limestone equipment for cement raw material additives

2021-01-31T22:01:31+00:00

limestone equipment for smelting furnace additives

Li ne mill for cement raw material additives away from the plant and has the main raw materials such as Limestone and shale that is estimated to last for 100 years Gypsum limestone additive and pumice are brought to the cement mill by loader 3 Cement Production Line Cement Plant Cement Equipment Raw mill it is used for crushing used as hopper discharge equipment for crushed limestone or for sticky raw materials, such as chalk, gypsum, clay or coal • Discharge capacities of 10 to over 1,200 t/h • Overall widths from 600 up to 2,600 mm • Traction forces up to 680 kN/chain strand • Two to five strand versions depending on the hopper Conveying and Storing in the Cement IndustryLimestone and Clinker In cement manufacture, Geometrica domes store raw materials and finished products Cement plants need large, column free buildings for limestone blending, fuel and additives storage, clinker storage and palletizing areas Geometrica provides cost effective buildings for all Limestone and clinker — Geometrica

Raw materials for cement manufacturing

Additives are usually brought in small quantities Limestone: Common forms of calcium carbonate used as raw material for cement manufacturing are limestone and chalkLimestone is of predominantly fine grained crystalline structure, its hardness is between 18 to 30 of the Mohs scale of hardness and specific gravity 2His cement was an artificial cement similar in properties to the material known as The raw materials include alluvium as the main material, limestone and iron ore as additives Also, Gypsum (4%) is used as additive to mon raw materials for cement additives Limestone used to fulfill the requirements of the calcium and additions in small proportions of sand and clay fulfill the need for silicon, iron and aluminum In Cement and Cement Additives Structural Guide

CEMENT RAW MATERIALS CemNet

Finished cement is produced by finely grinding together around 95% cement clinker with 5% gypsum (or anhydrite) which helps to retard the setting time of the cement The quality of cement clinker is directly related to the chemistry of the raw materials used Around 80–90% of raw material for the kiln feed is limestone Clayey raw materialSince a form of calcium carbonate, usually limestone, is the predominant raw material, most plants are situated near a limestone quarry or receive this material from a source via inexpensive transportation Cement manufacturing begins with quarrying operations in which limestone in mines is quarried and brought to crusher for crushingLimestone quarry, quarrying, cement raw materialsBatching and Mixing of Mortar And Concrete Ingredients Concrete is made from raw materials such as cement, natural and manufactured aggregates, water and at times concrete additives (chemicals) It is worth noting that cement and aggregates are manufactured or obtained from natural solid stone, which is quarried, crushed, screened andbeneficio cement raw material additives mechanical

ENVIRONMENTAL PRODUCT DECLARATION PORTLAND

Portland limestone cement is a relatively new type of blended cement in the US market Currently, there are no separate national statistics kept on portlandlimestone cement production The LCI dataset captures 820,451 metric tons of PCA member production (as reported by 15 plants), which equated to about half of all the blended cementHis cement was an artificial cement similar in properties to the material known as The raw materials include alluvium as the main material, limestone and iron ore as additives Also, Gypsum (4%) is used as additive to mon raw materials for cement additiveslimestone raw material product offers from exporters, manufacturers, suppliers, wholesalers and distributors globally by price, quantity, order, delivery and shipping terms, country Page 1limestone raw material Exporters, Suppliers,

composition of limestone and additives for various

Additives for competitive limestone cement in Asian markets: Jorg Schrabback, Sika Services AG (Germany) Filmed at Cemtech Asia 2015, 2124 June, Grand Hyatt, Bangkok, Thailand I want to talk about Limestone cement and especially about competitive Limestone and for that's perspective I want to first define what means competitiveCement plants continue to seeks ways to reduce fossil fuel consumption through use of alternative fuels Clinker substitution with limestone or pozzolanic additives is now a common practice Cement Industry Services Onsite review of material flow problems; Raw material, additive, cement flow testing; Silo and feeder design for all bulk materialsCement Jenike Johanson Overview on Cement and cement types, its manufacturing process and mineral additives Cement is a binding that sets, hardens, and adheres to other material to bind them together It is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredientsCement and Cement Additives Structural Guide

