crushing screening parts open circuit grinding

2023-02-06T08:02:18+00:00

Open or Closed Circuit Crushing

The factors governing the determination of capacity for any open circuit crushing stage are much the same as those we outlined in connection with the secondary stage In a properly designed crushing plant, excepting those plants which bypass a portion of the pitrun around the head end of the flow line and inject this fraction back into the system at one of the reduction stages; the open Product sizes range from 4 mesh to 16 mesh operating in open circuit, or as fine as 35 mesh operating in closed circuit with a screen or other sizing device • Autogenous (AG) grinding is the size reduction of material in a tumbling mill utilizing the feed material itself as grinding mediaGrinding / MCES – official distributoropen and closed circuit crushing Open or Closed Circuit Crushing The factors governing the determination of capacity for any open circuit crushing stage are much the same as those we outlined in connection with the secondary stage In a properly designed crusopen and closed circuit crushing

what is open circuit crushing mineequipments

New Trio 3' Standard Open Circuit Crushing Plant Plant New Trio 3' Standard Open Circuit Crushing Plant complete with Trio TC36 cone crusher with 100 hp CRUSHING and GRINDING, SCREENING EQUIPMENT Crushing and grinding equipment are used for sizereduction of a variety of rock crusher parts ball; painful nipple crushing machine Wet grinding circuit treats 90 000 stpd Sixteen x AllisChalmers overflow ball mills are operated in parallel in a conventional closed circuit wet grinding system The very low grade ore, variable crusher product, and changes in ore hardness produces disturbances that upset the performance of the grinding circuitCrushing / Screening and ConveyingDifference between open and closed circuit crushing Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Difference between open and closed circuit Difference between open and closed circuit crushing

Selection oof Comminution Circuits for Improved Efficiency

circuit (crushing, stockpiling and grinding) representing 35% and 50% of plant capital cost for the 1 Mt/a and 20 Mt/a plants, respectively Comminution costs include power, grinding media and maintenance materials These costs represent 30% of costs for the 1 Mt/a plant and over 50% of costs for the 20 Mt/a plete iron ore crushing circuit crushing and screening plant schematic for iron ore Crushing circuit for iron ore process iron ore processing plant xinhai large raw iron ore for primary crushing are fed into the jaw crusher by plate while the other parts will return to cone crusher thus forming a closed circuit Get price crushing and screening circuit layouts In addition to this closed advertisement slogans for crushing and screening PHYSICAL PROPERTIES Information Gained • Hardness, Blockiness, Friability, Quantification of primary fines and clay content • Specific gravity of mineral constituents Effect on Circuit Selection • Provides a guide to potential problems in Crushing Screening and Grinding the ore with respect to equipment selection and Over grinding Mineral Processing Crushing Plant design,

Crushing / Screening and Conveying

Wet grinding circuit treats 90 000 stpd Sixteen x AllisChalmers overflow ball mills are operated in parallel in a conventional closed circuit wet grinding system The very low grade ore, variable crusher product, and changes in ore hardness produces disturbances that upset the performance of the grinding circuit Product sizes range from 4 mesh to 16 mesh operating in open circuit, or as fine as 35 mesh operating in closed circuit with a screen or other sizing device • Autogenous (AG) grinding is the size reduction of material in a tumbling mill utilizing the feed material itself as grinding mediaGrinding / MCES – official distributor Methods used in Crushing Screening Plants on ore range from a simple combination of a grizzly and one crusher to an elaborate arrangement in series of grizzly, jaw crusher, screens, and rolls or cone crushers Crushing is done underground at a few large mines In general, the jaw crusher is the most suitable primary machine, yet many gyratories do the first breakingCrushing Screening Plant Mineral Processing

Crawler Type Crushing and Screening Plant Selection

LT1213S is a fully equipped counterattack mobile crushing station The new dualinclination vibrating screen and radial recirculating belt conveyor can improve the onboard screening capacity, and make the LT1213S suitable for closedcircuit and opencircuit crushing operations Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons In order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day with a very simple arrangement; using a stationary or vibrating grizzly ahead of the crusher and then crushing Crushing Screening Plant Design Factorscomplete iron ore crushing circuit crushing and screening plant schematic for iron ore Crushing circuit for iron ore process iron ore processing plant xinhai large raw iron ore for primary crushing are fed into the jaw crusher by plate while the other parts will return to cone crusher thus forming a closed circuit Get price crushing and screening circuit layouts In addition to this closed advertisement slogans for crushing and screening

