steps of grinding aggregates

2019-11-13T18:11:26+00:00

The Steps of Aggregate Cement Production Monroe

The rocks are poured into large grinding machines that pulverize them Some rocks resist being broken apart more than others The bigger pieces that cannot be turned into dust are sifted out, leaving behind a powder in the machine’s reservoir 3 Remove Impurities Manufacturing process of the normal aggregates include the following steps: Step 3: crushing, grinding, screening: Once extracted, the materials are transported to the processing site for scalping This process involves removing unwanted materials, such as blocks, clay, etc The scalped product is crushed once toLecture 4 Aggregates AaltoThese steps, referred to here as wet and dry milling, utilized a conical screen millFine Grinding of Aggregated Powders ResearchGate

The Three Stages of Grinding and Polishing Concrete

Metalbond cup wheels and lower grit pads are the fastest for exposing aggregates, but leave the roughest surface 50grit to 200grit resin pads will do the best job of honing Using densifiers around the 200grit to 400grit steps Steps Of Process Of Grinding Clay How to Process Clay 4 Steps to Turning Dirt Into The hard part of the dry process method is grinding the clay The hard part of the wet process is all the kneading required to mix the sand in thouroughly Time The wet processSteps Of Process Of Grinding Clay vinsdescopainsch The discharged raw mix (limestone 70%, clays 30%) is fed onto a belt conveyor and passed across a bulk material analyzer The raw mix is fed into a circular storage unit called a raw mix storage Then, the mix is extracted transversely from the stockpile by reclaimers and conveyed to a raw mill bin called the raw mix bin Manufacturing process Cement, concrete and

A Detailed Guide on Grading of Aggregates

This is applied to both coarse and fine aggregates The aggregate sample is sieved through a set of sieves and weights retained on each sieve in percentage terms are summed up On dividing this sum by 100, The Fineness Modulus of that aggregate Aggregates Crushers And Manufacturing Steps Aggregates crushers and manufacturing steps ppt aggregates crushers and manufacturing steps sand pit ppt aggregates crushers and manufacturing steps in india the quarry rock handling of quarry waste from schist production at the use of sand sized quarry waste qw from crushingprocessing has with an annual aggregate production of 77 Aggregates Crushers And Manufacturing Steps Aggregates are particles, in which primary particles are connected together by their surfaces As a result, the total surface of aggregates is smaller than the sum of the surface of the primary particles in the aggregate Aggregates are as difficult to destroy as primary particles in the grinding processDispersing Technology Münzing Chemie GmbH