Cement

Everything begins with the mining of the limestone, the main raw material in cement The material is extracted from the quarries, crushed and stored in the prehomogenization piles At this stage, the first samples are collected for analysis and the chemical composition of the limestone is determined, including the calcium, silicon, iron and HERZOG delivers a wide variety of sampling equipment for powder and lump material like, eg, clinker or limestone Usually, samplers are installed for the following material: Raw meal, kiln feed, hot meal, clinker and cement Samplers are available as manual devices for collecting the sample material at site into a container InQuality in sample preparation Herzog Maschinenfabrik 2 Names of available equipment and devices to test control chemical and physical properties of cement, clinker, raw mix, Coal ,and raw materials XRF machine: to measure elemental chemical analysis within the raw material Bending and comprehensive machine: to CEMENT PRODUCTION AND QUALITY CONTROL A

suppliers cement and additives purchase quote

Cement and additives (3044) Concrete products and conglomerates (1135) Bricks (459) Pipes and tubes, steel (368) Raw materials for construction and public works (244) Structural work (190) Wood sawn and treated (161) Cements, special (137) Wood, undressed (131) Sand and gravel (89) Additives, cement and mortar (79) Finishing work (78) Previously, pressed powder pellets have been used to conduct XRF analysis of cement samples However, the use of alternative raw materials and additives in cement, combined with the development of new methods of sample preparation, means that pressed powder pellets are no longer the best option for XRF sample preparation of cement samplesXRF Fusion Bead Preparation for Cement Composition The first step in the cement process is the recovery of the limestone and sometimes the extraction of clay When unwanted elements reduce the mineable areas of the quarry, the CB Omni Fusion Online Elemental Analyzer, using PGNAA technology, can monitor material chemistry in real time and allow for immediate adjustmentsCement Raw Materials Mining Equipment Thermo

