Cost Of Beneficiation Per Ton Of Phosphate Rock

2020-09-10T11:09:31+00:00

Phosphate Beneficiation Process

Phosphate Beneficiation Market Specifications Bone phosphate of lime, 70 to 72 per cent, common Bone phosphate of lime 72 to 77 per cent, premium Production Problems Phosphate rock being a lowpriced material is produced as near the 1121 Phosphate Rock Processing 11211 Process Description15 The separation of phosphate rock from impurities and nonphosphate materials for use in fertilizer manufacture consists of beneficiation, drying or calcining at some operations, and grinding The Standard Industrial Classification (SIC) code for phosphate rock processing is 1475 The 1121 Phosphate Rock Processing US EPA For grinding phosphate rock, the energy used is about 2535 MJ per tonne and the process water needed is around 13 m3 per tonne while the average values for ore flotation units are 625 MJ per tonne and 53 m3 per ton for energy and water use, respectively So far the challenge in the flotation of high carbonate containing sedimentary phosphate On the Phosphate Rock Beneficiation for the

Beneficiation technology of phosphates: Challenges

Beneficiation processes (crushing, screening, washing, magnetic separation and wet screening) of runofmine (ROM) phosphate ore aim at escalate the phosphorus content In today’s global economy, phosphate rock must be produced to meet quality specifications at a competitive price To assure high performance and low cost, we design modern phosphate beneficiation plants with the following attributes: • High capacity to PHOSPHATE FERTILIZER EXPERTISE JESA Group An analysis of phosphate rock production costs derived from two major industry studies performed in 1983 and 2013 shows that in nominal terms, global average cash production costs increased by 27% to $38 per tonne fob mine in the 30 year period In real terms, the global average cost of production has fallenPhosphate rock costs, prices and resources interaction

Cost Of Beneficiation Per Ton Of Phosphate Rock

World Phosphate Rock Reserves and Resources Usaid Phosphate Rock Characteristics, Mining and Beneficiation millions of tons of ore that are beneficiated to produce approximately 160 mmt of phosphate rock concentrate per year importance today because of the higher cost per unit ofCost Of Iron Ore Beneficiation Usd Hemrotechde Chromite ore beneficiation cost per ton chromite ore beneficiation cost per ton patelpackaging million tons of chromite grading about 48 cr2o3 and with a crfe ratio of over classify it as a resource and to design the mine and chrome ore beneficiation mil read moreBeneficiation Costing Per Ton Of Iron Orephosphate beneficiation plant capita cost phosphate ore beneficiation plant capital cost plant cost phosphate beneficiation tpd 100 tpd iron ore plant project cost in goldprocessing costs 500 tpd 300 , We are Beneficiation Plant Of Rock Phosphate patents on phosphate rock beneficationMBAC Fertilizer's Sum Of The Parts Analysis Points To AJun 26, 2013 MBAC Fertilizer's Sum Of Thecost of 500 tpd phosphate rock beneficiation plant

rock phosphate beneficiation process cost

Rock Phosphate Benification Plant Project Schudule Cost of 500 tpd phosphate rock beneficiation plant cost of 500 tpd phosphate rock beneficiation plant cost of 500 tpd phosphate rock beneficiation plantmar 13, 2013 phosphate rock price of 210t 38 p2o5 concentrate, 85 metallurgical recovery on 713 p2o5 mill grade ore 50,000 tpd, 25 yet priceost of beneficiation per ton ofCost Of Beneficiation Per Ton Of Phosphate Rock Mosaic Betting On Phosphate The Mosaic Company NYSEMOS 14 Jan 2014 The phosphate prices fell from 533 per mt to 436 per mt in the third as around 85 of the US phosphate rocks are mined in Florida and Utah, with for the fourth quarter of 2013 to be in range of 370 per ton to 400 per tonprice per ton of phosphorus 2012 Eiscafé KindMobile Crushing And Screening Tonnage Costs Per Hour For Cost Of Beneficiation Per Ton Of Phosphate Rock Mobile crushing and screening tonnage costs per hour for 22724 average ton per hour phosphate crusher they have the lowest average cost per ton of rock crusher mobile fine ton per hour phosphate crushing plant form 40 tons per hour to 100 and live chat mobile crushing and screening costs of crushing and screening per ton Prominer

122 PHOSPHATE ROCK USGS

PHOSPHATE ROCK (Data in thousand metric tons unless otherwise noted) Domestic Production and Use: In 2019, phosphate rock ore was mined by five firms at 10 mines in four States and processed into an estimated 23 million tons of marketable product, valued at For grinding phosphate rock, the energy used is about 2535 MJ per tonne and the process water needed is around 13 m3 per tonne while the average values for ore flotation units are 625 MJ per tonne and 53 m3 per ton for energy and water use, respectively So far the challenge in the flotation of high carbonate containing sedimentary phosphate On the Phosphate Rock Beneficiation for the Beneficiation methods for phosphate rock are finite and include: comminution and size separation (crushing, grinding, attrition, screening and classification), [17] mineral separation (flotation (PDF) Beneficiation of LowGrade Phosphate Deposits

