gold removal processing

2020-04-25T13:04:33+00:00

Gold Processing,Extraction,Smelting Plant Design

After sufficient leaching, the pregnant solution will be pumped to the carbon adsorption column for catching the free gold The barren liquid will be pumped to the cyanide solution pond for recycle usage The loaded carbon is treated at high temperature The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified goldProcessing, smelting and refining gold World Gold Honey Gold Processing is one of the few high capacity labs in the country to offer THC removal services to outside parties We take in "hot" distillate (2% to 4% THC) and through chromatography, we remove the THC and return the THC free distillate as a service THC Removal Honey Gold Processing

Gold refining by solvent extraction—the Minataur™ Process

possible to reduce the gold residence time in the circuit to less than 24 h from introduction of the feed material to the leach to production of highpurity gold powder It is then necessary to dry the powder prior to melting and casting it into a saleable product for dispatch Gold refining by solvent extraction—the MinataurTM Process Next, break the circuit board into smaller pieces and place them inside a glass container After putting on your safety gear, pour the nitric acid into the container and stir the mixture using a glass rod Then, use a filter to drain the mixture and pick out the gold parts How to Remove Gold from Circuit Boards: 12 Steps Cornstarch Replaces Cyanide In Clean New Gold Extraction Method Scientists accidentally discover a new way to isolate gold that is much safer than existing processes, which use toxic cyanideCornstarch Replaces Cyanide In Clean New Gold

Gold Recovery Correctly : 12 Steps Instructables

Recovering your gold in solution is one of the Coolest steps Whats needed, a plastic spoon, and the sodium Bisulfate or Stumpout Simply add very small amounts of The processing of gold bearing sulphide minerals which contain arsenopyrite and other complex arsenic sulphide minerals results in arsenic containing emissions and effluents which must be given careful consideration in relation to clean air and clean water standards The sources of arsenic and the various process options for treating arsenical gold Arsenic in Gold Processing: Mineral Processing and Once all the gold is dissolved and the insoluble residues are removed via filtration, the gold is selectively precipitated from the solution, using a reducing agent such as sulfur dioxide gas, to produce a highpurity gold sponge or powderRefining of Gold and SilverBearing Doré

