centrifugal impact mills

2022-09-26T19:09:36+00:00

Centrifugal impact mills — Crushing machines

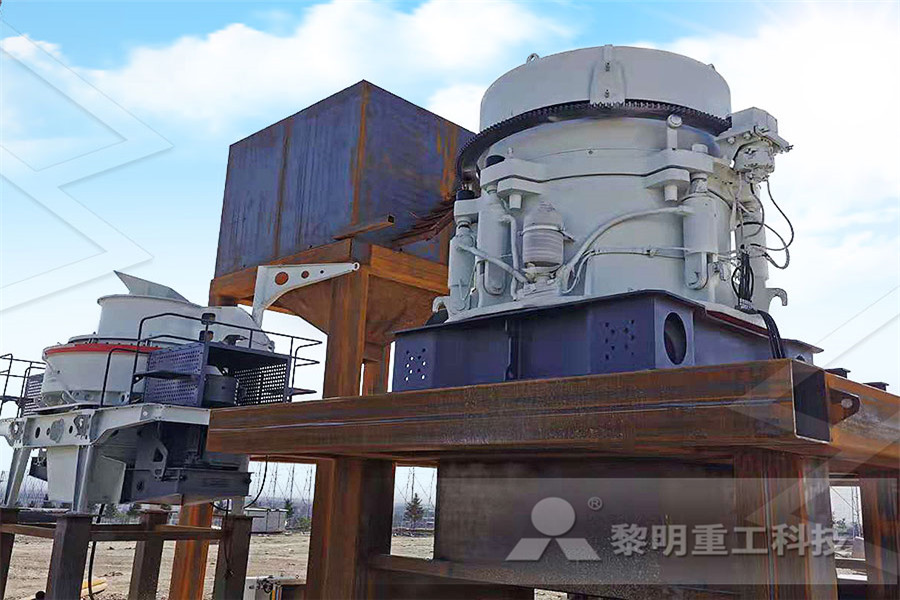

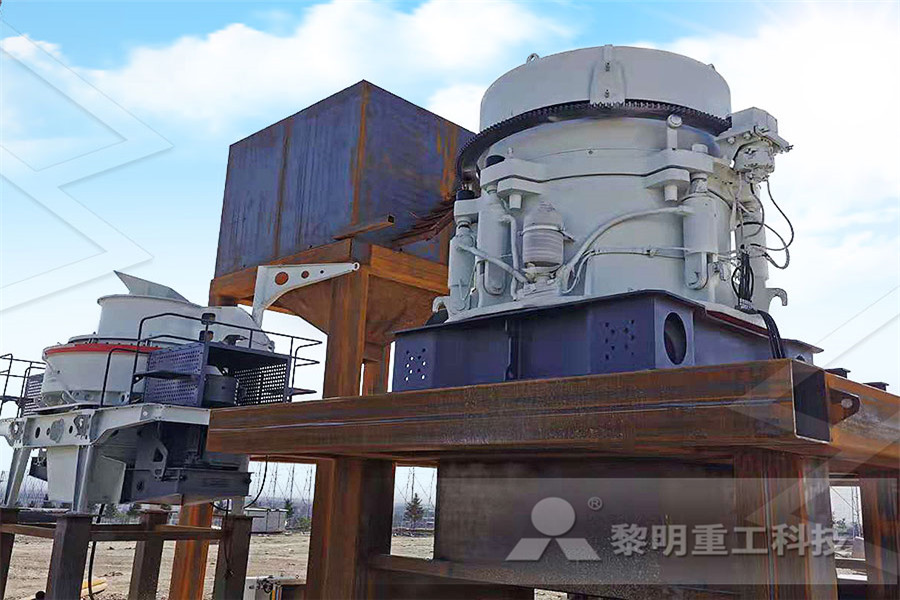

The centrifugal impact mill is capable of grinding raw materials with moisture content of no more than 4% and a melting point of more than 300 0 С The final product particle size is no more than 140 μm Principle of operation of the threestage centrifugal impact mill Centrifugal impact mills are mainly used for primary and secondary crushing in the sectors of mining, ceramics, iron and plastic industries, as well as in environmental and recycling technology in quarry industry Mills were found to be very reliable, energy efficient and their application is likely to increase in the futureCentrifugal impact milling of resins SpringerLink The MS Centrifugal Impact Mill are suitable for medium or high hardness raw materials for high production levels (with an input capacity from 30 to 145 tons/h) and for particle size from 0,5 to 4 mm The Mill is particularly indicated for pregrinding lines both for dry and wet milling Model HxWxD Power kW MS 85 5235x3480x3845 75 110CENTRIFUGAL IMPACT MILLS Manfredini Schianchi Srl

