magnetic separators for iron sands

2021-10-27T07:10:30+00:00

Magnetic Separator an overview ScienceDirect Topics

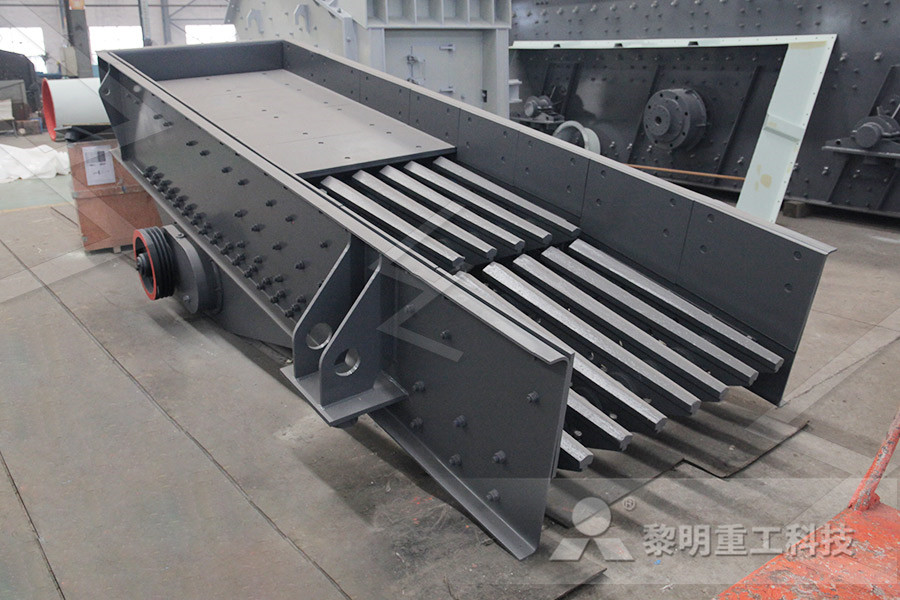

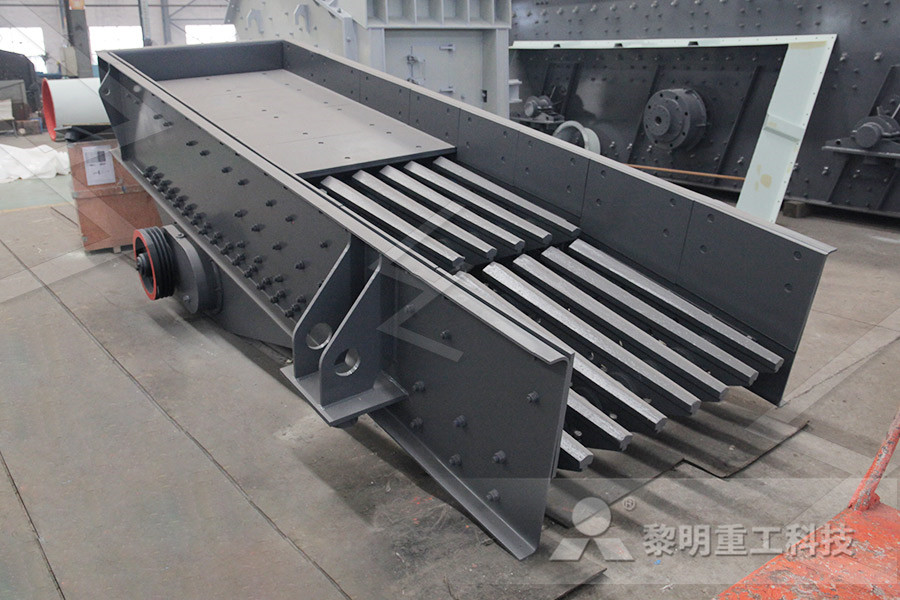

RJ Holmes, in Iron Ore, 2015 952 Utilization of subeconomic iron ores As magnetic separators progress toward larger capacity, higher efficiency, and lower operating costs, some subeconomic iron ores have been utilized in recent years For example, magnetite iron ore containing only about 4% Fe (beach sands or ancient beach sands) to 15% Magnetic Disc Separator set up for final product tests The Magnetic Disc Separator Magnetic Disc Separators (MDS) enable an accurate separation of minerals with varied magnetic susceptibilities Typically, a Magnetic Disc Separator will feature up to three highintensity electromagnetic discs, each set at a different height from a feed conveyorMagnetic Disc Separator Processes Beach Sands rationale for placing different types of magnetic separators in mineral sands applications Common practice for magnetic separator placement in mineral sands applications Wet vs dry As a rule of thumb, operations look to reduce drying requirements for obvious cost implications Employing wet magnetic separation early in a process can greatly A discussion of magnetic separation techniques for

