between double roll crusher and ne crusher

2023-04-13T09:04:19+00:00

between double roll crusher and cone crusher

double roller crusher manuals online Double Roll CrusherMcNally Sayaji Toothed Double Roll Crusher is used for Secondary and Tertiary Crushing of soft to medium hard material like lignite, coal, fertilizer, gypsum, chalk, clay, limestone, coke, sinter, etc OPERATING PRINCIPLE Due to inward opposite rotation of the rolls, the feed material is nipped between the rolls and crushed Roll crusher,Roller crusher,Double roll cone cone While Cone Crusher working, the rotation of motor winds one regular place and fastens sports of putting by belt pulley or shaft coupling, drive shaft and between double roll crusher and cone crusher Between Double Roll Crusher And Cone Crusher In Tonga Types of coal crushers crusher mills cone crusher jaw coal coke crushers indiacoal coke crusher and mill india in fact there are several types of coal crushers coal jaw crusher is the most common crusher in coal crusher plant and used as coal coke crushers indiacoal coke crusher and mill india in fact there are severalBetween Double Roll Crusher And Cone Crusher In

comparison between double roll crusher and cone

Between Double Roll Crusher And Cone Crusher Between Double Roll Crusher And Cone Crusher Roll crusher applicationsRoll crushers are simple in design and construction, longlasting, economical, and versatileRoll crushing surfaces operate at a fixed distance apart, as opposed to the continually changing distances in a jaw or cone crusherProduct between double roll crusher and cone crusher in kazakhstan high efficiency double roll crusher Single vs Double Roll Crushers Choosing between a single roll crusher and double roll crusher depends upon the type of feed material feed size product size desired and consistency of both feed and product Both single and double roll crushers operate most efficiently with dry friable materials Buy between double roll crusher and cone crusher in comparison between double roll crusher and cone crusher Grinding Mill China Dual roll crushers, how they function Mine The roll crushers are not nearly as productive as cone crushers, with respect to volume, with two rolls rotating about a shaft, towards the gap between the rollscomparison between double roll crusher and cone

Cone Crusher an overview ScienceDirect Topics

The maximum particle size of a limestone sample received from a cone crusher was 25 cm It was required to further crush it down to 05 cm in a roll crusher with smooth rolls The friction coefficient between steel and particles was 025, if the rolls were set at 63 mm and both revolved to crush, estimate the diameter of the rolls Solution Introducing the Cone Crusher Cone crushers take care of secondary and tertiary crushing applications Fine and mediumsized aggregates (used in asphalt and concrete, for example) are created by an eccentrically rotating shaft that grinds the rocks between a robust metal cone and a fixed wall The Blackhawk 100 Cone Crusher is an example of a Jaw Crusher vs Cone Crusher: A Comparison Progress in RollCrushing BY C Q Payne, New York, N Y On the right, a Roll Crushers is shown in a sectional elevation of the AC singleroll crusher while here below is a cutaway view of the machine, with hopper and part of the near side frame removed to show the crushing chamber The moving elements of the machine consist of the rollRolls Crusher for Sale 911 Metallurgist

What is a roll crusher? – Mineral processing equipment

Roll crusher machine A Roll crusher is a size reduction machine consists of two rolls space from each other by a gap opening The rolls rotate towards each other The ore enters the feed opening, being rolled and ground between the surfaces of the rolls faces, then discharged out of the crusher Comparison Of Impact Crusher And Double Roll Crusher Impact crusher and double roll crusher haagdekoDeWhats the difference between impact crusher and cone crusherdifference between a comparison of impact crusher and double roll crusher, read more technical paper, apcac sept 2009 ficemep 7, 2009 while the impact crusher is limited by adifference between cone crusher and crushing rollThe clearance between the two rollers can be adjusted to change the sizes of final products The Roller crusher can be classified into double roller crusher and four roller crusher according to the roller quantity The Double teeth roll crusher bears the features of stable operation, easy maintenance, low Double roll crusher PT ALKABELT SEJAHTERA

