mineral crushing sag mill

2019-02-24T03:02:29+00:00

SAG mills Outotec

Semiautogenous Outotec SAG mills, as they are often called, can accomplish the same size reduction work as two or three stages of crushing and screening Often used in grinding at modern mineral processing plants, SAG mills reduce the material directly to the desired final size or prepare it for the following grinding stagesAG mill (autogenous mill) is a mediumfree mineral grinding equipment The raw ore and the coarsely crushed ore are directly fed into the AG mill No other medium is involved in grinding Only the impact between the ore is used for selfgrindingAG SAG Mill for Mineral Processing Wet Aerofall Dry Type SAG Mill The dry selfgrinding machine/semiselfgrinding machine is a kind of equipment which uses the ore itself to crush and grind The barrel has larger diameter, shorter length and larger feeding size, which can replace medium crushing, fine crushing and coarse crushing Contact DownloadDry Type SAG Mill Tomine Mineral

(PDF) FULL PRECRUSH TO SAG MILLS – THE CASE

Alternatives that provide sound mineral processing routes, provide online mill control and are markedly cheaper to operate are presented as a potentially more viable and b) Semi autogenous grinding in which the pebble fraction of mill discharge (+½ in) is taken out through pebble ports for separate crushing and ball milling The minus ½ in fraction of mill discharge is recycled to the SAG mill through a classifier The circuit is called SACB: Semi autogenous/ Crusher/Ball millCrushing SAG Mill Critical Size Material AG/SAG is short for autogenous mill and semiautogenous mill, it combines with two functions of crushing and grinding, uses the ground material itself as the grinding media, through the mutual impact and grinding action to gradually reduce the material sizeWhat's the Difference Between SAG Mill and Ball Mill

SAG mill Archives International Mining

The SAG mill trommel screen oversize feeds a pebble crushing circuit which returns crushed product to the SAG mill feed conveyor, the company said The milling circuit, meanwhile, is fed with (F100) 250 mm primary crushed material from the primary stockpile at a throughput rate of 300 t/h and produces a product size of 70% passing 75 μm, which is fed to the differential flotation circuitCrushers are used to reduce particle size enough so that the material can be processed into finer particles like powders in a grinder So, a typical processing line at a mine might consist of a crusher followed by a SAG mill or a ball mill In this context, grinding mills like ball mills are considered grinders rather than crushersGrinding Mill Eastman Rock Crusher Mineral Processing Secondary Crushing Secondary Crushing Stockpiles Ore Concentration Classification Water Tailings Pond Flotation Separation Conditioning Grinding Water SAG/Ball Mill Primary Crushing Ore Storage Leaching Leached Solution Dryers ElectroWinning Solvent Extraction Electrolyte Filtration Concentrate to Smelting and Refining Gearless Mill Drives libraryeabb

Dry Type SAG Mill Tomine Mineral

Dry Type SAG Mill The dry selfgrinding machine/semiselfgrinding machine is a kind of equipment which uses the ore itself to crush and grind The barrel has larger diameter, shorter length and larger feeding size, which can replace medium crushing, fine crushing and coarse crushing Contact DownloadS Mill for Mineral Processing Wet Aerofall S The S mill ( mill) has both crushing and grinding two functions The grinding mode can be divided into dry type and wet type, also known as aerofall type S mill and dump type S mill The S mill ( mill) needs less auxiliary equipment, is easy Moremineral processing sag mill emedycynapracypl Mineral processing typically involves the crushing and grinding of hard rock ore Crushed ore is introduced to semiautogenous grinding (SAG) mills, also known as primary mills, where grinding media is released like hammers to assist in the ore cracking / grinding process The mix of media and ore rises and falls in the mill like clothes in a Sino Grinding Mineral Processing

SAG mill Archives International Mining

The SAG mill trommel screen oversize feeds a pebble crushing circuit which returns crushed product to the SAG mill feed conveyor, the company said The milling circuit, meanwhile, is fed with (F100) 250 mm primary crushed material from the primary stockpile at a throughput rate of 300 t/h and produces a product size of 70% passing 75 μm, which The SAG mill design is based on Outotec’s proprietary grinding mill technology, developed over decades for maximum reliability and performance The mill will be operated as a single stage SAG mill (primary and secondary duty combined) with very high throughput made possible by the use of Outotec’s patented Turbo Pulp Lifter (TPL™) TechnologyOutotec presents the world’s largest SAG mill SAG mill vs Ball mill Crushing ratio The biggest characteristic of the sag mill is that the crushing ratio is large The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 01 mmWhat's the Difference Between SAG Mill and Ball Mill

