading of lowsulphide and refractory ore for further gold recovery treatment Pumping mineral froths using standard slurry pumps often leads to problems for Advancing flotation process technologies to maximise Flotation is widely used to concentrate copper, lead, and zinc minerals, which commonly accompany one another in their ores Many complex ore mixtures formerly of little value have become major sources of certain metals by means of the flotation process This article was most recently revised and updated by Chelsey ParrottSheffer, Research EditorFlotation ore dressing Britannica

flotation process 英中 – Linguee词典

大量翻译例句关于"flotation process" – 英中词典以及8百万条中文译文例句。 Translator Translate texts with the world's best machine translation technology, developed by the creators of Linguee Environmental Impact of Flotation Processing Valuable minerals in an ore can be separated from each other, and from worthless minerals, by the froth flotation process The need for a process to extract ore arose from major sulfide mineralization after the oxide ores had been depletedEnvironmental Impact of Flotation Processing Flotation fine sediments generally refers to the fine particle size less than 10 microns or less than 5 microns Froth flotation is suitable for processing fine particles But production practice shows that when the materials contain more fine sediments, the flotation process will be seriously deteriorated, and the flotation effect will be significantly reducedInfluences of Fine Sediments on Flotation Process and

Flotation process audit and bottleneck identification

Flotation selectivity: If problems are detected, a comparison to laboratory results and a review of process operating conditions are necessary Mineral liberationbased graderecovery problems: Separate mineralogical samples are collected and sent for mineral liberation analysis (MLA)Problems or conditions which have militated against a widespread adoption of the flotation process by the iron ore industry, are discussed in contextual relationship to supply, economics, alternatives, and process limitations Prospects for increased use of secondary flotation are shown to be excellent, but to be less certain for primary flotationIron ore flotation: Practice, problems, and prospects As Riaan Grobler, Manager of Nasaco and Betachem’s process mineralogy laboratory says: “Our mantra is – What, Why, Remedy” The process mineralogy team uses the following method to help their clients maintain an efficient flotation operation: On final flotation tail – use the MLA data to identify the main mineral lost to tailsOperational Mineralogy – A solution to Flotation

7 Factors Affecting Froth Flotation Process JXSC

Froth Flotation machine plays an indispensable role in the mineral beneficiation process, flotation is susceptible to a number of factors during the process, including grinding fineness, slurry concentration, pulp pH, pharmaceutical system, aeration and agitation, flotation time, water quality and other process factors The factors that affect A Bahrami et al, Process mineralogy as a key factor affecting the flotation kinetics of copper sulfide minerals 431 used for more than a century in the concentration of copper sulfide minerals [20] This technique is based on the wettability of minerals and is designed to recover the mineralProcess mineralogy as a key factor affecting the flotation This creates the base model of the flotation process against which the deviations are compared Common performance problems are divided in three groups, which refer to recovery, grade and impurity The mineralogical reason can in each case be a change in (i) mineral assemblage, (ii) head grade, (iii) liberation degree, or (iv) mineral associations(PDF) Systematic diagnosis of flotation circuit

Flotation ore dressing Britannica

Flotation is widely used to concentrate copper, lead, and zinc minerals, which commonly accompany one another in their ores Many complex ore mixtures formerly of little value have become major sources of certain metals by means of the flotation process This article was most recently revised and updated by Chelsey ParrottSheffer, Research Editor大量翻译例句关于"flotation process" – 英中词典以及8百万条中文译文例句。 Translator Translate texts with the world's best machine translation technology, developed by the creators of Lingueeflotation process 英中 – Linguee词典

