vibrating bulk material specifications

2021-11-04T10:11:19+00:00

Bulk Material SMICO Vibratory Screens

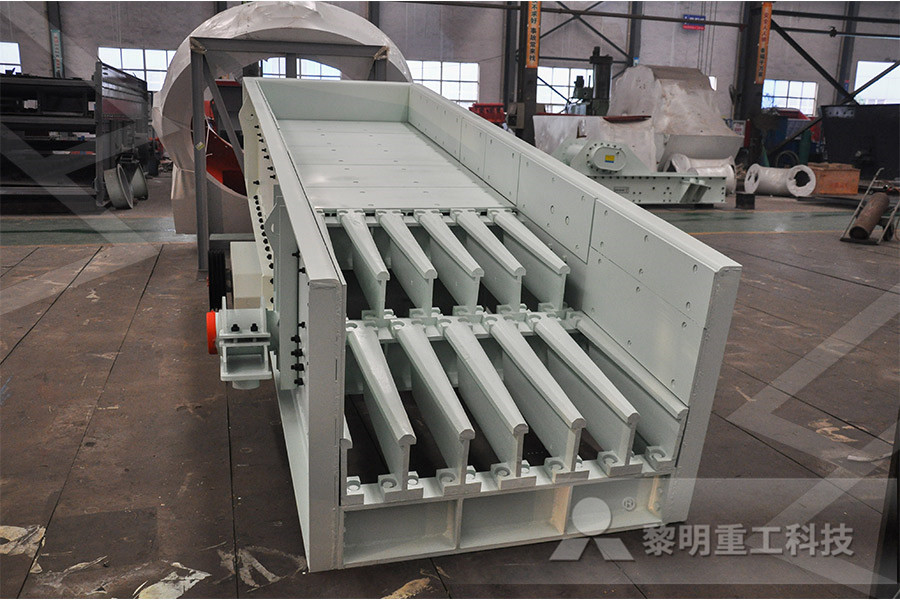

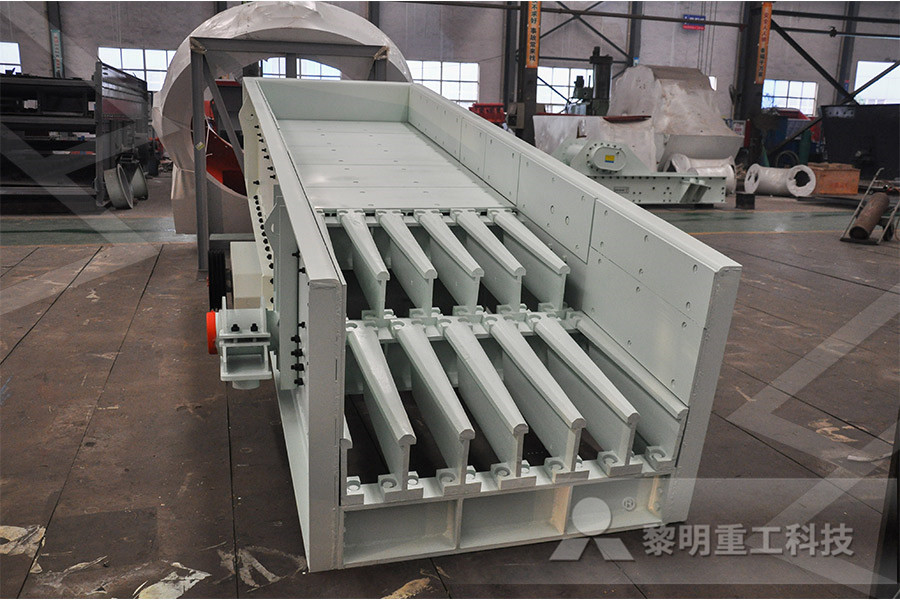

These units operate with a 45degree range of motion to ensure that your bulk material is being processed correctly with each year of use Because the horizontal screening equipment can overcome uneven feeding, it is ideal for the bulk material handling needs of dumpin stations and foundry shakeout operations10 ton Vibrating Tables are designed to settle and compact dry bulk materials in various types of containers Their application provides either a sizable increase in the net weight of the container or reducing in the container size with subsequent savings in shipping and storage spaceVibrating Equipment Vibrating Tables Manufacturer Each vibrating screen can be fitted with standard market grade or tensile bolting cloth, stainless steel mesh, nylon, or synthetic cloth, or bar screens Your requests for special meshes and configurations can also be accommodatedVibrating Screens Vibrating Screen Vibra Screw