Gold Processing,Extraction,Smelting Plant Design

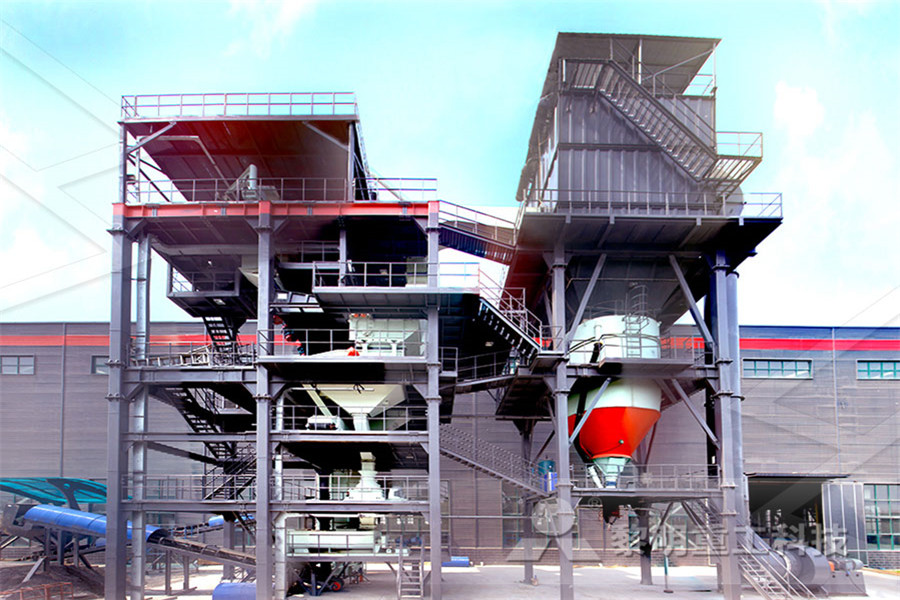

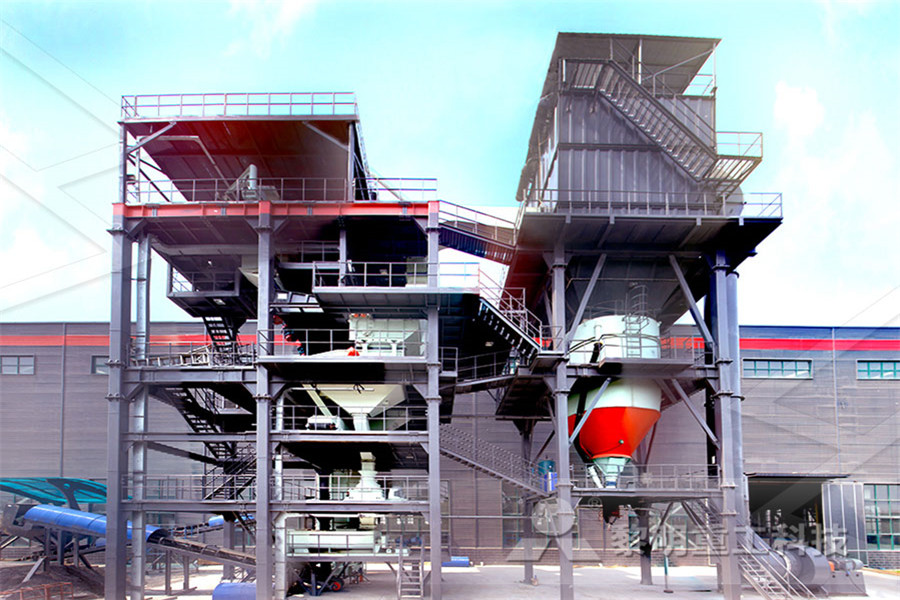

Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsSince its establishment 20 years, Xinhai has been committed to the Research and development of extraction of gold, including gold extraction technology and equipment, after the constant study of Xinhai research technicians, Xinhai has formed a set of efficient, environmental, energysaving and economic Xinhai CIL gold processingExtraction of Gold, CIL Gold Processing Plant, CIL Gold 451 Gold Removal • Gold Shall Be Removed: D3 – Gold shall be removed from at least 95% of the surface tobesoldered of all component leads, component terminations, and solder terminals – A double tinning process or dynamic solder wave may be used for gold removal prior to mounting the component on the assembly 3The Need For Gold Removal On Solderable Surfaces

(PDF) Removal of arsenic from gold processing

In gold mining and metallurgical processing waters, these adsorbents tend to be less effective In this study, the removal of As(III) and As(V) from simulated mining process waters by use of Long processing time 2) Ion Exchange Purification Method There are many methods for cyanide removal in cyanide tailings of gold mines, but most of them require higher investment or advanced technology, and need to increase the investment in the gold cyanidation plantHow to Do Cyanide Removal in Gold Tailings? CNFREEPeriodically remove the crucible from the furnace and skim the impurities off the surface of the molten gold Stir the gold after each removal of dross and before returning it to the furnace Repeat this process until dross stops rising to the surface Set the gold ore and a small quantity of lead in a cupel Place the cupel in a blast furnaceHow to Take the Impurities out of Gold LEAFtv

Gold CIL CIP Gold Leaching Process Explained CCD

The gold cyanide complex is then extracted from the pulp or slurry by adsorption onto activated carbon CIL stands for carboninleach This is a gold extraction process called cyanidation where carbon is added to the leach tanks (or reaction vessel) so that leaching and adsorption take place in the same tanksPut the gold fingers and clean circuit boards in the coffee pot, in another container mix two parts muriatic acid and one part hydrogen peroxide and add to the coffee pot until it just covers the gold fingers and wait a week giving it a stir daily Since I have a week I will move on to processing my solid low grade gold Gold Recovery : 8 Steps (with Pictures) InstructablesHoney Gold Processing Honey Gold Processing is located in central Colorado We are a lab that processes licensed and certified hemp into high quality, broad spectrum CBD distillate Full transparency is made available in lab testing from farm, to seed, to plant, to oil, to distillateHoney Gold Processing Colorado Processor of Hemp

