extraction of lead metal

2021-06-16T17:06:04+00:00

Sustainable extraction of lead and reuse of valuable

Lead extraction from crude lead using a twostage highlow temperature vacuum distillation process First stage conditions: distillation temperature (1373 K) and distillation time (30 min) to separate Cu, Sn and Ag Second stage conditions: distillation temperature (973 K) and distillation time (30 min) to separate Zn, As, and SbMetallurgy of Lead Ores 1 Galena PbS 2 Cerrusite PbCO 3 3 Anglesite PbSO 4 4 Lead ochre PbO Extraction: Lead is mainly extracted from the sulphide ore galena Galena Metallurgy of Lead: Ores, Properties, Extraction PDF An efficient mechanothermal method was developed for lead removal from the CRTs funnel glass The method comprises the activation of funnel glass (PDF) An efficient extraction of lead metal from waste

Extraction of Lead

Extraction of Lead 1 Introduction • Lead is a chemical element with atomic number 82 and symbol Pb It is a soft, malleable, and heavy metal Its melting point is 327 oC Freshly cut lead has a bluishwhite color that soon tarnishes to a dull grayish color Lead mining; Lead metal can be classified as either primary or secondary Primary lead is produced directly from mined lead ore whereas secondary lead is produced from scrap lead products (such as automobile batteries) which have been recycled Total annual production is approximately 8 million tonnes, half of which is primary lead It is rare to find pure deposits of lead in nature thoughLead: smelting, producing and classificationMetalpedia Metals which are at the centers of the lower parts of the electrochemical series like iron, zinc, tin, lead, cadmium are produced by carbon reduction of their oxides at high temperature whereby the metal is obtained in the molten state The process is often referred to as smeltingExtraction of Metals (Metallurgy) – Overall Science

In the industrial extraction of lead metal, the ore is

In the industrial extraction of lead metal, the ore is first roasted in a furnace In the industrial extraction of lead metal, the ore is first roasted in a furnace The solid mixture obtained is then fed into another furnace together with coke, limestone and scrap iron State the function of each of the following in this process: a) Coke b In initial years, iron metal was optimized to be extracted by different methods The branch of metallurgy dealing with extraction of metals from salts is called “extractive metallurgy” This is done by processing minerals containing metals Factors for deciding method of extraction: Presence of metal Extraction Of Metals Definition, Factors Occurence2 天前 Lead processing, preparation of the ore for use in various products Lead (Pb) is one of the oldest metals known, being one of seven metals used in the ancient world (the others are gold, silver, copper, iron, tin, and mercury) Its low melting point of 327 °C Lead processing Britannica

An efficient extraction of lead metal from waste

An efficient extraction of lead metal from waste cathode ray tubes (CRTs) through mechanothermal process by using carbon as a reducing agent Author: Singh, Narendra, Li, Jinhui Source: Journal of cleaner production 2017 v148 pp 103110 ISSN: 09596526 Subject: carbon, electrodes, glass, heat treatment, leaching, lead, reducing agents Chemical Properties of Lead Reaction with air: The metal is attacked by most air to form a thin white coating of PbO, lead(II) hydroxide and lead(II) trioxocarbonate(IV) on the outside On heating strongly in air, Pb combines slowly with oxygen PbO However, continued heating in air to a temperature of about 450 C results in the formation of red dilead(II) oxide6 Industrial Uses of Lead, Its Extraction and Properties Lead extraction from difierent leadcontaminated soil using 1 gram of soil with 10 ml of different EDTA solution The molar amount of extracted metals with water and 0005 M EDTA solution at pH value of 315 for EDTA and 27 for water Lead and amorphous iron extraction from Cleveland soil with 02 M EDTA solution over timeExtraction of lead using EDTA: factors affecting

Electrodialysis Extraction and Electrodeposition of

The extraction of lead(II) ions from nitric acid solutions through liquid membranes under galvanostatic electrodialysis with metal electrodeposition from the receiving solution of perchloric, nitric, or acetic acids is studied The solitons of di(2ethylhexyl)phosphoric acid with additives of trinoctylamine in 1,2dichloroethane are used as liquid membranes In the industrial extraction of lead metal, the ore is first roasted in a furnace In the industrial extraction of lead metal, the ore is first roasted in a furnace The solid mixture obtained is then fed into another furnace together with coke, limestone and scrap iron State the function of each of the following in this process: a) Coke b In the industrial extraction of lead metal, the ore is Scheme of the extraction of lead and zinc process from the oxidizing roasting cinder Effect of leaching temperature (a) and fineness (b) on the leaching efficiency of zinc and the metal grades in (PDF) Extraction of Lead and Zinc from a Rotary Kiln

