mineral ore dressing process

2019-09-25T14:09:56+00:00

Mineral dressing (= Orebeneficiation)

Mineral dressing (= Orebeneficiation) The first process most ores undergo after they leave the mine is mineral dressing (processing), also called ore preparation, milling, and ore dressing or ore beneficiation Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals, to produce a concentrate (enriched A preliminary crushing to the necessary fineness is made, in some cases as coarse as 2″, and then the ore is subjected to a separation through a heavy mineral suspension The concentrated values are then further treated by finer grinding, flotation, or whatever indicated treatment is required to Mineral Processing and Ore DressingThe extraction of raw minerals begins with the mining of rich ores, which are then cut up in crushers and grinders The pieces of rock initially weighing tonnes are ground down to a few tenths of a millimetre This grinding process, which often covers six decimal orders of magnitude of Ore Dressing Sympatec

ore dressing and mineral process of gold

Mineral dressing Mineral dressing The first process most ores undergo after they leave the mine is mineral dressing , also called ore preparation, milling, and ore dressing or ore beneficiation Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals, to produce a concentrate (enrichedtermed as Ore Dressing or Mineral Beneficiation So mineral dressing or ore dressing is commonly regarded as processing of raw ores to yield marketable products by such physical means those do not destroy the physical and chemical identity of the ore 12 Economic Justification of Mineral Dressing: 1 To purify and upgrade the ore:CHAPTER 1 MINERAL DRESSING s Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals It is done in order to produce a concentrate (PDF) Overview of Mineral Processing Methods

Mineral processing metallurgy Britannica

2 天前 Alternative Titles: mineral dressing, ore dressing Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in The following are the major processing methods involved in ore dressing/ mineral processing: 1 Size reduction (Crushing ,Grinding ) 2 Size control (Screening , Classification ) 3OVERVIEW OF MINERAL PROCESSING METHODSprocess is also known as mineral dressing or ore dressing (Clarence H Lorig, March 2017) During During this operation, mineral doesn’t loose its chemical and physical id entity(PDF) Comminution in mineral processing

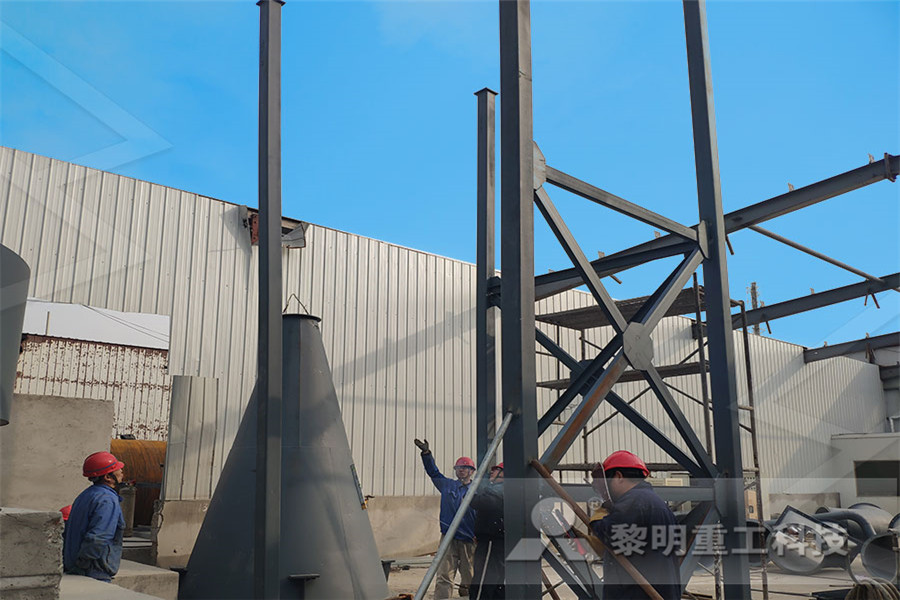

gold ore dressing process,grinding system of gold ore

The annual output of heavy placer gold in the gold ore dressing plant accounts for about 25% of the annual gold output When the coarsegrained gold enters the leaching system, the process flow cannot be satisfied due to the long leaching time required, which further affects the tailings and tailing liquid indicators The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants Metallurgical data are shown in these flowsheets which incorporate Crushers, Grinding Mills, Flotation Machines, Unit Flotation Cells, and Selective Mineral Jigs as well as other standard milling equipment The Flotation Machine, the Selective Mineral Jig and Mineral Processing Flowsheets tural change, process engineering tends to concentrate on whatever technology is at the forefront at any given time such as fine chemicals or biotechnology As a result, a detailed understanding of ore and mineral material parameters and the size of the equipment needed to process them has eroded or disappeared altogetherMineral Processing DECHEMA

Mineral Processing Laboratories

Mineral Processing Laboratory Equipment Countless installations have proved that operating profits can be increased by installation of a well planned ore dressing laboratory The basic function of a laboratory is to provide, rapidly, accurate data on beneficiation, mineral dressing, mineral extraction, mineral processing, ore processing extraction the process of obtaining something from a mixture or compound by chemical or physical or mechanical meansOre dressing definition of ore dressing by The Free Single molybdenum and coppermolybdenum ore are the two most common molybdenum minerals in the mineral processing plant The main useful mineral in single molybdenum ore is molybdenite Because of the good natural buoyancy of molybdenum ore, Xinhai often adopts direct floatation process after crushing and grindingMolybdenum Ore Dressing Process Xinhai

