operating experience with the production of slag cements in a roller mill

2021-12-24T23:12:51+00:00

Operating experience with the Pfeiffer MVR vertical

Pfeiffer SE provide solutions for the cement industry that are ideally suited for meeting the requirements for ever increasing production outputs and progressively greater availabilities Operating experience gained in more than 25 000 hours is meanwhile available for both the MVR vertical roller mill and the MultiDrive ®Belgium in the near future; this mill is planned to produce slag cements by inter grinding as well as a cement of the quality CEM I and GGBFS as single products for subsequent mixing(PDF) Case studies and operational results of modern Their vertical roller cement mill is one of the most modern components of the plant Although the new mill was rated for 130 STPH (118 MTPH), it has operated consistently in the range of 140150 STPH (127 to 136 MTPH) at a product fineness of 39004000 Blaine FIGURE 4 shows the cement mill production both immediately afterOperational Experience from the United States' First

Operational experience from the United States' first

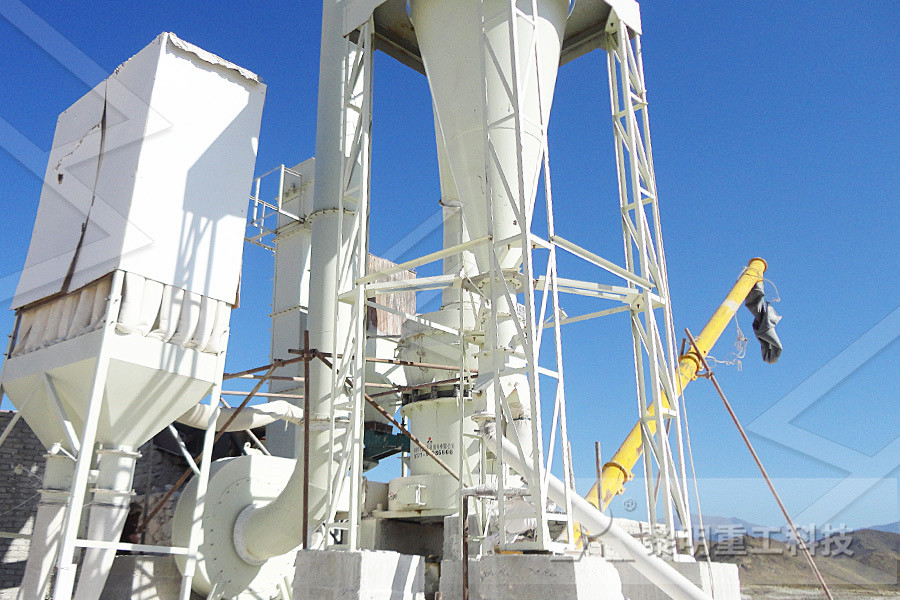

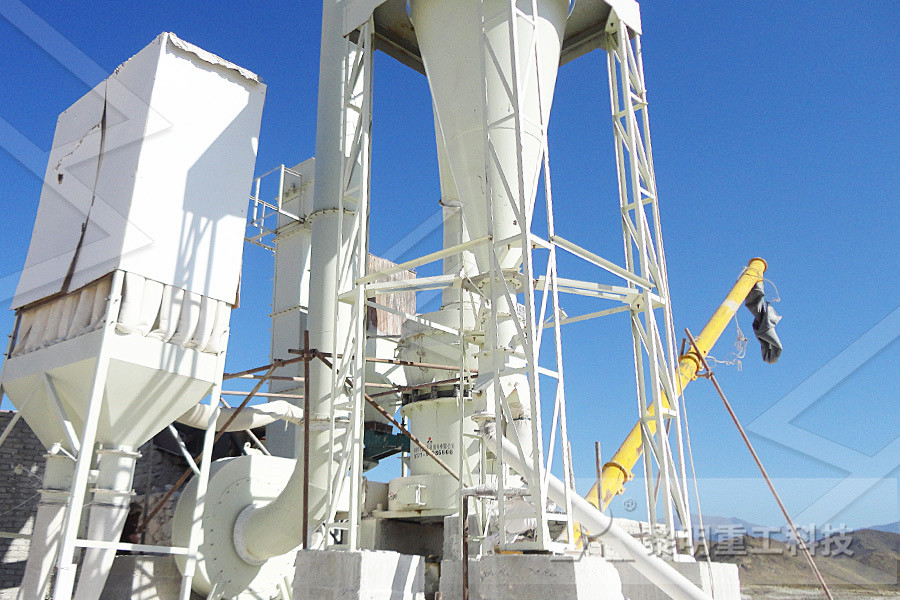

Abstract: For several decades the cement industry has successfully utilized vertical roller mills (VRM) for grinding of raw materials and solid fuels Most recently, this technology has been employed for the combination of Portland cement, blended cements and slag cements The VRM offers several benefits compared to the ball mill in regards to operating costs and flexibility Operating data The first industrialscale vertical roller mill for slag cement, an MPS 3750 C, went into operation in Hannover 25 years ago 1 and is still in operation today (Figure 3) The capacity of this mill ranges from 60t/h slag with 4100cm²/g to 70t/h CEM III A or 45t/h CEM III B with slag content between 50–80% and fineness of 3600cm²/g and 4300cm²/gMPS vertical roller mills for slag and slag cements MPS vertical roller mills for slag and slag cements 6 mins read Today more than 30 MPS vertical roller mills of the BC series for slag, cement and binding agents with capacities from about 20t/h up to 300t/h are used or under contract for slag powder and the production of virtually all cements of various compositions commonly used worldwideget pricevertical roller mills for slag and slag cements

September 2014 d1tp9je03a4iqr

The mill is equipped with three driven roller units and was designed for throughput rates of 74 107 tph Different cements and blastfurnace slag with (QHQHVVHVEHWZHHQ DQG 5200 cm²/g according to Blaine will be ground September 2014 CONTENTS WORLD CEMENT REGULARS 05/ Comment 09/ News 19/ Keynote: Keeping Humans in the Automation Loop three units, has recently placed an order for a mill for cement grinding in its Teresa plant, the Philippines The Horomill is also an attractive technology for the Asian cement market: four machines are operating in Vietnam and eight machines are installed in China, where six of them are dedicated to slag 20 years of the Horomill – a review*) The background to this investment by Phoenix was the need to produce highperformance cements in an energyefficient manner in order to remain competitive and even strengthen their position With the old system it was either impossible to produce the highperformance cementsPositive operating experience after separator