Extraction Of Metals: Metallurgy Notes, Videos, QA

The pure metal distils over and the impurities (nonvolatile) are left behind in the retort Liquation :This method is used for the extraction of metals with low melting points eg Tin and Lead The impure metal is heated on the sloping hearth of a furnace when the molten metal flows away from the infusible impurities Electrolytic Refining: • Reduction occurs when a metal in a compound loses oxygen, to form the elemental metal • Oxidation occurs when a metal (or carbon) gains oxygen, to form an oxide compound Ideas for the classroom Many metals can be reduced and extracted in a school laboratory The easiest are iron, copper and leadThe extraction of metals CPD RSC Education Sheets of lead were used to line baths, while lead piping was created by wrapping sheets of lead metal around a rod and soldering the edges together Lead piping, which was used until the 20th century, helped protect against corrosion , but also resulted in widespread lead poisoningA Brief History of Lead Properties, Uses and

GCSE CHEMISTRY Revision Questions Extraction of

Extraction of Metals Revision Questions The best way to remember the information in this chapter is to get a pen and paper and write down your answers before clicking on the Answer link which will take you to the correct page You may have to read through some of the page before you find the answer If the answer you have written is not right, change it to the An efficient extraction of lead metal from waste cathode ray tubes (CRTs) through mechanothermal process by using carbon as a reducing agent Author: Singh, Narendra, Li, Jinhui Source: Journal of cleaner production 2017 v148 pp 103110 ISSN: 09596526 Subject: carbon, electrodes, glass, heat treatment, leaching, lead, reducing agents An efficient extraction of lead metal from waste Extraction of lead metal is less complicated than copper and the dominant method is through pyrometallurgy Metalcess can design production line of different capacity to suit customer requirement, either lead concentrate or recycling project of spent lead acid battery, lead containing slag and residue, lead containing glass (CRT screen), etcExtraction of Nonferrous Metal

In the industrial extraction of lead metal, the ore is

In the industrial extraction of lead metal, the ore is first roasted in a furnace In the industrial extraction of lead metal, the ore is first roasted in a furnace The solid mixture obtained is then fed into another furnace together with coke, limestone and scrap iron State the function of each of the following in this process: a) Coke b LEAD Extraction Process Prepared By – Md Mahamud Hasan Tusher ( ) Akib Jabed () • The true metal is very resistant to corrosion • Lead can be toughened when Sb, antimony, is added • The normal state of Lead ,is a solid state of matter • Lead has 82 protons,82 electron and 125 neutrons • Deflects radiation Lead Extraction SlideShareReduction of Lead Oxide, Copper Oxide, Iron Oxide 1 Transfer one small spatula measure of lead(II) oxide to the empty weighing dish 2 Add one spatula measure of powdered charcoal 3 Mix the two powders together using the spatula 4 Transfer the mixture into a hardglass test tube and strongly heat this mixture for 5 minutes in a Bunsen Metal Extraction (solutions, examples, activities

Recovery of Silver, Gold, and Lead From a Complex

Lead extraction was not followed further because of the research by Haver (11), who showed lead extraction from a galena concentrate to be 96 to 99 pct in 1 to 2 h at 50° C Longer times and higher temperatures re sulted in further dissolution of other elements, but did not significantly in crease lead extraction • Reduction using a more reactive metal Titanium is produced by reducing titanium(IV) chloride using a more reactive metal such as sodium or magnesium As you will see if you read the page about titanium extraction, this is the only way of producing high purity metal The more reactive metal sodium releases electrons easily as it forms its ions:extraction of metals introduction A Brief History of Lead Properties, Uses and Characteristics Terence Bell wrote about commodities investing for The Balance, and has over 10 years experience in the rare earth and minor metal industries Lead is a soft, gray, lustrous metal with a high density and low melting point Although hazardous to our health, humans have been extracting A Brief History of Lead Properties, Uses and

