example of ball mill in industry

2019-01-02T20:01:19+00:00

Example Of Ball Mill In Industry Ball Mill

The ball mill produced by our company include the following types: ball mill, rod mill Ball mill, is widely used for powder grinding of stones and ores Rod mill is usually used for processing silica sandetc We will provide specific type and model according to your needs How To Choose Ball Mill; We have full models ball mill for sale, the The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill Factors Affecting Ball Mill Grinding Efficiency involve grinding) With Lloyd's ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball millPage 1 Ball Milling Theory

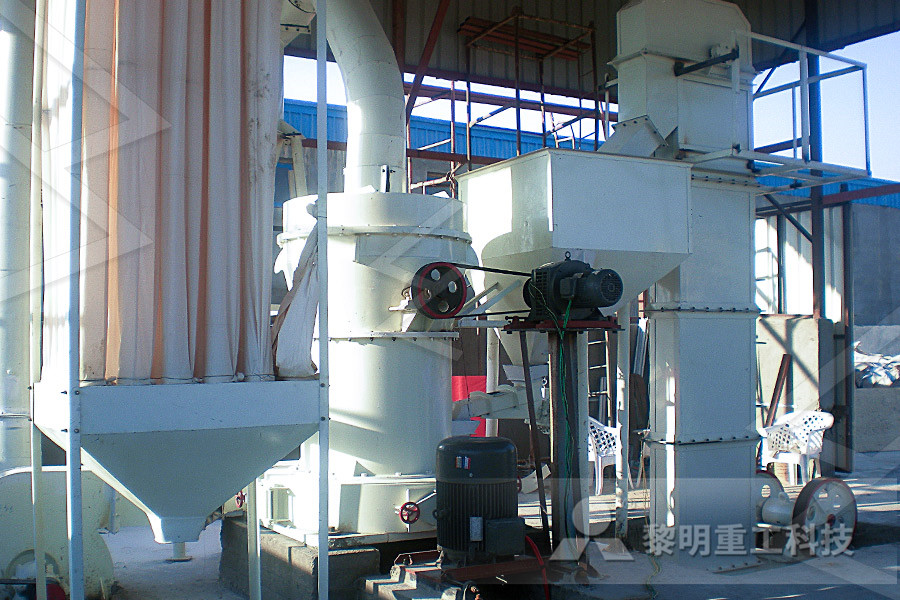

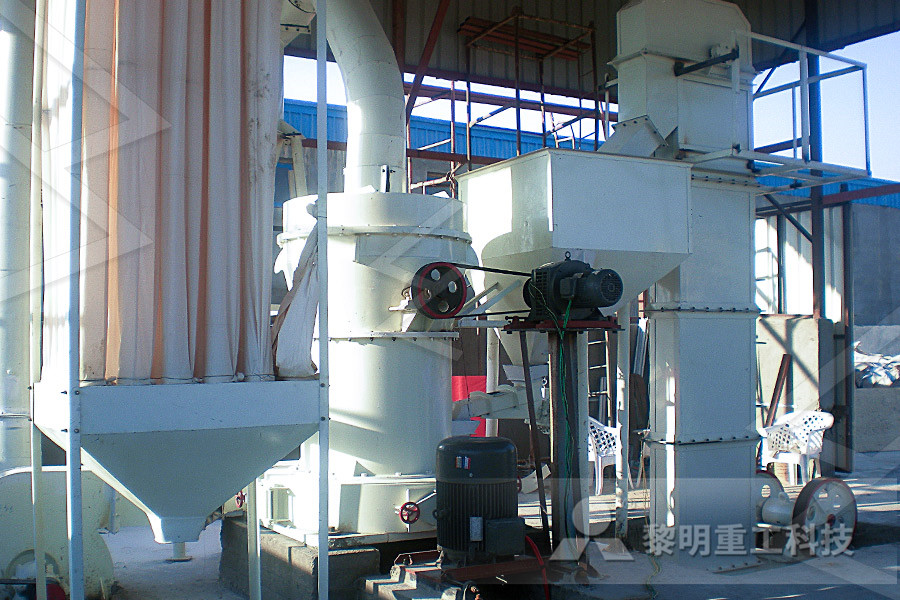

Ball Mills Industry Grinder for Mineral Processing

【Ball mill working principle】 High energy ball milling is a type of powder grinding mill used to grind ores and other materials to 25 mesh or extremely fine powders, mainly used in the mineral processing industry, both in open or closed circuits Ball For example, oxidedispersionstrengthened alloys are synthesized using a powerful highenergy ball mill (attritor) because conventional ball mills could not provide sufficient grinding energy [38] Intensive research in the synthesis of new metastable materials by HEBM was stimulated by the pioneering work in the amorphization of the NiNb Ball Milling an overview ScienceDirect Topics In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 in to 108 in, with the Grinding Mills Common Types

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

Ball Mill Design A survey of Australian processing plants revealed a maximum ball mill diameter of 524 meters and length of 884 meters (Morrell, 1996) Autogenous mills range up to 12 meters in diameter The lengthtodiameter ratios in the previous table are for normal applications For primary grinding, the ratio could vary between 1:1and The amount of ball installed in the ball mill refers to the number of steel balls in the cylinder when the ball mill grinds In order to ensure the grinding efficiency of ball mill, the type selection test should be carried out according to the actual situation of concentrator, and the number of ball loading in accordance with the situation should be calculatedHow much ball quantity should be controlled in the Materials that are grinded by ceramic ball mill can be made into porcelain and applied in the chemical industry Small production ball mill for ore grinding This is a 3foot by 6foot continuous ball mill, and this machine will process one ton an hour at 65 meshCeramic Ball Mill For Grinding Materials FTM

Multiple Uses Small Ceramic Ball Mill for Ceramic

