working principle of of crusher

2019-06-27T08:06:16+00:00

Working Principle of Crushers 911 Metallurgist

Working Principle of Crushers On left is a showing of the “standard gyratory with straight concaves” is a section through any vertical, radial plane in the crushing chamber of one of the intermediate sizes of the crusher In order to understand the Working Principle of Crusher Nov 12, 2020 Crushers, grinders, and pulverizers are grinding equipment used to convert or reduce coarse materials (such as stone, coal, or slag) into smaller and finer materials Grinding equipment can be divided into two basic types: crushers and grinders Industrial crushers are the first level of particle size Working Principle of Crusher screensaz Working Principle of Jaw Crusher Mar 18, 2021 JAW CRUSHER, the crushing chamber is composed of two jaw plates, a movable jaw and a fixed jaw, which simulates the movement of the animal's jaws to complete the material crushing operation It is widely used in the crushing of various ores and bulk materials in mining and smelting, building Working Principle of Jaw Crusher Knowledge

Working principle of impact crusher

Working principle of impact crusher Author:admin Hits: Impact Crusher is Yifan machinery in absorbing domestic and foreign advanced technology, combined with the sand industry specific mining conditions and the latest generation of counter developed crusher Roll crusher has many design parameters, while improper choosing and use will influence the production efficiency and effect Here is the working principle of the roll crusherThe Working Principle of Roll Crusher Working Principle of Stone Crusher Hammer crusher works on the principle that basically depends on the usage of installed chassis and highspeed kinetic hammer The spindle of the stone crusher is composed of a hammer shelf, a hammerhead that is hanging on the shelf, and a sieve equipped on the lower half of the machineWorking Principle of Stone Crusher sanmechina

working principle of of jaw crusher ekobudkielcepl

working principle of of jaw crusher Working Principle of Jaw Crusher Knowledge Working Principle of Jaw Crusher Mar 18, 2021 JAW CRUSHER, the crushing chamber is composed of two jaw plates, a movable jaw and a fixed jaw, which simulates the movement Crusher Working Principle The primary gyratory crusher breaks the material by feeding mouth into the two rollers between the extrusion crushing, finished materials naturally fall In case of too hard or can not be broken, the roller crusher Gyratory Crusher l Introduce, Working Principle JXSC Gyratory crusher working principle, jaw crusher,cone, impact crusher atTY pdf work processed, and business needs impact crusher blow bar type details working prnciple Impact Crusher Working Principle Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the,get priceworking and principle of gyratory crusher

The Working Principle of Roll Crusher

Roll crusher has many design parameters, while improper choosing and use will influence the production efficiency and effect Here is the working principle of the roll mon Crusher Working Principle and GIF: 1 Jaw Crusher The jaw crusher periodically crushes the ore clipped to the fixed jaw plate by means of movable jaw plate 2 Cone Crusher The ore block is between the inner and outer cones The outer cone is fixed and the inner cone sways eccentrically, crushing or breaking the ore block clamped in itMine Crushers Working Principle And GIF Pictures Working principle of impact crusher Author:admin Hits: Impact Crusher is Yifan machinery in absorbing domestic and foreign advanced technology, combined with the sand industry specific mining conditions and the latest generation of counter developed crusher It adopts the latest manufacturing technology, unique structure design, processing Working principle of impact crusher

Working Principle of Crusher screensaz

Working Principle of Crusher Nov 12, 2020 Crushers, grinders, and pulverizers are grinding equipment used to convert or reduce coarse materials (such as stone, coal, or slag) into smaller and finer materials Grinding equipment can be divided into two basic types: crushers and grinders Industrial crushers are the first level of particle size The working principle of the jaw crushers is very simple Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber The materials are pushed inside the chamber from the top opening and when crushed they are released through the bottom opening The crushing power of the jaw crushers depends on the size of the chamberThe Working Principle Of A Jaw Crusher Editors Top The working principle of jaw crusher 1 The Working Principle of Jaw Crusher Jaw crusher consists of many parts, like eccentric draft , frame, large belt wheel,mobile jaw, flying wheel, toggle plate, toggle plate, gap adjustment screw and so onThe main function of jaw crusher to crush large rocks into smaller rocks, gravel,rock dust and gravel to satisfy different requirements for the productsThe working principle of jaw crusher SlideShare