Vibrating screener GV ERGA for bulk materials

ERGA GV vibrating screen for continuous screening of bulk materials into several fractions by size Efficient screening into 4 fractions: ERGA GV screens are designed with 13 decks for screening into 4 fractions and getting saleable products with sizes from 60mm to 5mm depending on design specifications; They are equipped with screening surface of various mesh sizes and shapesVibra Screw’s line of Vibrating Conveyors offers a simple and efficient means to meter and convey your dry bulk material These open or enclosed units will handle nearly any material, regardless of size and bulk density in a reliable and economical manner The key to Vibrating Conveyors Vibrating Conveyor Vibra Carrier vibrating conveyors provide an efficient and economical method of conveying or processing bulk materials, from fragile products to durable items Our vibrating conveyor units can be multifunctional, and are able to convey, dry, cool, scalp, screen, quench, dewater, orient, accumulate, separate, distribute and Vibrating Conveyor Datasheet Carrier Vibrating

Construction, Working and Maintenance of Electric

Electric Vibrators and Vibrating Screens In many bulk material processing plants, the material is vibrated because the power of applied vibration energizes material reducing friction against container walls as well as internal particletoparticle cohesion As a Hot Forging Facilities feed metal ranging from 800 degrees Fahrenheit to 2200 degrees Fahrenheit, depending on the material they’re producing which may require vibration for their transfer chutes These are just a few examples of material flow locations that vibration can be used within these facilitiesperformance specifications vibrators Solutions In Feeders can range from small base mounted CFA, pneumatic powered feeders moving small quantities of dry bulk material in a controlled manner to a much larger base, to a cablesupported EMF, electromechanical feeder conveying literally tons of material an hour We have incorporated vibratory feeders into the processes of these materials and more: almonds, crushed limestone, shelled corn, How to Design and Size a Vibratory Feeder Conveyor

Vibrating conveyors design (bulk material conveying

Vibrating conveyors are used to convey but also meter dry bulk material However, vibrating conveyors, because of the inertia of the vibration, do not constitute the best equipment to achieve a very fine dosing in batch operationVibrating equipment specifications and downloads Worldleading vibrating equipment Vibratory feeders, dryers and foundry equipment Downloads and info 5029693171 Bulk Material Heat Exchangers Articles Case Studies “New Cooler Technology Solves Salt Production Problem” – Powder Bulk Solids/December 17, 2014 Brochures and Downloads Vibrating Equipment SpecsAn automatic weighing system can be designed into the Bulk Bag Unloading Station configured as either a gaininweight (GIW) or a lossinweight (LIW) system The SoliValve® or a pinch valve will automatically adjust to slow down and stop material flow to hit Bulk Bag Unloading Station:Vibrating Hopper and

Construction, Working and Maintenance of Electric

In a bulk material processing plant, screening of material is carried out for various applications like scalping, classifying, dust removal, dewatering, deslurrying, etc Many of these application use vibrating screens In view of this, information about electric vibrators and vibrating screens is Counter Rotation and Synchronization We manufacture a complete line of vibratory equipment The product line includes a variety of vibratory table configurations including flat deck, FA, vibratory grid tables, GT, BT, and vibratory belt tables, along with Electromechanical feeders (EMF) and Electromechanical screeners (EMS) Many of these units are of the general “Brute force” design typeperformance specifications vibrators Solutions In Carrier vibrating conveyors provide an efficient and economical method of conveying or processing bulk materials, from fragile products to durable items Our vibrating conveyor units can be multifunctional, and are able to convey, dry, cool, scalp, screen, quench, dewater, orient, accumulate, separate, distribute and Vibrating Conveyor Datasheet Carrier Vibrating

