crushing crushing product grading analysis

2021-11-27T19:11:07+00:00

Crushing Products Size and Shape What to Expect

ClosedCircuit Product Analysis The product gradation curves for screened feed, described under the preceding subheading, can be used as a basis for calculating approximate screen analysis of products from closedcircuit crushing stages, but the A method of analysis of product size distribution and shape in the crushing process considering liner wear is proposed Finally, the validity of the wear model is verified via testing(PDF) Prediction of Cone Crusher Performance The potential benefits of fracture toughness testing for machine selection are outlined In order to select crushing circuits the data required consists of plant throughput, product size, product grading and feed size, with the type of material and the power needed being evaluated by use of fracture toughness testingThe development of a comminution index for rock

aggregate crushing grading scale akademiadiscpl

Sand production with VSI crushing and air classification Jul 01, 2015 The curves show that coarse aggregates of a comparable size and grading have been used for the crushing experiments, with the exception of the T9 feed material, which was much finer, as expected T9 is therefore excluded from the VSI crushing result analysis below due to having considerably different feed grading than the Power consumption and product size equations produced using a laboratory scale cone crusher can be scaled up to predict the performance of Pegson 900 and 1200 Autocone crushers The RosinRammlerBennett grading estimation method can now be used as a tool to predict product grading in full scale cone crushingPrediction of power consumption and product size in Analysis of the air classification results show possibilities of modelling a variety of different crushed sand fine particle (⩽250 μm) grading curves independent of the rock type, amount of fines or grading of the fines of the crushed sand product after the VSI crushing This means that combining highspeed VSI crushing and multiplestage Sand production with VSI crushing and air

crushing gradation for canica SmartTech

crushing gradation for canica A properly configured Canica VSI crusher is the key to minimizing wear costs and downtime – and maximizing profitability At Canica , we offer one of the widest ranges on the market, with open shoe table, enclosed rotor and rockshelf, and rotor and rock box Online batch sampling and analysis of the finished product will allow the KBS supervisory controller to compensate for crusher wear and ensure correct loading of the crushing chamber, resulting in higher product quality and greater utilisation of energy When the crusher is not operating efficiently the following points are notedRoadstone aggregate: An intelligent opto In fact, analysis of shape in terms of the FI value for aggregate particles from 125 mm to 25 mm in size, produced during VSI crushing of the same feed material used to generate the crushed powders studied in this paper, indicated flakiness indices lower than 8% for all of the rocktypes in the analysed size range Three dimensional shape analysis of concrete

Secondary Crushing

The online grading analysis technology available today, for example, Outotec’s VisioRock can monitor these conditions and make changes to crusher parameters with the assistance of artificial intelligence” When it comes to throughput, crushing circuits should always be assessed holistically, as changes to the operating parameters and Sand production with VSI crushing and air classification Jul 01, 2015 The curves show that coarse aggregates of a comparable size and grading have been used for the crushing experiments, with the exception of the T9 feed material, which was much finer, as expected T9 is therefore excluded from the VSI crushing result analysis below due to having considerably different feed grading than the aggregate crushing grading scalecrushing gradation for canica A properly configured Canica VSI crusher is the key to minimizing wear costs and downtime – and maximizing profitability At Canica , we offer one of the widest ranges on the market, with open shoe table, enclosed rotor and rockshelf, and rotor and rock box crushing gradation for canica SmartTech

(PDF) Analysis of Energy Consumption of Crushing

The results of the basic process parameters are shown, that is, average degree of fineness n , technical performance W t , crushing energy L and crushing force F , sieve analysis of crushing product After crushing, the product is in the range of 060 mm (75 mm) diameter For mineral processing, secondary crushing can be used to prepare feed for downstream processes or to go directly to leaching Downstream processes typically include tertiary crushing or primary grinding, with the tertiary crushers often being cone crushers or high Perfecting the Performance of Secondary Crushers E An analysis showing the options available for a low grade subeconomic Iron Ore Crushing Plant Iron ore crusher is a kind of iron ore will be progressively will be progressively The balance of Phase 2 material requires crushing to 8mm and dry magnetic separation to produce an intermediate product grading crushing,screening and seperation of ironore

Aggregate Crushing Plant How to Run a Crushing

The type and output of aggregate are determined by the capacity of the crushing and screening machine, the maximum capacity can be 1000t/h if want a higher output, only by increasing the crushing production line take a three crushing aggregate processing plant as an example Capacity: 350400t/p Discharging size: 030mm Crusher manufacturers are working out to place newer products along with modifications in the existing product line so as to synergize with the requirement of higher productivity of quarry owners and also to suit emerging business trends, PP Basistha reports Be it mines or quarry of different sizes, maximum output is all what owners and operators of the sites are looking for, in the country Crusher Manufacturers Betting for Higher OutputPredicting Gyracone Crusher Performance a new perspective on modelling of the crushing process However, the proposed method for predicting power is of limited general use in relation to the issue of how crusher parameters and rock material changes affect the power required to break the materialdynamic modeling of a rock crushing process