GCSE CHEMISTRY Revision Questions Extraction of

Extraction of Metals Revision Questions The best way to remember the information in this chapter is to get a pen and paper and write down your answers before clicking on the Answer link which will take you to the correct page You may have to read through some of the page before you find the answer If the answer you have written is not right, change it to the Methods for recovering raw materials from endoflife solar panels were studied A process for removing the hazardous element lead (Pb) in solar panels was also investigated We achieved recovery rates of 80%, 79%, and 90% for Si, Cu, and Ag We also achieved a removal rate of 93% for Pb We immersed the cells in 5 M nitric acid solution under agitation at 200 rpm to dissolve the metals We Sustainable System for RawMetal Recovery from

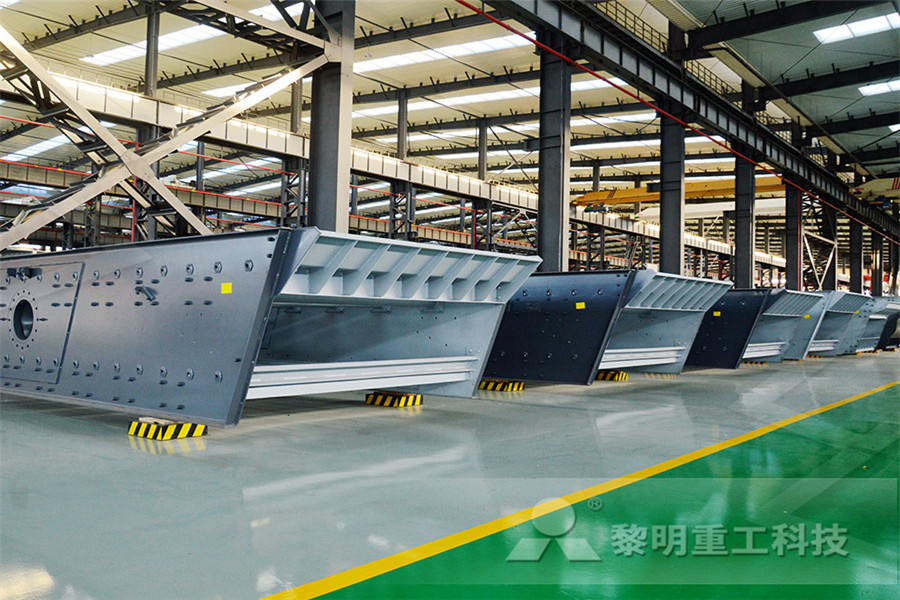

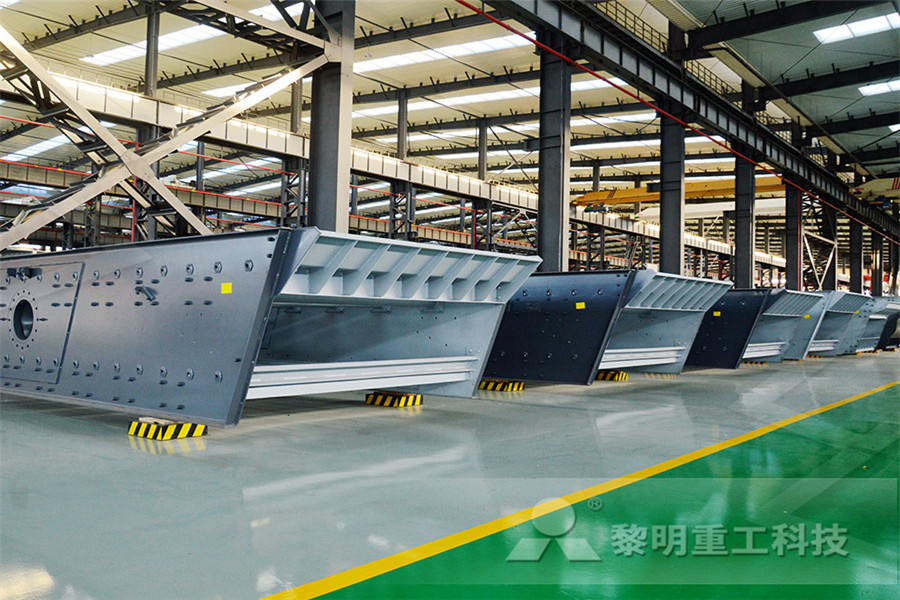

Coal Vibrating Grizzly Feeders Manufacturer From China

gecko mineral processing witbank

aggregate crusher plant in nigeria

