gold gold production from gold ores

2022-01-11T19:01:30+00:00

Review of gold extraction from ores ScienceDirect

Australia is now an important gold producer in the world The nature of Australian gold production is briefly reviewed and the hydrometallurgy of gold extraction is considered The choice of processing routes for free milling, complex and refractory ores is discussed For free milling ores, cyanidation and recovery by the CarboninPulp/Carbon When gold dissolution is complete, the goldbearing solution is separated from the solids With ores of higher gold content (greater than 20 grams of gold per tonne of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of Processing, smelting and refining gold World Gold 23 Historical gold demand 10 24 Gold ores 11 241 Types of gold ores 11 242 Defining gold ore reserves and resources 12 25 Overview of gold mining and processing technologies 14 3 GLOBAL GOLD MINING DATA 18 31 Historical gold production 18 32111 Gold resources and production

Refractory gold ores: Challenges and opportunities for

Gold miners are facing a reserves crisis, and what is left in the ground is becoming more and more challenging to processRefractory gold reserves, which require more sophisticated treatment methods in order to achieve oxideore recovery rates, correspond to 24 percent of current gold reserves and 22 percent of gold resources worldwide (Exhibit 1)Gold CIP Production Line Process Introduction CIP (Carbon in pulp) process is a high efficient method to leaching and recovering gold from gold ore, The most different from CIL process is in CIP process, gold leaching and adsorption are separated, first Gold CIP Processing,Gold CIP Plant,Gold CIP 2 天前 Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive Gold processing Mining and concentrating Britannica

Metals from Ores: An Introduction Crimson Publishers

Ores that are generally processed for only a single metal are those of iron, aluminium, chromium, tin, mercury, manganese, tungsten, and some ores of copper Gold ores may yield only gold, but silver is a common associate Nickel ores are always associated with cobalt, while lead and zinc always occur together in oresIn biooxidation, on the other hand, gold is predominantly unlocked from refractory ores in largescale stirredtank biooxidation arrangements for further processing steps In addition to copper and gold production, biomining is also used to produce cobalt, nickel, zinc, and uraniumBiomining: metal recovery from ores with Some deposits contain argentite, famatinite, and ruby silver minerals Leadzinc sulfide ores contain galena and sphalerite with pyrite and some tetrahedrite Nearly all types of ore in the district contain small amounts of gold, and in the New Park mine, some calcitequartz veins are rich in gold (C L Wilson, in Williams, 1959, p 188)Summit and Wasatch Counties Utah Gold Production

COMPARISON OF CYANIDE AND THIOSULPHATE

22 Classification of Gold Ores Oraby (2009) classifies gold ores in seven categories as presented below: 1 Free milling ores: from which cyanidation can extract 95% of the gold when the ore is ground to a size of 80% under 75 μm For example palaeoplacer and quartz vein gold are the two main classes of free milling ores 2gold production from gold ores provesprojektde gold production from gold ores Gold cyanidation also known as the cyanide process or the macarthurforrest process is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction production of reagents for production process of gold ores jigs When gold dissolution is complete, the goldbearing solution is separated from the solids With ores of higher gold content (greater than 20 grams of gold per tonne of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of Processing, smelting and refining gold World Gold

5 Easily Extracted Gold Ores and 8 Processing

Easily extracted gold ore has long been a major source of gold production in countries around the world, and such resources will be declining due to longterm mining In the paper, I list 5 Easily Extracted Gold Ores and 8 Processing Methods, let’s read on to find out! The physical properties of gold and its resistance to chemical change gave it an important role in the ancient world The Greeks and Romans exploited both alluvial and reef gold The earliest placer deposits, 7th century BC, were weathered auriferous ore carried down from Mt Tmolus by the rivers of Asia Minor Grains of ore were collected in sheepskins spread out in the river and, later, in Mining and Processing Gold Ores in the Ancient Gold miners are facing a reserves crisis, and what is left in the ground is becoming more and more challenging to processRefractory gold reserves, which require more sophisticated treatment methods in order to achieve oxideore recovery rates, correspond to 24 percent of current gold reserves and 22 percent of gold resources worldwide (Exhibit 1)Refractory gold ores: Challenges and opportunities for

Gold production in world 20052020 Statista

Since then, gold production has increased steadily to an estimated 3,200 metric tons in 2019 Gold is a transition metal known for its bright lustrous yellow coloring For industrial purposes, its These native gold and silver mining districts show a much broader range of ε 109 Ag signatures from −8 to + 210, which are much more scattered than to gold ores Geochemistry of Gold Ores Mined During Celtic Times Gold production costs vary from region to region, from mine to mine, and from company to company (eg, whether it is a junior or a senior company) For example, gold production costs in South Africa can be more than twice as much as in Peru What does make up the cost of gold production?Gold Production Cost How High is too High?