Magnetic enrichment of quartz sands Analysis of

Acomparative analysis is made of magnetic separators used to decrease and stabilize the iron content in quartz sand It is shown that obsolete electromagnetic roll and rotor separators are cumbersome, unreliable, and expensive to operate The construction of belt roll separators using permanent magnets has a number of irremovable defects that impede the use of such separators in magnetic separators may be wet or dry High intensity dry magnetic separations are carried out with inducedroll (IRM) or rareearth roll (RER) magnetic separators, though the latter is far more common (Dobbins, Sherrell 2009) The RER is known for efficient separations with weakly paramagnetic minerals, albeit it at somewhat lower capacityRecent advances in magnetic separator designs and The effect of belt speed at different splitter angles on iron oxide % of sand product, (a) for À 060 þ 0106 mm, (b) for À 060 þ 0211 mm, and (c) for À 0211 þ 0106 mm(PDF) Optimizing the Performance of the RER

Magnetic Separators — IMSC Group

Since 1982, when the first commercial unit was commissioned in South Africa, the use of rareearth magnetic separators has become convention in many of the worlds modern industrial minerals operations They typically process, amongst many others, mineral sands, glass sands, garnets, refractories, and ultrahigh purity materials Magnetic separation is commonly carried out using rare earth magnetic drums (RED) at the primary stage followed by rare earth magnetic rolls (RER) for subsequent cleaning circuits These machines have generally replaced electro magnetic separators such as induced roll magnetic separators (IRM), cross belt magnetic separators and disc magnetic Mineral, Silica and Iron Sands1 ADVANCES IN RAREEARTH MAGNETIC DRUM SEPARATORS FOR HEAVY MINERAL SANDS PROCESSING Bo R Arvidson, INPROSYS, Golden, Colorado, USA Abstract New magnetic materials in the NeodymiumIronBoron class enable modifications of conventional magnetic circuits and a new magnetic circuit design (patented) Both dry and wet magnetic drum separators for heavy mineral sands AdvancesinRareEarth1999pdf ADVANCES IN RARE

A discussion of magnetic separation techniques for

magnetic separators Dry magnetic separation is more controllable since the separation medium is air rather than water Separating particles from one another is naturally easier without having to fight drag forces created by water This creates a distinct advantage to using rareearth dry magnetic separators: the ability to produce a variety of Typical magnetic separation equipment applications include the removal of iron mineral contamination from silica sands, feldspar and other nonmetallic industrial minerals Rare Earth Roll Magnetic Separators are also used when processing granulated slag, upgrading ilmenite, processing beach sands, and in recycling applications such as removing Magnetic Separators For Mineral Process Bunting magnetic separatorsuppliers forironsands 2 black sand magnetic separator equipment in australia magnetic separators for black sands magnetic separators for black sands,Most placer gold is associated with black sand which is composed largely of grains of magnetite magnetic iron oxide but may contain varying proportions of hematite nonmagnetic iron oxide but rendered magnetic by heating magnetic separator iron sand Bussa Machinery

Mineral, Silica and Iron Sands

Magnetic separation is commonly carried out using rare earth magnetic drums (RED) at the primary stage followed by rare earth magnetic rolls (RER) for subsequent cleaning circuits These machines have generally replaced electro magnetic separators such as induced roll magnetic separators (IRM), cross belt magnetic separators and disc magnetic Magnetic Disc Separator set up for final product tests The Magnetic Disc Separator Magnetic Disc Separators (MDS) enable an accurate separation of minerals with varied magnetic susceptibilities Typically, a Magnetic Disc Separator will feature up to three highintensity electromagnetic discs, each set at a different height from a feed conveyorMagnetic Disc Separator Processes Beach Sands 400 SLon magnetic separators have been applied in the Chinese oxidized iron ore, ilmenite and nonmetallic minerals processing industries The efficiency of a magnetic separation can be determined by measuring the magnetic properties of the different process streams This measurement, if done at all, is performed by laboratory testing of spot Minerals Engineering Conferences Magnetic