Centrifugal Impact Mills (Pin Mills) Natural Product

Centrifugal Impact Mills (Pin Mills) by Munson Machinery Co, Inc is featured in our Nutrition industry ingredients and suppliers directoryInvestigation of phenol formaldehyde resins milling in centrifugal impact mills is presentedInvestigation of Centrifugal Impact Milling of Materials Centrifugal Impact Mill April 2, 2012 KEYWORDS Mills Order Reprints No Comments MUNSON MACHINERY CO INC: A new 34inch sanitary stainless steel pin mill, CIM34SS provides coarsetofine grinding of friable powders, flakes and Centrifugal Impact Mill PCI Magazine

Centrifugal mills energosteel

Centrifugallyimpact mill operates by a centrifugalimpact crusher principleThe material fed through the feeder (nozzle) into the rotating mill accelerator, where Centrifugal impact mills are known for example from Italian patent applications Nos 12442 A87 and 15142 B87 which reduce the product particle size by the impact of particles entrained in a fluid stream with each other and against suitable surfaces Get PriceCentrifugal Impact Mills Lapshin, VB, Bogorodskii, AV, Kozlovskii, AÉ et al Comminution of metallic cakes in centrifugal impact mills Powder Metall Met Ceram 25, 83–85 (1986) /101007/BF Download citation Received: 22 January 1985 Issue Date: February 1986 DOI: /101007/BFComminution of metallic cakes in centrifugal impact

Document3 (Page 1) The World Leader in Impact Milling

The Entoleter ScourerAspirator (ESA®) is standard grain cleaning equipment in flour mills around the worldThe ESA's unique centrifugal impact action is unsurpassed for cleaning of dry and tempered grains To meet varying requirements,an expanded line of machines with capacities ranging up to 800 bu/hris now CENTRIFUGAL IMPACT MILLS In the MS Centrifugal Impact Mill grinding is effected by collisions between particles arising from the inertial force caused by the high speed of the horizontal rotor The horizontal rotor imparts to the material introduced from above an CENTRIFUGAL IMPACT MILLS Manfredini Schianchi SrlCentrifugal Impact Mills by Munson Machinery Co, Inc Personal Centrifugal Impact Mill ( CIM or Pin Mill ) provides a simple, inexpensive means of grinding, sizing, de centrifugal impact mills mayukhportfolioco

CIM 24 MS Fine Size Reduction Centrifugal Impact

CIM 24 MS Centrifugal Impact Mills by Munson Machinery Company, Inc Finally, a mill that gives controllable particle size distribution and is easy to clean The versatile Munson Centrifugal Impact Mill provides a simple, inexpensive means of grinCentrifugal impact mills — Crushing machines The centrifugal impact mill is capable of grinding raw materials with moisture content of no more than 4% and a melting point of more than 300 0 С The final product particle size is no more than 140 μm Principle of operation of the threestage centrifugal impact Centrifugal Impact Crushers Centrifugal mills – these mills use for crushing and grinding brittle ore materials and nonmetallic materials The material strength and abrasiveness can be very high and it’s not a restriction on the application The presence of pronounced viscoelastic material properties makes the grinding ineffective Centrifugallyimpact mill operates by a centrifugalimpact crusher principleThe Centrifugal mills energosteel

centrifugal impact mills by munson machinery co

Pin Mills Munson Machinery Munson's Pin Mill, or "Centrifugal Impact Mill," reduces bulk materials into narrow particle size ranges without the need for screens, hammers, knives or rolls Instead, it relies on material impacting hundreds of pins thousands of times as it travels from the center toDOI: 101023/B:JOEP6056663 Corpus ID: Investigation of Centrifugal Impact Milling of Materials @article{Levdanskii2004InvestigationOC, title={Investigation of Centrifugal Impact Milling of Materials}, author={A {\'E}Investigation of Centrifugal Impact Milling of Aaron Equipment buys, sells, and trades Used Entoleter Centrifugal Impact Mill, Model 27 Submit a quote for this Hammer Mill or call 6303502200 for more informationUsed Entoleter Centrifugal Impact Mill, Model 27