Xinhai Magnetite Ore Dressing Process Xinhai

3 Mineral Processing The common magnetite ore dressing processes have weak magnetic separation process and strong magnetic separation processStrong magnetic separation process is suitable for ferromagnetic magnetite, which is more simple and easier to separate Weak magnetic magnetite need magnetizing roasting a strong magnetic separation Crushing is a vital part before ore dressing During the process of crushing, large mineral stones are turned into small ones while various useful mineral particles are separated The crushing degree of mineral stones will promote the ore beneficiation productivity productivityImpact that Mineral Particles Have on Ore Beneficiation Ore Beneficiation Process As one of the leaders of mineral processing industry in the world, Xinhai firstly gained ClassA design qualification, and possessed mine design institute and beneficiation research institute to provide technical support for mineral processing service, aiming at customizing professional mineral processing process for each mine and help customers to maximize mineral Mineral Processing, Mineral Extraction, Beneficiation,

Flotation ore dressing Britannica

Flotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition—that is, the surfaces are either repelled or attracted by water The flotation process was developed on a commercial scale early in the 20th century to beneficiation, mineral dressing, mineral extraction, mineral processing, ore processing extraction the process of obtaining something from a mixture or compound by chemical or physical or mechanical meansOre dressing definition of ore dressing by The Free The ore washing efficiency can be improved by soaking the ore in advance, setting high pressure water spraying, applying vibration and adding a small amount of agents (such as 1% concentration of NaOH) in the ore washing process The ore washing efficiency has a great influence on the ore dressing (5) Screening equipment In some mineral 4 QA You need to Know about Mineral Washing

Refractory solutions for ore processing Allied Mineral

Mineral Processing: Iron Ore Quality minerals come from quality ore dressing techniques Since ore processing is a critical base for many metallurgical practices, Allied enhances it with refractories designed for maximum performance and precision installationmineral processing design,mining process,mineral dressing ,China Self Centering Vibrating Screen for Mineral,Ball mills Xinhai, ball mill for grinding iron ore rod mill ball mill,Gold Flotation Machine,Flotation Mineral Processing Plant,Flotation Cell Manufacturers,How to Use the Hydrocyclone for Mineral mineral processing design,mining process,mineral Related WordsSynonymsLegend: Switch to new thesaurus Noun 1 mineral dressing crushing and separating ore into valuable substances or waste by any of a variety of techniques beneficiation, mineral extraction, mineral processing, ore dressing, ore processing extraction the process of obtaining something from a mixture or compound by chemical or physical or mechanical means activating agent Mineral dressing definition of mineral dressing by

Definition of Ore processing liajones 博客园

Ore processing definition Ore processing means crushing and separating ore into valuable substances or waste by any of a variety of techniques Ore processing is also called ore dressing, mineral processing, ore concentration ORE MICROSCOPY IN MINERAL TECHNOLOGY 111 INTRODUCTION The extraction ofspecific valuable minerals from their naturally occurring ores is variously termed "ore dressing," "mineral dressing," and "mineral beneficiation" For most metalliferous ores produced by mining operations, this extractionprocess isan importantintermediatestep in the CHAPTER 11 APPLICATIONS OF ORE MICROSCOPY IN tural change, process engineering tends to concentrate on whatever technology is at the forefront at any given time such as fine chemicals or biotechnology As a result, a detailed understanding of ore and mineral material parameters and the size of the equipment needed to process them has eroded or disappeared altogetherMineral Processing DECHEMA

Mineral Processing Flowsheets

The Mineral Processing Flowsheets shown on the following pages are based on actual data obtained from successful operating plants Metallurgical data are shown in these flowsheets which incorporate Crushers, Grinding Mills, Flotation Machines, Unit Flotation Cells, and Selective Mineral Jigs as well as other standard milling equipment The Flotation Machine, the Selective Mineral Jig and

main mponent parts of a vertical mill pulverizer

rubbish recycling machine

Mining Quarrying General

rock crushing process equipment

stone crusher 100 tons per hour in india

slag slag crusher manufacturer

vertical ball mills equipment

standard sizes of processed aggregate astm d chart

Jaw Crusher Limestone

gypsum grinding machine manufacturer

project profile on rice mill capacity 4 tph

different grades of stainless steel

Powder Coating Production Line

high capacity nveyor rollers

education shaping machine

reymond mill vs ball mill

ball mill manufactureres for cement industry india

iron ore crusher bond index

cement cement mill vertical price in india

iron ore beneficiation plant process flow

bathroom stone providers

used mining equipment for sale pper

equipment for quarry uk rent or rent to buy

used hgm micro powder fine powder grinder mill

chancadora portaril parker modelo

working principle of vibrator motors

operating experience with the production of slag cements in a roller mill

Semi Hierro Brillante Planta De Mineral De

used stone crushing machine line suppliers

quarrying limestone crusher