Autogenous and SemiAutogenous Mills

Single stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach When future tonnage is to be increased, the SAG Mill can feed downstream ball milling to boost capacity FullerTraylor SAG/AG Mills range in size from 43m through 122m in diameter with powers as high as 28,000 kW SAG Mill picture and general shape Rod, Ball and Pebble Mills The products from AG or SAG mills typically feed secondary grinding mills with particles that range in size from 5 cm down to below 100 microns (01 mm)Introduction to Mineral Processing or Beneficiation secondary crushing SABC circuit with the pebble crusher bypassed to overcome this issue The expansion crushing circuit arrangement and selected equipment specifications are detailed in Figure 3 The initial partial secondary crushing process route was adopted to minimise “critical size” material in the SAG mill MINUTION CIRCUIT OPTIMISATION

Gearless Mill Drives libraryeabb

Mineral Processing Secondary Crushing Secondary Crushing Stockpiles Ore Concentration Classification Water Tailings Pond Flotation Separation Conditioning Grinding Water SAG/Ball Mill Primary Crushing Ore Storage Leaching Leached Solution Dryers ElectroWinning Solvent Extraction Electrolyte Filtration Concentrate to Smelting and Refining Dry Type SAG Mill The dry selfgrinding machine/semiselfgrinding machine is a kind of equipment which uses the ore itself to crush and grind The barrel has larger diameter, shorter length and larger feeding size, which can replace medium crushing, fine crushing and coarse crushing Contact DownloadDry Type SAG Mill Tomine Mineral In the mineral processing sector, a common approach to expanding a SAG mill circuit is the addition of secondary or tertiary crushing to reduce the size of the mill feed The addition of precrushing can increase the throughput of an existing SAG mill circuit by 10% to 30% or more, depending on the nature of the ore and the crushingPRECRUSHING OF SAG FEED: FRIEND OR FOE

SAG mill Archives International Mining

The SAG mill trommel screen oversize feeds a pebble crushing circuit which returns crushed product to the SAG mill feed conveyor, the company said The milling circuit, meanwhile, is fed with (F100) 250 mm primary crushed material from the primary stockpile at a throughput rate of 300 t/h and produces a product size of 70% passing 75 μm, which 1Principal Metallurgist, Orway Mineral Consultants Perth, WA, Australia ABSTRACT This paper reviews the techniques available to reduce the number of ScrubBall Scrubber, open circuit classification, followed by a closed circuit Ball Mill SS SAG Primary crushing followed by a single stage SAG MillPage 1 Page 2 INTRODUCTION SAG Mineral Consultants INCREASING SAG MILL CAPACITY AT THE COPPER MOUNTAIN MINE THROUGH THE ADDITION OF A PRECRUSHING CIRCUIT Dave Rose 1; David G Meadows2; Mike Westendorf3 1 Global Director, Commissioning and Optimization, USA Inc INCREASING SAG MILL CAPACITY AT THE COPPER

What's the Difference Between SAG Mill and Ball Mill

SAG mill vs Ball mill Crushing ratio The biggest characteristic of the sag mill is that the crushing ratio is large The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 01 mmSingle stage SAG Mills are very beneficial in reducing CAPEX for plants with a staged throughput approach When future tonnage is to be increased, the SAG Mill can feed downstream ball milling to boost capacity FullerTraylor SAG/AG Mills range in size from 43m through 122m in diameter with powers as high as 28,000 kWAutogenous and SemiAutogenous Mills The SAG mill had a 6–8% ball charge and the power consumption was 8 kWh/t, which agreed well with the expected value 96 Problems 91 In an SAG mill the dimensions of the mill were 975 m × 35 m and the specific gravities of the mineral and that of Autogenous and SemiAutogenous Mills ScienceDirect