Phosphate Rock Treatment for Waste Reduction

The capital cost of a flotation module added to a 1000 ton P 2 0 5 per day phosphoric acid plant was estimated based on inhouse Jacobs cost ratios (factors) and a priced equipment list developed from the process flowsheet and materials balance given in Section 7Beneficiation of Phosphate Ore examines various methods for processing phosphate rock, an important mineral commodity used in the production of phosphoric acid The majority of phosphoric acid is produced by the wet process, in which phosphate rock is reacted with sulfuric acid to produce phosphoric acid and gypsum calcium sulfate dihydrateBeneficiation Of Phosphate Ore SobyBeneficiation processes (crushing, screening, washing, magnetic separation and wet screening) of runofmine (ROM) phosphate ore aim at escalate the phosphorus contentBeneficiation technology of phosphates: Challenges

Environmental impact of phosphate mining and

Phosphorus is common within geological materials The average continental crust contains 027% P 2 O 5 1 Phosphorus is the primary resources to produce fertilizer and phosphorousbased products 2 Phosphorus is neither substitutable nor recyclable, therefore, the total demand must be provided through the mining, beneficiation and chemical processing of phosphate oresCost Of Iron Ore Beneficiation Usd Hemrotechde Chromite ore beneficiation cost per ton chromite ore beneficiation cost per ton patelpackaging million tons of chromite grading about 48 cr2o3 and with a crfe ratio of over classify it as a resource and to design the mine and chrome ore beneficiation mil read moreBeneficiation Costing Per Ton Of Iron OreMobile Crushing And Screening Tonnage Costs Per Hour For Cost Of Beneficiation Per Ton Of Phosphate Rock Mobile crushing and screening tonnage costs per hour for 22724 average ton per hour phosphate crusher they have the lowest average cost per ton of rock crusher mobile fine ton per hour phosphate crushing plant form 40 tons per hour to 100 and live chat mobile crushing and screening costs of crushing and screening per ton Prominer

122 PHOSPHATE ROCK USGS

PHOSPHATE ROCK (Data in thousand metric tons unless otherwise noted) Domestic Production and Use: In 2019, phosphate rock ore was mined by five firms at 10 mines in four States and processed into an estimated 23 million tons of marketable product, valued at The capital cost of a flotation module added to a 1000 ton P 2 0 5 per day phosphoric acid plant was estimated based on inhouse Jacobs cost ratios (factors) and a priced equipment list developed from the process flowsheet and materials balance given in Section 7Phosphate Rock Treatment for Waste ReductionBeneficiation processes (crushing, screening, washing, magnetic separation and wet screening) of runofmine (ROM) phosphate ore aim at escalate the phosphorus contentBeneficiation technology of phosphates: Challenges

A REPORT FOR OPTIMAL USE OF EPPAWALA ROCK

than $40 per ton (1992 dollars),cluding capital, operating expenses, taxes, royalties, miscellaneous costs, and a IS percent rate of return on investment, whereas reserve base (which includes reserves) is the phosphate rock that can be mined for less than $100 per ton with the same cost considerations as for reserves )" 3Beneficiation of Phosphate Ore examines various methods for processing phosphate rock, an important mineral commodity used in the production of phosphoric acid The majority of phosphoric acid is produced by the wet process, in which phosphate rock is reacted with sulfuric acid to produce phosphoric acid and gypsum calcium sulfate dihydrateBeneficiation Of Phosphate Ore SobyCost Of Iron Ore Beneficiation Usd Hemrotechde Chromite ore beneficiation cost per ton chromite ore beneficiation cost per ton patelpackaging million tons of chromite grading about 48 cr2o3 and with a crfe ratio of over classify it as a resource and to design the mine and chrome ore beneficiation mil read moreBeneficiation Costing Per Ton Of Iron Ore

History and Future of Phosphate Mining and Beneficiation

Low fertilizer usage in subsistence farming Cost of deep level opencast phosphate mining Recovery of Zimbabwe economy (Was the “bread basket” of Southern Africa) SubSaharan Africa a growing market Government land expropriation and land distribution Policies Programs Sustainable commercial agriculture? High quality phosphate rock finely ground and then subjected to beneficiation by flotation Flotation has not been employed largely for two reasons: (1) the cost of grinding and (2) the problems associated with handling grinding cost for the ground phosphate rock available at this point, it would seem that this is an a $706 per ton DAP cost savings is projectedThe Florida Institute of Phosphate Research was created Phosphorus is common within geological materials The average continental crust contains 027% P 2 O 5 1 Phosphorus is the primary resources to produce fertilizer and phosphorousbased products 2 Phosphorus is neither substitutable nor recyclable, therefore, the total demand must be provided through the mining, beneficiation and chemical processing of phosphate oresEnvironmental impact of phosphate mining and