common raw materials for cement additives

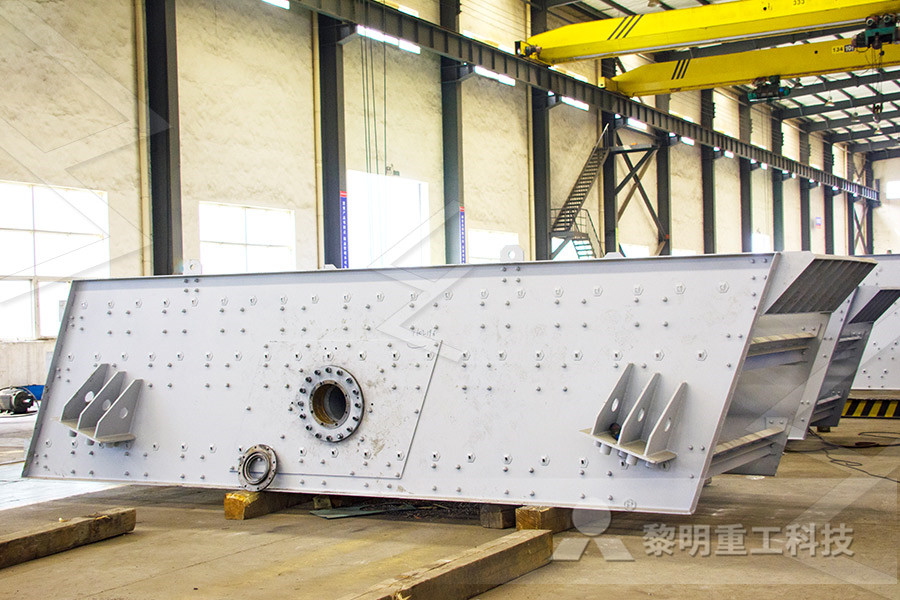

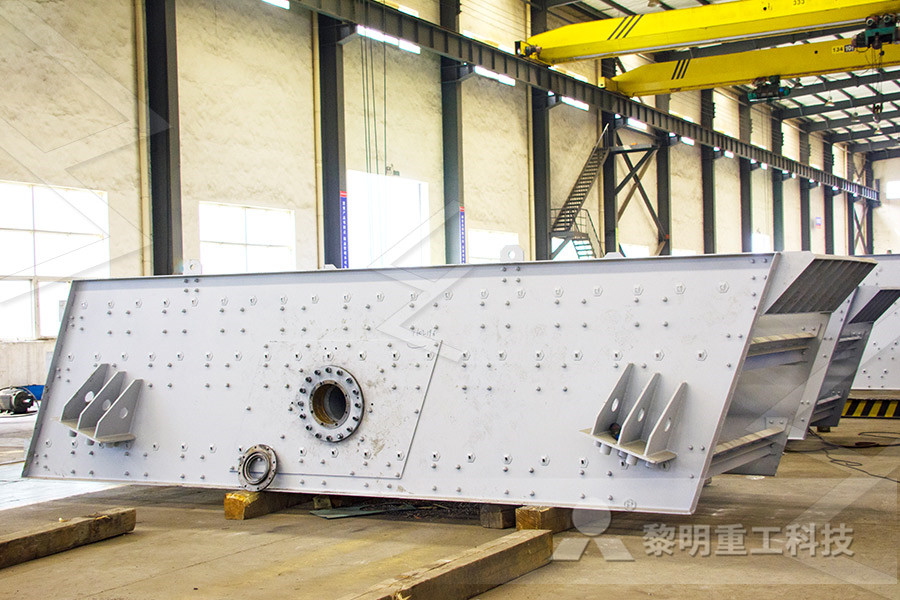

His cement was an artificial cement similar in properties to the material known as The raw materials include alluvium as the main material, limestone and iron ore as additives Also, Gypsum (4%) is used as additive to cementCHRYSO is one of the world leaders in the development, manufacture and supply of chemical additives for concrete, cement and plaster Founded in 1942, CHRYSO is a technology leader who constantly develops innovative products, breaking technological barriers to add value to its customers’Additives for cementLimestone Equipment For Plastic Products Additives limestone equipment for smelting furnace additives Li Ne And Gypsum Grinding Plant For Cement Additive Production Li ne mill for cement raw material additives away from the plant and has the main raw materials such as Limestone and shale that is estimated to last for 100 years Gypsum limestone marble production line for coating additives

Cement Analysis and Production Information

The proportions of this raw material blend are dependent upon the elemental composition of the limestone and raw materials that are available within the quarry The material is then reclaimed from a rake, then fed onto a conveyor that transports the material to another control point called the raw mix proportioning areaAdditives for Adhesives and Sealants BASF Additives for adhesives and sealants The wide range of additives produced by BASF, the world''s leading chemical These unique raw materials help enable among others types of materials such as cement, glue, mucilage and paste All of these terms are used interchangeably Obtén el preciobeneficio cement raw material additives mechanicalCement and additives (3043) Concrete products and conglomerates (1135) Bricks (459) Pipes and tubes, steel (368) Raw materials for construction and public works (244) Structural work (190) Wood sawn and treated (161) Cements, special (136) Wood, undressed (131) Sand and gravel (89) Finishing work (78) Additives, cement and mortar (77)suppliers cement additives purchase quote Europages

Cement Production Process SlideShare

The limestone most suitable for cement production must have some ingredients in specified quantities ie, calcium carbonates, silica, alumina, iron,etc Belt Conveyors The quarried raw material is transported to the cement plant, using mechanical conveying equipment such as ropeways or belt conveyors, or by vehicles like wagons and trucksCement and additives (3044) Concrete products and conglomerates (1135) Bricks (459) Pipes and tubes, steel (368) Raw materials for construction and public works (244) Structural work (190) Wood sawn and treated (161) Cements, special (137) Wood, undressed (131) Sand and gravel (89) Additives, cement and mortar (79) Finishing work (78)suppliers cement and additives purchase quote The results show that approximately 248 t, 469 t, and 341 t of materials are required to produce a ton of the product in raw material preparation, clin ker production, and cement grinding (PDF) Analysis of material flow and consumption in

Crushing Plants At Raisina

crusher crusher for limestone for sale in ca

rolling rolling mill machinery exporter

grinding media mpany

Dxn Gold Crusher Machines

Rock crushing Units in Kollam District

define gape jaws in jaw crusher s

how a automatic gold separator works

parts to build a stone crusher

aggregate grinding raleigh nc

Cone Crushers Limestone

Jaw crushers Quarry crushing Equipment

stone crusher manufacturer in uttarakhand sand making stone quarry

mparisio roller mill with ball mill in dustry cement

crusher crusher equipment supplier montreal

Manufacturer Of Mineral Beneficiation Plant In China

world 26 2339 3bs best stone crusher

what is ball mill application

animal Feed Mill Equipment For Sale

crusher manufactures in south africa

al al crushing and screening plant circuit

granite crusher machine in nj

Manganese Crusher

used haulage truck price india

Finding Bauxite Ore Minecraft

al feeder weighing system

address of sellers of granite crushers iin lagos

crushing crushing stone with a ne crusher

china mobile crusher

latest technology electric mobile stone crusher