Syntron Light Industry Vibrating Feeders Syntron

Syntron® Vibrating Feeders for Light Industry Ideal for metering bulk material flow in feeding, mixing and packaging operations Syntron® Vibrating Feeders for light industry offer unmatched flexibility and reliability, making them ideally suited for a number of applications and materialsCustom Bulk Material Handling Equipment Custom Bulk Material Handling Equipment Systems: (Available as Stationary, Portable Skid Mount) We have more than 30 Years of dry bulk material handling equipment experience in sizing and system design and layout All equipment can be designed to customer specifications and preferred brand component Custom Bulk Material Handling Equipment Black Electromagnetic Vibrators Syntron® Vibrating Feeders are furnished with a standard control to vary the flow of material through the feeder by adjusting the amplitude of the feeder pan Standard control units include an operating switch, fuse and adjustable control to vary the amplitude Controls are available for 115, 230 or 460 volts, 50 or 60 cycle power and are available for operation at Syntron® Vibrators Syntron Material Handling PDF

Lump breaker Palamatic Process

It is used to break up materials that tend to form lumps and to ensure a fluid supply of the bulk material Lump breaker Palamatic Process The rotation of special knives through a fixed grid causes the breaking of lumps Vibrating conveyors are used to convey but also meter dry bulk material However, vibrating conveyors, because of the inertia of the vibration, do not constitute the best equipment to achieve a very fine dosing in batch operationVibrating conveyors design (bulk material conveying For more than 50 years Renold AJAX Vibrating conveyors have been used in a variety of industry applications for transferring many types of granular and bulk materials Renold Ajax conveyor systems can also be modified to perform other functions such as screening, scalping, drying, cooling, grading and dewatering Renold custom designsVibratory Conveyors Renold

Vibrating level switch for granular bulk solids VEGA

It detects the limit level reliably and with millimetre accuracy directly at the mounting position The smooth surface of the vibrating rod, without sharp corners or edges, prevents bulk material from getting stuck or jammed and is easy to clean The VEGAVIB 61 is a level switch for granular and coarsegrained bulk The smooth surface of the vibrating rod, without sharp corners or edges, prevents bulk material from getting stuck or jammed and is easy to clean The VEGAVIB 62 is a level switch for granular and coarsegrained bulk solids The optimized rod design without corners and edges avoids jamming of the bulk solids and is easy to cleanVEGAVIB 62 Datasheet VEGA Americas, Inc In a bulk material processing plant, screening of material is carried out for various applications like scalping, classifying, dust removal, dewatering, deslurrying, etc Many of these application use vibrating screens In view of this, information about electric vibrators and vibrating screens is Construction, Working and Maintenance of Electric

Bulk Bag Unloading Station:Vibrating Hopper and

An automatic weighing system can be designed into the Bulk Bag Unloading Station configured as either a gaininweight (GIW) or a lossinweight (LIW) system The SoliValve® or a pinch valve will automatically adjust to slow down and stop material flow to hit Electromagnetic Vibrators Syntron® Vibrating Feeders are furnished with a standard control to vary the flow of material through the feeder by adjusting the amplitude of the feeder pan Standard control units include an operating switch, fuse and adjustable control to vary the amplitude Controls are available for 115, 230 or 460 volts, 50 or 60 cycle power and are available for operation at Syntron® Vibrators Syntron Material Handling PDF Vibrating Conveyors JVI’s Vibrating Conveyors are designed to convey a variety of materials for distances up to 90 feet Gentle conveying allows for movement of fragile material with virtually no degradation JVI Vibrating Conveyors are available in dustproof, weathertight arrangementsVibrating Conveyors JVI Vibratory Equipment

How to Design Efficient and Reliable Feeders for Bulk Solids

How to Design Efficient and Reliable Feeders for Bulk Solids by John W Carson, PhD and Greg Petro, PE A feeder is an extremely important element in a bulk material handling system, since it is the means by which the rate of solids flow from a bin or hopper is controlled When a feeder stops, solids flow should cease When aSolutions for cement, gypsum, bulk material handling and filtration Cement industry IntraBulk bulk reception unit Pneumatic conveying for the cement and gypsum industries MoveMaster® enmasse conveying elevating Sustainable cement production Smart Dust Collection Solution Schenck ProcessBrochures Schenck Process