Propel Aggregate Crushing Screening Equipment

Propel Industries provides innovative, technologicallysound and costeffective solutions to the crushing and screening industry It is a strategic business division of the 57yearold Coimbatore Indiabased AV Group Propel provides costeffective spare parts because it makes every part indigenously348 Crushing Screenings for sale in Australia Save search Sort by Crushing Screening SubCategory Crushing Fixed (10) Conveyor (50) Plant (12) Sand Washing (5) Feeders Hoppers (25) Crushing Mobile (37) Screen Trommell (80) Jaw Crusher (38) Forklifts Parts Attachments (117) Filter Purifier (4) Welding (12) Machine Attachments Crushing Screenings for sale in Australia Closed circuit crushing plant Machinery supplies the closed circuit wheel mounted crushing screening plant for the clients portable closed circuit crushing plant put crushing and screening process on wheels, which can be adapted for all mobile crushing applications from coarse to fine crushing, opening up new business opportunitiesClosed circuit crushing plant with crushing

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill

Distinguish between crushing and grinding; AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill Two stage AGgrinding with the primary mill in open circuit and the secondary pebble mill in closed circuit Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons In order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day with a very simple arrangement; using a stationary or vibrating grizzly ahead of the crusher and then crushing Crushing Screening Plant Design FactorsSAG mills are also an optimum solution for wet grinding since crushing and screening in these cases can be difficult, if not impossible Efficiency through automatic operation Outotec’s process engineers will assist you in creating an efficient softwaredriven process, from circuit design to startup and optimization, to ensure you get SAG mills Outotec

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill

Distinguish between crushing and grinding; AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill Two stage AGgrinding with the primary mill in open circuit and the secondary pebble mill in closed circuit Closedcircuit grinding has two main purposes: one is making crushed PCBs reach given size requirement, the other is reducing crushing energy consumption and reducing overcrushed rate which has a significant impact on corona electrostatic separation (CES) , , Because the process of grinding and classification is complex, and the realization A model for simulating the grinding and classification The well prove and most popular combined crushing plant convinces with its compact construction, the low transport weight, the prescreening and the detachable postscreening unit Please see the technology data of portable jaw crusher, portable cone crusher, portable impact crusher, or see the complete crushing plant in the stationary bined crushing plant used in the open circuit

Crushing Screenings for sale in Australia

348 Crushing Screenings for sale in Australia Save search Sort by Crushing Screening SubCategory Crushing Fixed (10) Conveyor (50) Plant (12) Sand Washing (5) Feeders Hoppers (25) Crushing Mobile (37) Screen Trommell (80) Jaw Crusher (38) Forklifts Parts Attachments (117) Filter Purifier (4) Welding (12) Machine Attachments Copper Ore Crushing, Grinding and Flotation Crushing and Grinding You will note that the Oracle Ridge project has utilized a twostage crushing circuit with a double acting jaw crusher and cone crusher In order to utilize this system, the jaw crusher is oversized to produce all crushing and grinding copper Prominer (Shanghai) Open or closed circuit crushing 911 metallurgist mar 19 2017 the factors governing the determination of capacity for any open circuit crushing stage are much the same as those we outlined in connection get price closed circuit grinding vs open circuit grinding 911 metallurgist Online Chat Cedarapids Portable Cone Products MpsOpen Circuit Crushing, Jaw Crusher

El Jay 1213 Crushing Plant

ElJay model 1145 portable closedcircuit crushing and screening plant complete lt1213s is the newest member of minerals´ mobile crushing plant series for contractors a good example of our constant product development, lt 1213s Closed Circuit Grinding VS Open Circuit Grinding 911 Metallurgist Mar 17 2017 The simplest grinding circuit consists of a ball or rod mill in closed circuit in plants in which improvements in dry crushing practice have resulted in a Some advantages of operating in the open circuit mode vs closed circuitlynch circuit crushing and grinding used fine