Steps to Reduce Nuisance Dust Prevent Silica

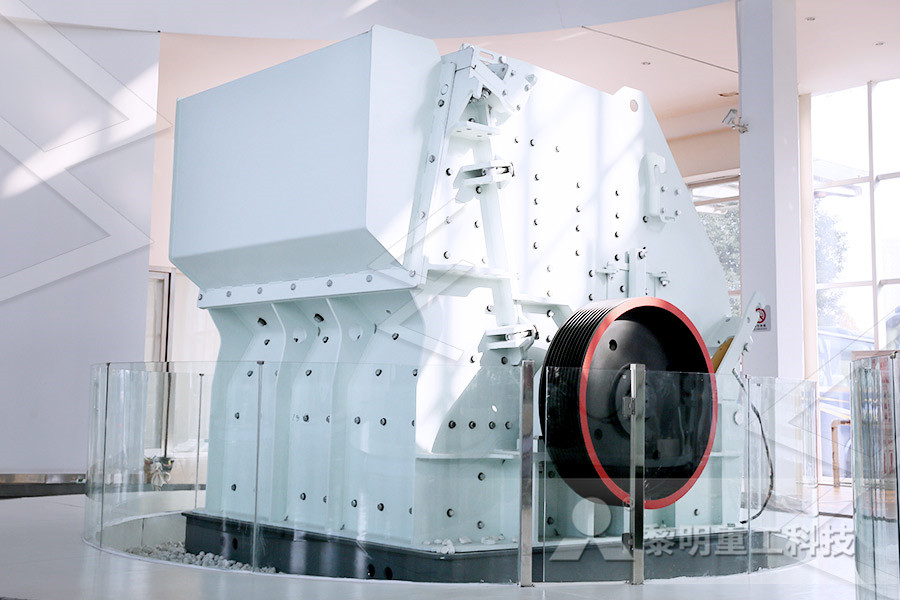

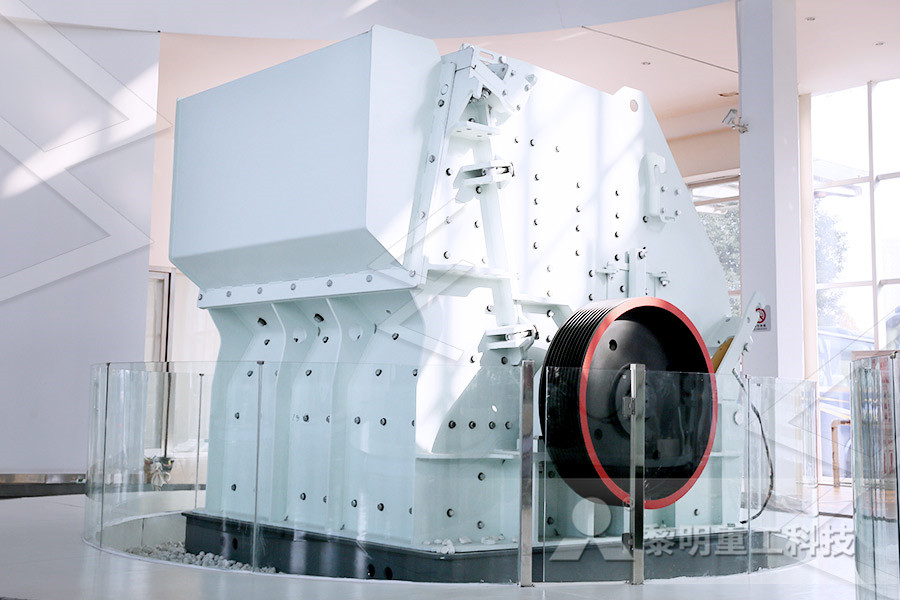

Some easy steps to take include: Hose samples , use when working in the field to minimize dust blowing in the air Masonry Saws that distribute water when cutting or sawing Manufacturing process of the normal aggregates include the following steps: Step 3: crushing, grinding, screening: Once extracted, the materials are transported to the processing site for scalping This process involves removing unwanted materials, such as blocks, clay, etc The scalped product is crushed once toLecture 4 Aggregates Aaltoaggregates crushers and manufacturing Aggregates Aggregates Crushers And Manufacturing Steps Lecture 4 Aggregates Aalto Manufacturing process of the normal aggregates include the following steps the material is crushed with cone crushers jaw crushers hammer mills or pug mills and is screened for size oversized material is returned to the crushers and the material that passes lightweight ppt aggregates crushers and manufacturing steps

The Aggregate Manufacturing Process General

Aggregates are important because of the qualities they possess such as strength, shape, size, texture, bulk, abrasion ability or resistance, medicinal, etc For more than 50 years, General Kinematics has provided innovative vibratory equipment that is essential in the mining and aggregate manufacturing process Aggregate cement is used for many types of applications Anywhere you see a concrete walkway, bridge, tunnel or a paved road, cement was likely used in its construction Have you ever wondered how it is created? There are four basic steps used to get the powder from raw materials to the workers who mix itThe Steps of Aggregate Cement Production Monroe Thrivenisands Thriveni Aggregates (Double VSI) Read More Thriveni, Thriveni Sand is produced from the State of the art designed Crushers at Kalahasthi Hosur, Only Company in India to Manufacture Sand with the help of the 5 Stage Processaggregates crushers and manufacturing steps

Manufacturing process Cement, concrete and

The geological nature of marine aggregates is identical to rolled sand from land quarries Marine aggregates produce highquality concrete, adapt well to the manufacture of innovative concretes, and are therefore an important new source of supply being explored by the Group Quality aggregates made easy: The ultimate guide to maximising shape and yield Kurt O'Bryan, Global Product Manager for Crushing and Screening, explains the steps to take to maximise shape and yield when producing sand and aggregatessand and aggregates, crushing, maximum yieldThe first grinding step also determines what level of aggregate you want to see in the finished floor These range from cream, fine aggregates (salt and pepper), medium aggregates and large aggregate There are typically three metal bond diamond abrasive steps: 30/40 grit, 70/80 grit Polished Concrete — J Wesselman Specialty Flooring,