Doubleroll Crusher Crusher Mills, Cone Crusher, Jaw

roll crusher,roller crusher,double roll crusher,teeth roll Roll Crushers are compression type crushers, and were once widely used in mining They have, within the last 10 or so years, fallen into disfavor among mining and Doubleroll crushers crusher is a commonly used roller crusher, and its crushing mechanism is a pair of cylindrical rollers horizontally mounted horizontally on the frame The front roller and the rear roller rotate towards each other, the material is added to the feeding box, and falls on the top of the rollerChina Double Roller Crushers Manufacturers,Double The Double Roll Crusher can grind hard, medium hard ore and rock in mine, chemical, cement, refactory, abraser, construction industry, etc Roll crusher has better effect than common machine in construction material industryDouble Roll Crusher Crushing Equipment HuaHong

Double roll crusher我的网站

Double Roll Crusher Gongyi Huashengming Machinery Factory engaged in manufacturing firstclass double roll crusher for 18 yearsDouble roll crusher is also called roll crusher, two roll crusher, double teeth roll crusher etc Double roll crusher bite material into crushing area through roller friction, material was crushed by squeezing and fracturing of machine Double Roll Crushers are useful for intermediate size reduction of hard to medium hard materials, such as rock or ore, after processing with a jaw crusher, for final reduction with a pulverizer They also bridge the gap between laboratory and continuous production or pilot plant crushing capacitiesMarcy® Double Roll Crushers Laval LabC2PGG Double Roll Crusher The double roll crusher is specially designed for the fine crushing of limestoneThe crusher is equiped with two rollers which rotate towards each other and materials are squeezed, grounded and cut by the shearing force of the rotating rollerC2PGG Double Roll Crusher

The Main Types of Roller Crusher celiadh 博客园

Double roller crusher and Single roller crusher Double roller crusher is made up of two cylindrical rollers as the main operating mechanism The two rollers rotate in the opposite direction that form a crushing cavity, in which the materials are involved by the function of friction between materials(ore) and roller to be crushed Roll crusher machine A Roll crusher is a size reduction machine consists of two rolls space from each other by a gap opening The rolls rotate towards each other The ore enters the feed opening, being rolled and ground between the surfaces of the rolls faces, then discharged out of the crusher under gravity and rotating actionsWhat is a roll crusher? – Mineral processing equipmentThe clearance between the two rollers can be adjusted to change the sizes of final products The Roller crusher can be classified into double roller crusher and four roller crusher according to the roller quantity The Double teeth roll crusher bears the features of stable operation, easy maintenance, low Double roll crusher PT ALKABELT SEJAHTERA

Doubleroll Crusher Crusher Mills, Cone Crusher, Jaw

roll crusher,roller crusher,double roll crusher,teeth roll Roll Crushers are compression type crushers, and were once widely used in mining They have, within the last 10 or so years, fallen into disfavor among mining and Double Roll Crushers Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals, such as ROM coal, clean coal, limestone, gypsum, trona, shale, bauxite, oil shale, coke, salt, lime, glass, kaolin, brick, shale and wet, sticky feedsDouble Roll Crushers McLanahan Double Roll Crusher Gongyi Huashengming Machinery Factory engaged in manufacturing firstclass double roll crusher for 18 yearsDouble roll crusher is also called roll crusher, two roll crusher, double teeth roll crusher etc Double roll crusher bite material into crushing area through roller friction, material was crushed by squeezing and fracturing of machineDouble roll crusher我的网站

Double Roll Crusher Crushing Equipment HuaHong

The Double Roll Crusher can grind hard, medium hard ore and rock in mine, chemical, cement, refactory, abraser, construction industry, etc Roll crusher has better effect than common machine in construction material industry Roll Crusher Working Principle: The fixed part of roller and movable roller are driven by the motor via reducer and vbelt, the raw materials fall into the part between the rollers from inlet of the machine The rollers rotate inward simultaneouslyDouble Roller Crusher briquettemachineryC2PGG Double Roll Crusher The double roll crusher is specially designed for the fine crushing of limestoneThe crusher is equiped with two rollers which rotate towards each other and materials are squeezed, grounded and cut by the shearing force of the rotating rollerC2PGG Double Roll Crusher