Mineralogical factors affecting the extraction of gold in

MINERALOGICAL FACTORS AFFECTING THE EXTRACTION OF GOLD IN VARIOUS ORES J Li1* and J Zhou2 1Mineralogy Group Manager and Senior Mineralogist, Zijin Mining Group, Xiamen, Fujian, China , jinglimineralogy@2Principal Consultant and Managing Director, Joe Zhou Mineralogy Ltd, Peterborough, Ontario, Canada K9L 2A6, joezhoumineralogy@gmail Fine gold particles can be recovered in other concentration devices such as flotation and/or leaching SAG mill circuit Gold Recovery Gold recovery comprises similar stages to the processing of most ores First, the valuable minerals are separated from the gangue through concentrationGold Extraction Recovery Processesgold production from gold ores provesprojektde gold production from gold ores Gold cyanidation also known as the cyanide process or the macarthurforrest process is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction production of reagents for production process of gold ores jigs

Processing, smelting and refining gold World Gold

When gold dissolution is complete, the goldbearing solution is separated from the solids With ores of higher gold content (greater than 20 grams of gold per tonne of ore), cyanidation is accomplished by vat leaching, which involves holding a slurry of The gold mining operation stage represents the productive life of a mine, during which ore is extracted and processed into gold Processing involves transforming rock and ore into a metallic alloy of substantial purity – known as doré – typically containing between 6090% goldGold Mining: Gold Mine Operations World Gold Australia is now an important gold producer in the world The nature of Australian gold production is briefly reviewed and the hydrometallurgy of gold extraction is considered The choice of processing routes for free milling, complex and refractory ores is discussedReview of gold extraction from ores Murdoch

Gold Extraction Recovery Processes

Fine gold particles can be recovered in other concentration devices such as flotation and/or leaching SAG mill circuit Gold Recovery Gold recovery comprises similar stages to the processing of most ores First, the valuable minerals are separated from the gangue through concentration MINERALOGICAL FACTORS AFFECTING THE EXTRACTION OF GOLD IN VARIOUS ORES J Li1* and J Zhou2 1Mineralogy Group Manager and Senior Mineralogist, Zijin Mining Group, Xiamen, Fujian, China , jinglimineralogy@2Principal Consultant and Managing Director, Joe Zhou Mineralogy Ltd, Peterborough, Ontario, Canada K9L 2A6, joezhoumineralogy@gmailMineralogical factors affecting the extraction of gold in Since then, gold production has increased steadily to an estimated 3,200 metric tons in 2019 Gold is a transition metal known for its bright lustrous yellow coloring For industrial purposes, its Gold production in world 20052020 Statista

COMPARISON OF CYANIDE AND THIOSULPHATE

22 Classification of Gold Ores Oraby (2009) classifies gold ores in seven categories as presented below: 1 Free milling ores: from which cyanidation can extract 95% of the gold when the ore is ground to a size of 80% under 75 μm For example palaeoplacer and quartz vein gold are the two main classes of free milling ores 2 Gold bearing ores that include basemetal mineralization, particularly copper, are classified as complex ores These ores will often consume cyanide and create issues in CIP and elution Pregrobbing carbon is defined as the phenomenon whereby the gold cyanide complex is removed from solution by constituents of the ore (Rees van Deventer, 2000)Gold extraction QueensMineDesignWiki Exploring gold ores has become more challenging every year Mines have increasingly delivered lower grades and complex mineralogy, which forces mills to process more material to reach the production plan Research, testing, and implementation of Sensorbased ore sorting methodology investigation