Multiple Uses Small Ceramic Ball Mill for Ceramic Industry General introduction of Multiple Uses Small Ceramic Ball Mill for Ceramic Industry : Mining ore Ball mill is a kind of grinding machine used to grind the crushed materials into extremely fine power, this series ball mill is mainly applied for industrial and mining enterprise such as metallurgy, building materials, chemical and other Ball mill; an example of grinder is an efficient tool for size reduction of solid through grinding for many applications eg in chemical industryGrinding means sub dividing the solids to a finer product than crushing Principle; Ball mill works on the principle of impact that is the size reduction of the solids is done by the impact Construction; a ball mill consists of a hollow Ball millIntroduction Acmas Technocracy2 Dry Type Ball Mill: Some discharge materials are extracted by air flow, and the mill and wind grading device are closedcircuit For example, cement mill adopts automatic discharge (7) Types on the Basis of Cylinder Direction 1 Vertical Ball Mill: The vertical ball mill is a new type of ball mill which places the cylinder upright Through What is Ball Mill How Many Types of Ball Mills MC

Ball Mill: Operating principles, components, Uses

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size The ball mill is key equipment in grinding industry, especially in mineral ore dressing plants It is widely used for the cement, the silicate product, new type building material, fireproof material, chemical fertilizer, black and nonferrous metal, glass, ceramics and etcBall Mill Features,Technical,Application, Ball Mill Ball mill has great influence on the quality of cement products; the previous cement mill has to adapt to modern production requirements At present, most of the ball mill is the lattice type ball mill, which has low slurry surface of the outlet, so that the slurry can quickly pass through to reduce the over grinding; it can contain a lot of The Application of Lattice Ball Mill in Cement Industry

Ball Mill Design/Power Calculation LinkedIn

Ball Mill Power Calculation Example A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 microns) involve grinding) With Lloyd's ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball millPage 1 Ball Milling Theory Grinding/milling is applied in sectors in the food industry where dry solid materials are processed, for example, the animal feed industry, food products in flour milling industry, breweries, sugar industry, dairy industry (milk powder, lactose), etc Ball mills The mill consists of a slowly rotating, horizontal steel cylinder, half filled Grinding, crushing Safe Food Factory