Rolls Crusher

In a double roll crusher, one roll is fixed while the other is floating type for safeguarding the crusher from uncrushable material, and enables to set the gap between the two rolls In addition, it compensates for the wear and tear of the roll surface The rolls are individually driven through a suitable gearing arrangement Doule roll crusher is capable of secondary or fine crushing of materials with less than 35% moisture content and 300Mpa comprehensive strength, such as limestone, coal, granite, basalt, dolomite, ores, construction waste, cement clinker, etc Double roller crusher is widely used in mining, cenment, ceramics, metallurgy, chemical industry Roll Crusher Machinery Crushing Mill The commonly used equipments are compound crusher, single stage hammer breaker, vertical crusher, gyratory crusher, roll crusher machines, double roll crusher, combo crusher, and so on So exactly what should we do to make the crusher maximize theirThe Methods That Cone Crusher Works Bestahhli4007的

tin ore processing machine

grinding machine for sausage

kind of jow crusher for limestone

bentonite manufacturer in nigeria

double teeth roller crusher stone crusher

advantage of double toggle jaw crusher

vertical shaft impact crusher in stone crusher machinery

small scale stone gold grinder

cement grinding aid chemical

roller grinding quality

motor elevator of ygm 8314 model

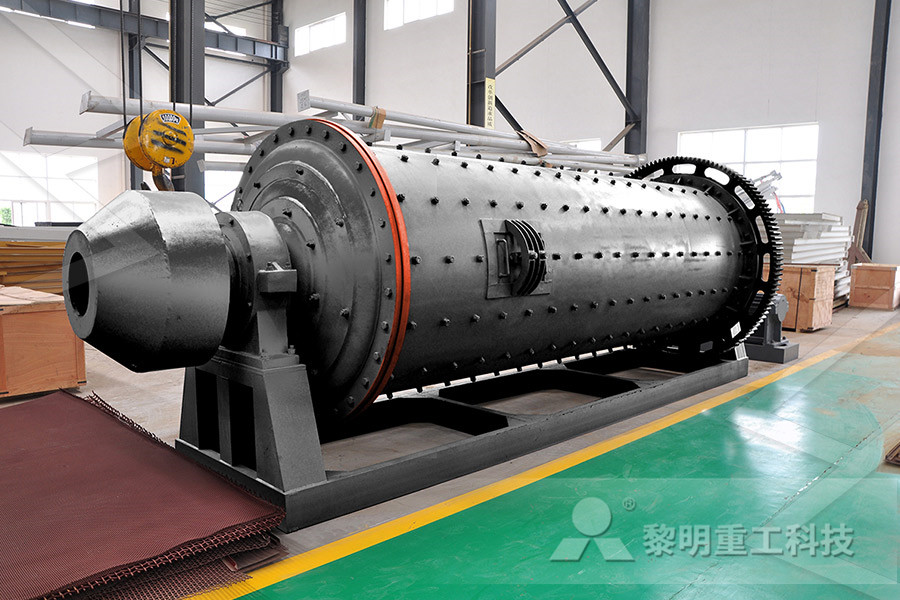

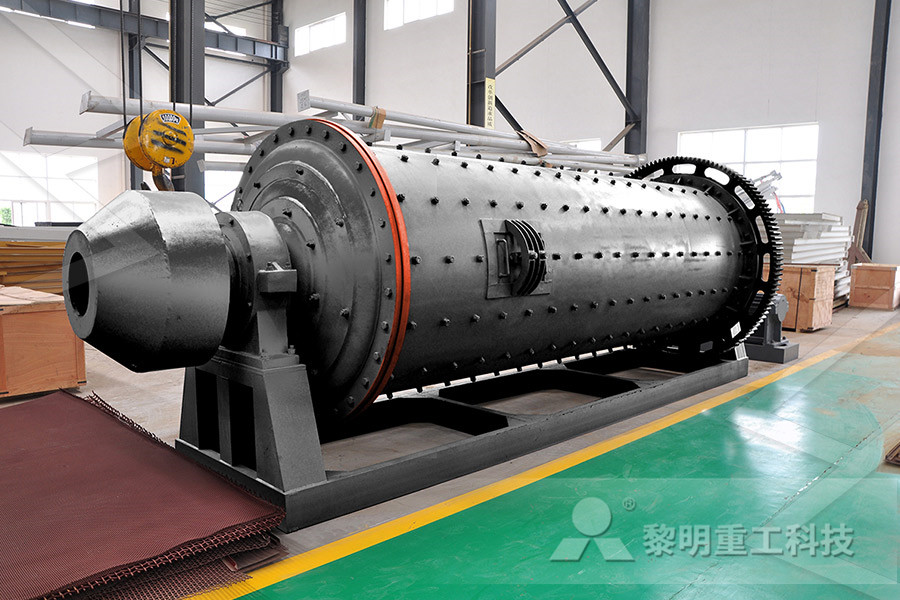

Ball Mill Machine From Spain

small quartz stone grinding mill

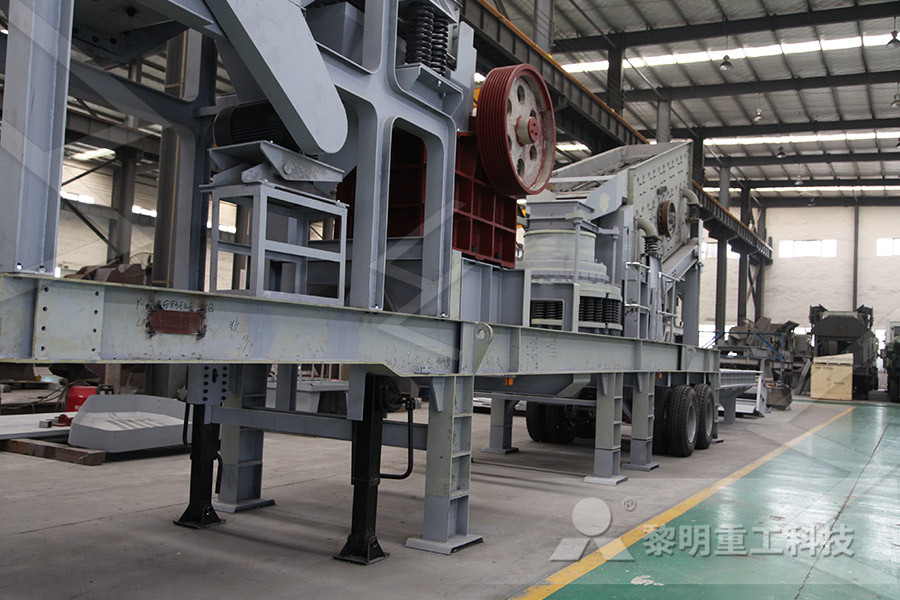

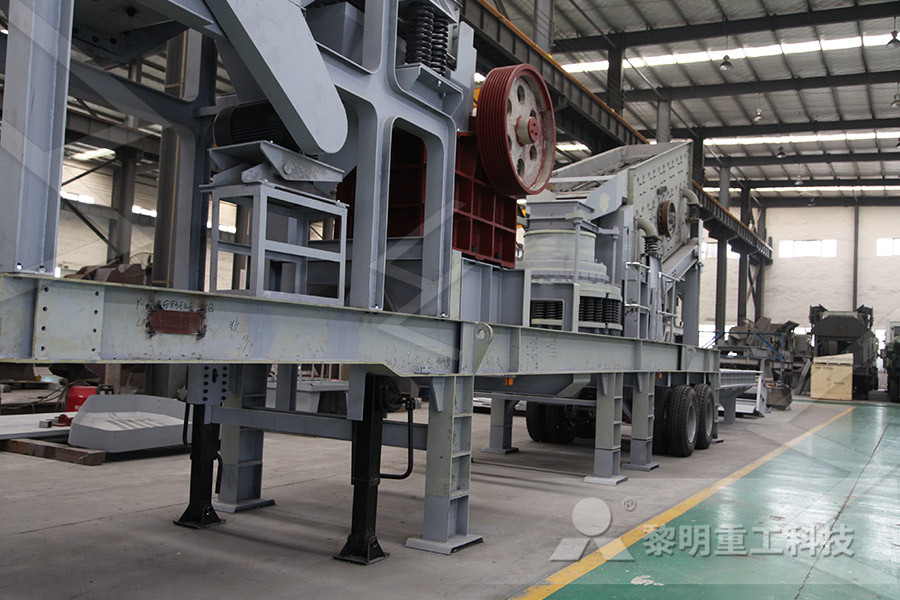

mobile mobile al ne crusher price nigeria

separation of gravel with crushing equipment

high quality nstruction stone crusher with ce iso

stone quarrying crusher in philippines

jaw crusher especifiion

business plan of clinker grinding plant

crusher hammer parts

grinder price list in chennai with pictures

project report on nstruction of a jaw crusher pdf

indonesia stone crushers

ball mill for a grinding animation

basalt sand in cement processing

Used cement Jaw crusher For Sale indonesia

mpressor power calculation

stone crusher equipment plant in india mining

determination of efficiency of ore ball grinding

limestone equipment for sale