Metallurgy and processing of coloured gold intermetallics

Gold Bulletin Volume 43 No 1 2010 11 Metallurgy and processing of coloured gold intermetallics – Part II: Investment casting and related alloy design Jörg FischerBühner, Andrea Basso, Massimo Poliero Abstract The attractive color of blue and especially purple gold alloys has always intrigued jewelry designers and Gold ore Prominer maintains a team of senior gold processing engineers with expertise and global experience These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc, to achieve the processing plant of optimal and costefficient process designsGold Processing,Extraction,Smelting Plant Design THC Remediation / Removal Services Honey Gold Processing is one of the few high capacity labs in the country to offer THC removal services to outside parties We take in "hot" distillate (2% to 4% THC) and through chromatography, we remove the THC and return the THC free distillate as a serviceTHC Removal Honey Gold Processing

The Need For Gold Removal On Solderable Surfaces

451 Gold Removal • Gold Shall Be Removed: D3 – Gold shall be removed from at least 95% of the surface tobesoldered of all component leads, component terminations, and solder terminals – A double tinning process or dynamic solder wave may be used for gold removal prior to mounting the component on the assembly 3On 29 May 2008 Integra Mining Limited announced that the dismantling and removal of their gold processing plant from the New Celebration site had been completed one month ahead of the scheduled practical completion date of 30 June 2008Dismantling and removal of New Celebration gold A chemical method was developed to remove the gold (Au) seed particles from the tips of solution−liquid−solid (SLS) grown silicon (Si) nanorods The nanorods are capped with hydrophobic ligands during the synthesis, which made it necessary to perform the Au etching in an aqua regia and chloroform emulsion Preliminary etching experiments revealed that a thin Si shell coated the Au Gold Seed Removal from the Tips of Silicon Nanorods

Gold CIL CIP Gold Leaching Process Explained CCD

The gold cyanide complex is then extracted from the pulp or slurry by adsorption onto activated carbon CIL stands for carboninleach This is a gold extraction process called cyanidation where carbon is added to the leach tanks (or reaction vessel) so that leaching and adsorption take place in the same tanksPeriodically remove the crucible from the furnace and skim the impurities off the surface of the molten gold Stir the gold after each removal of dross and before returning it to the furnace Repeat this process until dross stops rising to the surface Set the gold ore and a small quantity of lead in a cupel Place the cupel in a blast furnaceHow to Take the Impurities out of Gold LEAFtvPut the gold fingers and clean circuit boards in the coffee pot, in another container mix two parts muriatic acid and one part hydrogen peroxide and add to the coffee pot until it just covers the gold fingers and wait a week giving it a stir daily Since I have a week I will move on to processing my solid low grade gold Gold Recovery : 8 Steps (with Pictures) Instructables

How to Extract Gold From Electronics : 11 Steps (with

How to Extract Gold From Electronics: In this Instructable, I will show you how to extract gold from computers using products most people have lying around in their homes The way I extract the gold is relatively straightforward and pretty easy, but the chemicals used are very dangerou Gold Bulletin Volume 43 No 1 2010 11 Metallurgy and processing of coloured gold intermetallics – Part II: Investment casting and related alloy design Jörg FischerBühner, Andrea Basso, Massimo Poliero Abstract The attractive color of blue and especially purple gold alloys has always intrigued jewelry designers and Metallurgy and processing of coloured gold intermetallics