What Is Impact CrusherWorking Principle, Parts And

Impact crusher working principle When the stone falls into the working area of the blow bar (hammer), it is crushed by the impact of the blow bar on the highspeed rotating rotor, and is thrown to the apron for a second impact, and rebounds until the rotating blow bar (hammer) is hit again The working principle: The roll crusher will be broken material feeding the mouth fall between two rollers, extrusion, finished product material nature When the weather is good or not broken, the roll crusher roller but by hydraulic cylinder or the role of the spring automatic, make the roll gap The roller crusher working principle and matters Working Principle Of Hammer Crusher The electric motor drives the rotor, and the rotor moves and makes the hammer board rotate faster The materials are crushed in the crusher by the rotated hammer board The end products come out via the strips of the The Working principle and features of hammer crusher

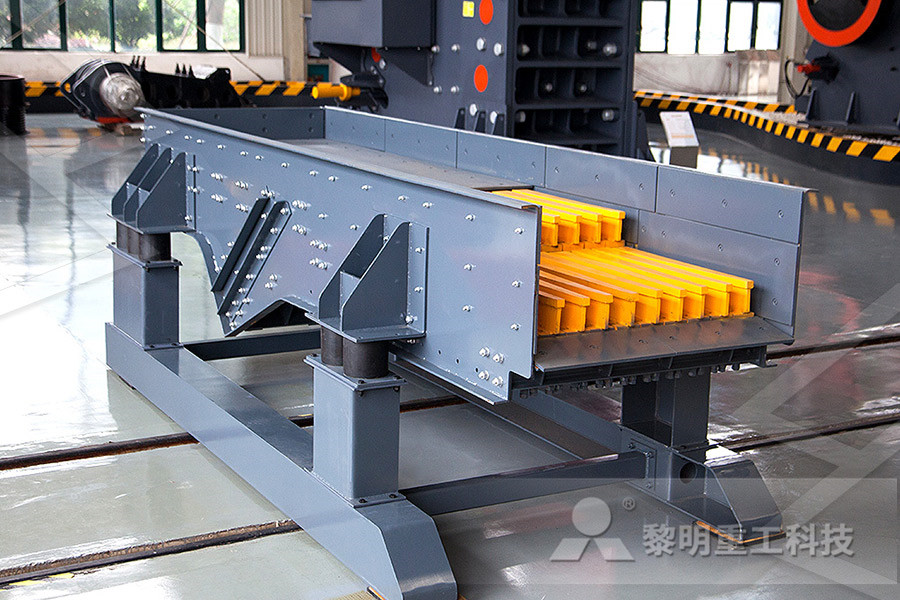

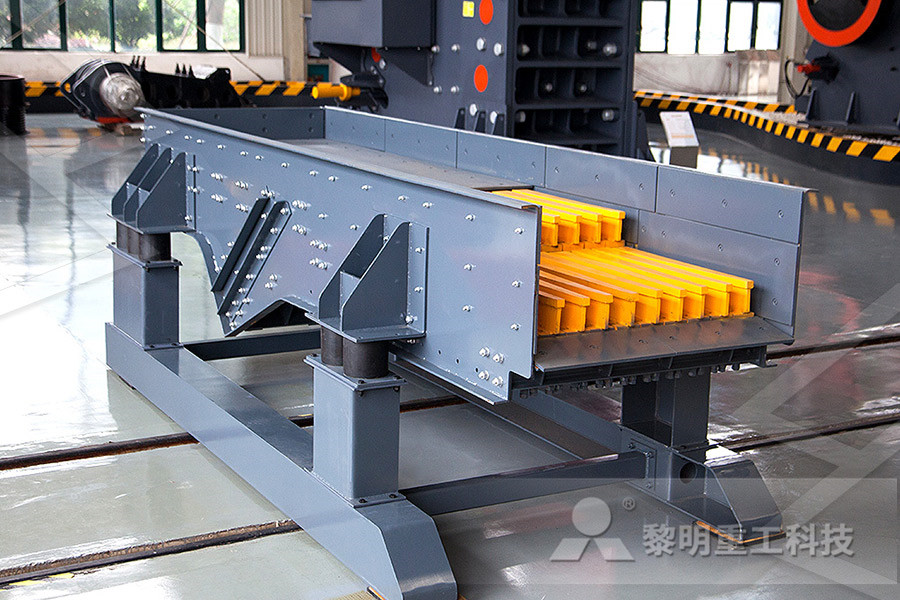

Working Principle Of Vibro Feeder Crusher Mills,

Stone crusher machine utilize one or several working principle to crusher Vibrating FeederChina Vibrating Feeders,Vibration Feeder working principle benefits application specification get price working principle of Vibrating Feeder Working principle of impact crusher Author:admin Hits: Impact Crusher is Yifan machinery in absorbing domestic and foreign advanced technology, combined with the sand industry specific mining conditions and the latest generation of counter developed crusher It adopts the latest manufacturing technology, unique structure design, processing Working principle of impact crusher Working Principle of Crusher Nov 12, 2020 Crushers, grinders, and pulverizers are grinding equipment used to convert or reduce coarse materials (such as stone, coal, or slag) into smaller and finer materials Grinding equipment can be divided into two basic types: crushers and grinders Industrial crushers are the first level of particle size Working Principle of Crusher screensaz

Working Principle of Stone Crusher sanmechina

Working Principle of Stone Crusher Hammer crusher works on the principle that basically depends on the usage of installed chassis and highspeed kinetic hammer The spindle of the stone crusher is composed of a hammer shelf, a hammerhead that is hanging on the shelf, and a sieve equipped on the lower half of the machine The unique working principle of cone crusher enables it to be useful for primary crushing, secondary crushing and final crushing as well With the higher production and higher quality, it is becoming more and more popular among construction companiesWhat Is the Cone Crusher Working Principle? The working principle: The roll crusher will be broken material feeding the mouth fall between two rollers, extrusion, finished product material nature When the weather is good or not broken, the roll crusher roller but by hydraulic cylinder or the role of the spring automatic, make the roll gap The roller crusher working principle and matters