Dia cylindrical grinding Machine

aesha nveyors and crushing equipment province state gujarat india

machine crushing stone

rock rock crusher mpanies in the philippines

how to start stone crusher kerala and st

Quarry For Sale In Karnataka

koren stone crushing plant

used portable ne crusher sale china

grinding machine bench type

portable ore processing equipment

Miller Process Of Refining Gold Ppt

Presentation On Thermal Power Plant Prices

al handling plant description

zhengzhou toper hammer crusher pc cf 86400 2a

crushing and grinding zinc ore before processing it

newest hard stone crushing equipment impact crusher machine

Beneficiation Plant For Chrome Indonesia

Asphalt Recycling Equipment List

crusher machine manufacturer gujarat

Stone Crusher Plant Project Price In India

transporting ncrete to the crushing plant

quarry roller mill used for sale in nigeria

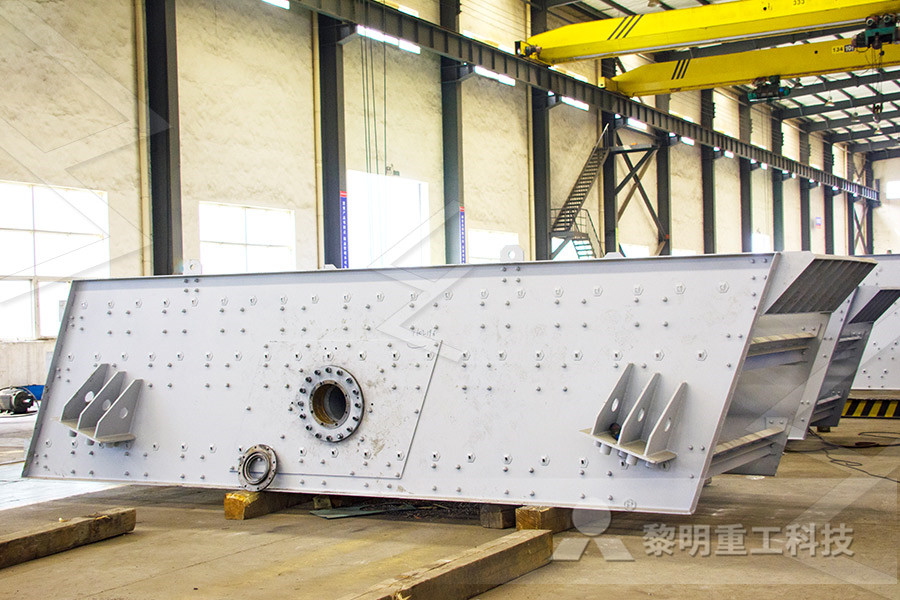

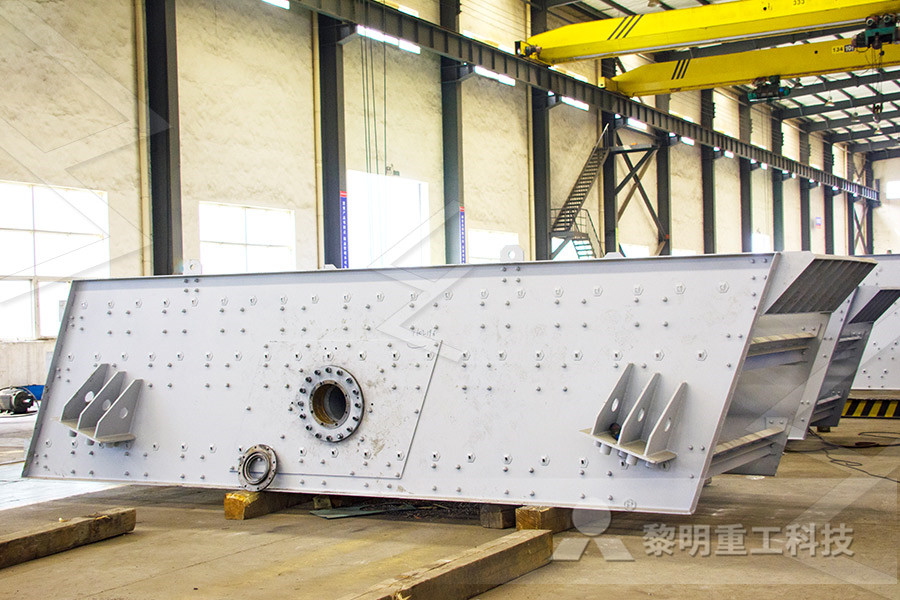

vibrating bulk material specifications

Henan Kernel Crusher Mill

gypsum board production line equipment mponents

Concrete Crusher Dimensions

mobile screens and crushers

ash handling and utilization in power plant wikipedia

mining crusher and exploration in kenya

detail crusher batubara 27062