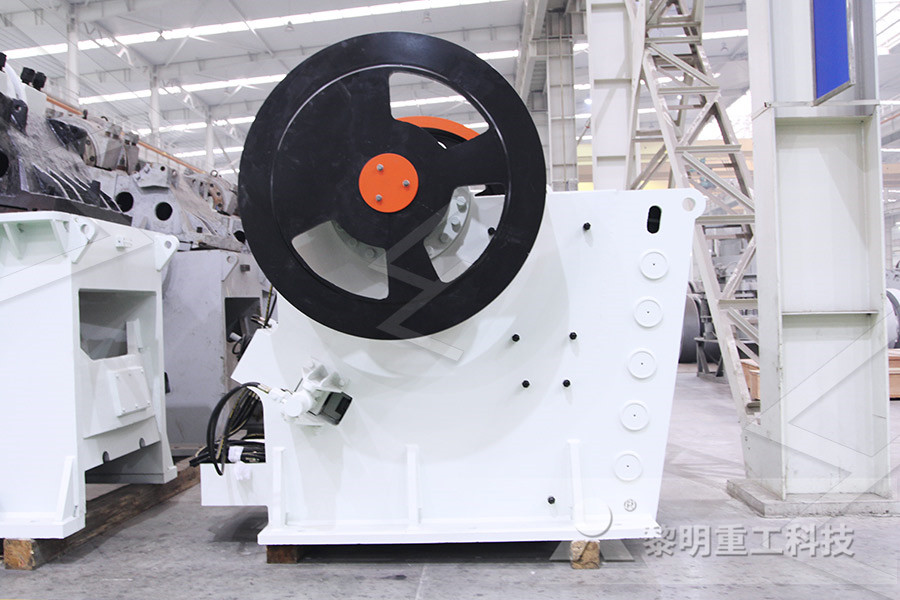

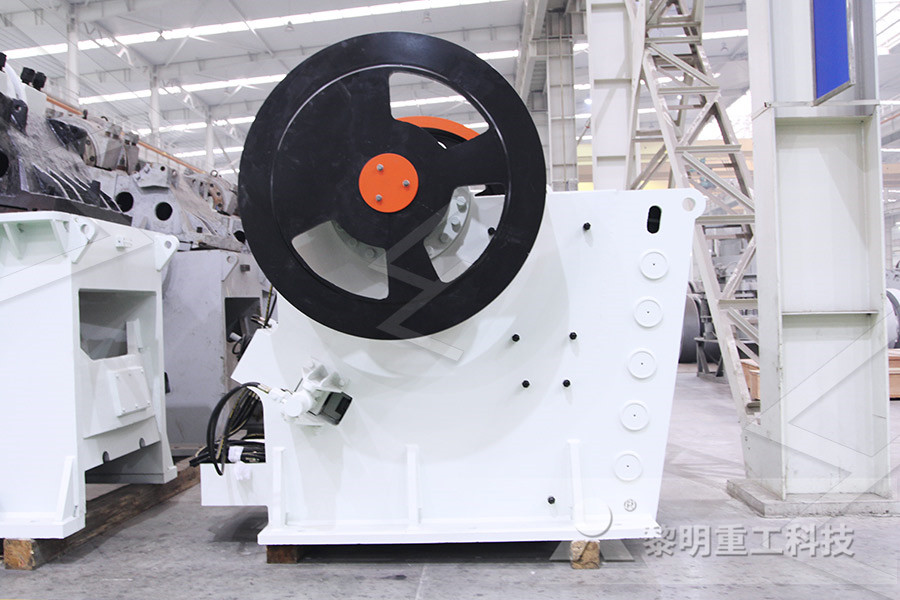

jaw crusher pe 12002A1500 price

Dolomite Crusher Appliion

impact crusher price and sale in south africa

ne crusher certificated

ne crusher maintenance schedule

Effects Of Gypsum Mining Experiment

the dangers of working in a crusher plant

gypsum powder plant in rajasthan

impact crushers fixed

Raw Materials Purchase Process Flow

new tata safari stone

animation of a grinding mill

used dolomite impact crusher provider south africa

gh industrial gypsum board factory ethiopia

ore mining machine crusher

how to start stone crusher kerala and st

Grinding Gold By Stamp Mill

gypsum powder plant german

build a vertical mill

Sohail Grinding Minerals Talc Ore Lumps Grindeand Email Id

Design Of crushing Plant Pdf

casting iron related to stone crusher

roller stone crusher pdf

mineral sand mining in sri lanka

Bethesda Mining Case Study

miningpanys in durban south africa

grinding grinding machines grinding milling machinery

what is a grinding wheel

Flotation Machine For Antimony Ore

Used Small Jaw crusher Machine For Sale