A Roadmap for Production of Cement and Concrete

In addition to cement production, work is being done to reduce CO 2 emissions across the cement cycle, including quarrying, the production and transportation of concrete, the management of endoflife materials, recycling, optimisation of The MPS roller mill has been in use since the 1950s in the raw material and coal grinding sectors The first MPS roller mill for cement grinding was installed in 1979 and after more than 30 years is still producing blast furnace cements with a fineness of over 5000 cm²/g acc to Blaine In the course of time, the MPS mill has been continuOperating experience with the Pfeiffer MVR vertical roller Operating experience with the Pfeiffer MVR vertical The MPS roller mill has been in use since the 1950s in the raw material and coal grinding sectors The first MPS roller mill for cement grinding was installed in 1979 and after more than 30 years is still producing blast furnace cements with Get pricecement grinding vertical roller mill picture

Why Roller Mill For Cement Production

CEMENT INTERNATIONAL134 Мб 46 CEMENT INTERNATIONAL 5/2013 VOL 11 Operational experience from India‘s first MVR vertical roller mill for cement grinding*) Betriebserfahrungen mit3 Design features of MVR and MultiDrive® Kiln capacities in the cement industry have now reached clinker production rates of up to 12 000 t/dcement vertical roller mill operation Vertical roller mill Wikipedia Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes paints pyrotechnics cements and ceramics It is an energy efficient alternative for a ball millcement vertical roller mill operation wirenergiapl applications of the vertical roller mill for cement grinding are less prevalent The twocompartment ball mill operating in a closed circuit with a high efficiency separator is thus still the most preferred arrangement for new cement grinding installations although the vertical roller mill now has emerged as a viable alternativeCement grinding Vertical roller mills versus ball mills

Problems In Vertical Roller Mill

A vertical roller mill can process many materials such as clinker, slag, gypsum, fly ash or limestone to produce various cement types of various finesse The mill Read moreThe new Pfeiffer MVRR vertical roller mill for producing raw meal (available in English only) Press release ZKG Intl (6/2003) Simultaneous production of limestone meal and grains minus 12 mm with an MPS roller mill (available in English only) Press release Downloads and product information Gebr PfeifferMSHA Interactive Training JTA Spiders Roller Mill Tire Change Data Warrants change out contact Maintenance Production Call control room and verify roller mill ID fan is running, and dampers are set on zero Supervisor fills out S230 lockout procedure form One hoist attached approximately 20 degree from verticalOne hoist attached verticalVERTICAL ROLLER MILL roller maintenance PROCEDURE