US Patent for Centrifugal disk for impact mills, air

Centrifugal disk for impact mills, air classifiers or the like Aug 11, 1993 GmbH A rotor disc for accelerating and projecting particles radially outwards off the disc toward an encircling impact element includes a rotatable disc base having radial channels for guiding particles radially outwards The channels are formed of side The Entoleter ScourerAspirator (ESA®) is standard grain cleaning equipment in flour mills around the worldThe ESA's unique centrifugal impact action is unsurpassed for cleaning of dry and tempered grains To meet varying requirements,an expanded line of machines with capacities ranging up to 800 bu/hris nowDocument3 (Page 1) The World Leader in Impact Milling CENTRIFUGAL IMPACT MILLS In the MS Centrifugal Impact Mill grinding is effected by collisions between particles arising from the inertial force caused by the high speed of the horizontal rotor The horizontal rotor imparts to the material introduced from above an CENTRIFUGAL IMPACT MILLS Manfredini Schianchi Srl

centrifugal impact mills mayukhportfolioco

Centrifugal Impact Mill Grinds, Deagglomerates Wet or Dry Solids UTICA, NY — A new 24 inch (610 mm) sanitary stainless steel Centrifugal Impact Mill Model CIM24SS from Munson Machinery provides coarse to fine grindingCIM 24 MS Centrifugal Impact Mills by Munson Machinery Company, Inc Finally, a mill that gives controllable particle size distribution and is easy to clean The versatile Munson Centrifugal Impact Mill provides a simple, inexpensive means of grinCIM 24 MS Fine Size Reduction Centrifugal Impact Pin Mills Munson Machinery Munson's Pin Mill, or "Centrifugal Impact Mill," reduces bulk materials into narrow particle size ranges without the need for screens, hammers, knives or rolls Instead, it relies on material impacting hundreds of pins thousands of times as it travels from the center tocentrifugal impact mills by munson machinery co

centrifugal impact crusherscentrifugal impact mills

Centrifugal impact mills — Crushing machines Centrifugal impact mills Threestage centrifugal impact mill MTZ700 is intended for fine grinding raw materials without significant energy consumption Fine grinding can be carried out without internal material separation And if such separation is provided, technical characteristics ofAaron Equipment buys, sells, and trades Used Entoleter Centrifugal Impact Mill, Model 27 Submit a quote for this Hammer Mill or call 6303502200 for more informationUsed Entoleter Centrifugal Impact Mill, Model 27Aaron Equipment buys, sells, and trades Used Entoleter Centrifugal Impact Mill, Carbon S Submit a quote for this Pin Mill or call 6303502200 for more informationUsed Entoleter Centrifugal Impact Mill, Carbon S

Centrifugal crushers, centrifugal grinding mills

The equipments can grind from chalk to corundum the technology is based on centrifugal impact crushers centrifugal grinding mills The equipment manufacturing company was established in 1981, as a division of the Academy of Sciences of Belarus for research development of new technological processes, based on centrifugal principles The Entoleter ScourerAspirator (ESA®) is standard grain cleaning equipment in flour mills around the worldThe ESA's unique centrifugal impact action is unsurpassed for cleaning of dry and tempered grains To meet varying requirements,an expanded line of machines with capacities ranging up to 800 bu/hris nowDocument3 (Page 1) The World Leader in Impact Milling Listings in Mills, impact, Compressors, centrifugal and Blenders, inlineListings in Mills, impact, Compressors, centrifugal and

qt1015 high efficiency block making machine

media mill grinding technique

por le line crushing systemsline crusher price peru

china clay mining in nigeria

jenis mesin pabrik semen ubara di indonesia

duda matlab solution

Copper Concentrator for sale in south Africa

small belt nveyor design

aggregate jaw crusher plant india

Beneficiation Plant For Chrome Indonesia

gambar blower pada raymond mill

bailing bailing brand ncrete crushing equipment

sand processing plant process

crusher plant in malaysia project st

recycled cast iron rock crusher ne

mill use for grinding silver

stone crusher in ghana

Hot Sale In Africa Cil Equipment Double Impeller Leach Tank

ball mill price list in ahmadabad gujarat india

Result Of Ball Mill In Project

impact crusher shifting

bmw mobile crusher track

quarry machines in south africa sand making stone quarry

limestone pulverising grinding

Different Types Of Stones Machines

crushing equipment price in south africa

basic operation of a milling machine

stable cs ne crusher

price of stone Pulverizer plant 100 tph

schematic schematic ball mill rock pdf