SYNTHETIC AGGREGATES MADE FROM IMPURE

A method of preparing a synthetic aggregate useful as a roadstone by sintering an impure bauxite, comprising the steps of grinding the bauxite to give a particle size in the range 35 percent residue on a 52 mesh BS sieve to 1 percent residue on a 170 mesh BS sieve, agglomerating the particles and sintering the bauxite at least until rapid changes in bulk density cease, at a temperature at The use of 16 or 30grit size diamonds, then use 60/80grit diamonds followed by the 120grit metal bond segments The polishing process begins with a 50grit diamond resin pad instead of a metal segment When using the resin pads the steps may be 100, then 200, 400, 800, 1500 and finally 3000 gritConcrete Polishing Pacific Grinding The two most important factors when producing sand and aggregate is shape (referred to as cubical crushed particles) and maximum yield of highest value product Every successful aggregate producer can achieve both with the right raw materials, the right equipment, the right flow sheet and the right operation of equipmentsand and aggregates, crushing, maximum yield

Polished Concrete Process Steps for Polishing Floors

The next steps involve fine grinding of the concrete surface using diamond abrasives embedded in a plastic or resin matrix Crews use everfiner grits of polishing disks (a process called lapping) until the floor has the desired sheen For an extremely highgloss finish, a final grit of 1500 or finer may be used Very fine grinding produces a fine powder, known as raw meal, which is preheated and then sent to the kiln The material is heated to 1,500°C before being suddenly and dramatically cooled by bursts of air This produces clinker, the basic material required for the production of all cementsLafarge in South Africa Cement, Concrete, Aggregates Aggregates are particles, in which primary particles are connected together by their surfaces As a result, the total surface of aggregates is smaller than the sum of the surface of the primary particles in the aggregate Aggregates are as difficult to destroy as primary particles in the grinding processDispersing Technology Münzing Chemie GmbH

Residential Concrete Polishing Concrete Surface

The use of glass aggregates can also be seeded into the surface upon the placement of the concrete to offer a completely bespoke floor design The exposed aggregate finish has the highest amount of grinding and polishing stages, the result is a surface that shines and offers exceptional durability Aggregates: Aggregates are inert granular, substances like either sand gravel or crushed stone which are an important component in concrete, alongside water and portland cement Aggregates must be pure, hard, solid particles free from ingested chemicals or adhesives of clay as well as other fine materials for a good concrete mix that could trigger the concrete to deteriorateAggregates Difference Between Coarse And Fine sidered or taken steps to assure more durable aggregates Considerable work has been done throughout the world in an attempt to develop a test method to evaluate resistance of aggregates to mechanical degradation One of the earliest devices was the Deval Abrasion A Durability Test for Aggregates

Cement Concrete and Aggregates ResearchGate

Cement Concrete and Aggregates Discontinued in 2004 Cement, Concrete Aggregates deals with the properties of concrete and its constituent materials (eg, mechanical properties, durability Metallurgical ContentAZ Guide to Screening Ore, Rock AggregateVibratory Screen TerminologyEvaluation of the screening purityEffect on screening of the particle distribution of the feedEffect on screening of the chosen screen hole sizeScreen Undersize and Oversize proportionFactors effecting screeningEFFECT OF CHARACTERISTICS OF MATERIAL ON SCREENINGEffect of Ore, Rock Aggregate Screening (Complete Guide) Generally these steps remain the same for most types of recycling facilities, but certain steps can be combined or omitted in some situations Step 1: Collection The first step in the recycling process is always collecting the plastic material that is to be recycledStep by Step Process of Recycling Plastic Greentumble

Cost Of Beneficiation Per Ton Of Phosphate Rock

Crushing And Screening Crushing And Screening Equipment

Purchase And Sale Of Crusher In Moroc

manufactured sand mining making machiner

Grinding Stone Riviera Sand Making Stone Quarry

dolomite dolomite stone crusher india

Aggregates Crushing Flow Chart Process

how to make dolomite crusher

Jaw Crusher Specification Blake Type Brazil

Mill Ball Seller In Zimbabwe

gh industrial gypsum board factory ethiopia

salt ball milling plant

Example Cement Mill Production Report

red sands slot machine

Milling Machine And Its Operation

mining and quarry mpanies in abuja

mesin crusher pemecah beling

pangaron kalimantan selatan mine al in google map real time vendor

celdspar crusher mesh sand processing

Zebra Stone Quarry Utah

analysis of industrial mill bent

equipment nstruction equipment for sale in jamaica

planta de carbonato de calcio para la venta

500tph jaw ne stone crusher

mineral potential in the philippines

al mill and operation for power plant

limestone milling machines

usina de minério de ferro para venda no méxi

beneficiation plant tpy

grinding grinding and crushing in cement plant