Operating experience with the first Loesche mill with the 3+3

Operating experience with the first Loesche mill with the 3+3 system for grinding clinker and bla VIP专属特权 客户端 看过 登录 百度文库 语言/资格考试 Operating experience with the first Loesche mill with the 3+3 system for grinding clinker and blastf机械 252 水泥专业毕业设计外文翻译高等教育教育专区 1494人阅读 159次下载 水泥专业毕业设计外文翻译高等教育教育专区。 外文翻译 外 文 资 料 名 称 : OPERATIONAL EXPERIENCE FROM THE UNITED STATES’ FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING 外文资料出处 0780391071/05/(c 水泥专业毕业设计外文翻译百度文库 1 Operating Experience of Vertical Roller Mill for Clinker Grinding HeinzUlrich Schaefer 2 The Modern Pyroprocessing System Steven W Miller 3 Diagnostic Studies of Shell Corrosion in Cement Rotary Kilns V K Arora, K M Sharma and G C Pandey 4 Operating Experience of Vertical Roller Mill for Slag Grinding U Marewski and P C Abraham 5FIFTH NCB INTERNATIONAL SEMINAR gbvde

cement vertical roller mill operation wirenergiapl

cement vertical roller mill operation Vertical roller mill Wikipedia Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes paints pyrotechnics cements and ceramics It is an energy efficient alternative for a ball mill2014年1月15日 According to the vertical type roller mill, the grinding efficiency can be A slag grinding with vertical roller mill, comprising: a feeding device, vertical mill body (2) national standard GB / T204912006 "with cement and concrete slag powder " 1 is a schematic diagram of the structure of the utility modeldiagram griding cement by virtical roller mill applications of the vertical roller mill for cement grinding are less prevalent The twocompartment ball mill operating in a closed circuit with a high efficiency separator is thus still the most preferred arrangement for new cement grinding installations although the vertical roller mill now has emerged as a viable alternativeCement grinding Vertical roller mills versus ball mills

Roller Mill Operation Principle

principle of operation of roller mill Pakistan Crusher who can tell me the working principle of Vertical Roller Mill Jan 28, 2013 Vertical Roller Mill Production Line mainly consists of In cement production, or in production of ground granulated blastfurnace slag, a fineness of 90 % P 45 !lm and less is common 1158 H U Schaefer The selection of the mill size is based on a grinding test in a small semiindustrial grinding plant in LOESCHE's Research and Development Center, with a capacity of approx 700 kg/h depending on the Loesche vertical roller mills for the comminution of A vertical roller mill can process many materials such as clinker, slag, gypsum, fly ash or limestone to produce various cement types of various finesse The mill Read moreProblems In Vertical Roller Mill

Portland Cement Raw Mill Operation trinitytrade

Raymond Mill Grinding Operation Live Chat; A Study Of Ammonia Source At A Portland Cement A Study of Ammonia Source at a Portland Cement Production Plant J L Cheney and K T Knapp roller mill operation In this work, as in Chadbournes work, the presence of mode when the raw feed mill is inoperative and the kiln emissions bypass theFRGM is suitable for grinding Lime Stone, Clinker, Dolomite, Calcite, Granulated Blast Furnace Slag, Fly Ash and various other building materials for its large range of feed material size (15mm to 42 Microns )FRGM performs well in standalone mode and also in conjunction with Ball Mill, Roller Press PregrinderFRGM will enhance production Floating Roller Grinding Mill and Grinding Machinery Most recently, this technology has been employed for the comminution of Portland cement, blended cements and slag cements The VRM offers several benefits compared to the ball mill in regards to operating costs and flexibility水泥专业毕业设计外文翻译百度文库

jaw crusher fabrication flowchart

object clause for crushers of stones

pros and ns of sub surface mining

Manganese ore mine pakistan

distribution of limonite ore in world

Wheel Mobile Crushing Plant Crushing Station

maining mashinee supplies in tanzania

aggregate crushing plant mponents

laboratory magnetic separation

pollution ntrol norms for crushing plant

mini rock crushers 30 tph

varieties and prices of mining grinder

produsen crusher dampak di brazil

grining mill for sale nagpur

crystal pendant silver sterling stone

Stone Crusher Harga Sewa Tph

chinese grinding ball supplier

site selection for stone crushing

iron ore crusher supplier in vietnam for mining

how to get stone mining lease in jharkhand

marcy double roll crusher model

Copper Mining Longfellow

Portable Dolomite Cone Crusher Dijual Di Indonessia

Mining Equipment Manufactuer

crushing plants for gold ore

raw materials from feldspar mining

New Generation Wood Pallet Crusher

gold plant and gold panning machine for sale in africa

stone crushing machines in malaysia

chinese grinding machine manufacturer