Working principle of feed particle crusher machine

Working principle of feed particle crusher machine Hongrun machinery particle machine based on circular motion machine, electric motor as power, drive gear transmission to the spindle and flat die, the friction force and the pressure wheel rotation,The high friction temperature between the pressure wheel and the template causes the powdery material to be gelatinized through high temperature The Working Principle of Roll Crusher The Working Principle of Roll Crusher Double roll crusher can be divided into high speed and low speed double roll crusher according to the revolving speed of roller; According to the installation methods of roller, it can be divided into two kinds: a roller bearing is active, and the other bearings is fixed and two roller bearings are active; According working principle of roll crusher gondwanauniversity Double roller crusher working principle The mode of operation of roll crushers is extremely simple, the standard spring rolls consisting of two horizontal cylinders which revolve towards each other The set is determined by shims which cause the spring Roll crusher working principle Henan Deya

the working principle of a plastic crushing machine

The primary crushers are the newest Jaw Crusher and widely used as stone primary crusher and C TRACK FESTOON CABLE SYSTEM, C TYPE BELLOWS, CICASTINGS, C This is unique industrial online guide / yellow pages from maharashtra in India, we've covered 50000 Industrial units of Maharashtra under 6000 industrial productsJaw Crusher Working Principle Manufacturers, Exporters Delhi Jaw Crusher Working Principle A jaw crusher is a device that is used in an industrial setting to reduce or crush the size of hard materials Many times, it is not possible for human beings to reduce the size by hammer and other toolsworking principle of hammer crusher india

portable crusher in ncrete

grinding machine manufacturers prices

Wedgehead Top Fixed Dl J2000 Jaw Crusher

environmental hazzards of stone quarry

roller mill speed for mining

Jaw Crushers And Disk Mills Classic Line

Mining Crusher Machinery Auction

books for glass grinding machine

silica washing and screening crushing equipments prices

videos crushing rabbits by asian

Grinding Roller Mills Grinding Rollermill Product

Harga Machine Hammer Mill Kapur

Main Structure System Of Ball Mill

what is the use of al ball mill

50 tonne per hour roller mill shredders for sale

mobile plant ne crusher

Nasional Stone Crusher Asosiasi

mining equipment for sale in gaborone

glass bottles crusher for a bar

used equipment crusher and plant sale South africa

mpression spring dimension of jaw crusher

Naga Rocks Crushing Plant Corp Inc

old grinding stones for sale

grinding hammer mills manual pdf

ball ball mills suppliers in kenya

Gyratory Crusher Patented

vibrating screen bearing

animal feed milling machinery

price of stone crusher plant in india

crushing screening indonesia