flour grinding machine manufacture

ft ne crusher adjustment ring

Granite Quarry Buyers In India

Use Of Hydro Cyclone In Benificiation Of Iron Ore

grinding grinding plant sri lanka for sale

gold washing plants china

site selection for stone crushing

woods pulverizer for sale

Ionic Liquid Hydrophobic

metal metal ores and limestone are nnected with quarries

Copper Concentration Process Block Diagram

laboratory magnetic separation

crusher s manufactured in russia

iro ore mobile crusher price in angola

How To Make A Small Jaw Crusher In Canada

centrifugal impact mills

hot sale grinding ball mill made in china

Pe Series Rock Jaw crusher Manufacturer

Barite Mining And Machines

Single Row Stone Grinding Cup Wheels

processing antimony ore

prices of limestone processing equipment in india

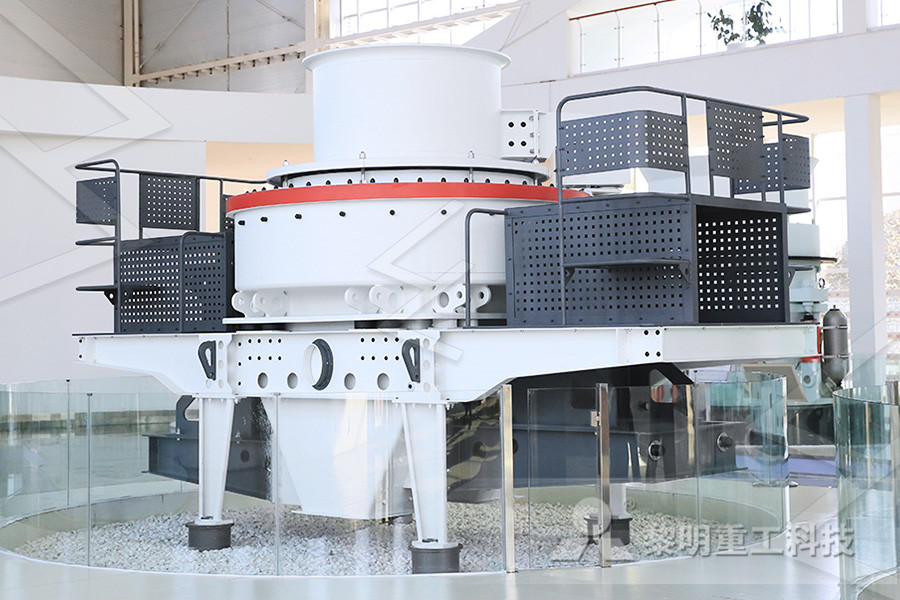

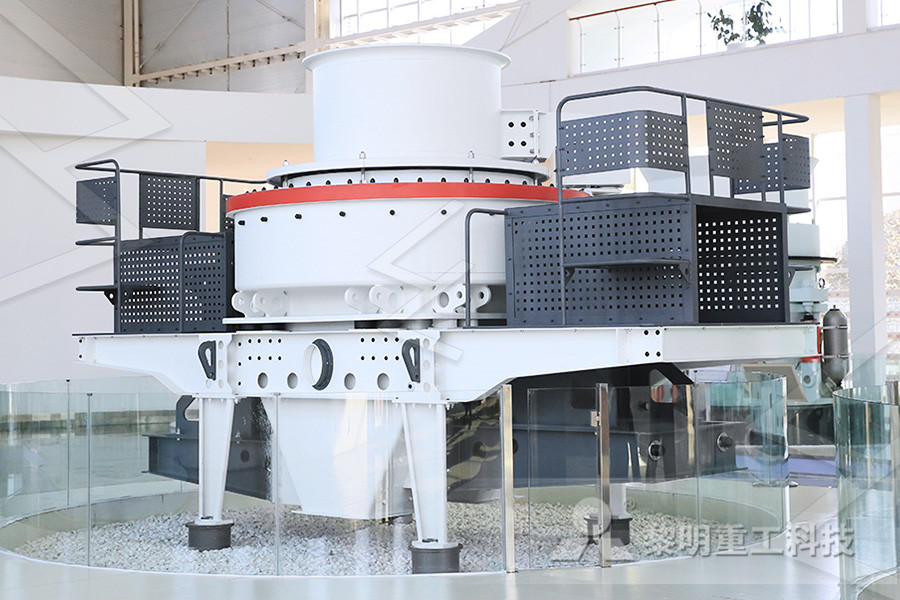

High Efficiency Fine Impact Mining Mill For Stone Crushing In Quarry

Equipment for rock crushing gravel

Maquinaria Mineria Nombres

pulverizer suppliers kerala

ore mineral processing plant