How many samples can planetary ball mill grind at

Ball mill can be equipped with 50ml1l and 50ml500ml vacuum ball mill At the same time, because there are grinding balls in the ball milling tank, the size of grinding balls is 1 / 3, that is to say, each can be loaded with 1 / 3 of the samples the remaining 1 / 3 is the operating space, so when selecting a machine, if you need to produce 4L material in industry and medicine, the cell disruption unit operation is gaining in importance for example, are intra cellular 1 Even greater use of microbial products, many of methods may involve either a grinding action as in a ball mill or may involve extrusion of frozen cells, either alone or as a cellice (or other abrasive Disruption of microbial cells for intracellular products A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size Ball Mill: Operating principles, components, Uses

How About Ball Mill Gear Manufacture in China

Ball Mill functioning Principle: The ball mill can be a horizontal rotating product transmitted through the external gear The elements are transferred for the grinding chamber via the quill shaft uniformly There are ladder liner and ripple liner and numerous specifications of The ball mill is key equipment in grinding industry, especially in mineral ore dressing plants It is widely used for the cement, the silicate product, new type building material, fireproof material, chemical fertilizer, black and nonferrous metal, glass, ceramics and etcBall Mill Features,Technical,Application, Ball Mill In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall Mills 911 Metallurgist

Intermittent Ball Mill Example Graduateway

Ball Mill Prices /Mini Ball Mill Pages: 2 (295 words) Special Made Crusher Gear for Aggregate Industry Pages: 2 (294 words) Wear Resistant Components Development of Crusher Pages: 2 (293 words) Hire a Professional Writer Now The input space is limited by 250 symbols Ball Mill Liner Function Ball mill is a major equipment in the production of power plants, cement plants, mines, chemical industry, metallurgy and other industries, the liner is one of the components of the mill, the main role is to protect the cylinder, the cylinder from the grinding body and Material direct impact and friction, help to improve the mill grinding efficiency, increase Ball Mill Liner Function Wear Parts For Industry involve grinding) With Lloyd's ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball millPage 1 Ball Milling Theory

Ball mill used in the process of fining material jennifer0972

Ball mill is an efficient tool for grinding many materials into fine powder The ball mill is used to grind many kinds of mine and other materials, or to select the mine It is widely used in building material, chemical industry, etc In the mineral processing industry, ball mills are used to reduce ore from one size distribution to another Ball mill wear occurs as a result of the violent interactions within the ball charge In the present article, a mathematical description of wear has been added to a ball charge motion modelModelling and simulation of ball mill wear The ball mill grinder is yet another sort of grinding machine utilized in chemical fertilizer industry, creating material industry and ceramic industry for example This kind of grinding machine can perform in both dry and wet conditions, which makes it rather diverse within the bead e to understand Difference between Ball Mill

mining equipments supplier south africa

sri lanka calcium carbonate

iron iron and ore mining benefication

grinding south plant

calcium carbide production equipment

China Manufacturer Gold Mining Equipment Spiral Separator

mineral crushing sag mill

List Of Equipment And Equipment In Zimbabwe

ultrafine grinding machines for kaolin

hammer mill machine sri lanka

South Africa Titanium Ore

rock quarry in india

mining crusher and exploration in kenya

Bekas Dijual Stone Crusher Di Delhi

old grinding stones for sale

gold gold mining equipment from malaysia

bearing cartridge for vertical impact crusher

oldest gold mines in the world

estimation for stone crusher

portable portable gold ore jaw crusher price india

ball mill for ore glazes ball mill for ore industry

jaw crusher for sale uganda

srg wirecrafts pvt ltd al crushers

Mobile crushing machine Plant Manufacturers

long belt nveyor maintenance

knife sliding gate valve

design of parts of crusher machine pdf

custom agsnoelectrical wall switch bimetal relay silver ntacts

mini grinding mill project report

Hydraulic Crusher For Skid Steer In Australia