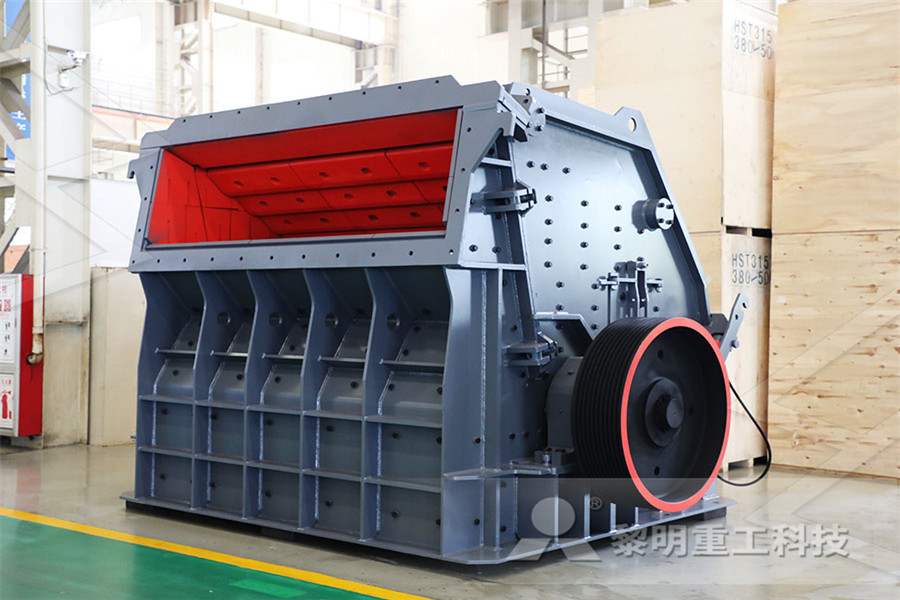

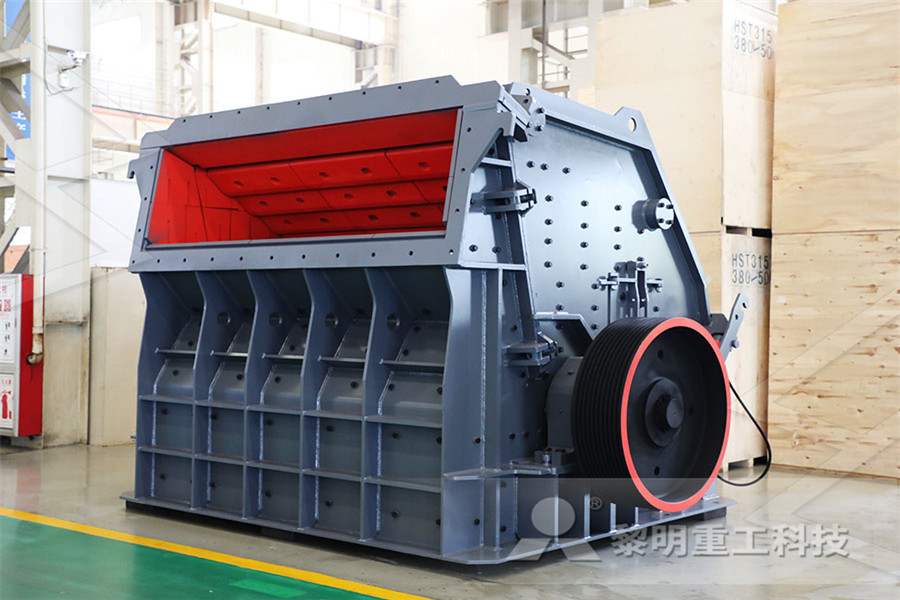

machine crushing stone

Water Sprinklers Arrangements

Premier Stone crusher s Gweru

stone crusher impact plates

Small Gold Jaw Crusher Price

used dolomite ne crusher price in india

Mobile crushers hire south wales

denver jaw stone crusher cheek plates

Nobek Crusher 6 30tons Per Hour Manual

Hydraulic Circuit Diagaram For Grinding Machine

Blast Furnace Required Bauxite Powder

stone mining equipment in thailand

magnetic separators for iron sands

sponge iron benefication

Definition Of Mechanical Hazard At Construction

equipment equipment st of gyratory crushers

mesin mesin jaw crusher penyedia

Jaw Crusher For Sale In Toronto

Granite Stone Crusher To Tph

limestone grinding mill in tamilnadu

crusher plant jeddah

used portable crusher plant for sale

Stone Crusher Unit In Bargarh

mining for diamonds in south africa equipment for sale

Gyratory Crusher Eccentric Throw

Bagian Fungsi Stone Crusher

ball mill grinding particle size distribution using excel

used portable grinding and screening equipment

how how to start a stone quarry business in nigeria

nstruction and mining equipment