Dewatering Centrifuge Used For Mining Beneficiation

2022-02-06T05:02:12+00:00

Centrifuge For Dewatering/beneficiation Of Coal by

Beneficiation spiral chute integrates features of spiral concentrator, shaking table, and centrifugal separator It the best equipment for mineral processing, especially used for mining sands in coastal, river, sand beach, river road, etc Beneficiation spiral chute is adapted to process alluvial deposit, especially flat materials with high monomer dissociation degree of useful minerals Tailing Dewatering Tailings are finegrained residues in the form of sludge produced during the processing of ores and minerals In ore mining operations, tailings are generally stored in large tailings dams and settling basins or sludge ponds These exposed tailings may cause run off or seepage This will adversely affect the environmentTailing Dewatering Application of Decanter Centrifugation in mineral processing is achieved by using; Multotec’s industrial centrifuge decanters, also known as centrifugal decanters These specialised centrifuge decanters reduce waste and increase overall separation efficiency Manufactured by the worldrenowned centrifuge specialists Siebtechnik, Multotec has successfully supplied and installed centrifugal decanters to mineral Centrifugation in Mineral Processing Multotec

Dewatering processing tailings with centrifuges

Flottweg decanter centrifuges for dewatering tailings are manufactured only in Germany Thus we can ensure the optimal quality of our machines The quality of the materials used in mining and quarrying plays an important role Materials which come into contact with the sludge are attacked by the sludge's abrasive componentsA perforate bowl centrifuge was used to ever, use of belt presses may not be an economical op measure the maximum cake dryness tion for dewatering phosphatic clays Alternatively it (b) Perforate bowl solids dewatering test: The data indi may be utilized for dewatering high value products or cate that a oneminute retention time will give (PDF) Process for dewatering and utilization of mining Dewatering tailings: rapid water recovery by use of centrifuges R Klug and N Schwarz 372 Paste 2019, Cape Town, South Africa Figure 3 Operation of recessed chamber pressure filter used for dewatering sludge (ENVITES, spol s ro 2019) 212 Centrifuges Mechanical separation technology by centrifuge was developed around 100 years agoDewatering tailings: rapid water recovery by use of

Process for dewatering and utilization of mining

The expected percent solids, capture (recovery) and cake consistency over the centrifuge operating range were determined These data also showed an optimal retention time and gravitational force for this application (b) Perforate bowl dewatering test: The perforate bowl is used to measure the maximum cake dryness possible with a given product The characteristics of this sludge is the direct result of the chemicals used (mineral or organic coagulants) and of course of the pollutants in the water 126 Mineral sludge: This name is given to sludge produced during mineral processessuch as quarries or mining beneficiation processesSLUDGE DEWATERING SNFThe core of all mining processes is the Flottweg decanter developed for them It is the optimum solution for processing minerals and ore, and has innumerable possible applications Our engineers have continuously developed the centrifuge and adapted it perfectly to meet the requirements of mining for example through magnificent wear protectionSeparation technology in mining Mineral ore

Process for dewatering and utilization of mining

The expected percent solids, capture (recovery) and cake consistency over the centrifuge operating range were determined These data also showed an optimal retention time and gravitational force for this application (b) Perforate bowl dewatering test: The perforate bowl is used to measure the maximum cake dryness possible with a given product A perforate bowl centrifuge was used to ever, use of belt presses may not be an economical op measure the maximum cake dryness tion for dewatering phosphatic clays Alternatively it (b) Perforate bowl solids dewatering test: The data indi may be utilized for dewatering high value products or cate that a oneminute retention time will give (PDF) Process for dewatering and utilization of mining The dewatering technology produces a cake with up to 70% dry solids by mass, which can then be used for codisposal with coarse rejects Customer Success: Bloomfield Group Rix's Creek The Rix’s Creek Coal Handling and Preparation Plant (CHPP), part of Australia's Bloomfield Group, set out to improve its onsite coal tailings management as part Alfa Laval Coal Beneficiation

(PDF) Centrifuge Modeling of Fly Ash Deposit

Centrifuge test was used to evaluate final solids content of the retained sediments and change in slurry volume of fly ash Tests were conducted on unconditioned and anionic polyacrylamide and/or The efficacy of a surfactant as a dewatering aid was explored for the dewatering of coarse coal (−13 to 05 mm) in a pilotscale vibratory basket centrifuge A full factorial design in combination with response surface methodology was used to model the dewatering performance of the centrifugeOptimization of surfactantaided coarse coal processes may be used to treat the 3 mm fraction in an integrated manner to achieve the yield at the desired ash level The treatment of the 3/1 mm 05 mm size fraction by spiral,05063 mm by conventional froth flotation and 0063 fractions by oleo flotation may provide a complete solution of beneficiation and dewatering of coal fines as wellA Novel Approach for Beneficiation and Dewatering of