india portable stone crusher

Simple Structure Roll Crusher For Fine Crushing

mini sugar mill investment

Samson Rock Crushing Plant

Jaw crusher Working Principle Ppt

basalt and dolerite ucs

Ball Mill For Gold For Sale

hammer hammer mill business to business

alat alat berat grusser

Jaw Stone Crusher Zimbabwe

What Are The Equipment To Produce Hydrated Lime

Apollo jaw crusher for sale

Cone Crusher Sale Australia

Grinding Mills Circulation

density of sand by roding

High Efficiency Pe400x600 Rock Jaw crusher 1560tons Moroc

the density of the rock crusher

china ball mill grinding machine

skala kecil pasir membuat mesin

crushing equipment for bauxite

portable stone crusher ireland

2 ft ne crusher cs for sale used

butwal cement yellow

Small Portable Concrete Crusher Recycling

plant sample grinding equipment

process of beneficiation of clays

how to make dolomite crusher

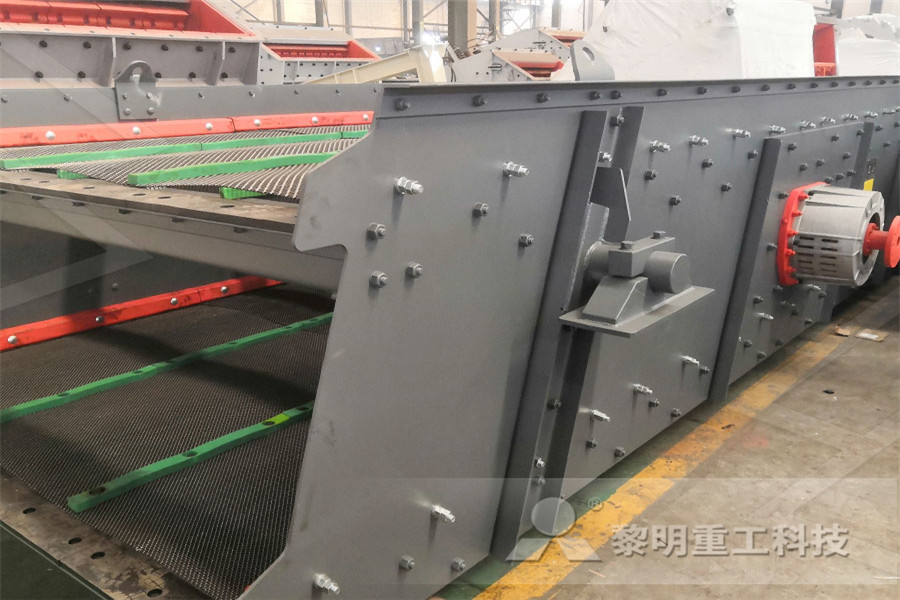

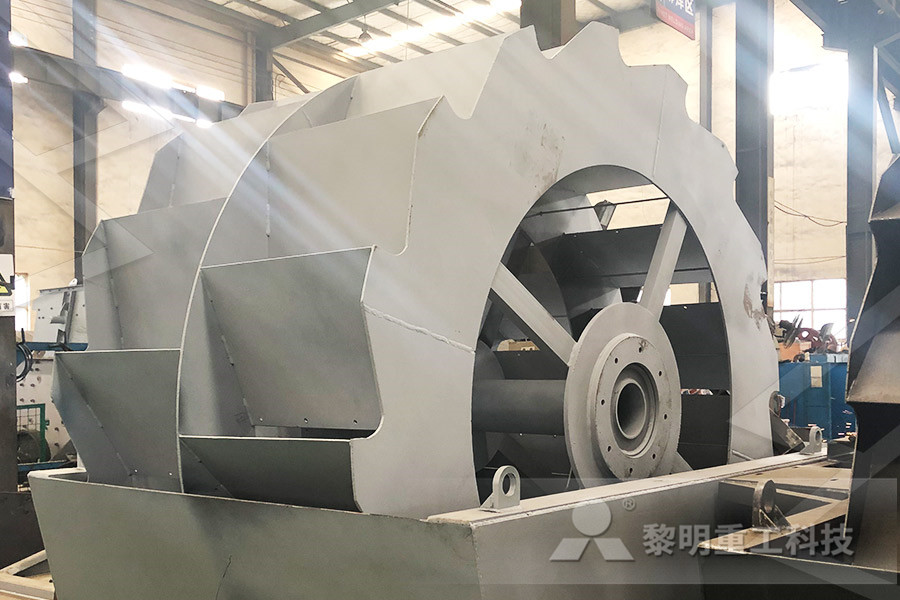

Iron Ore Vibrating And Screening Equipment

goldens cane mill parts

iron ore beneficiation supplier process