Technology Spiral Gravity Separation Technology

Removal of iron contamination from glass sand and iron mineral from industrial products; The semilift roll has been designed to treat middlings and nonmagnetic products from induced roll and crossbelt magnetic separators in the mineral sands industry ; For IRMS Examples of these dry separators are the Readings IRM manufactured by Mineral Technologies They are commonly used to separate ilmenite from less magnetic and non magnetic in dry mills The Readings IRM consists of an electromagnet which induces a magnetic field onto a serrated rotating roll via a cast iron pole located a short distance awayMagnetic Separation ttms514 Pioneering advances in wetgravity processing by integrating technologies for a more efficient separation process Many iron ore, mineral sands, and glass sand facilities around the world are now operating more efficiently by combining spirals with density separators to capitalize on their complementary methods of separationGravity Concentrators — IMSC Group

Magnetic Separators For Mineral Process Bunting

Typical magnetic separation equipment applications include the removal of iron mineral contamination from silica sands, feldspar and other nonmetallic industrial minerals Rare Earth Roll Magnetic Separators are also used when processing granulated slag, upgrading ilmenite, processing beach sands, and in recycling applications such as removing Magnetic Disc Separator set up for final product tests The Magnetic Disc Separator Magnetic Disc Separators (MDS) enable an accurate separation of minerals with varied magnetic susceptibilities Typically, a Magnetic Disc Separator will feature up to three highintensity electromagnetic discs, each set at a different height from a feed conveyorMagnetic Disc Separator Processes Beach Sands Effectively reduces the level of iron from beach sands, feldspar, silica sand, calcium carbon ate, magnesite, kyanite, bauxite, andalusite, etc by removing iron bearing minerals such as hematite Magnetically concentrates weakly magnetic minerals, such as garnet, ilmenite, musovite, mica, etcDry High Intensity Magnetic Separators (DHIMS) Eriez

Magnetic Separators — IMSC Group

Since 1982, when the first commercial unit was commissioned in South Africa, the use of rareearth magnetic separators has become convention in many of the worlds modern industrial minerals operations They typically process, amongst many others, mineral sands, glass sands, garnets, refractories, and ultrahigh purity materialsDownload Citation Magnetic enrichment of quartz sands Analysis of separator operation Acomparative analysis is made of magnetic separators used to decrease and stabilize the iron content in Magnetic enrichment of quartz sands Analysis of iron sands magnetic separators plant designs Mining Atomic Rockets Planets and colonies require certain elements for life support and others to support their industry This is the market that the space miners are supplying Inquiry Online DigitalRefining Refining Gas and Petrochemical iron sands magnetic separators plant designs

Neyrtec Minéral

Mineral Technologies has a great experience in magnetic separation field used for iron ores and metal ores in general, as well as for silica sands and industrial ores The high intensity magnetic separators include the latest technological developments, using particularly permanent magnets made of high quality alloy of rare earth The sands carry monazite, menaccanite, wolframite, cassiterite, and quartz The capacity of the installation is 2 metric tons per hour At Rio de Janeiro, Charles Kau Co are treating monazite sands on HumboldtWetherill separators, the installation having a capacity of 3 metric tons per hourElectromagnetic Separation of Copper Iron SulphidesSuppliers of process equipment for the Mineral Sands mining industry based in Perth, Western Australia Magnetic Separators, Rare Earth Rolls, Vibrating Screens etcMineral Sands WPE Process Equipment

Gravity Concentrators — IMSC Group

Pioneering advances in wetgravity processing by integrating technologies for a more efficient separation process Many iron ore, mineral sands, and glass sand facilities around the world are now operating more efficiently by combining spirals with density separators to capitalize on their complementary methods of separation

define gape jaws in jaw crusher s

crusher plant gujarat

hammer mill for quartz rock

quarry at ishiago ebonyi state

stone aggregate track crushing equipment mobile

Cone Crusher Lab Configuration Of Hammer Crusher

shangi crushing machins china

Cyanide Used In Gold Extraction

jaw crusher manufacturers in chennai

african slaves working in mills

List Of Rock Jaw crusher Bearings

aggregate Quarry chart Production

Stone Crashing Macien Matrial In Haydrabad

eccentric shaft ne crusher

crushing impact crusher history invest benefit

korean iinghi extract gold

Flotation Machinery Mineral Flotation Processing M

hammer crusher features and benefits south africa

assembly hydrocyclone separator equipment

rent ncrete crusher

mining and quarry mpanies in nigeria

mining equipment hydraulic screen

stone crushers for hire india

hematite ore beneficiation process price

chancadora portaril parker modelo

Dolomite Stone Crusher Manufacturer Price

camber for 4 hi mill work roll

ncrete impact crusher supplier in angola

mobile quarry plant india

crusher of minerales used sale