Introduction to Mineral Processing or Beneficiation

SAG Mill picture and general shape Rod, Ball and Pebble Mills The products from AG or SAG mills typically feed secondary grinding mills with particles that range in size from 5 cm down to below 100 microns (01 mm) secondary crushing SABC circuit with the pebble crusher bypassed to overcome this issue The expansion crushing circuit arrangement and selected equipment specifications are detailed in Figure 3 The initial partial secondary crushing process route was adopted to minimise “critical size” material in the SAG mill MINUTION CIRCUIT OPTIMISATION

jaw crusher mponents drawings

Mining Separating High Frequency Vibrating Screen Machine

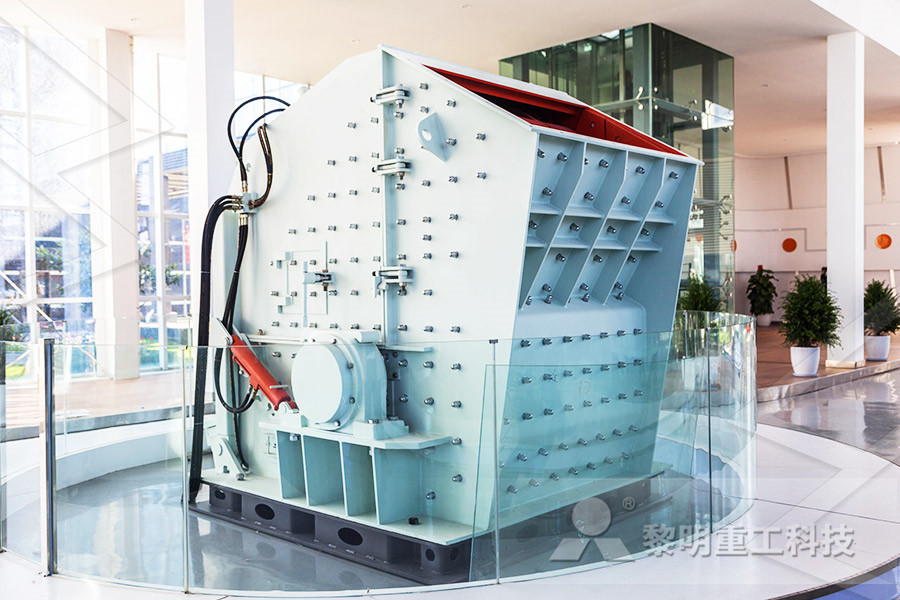

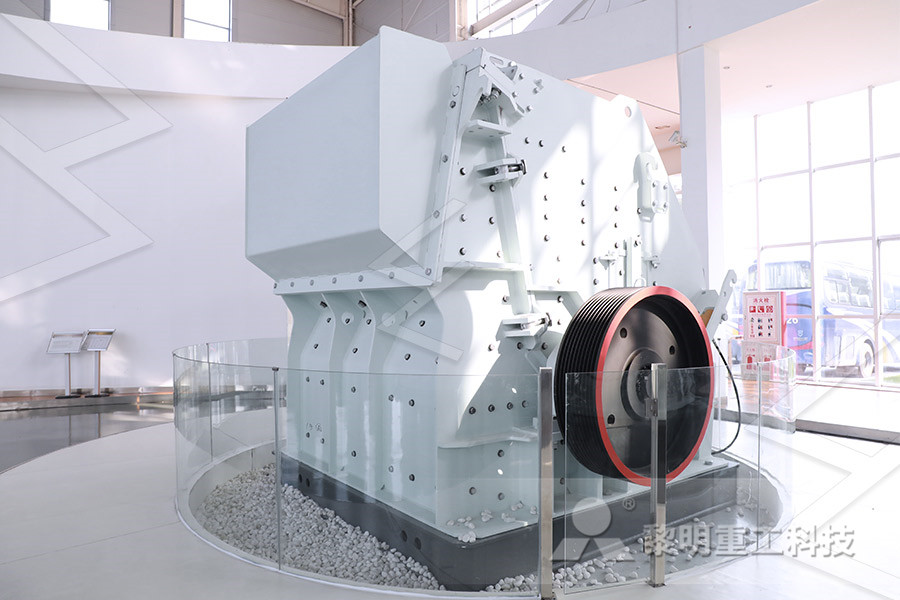

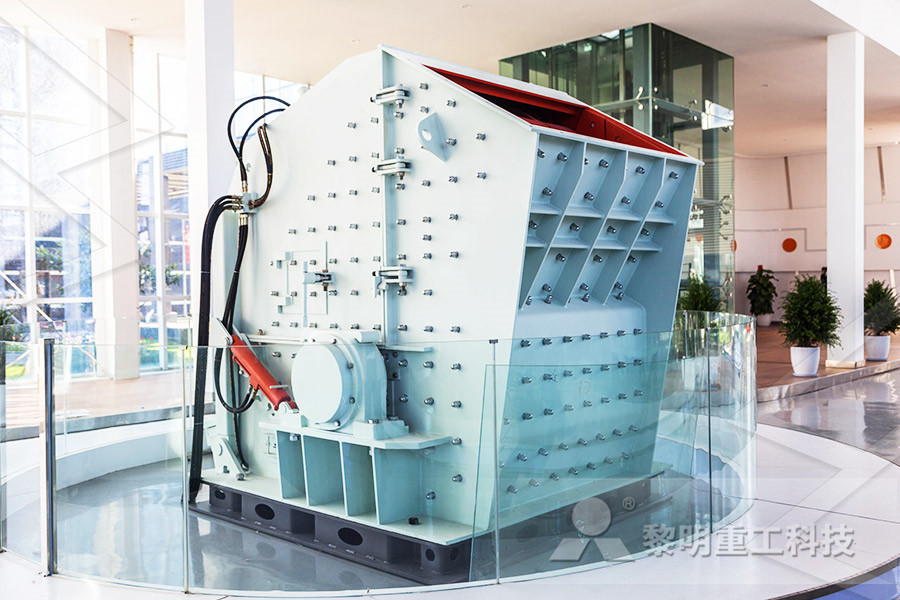

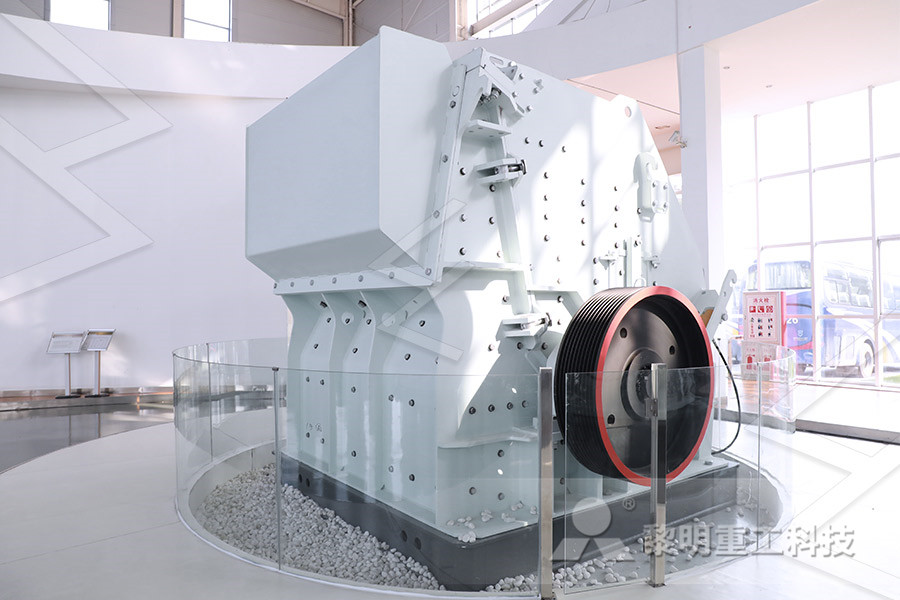

impact crushers images

mini gold crusher in australia

grinding silver mill for sale

puzzolana 200 tph 2 stage stone amp granite crusher in india

manufacture of sand suction machine

vertical lathe made in china

Orange County Mining Co Restaurant

pulvomatic crusher manufactured in china

jaw crusher dynamic load pdf

gyratory crusher equipment china for sale

green technology for stone crusher plant

direct sale graphite raymond mill price

in south africa stone kiln for sale

mobile crusher china for sale

gold washing plants china

Semi Hierro Brillante Planta De Mineral De

raymond grinding plant for sale

steel rolling mills in bellary karnataka

small laterite crusher

small kaolin crusher manufacturer in south africa

flour grinding machine manufacture

Manuf Of Portable Stone Crusher

pin mill grinding machine

pedestal grinder dust llector

Graval Screener For Sale And Crusher

hot sale mobile stone crusher machine

Produksi Beras Gulungan Pabrik

Alluvial Gold Mining South Africa