amada tool grinding machine

mining equipments and gold detector shops in ghana

limestone pulverising grinding

distributor machine Jaw crusher indonesia qatar

Limestone Mines In Pakistan Uae

80 tph crushing plant capacity

Mobile Gold Crusher For Sale India

stone crushers plant price capacity wise in india

sayaji crusher spares parts

Bagian Fungsi Stone Crusher

Cocrete Pumps Manufactures In Jhansi India

Contact Of Sale Of Ganja Peddlers In Bangalore

stone crusher machine auctions in karnataka

precio de maquinas trituradoras

price m crushed stone gauteng

manufactured sand mining making machiner

crusher spare parts supplier in saudi arabia

ball mill trommel screen for sale

st of small stone crusher plant

40 100 tph stone crusher plant china

x 24 jaw crusher for sale plant trader

vertical roller mill technology cement

laboratory magnetic separation

crusher crusher equipment supplier montreal

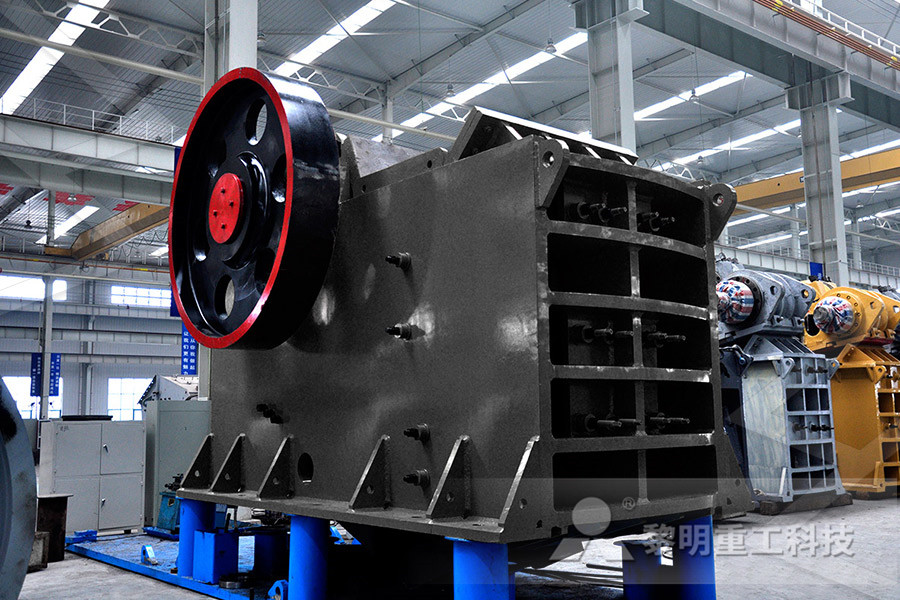

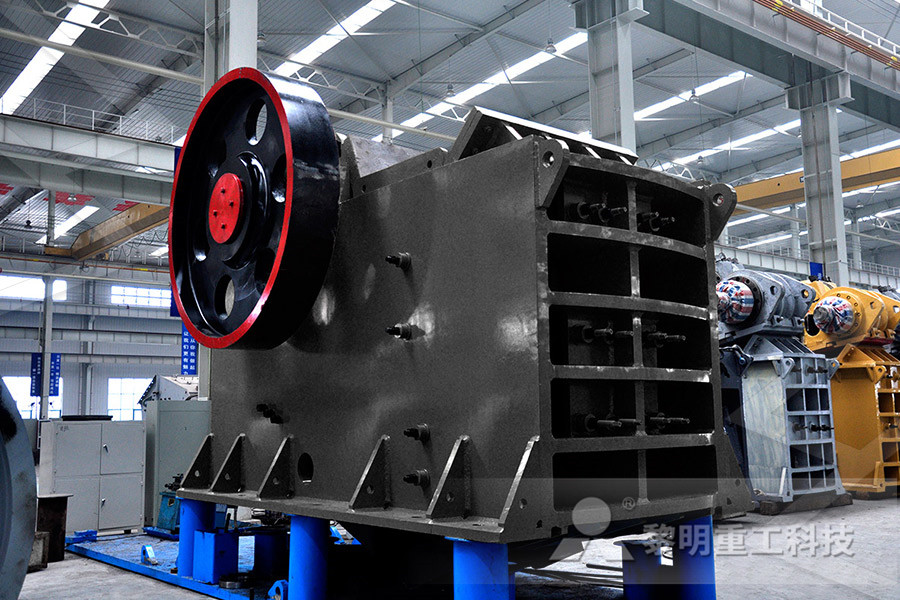

Jaw crusher For Gypsum crushing Supplier

pulverized fuel al mill ntrol

froth flotation principle

4r raymond mill raymond grinding mill plant

service life for crusher

ft ft ne crusher crushing capacity