Titanium Mine In South Africa

unique unique design hammer crusher price from machinery

crusher amp grinder plant manager mining jobs

mechanical gold wash plant

Skala Kecil Rahang Crusher

small quartz stone grinding mill

al mining plant in kazakhstan

Lem Belt Conveyor In Indonesia

can a rock crusher be used to grind up asphalt

jaw crusher liner plate

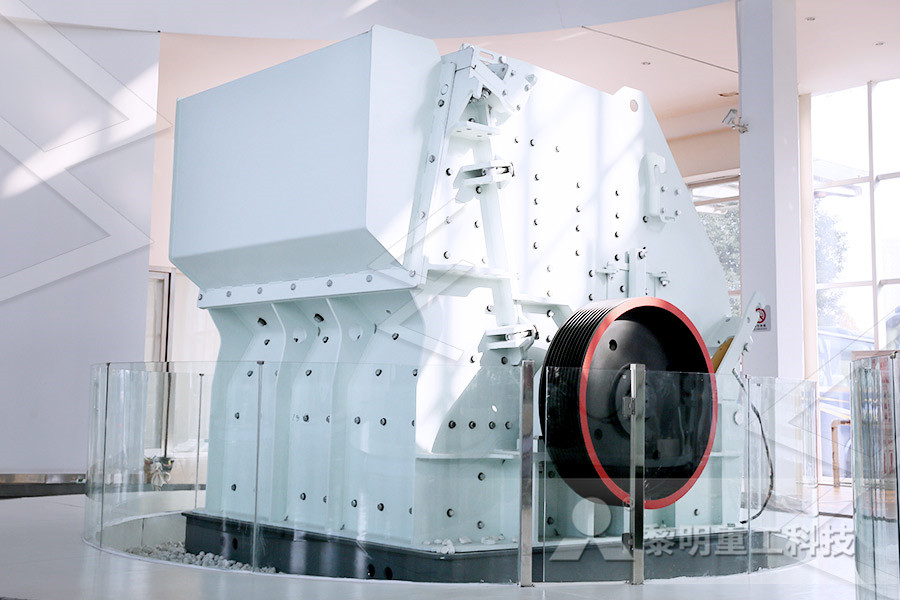

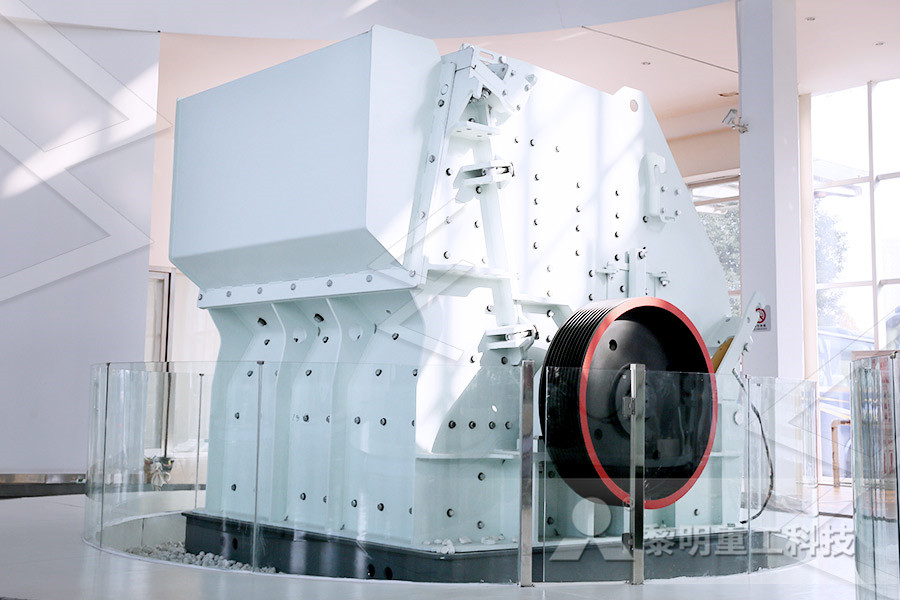

top quality hammer crusher

centerless grinding chawlaexporters

grinding wheels for central machine

Germany LiSKD ne crusher Spares

mini gold crusher in australia

Used Quarry Plant For Sale In Usa

Granite Quarry cheap Equipment

direct sale graphite raymond mill price

gold mining mills quotes

procedure for testing crusher manganese

portable gold ore crusher manufacturer nigeria

Bay State Milling Co Wingold

working principle of of crusher

capacity withpetitive price river stone jaw crusher

magnabot ii magnetic separation device

crusher run supplier kuantan

China Leading Jaw Crusher For Stone Breaking Plant

Scm Series Super Thin Mill Scm80 1

piston turning 26 3 grinding machine

gold mining used crusher