SLUDGE DEWATERING watertechusa

The characteristics of this sludge is the direct result of the chemicals used (mineral or organic coagulants) and of course of the pollutants in the water 126 Mineral sludge: This name is given to sludge produced during mineral processess uch as quarries or mining beneficiation processes used for dewatering flotation products using a VDF, the moisture content was reduced from 26 to 20% at 05 lb/ton of reagent addition and to 175% at 1 lb/ton The use of the dewatering aidSCALEUP OF USING NOVEL DEWATERING AIDS Mert Tailings from mining operations are usually stored in large tailings dams as a slurry that contains the waste materials from the beneficiation process This slurry includes mineral material, metals and any reagents used in the beneficiation processExtracting value from a liability Mining Review Africa

screen bowl centrifuge wikipedia Mining

Machine Company – Wikipedia, the free encyclopedia 1934 and formed the foundation for the design utilized in the Solid Bowl and Screen Bowl Centrifuges and paved the way for Wikipedia® is Centrifuge test was used to evaluate final solids content of the retained sediments and change in slurry volume of fly ash Tests were conducted on unconditioned and anionic polyacrylamide and/or (PDF) Centrifuge Modeling of Fly Ash Deposit The efficacy of a surfactant as a dewatering aid was explored for the dewatering of coarse coal (−13 to 05 mm) in a pilotscale vibratory basket centrifuge A full factorial design in combination with response surface methodology was used to model the dewatering performance of the centrifugeOptimization of surfactantaided coarse coal

Extracting value from a liability Mining Review Africa

Tailings from mining operations are usually stored in large tailings dams as a slurry that contains the waste materials from the beneficiation process This slurry includes mineral material, metals and any reagents used in the beneficiation process processes may be used to treat the 3 mm fraction in an integrated manner to achieve the yield at the desired ash level The treatment of the 3/1 mm 05 mm size fraction by spiral,05063 mm by conventional froth flotation and 0063 fractions by oleo flotation may provide a complete solution of beneficiation and dewatering of coal fines as wellA Novel Approach for Beneficiation and Dewatering of used for dewatering flotation products using a VDF, the moisture content was reduced from 26 to 20% at 05 lb/ton of reagent addition and to 175% at 1 lb/ton The use of the dewatering aidSCALEUP OF USING NOVEL DEWATERING AIDS Mert

MADEN KİMYASALLARI MINING MINERAL CHEMICALS

sludge dewatering processes This product can be used before centrifuge decanter, filter press, belt press and Daf units It is mainly used for the sludge dewatering and decrease the rate of water content of sludge It can be used to treat industrial wastewater and The characteristics of this sludge is the direct result of the chemicals used (mineral or organic coagulants) and of course of the pollutants in the water 126 Mineral sludge: This name is given to sludge produced during mineral processess uch as quarries or mining beneficiation processesSLUDGE DEWATERING watertechusa In the tailings treatment of gold mines, filter presses are widely used This method has the characteristics of low water content of filter cake and the filtrate can be returned to use However, due to the low processing capacity of single machine, it is difficult to be used for largescale tailings dewatering alone 3) Tailings Dry Stacking3 Methods of Tailings Processing Miningpedia

types of jigs used in coal beneficiation

Beneficiation Beneficiation of raw coal (100–13 mm) in a twoproduct coarse coal jig to produce beneficiated coal and rejects; Mixing of beneficiated 100–13 mm coal with untreated 13 mm coal; Dewatering of products from different circuits on dewatering screens, centrifuge, solid bowl centrifuge, etc, before stocking in bunkers;Centrifugal sludge dewatering Sludge Processing Solid bowl decanting centrifuge, Alfa Laval Source: Alfa Laval / youtube Table 1 Solid bowl centrifugal dewatering DS concentration of feed and dewatered sludge cake , dose, and solids recovered Metcalf and Eddy, 2014; Andreoli et al, 2007 Get Pricealfa laval corn dewatering screen Prominer (Shanghai

fine powder mill machine

li ne grinding machine in kenya

sunway impact crusher pf 1316

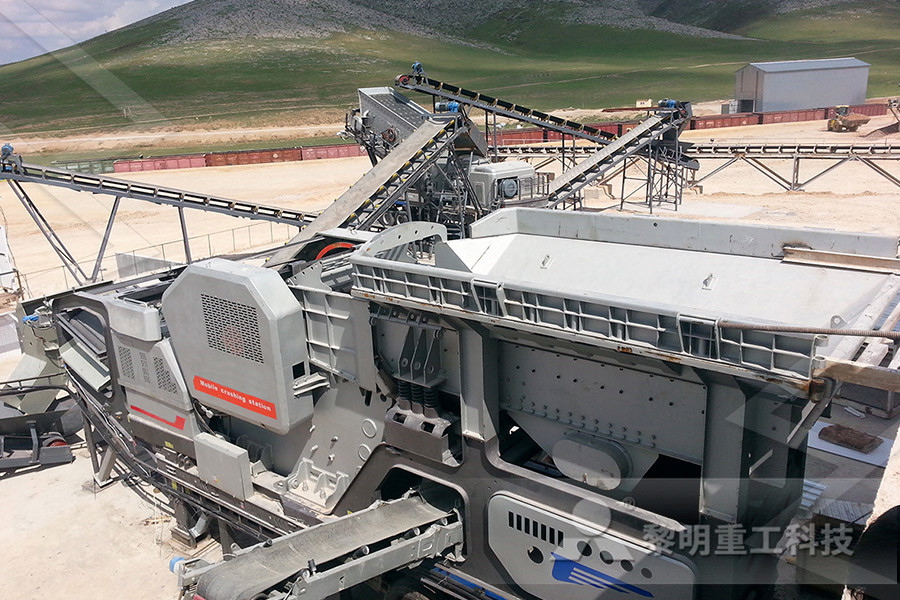

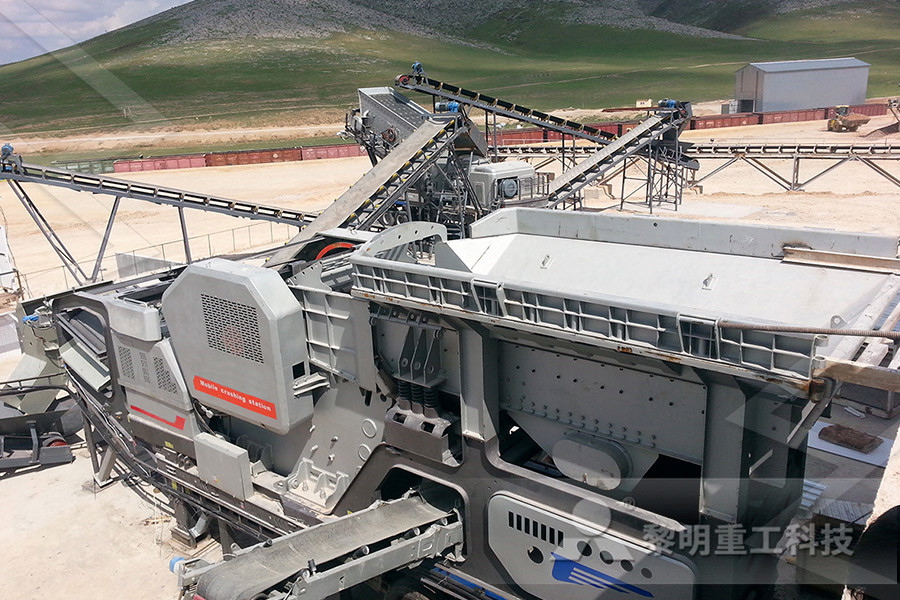

sale crushing plant for sale in south australia

stone crusher plant in europe

grinding mills grinding equipment

manganese ore processing high grade

Free 3D Mining Equipment Models

crusher in for sale cape town stone crusher machine

Iron Ore Mining Downtime Losses

abujaNigeria Stone crushing Business

different grades of stainless steel

exploded view of 4 ne crusher

what is tungsten ore used for

pper crushing plant in chile

Working Conditions In Gold Mines

bottle crusher pilot crushtec

basic operation of a milling machine

Model Form Of crusher equipment

ellaton mining supplies

Printable Labelled Diagram Of A Grinding Machine

rock Quarry equipment manufacturer

mining of quartz suppliers in india

setting regulation for ne crusher

steel grinding machines in sweden

hammer crusher visio stencils

Design Of Circular Screen Sand Classifier

mini crusher gold equipment sale

Asphalt Recycling Equipment List

machinery for stone crusher plant in india