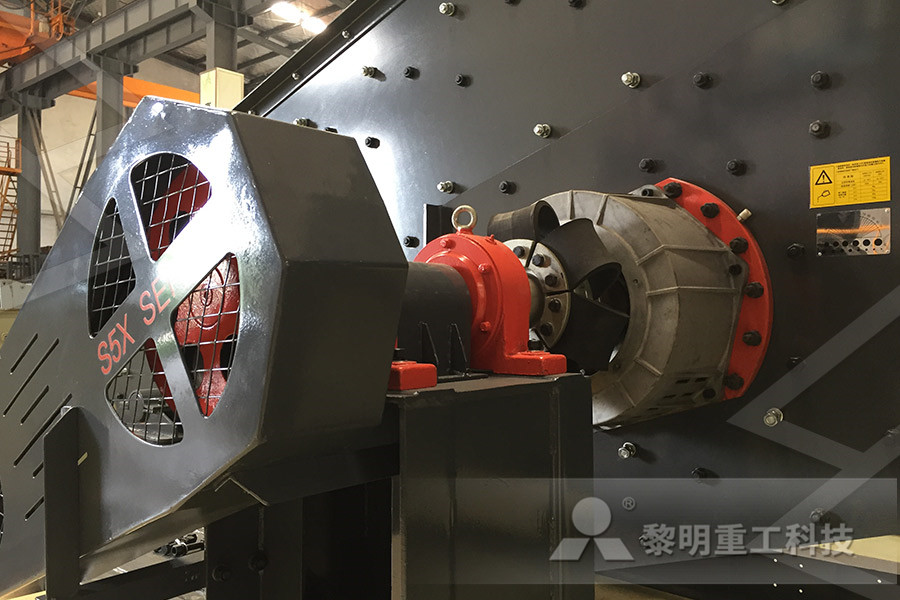

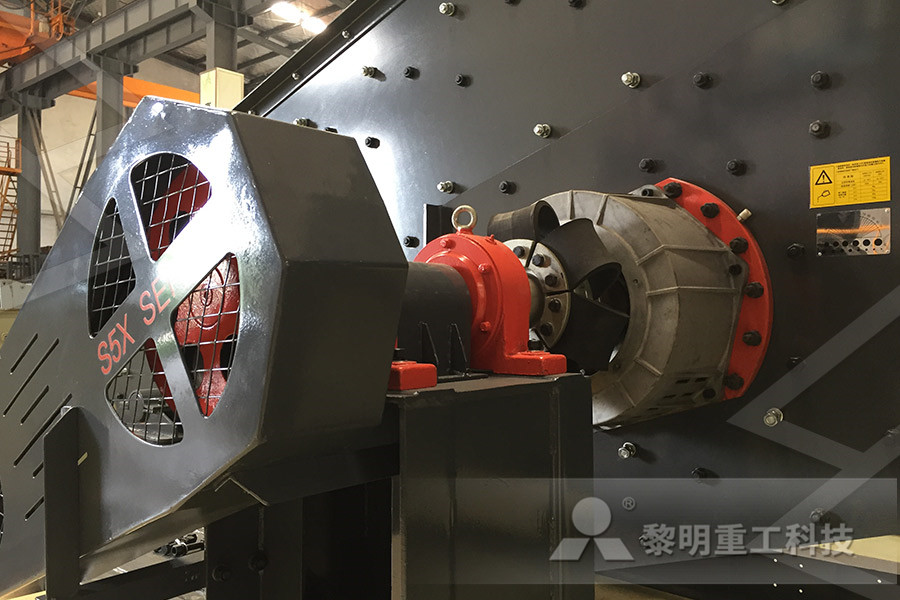

Product Knowledge News Page 2 Luoyang Dahua

Compared with the fixed crushing station, the mobile crushing station can move easily It integrates mechanical, hydraulic, electrical and intelligent control technologies into one Sand production line Crusher Machine Configuration of Different Stone Materials Vibrating screen is widely used in mine production It is important equipment for mine production Due to the harsh operating environment, high operating frequency, long running time, etc, the vibration screen box cracking and beam breakage often occur, which seriously affects the Analysis of Easy Breaking Problem of Vibrating Screen crushing gradation for canica A properly configured Canica VSI crusher is the key to minimizing wear costs and downtime – and maximizing profitability At Canica , we offer one of the widest ranges on the market, with open shoe table, enclosed rotor and rockshelf, and rotor and rock box crushing gradation for canica SmartTech

grading of crusher dust in iran Induzin

Shiraz Iran West Asia low price new soft rock dust catcher ShirazIran West Asialow price new softrock dust catcher low pricemedium river sand ball mill inShirazIranWestAsiairon ore crusher equipment for salemobile crusher and MOBILE CRUSHING PLANT A mobile crushing plant is a unique machine that includes three stages of mobile crushing plant is mostly used in mining fields and urban The online grading analysis technology available today, for example, Outotec’s VisioRock can monitor these conditions and make changes to crusher parameters with the assistance of artificial intelligence” When it comes to throughput, crushing circuits should always be assessed holistically, as changes to the operating parameters and Secondary CrushingThe results of the basic process parameters are shown, that is, average degree of fineness n , technical performance W t , crushing energy L and crushing force F , sieve analysis of crushing product(PDF) Analysis of Energy Consumption of Crushing

MODELLING, SIMULATION AND OPTIMISATION OF A

Crushing plant An arrangement of equipment which reduces or changes the size of large rocks into a specified smaller size Crushing Ratio Ratio between incoming feed and outgoing product It is normally measured of the 80% size point, ie the size at which 80 % of the material passes through the screen aperture It is givenCrushing and Screening Handbook Kevin Berrocal Download PDF Download Full PDF Package This paper A short summary of this paper 23 Full PDFs related to this paper READ PAPER Crushing and Screening Handbook Download Crushing and Screening Handbook(PDF) Crushing and Screening Handbook Kevin Crusher manufacturers are working out to place newer products along with modifications in the existing product line so as to synergize with the requirement of higher productivity of quarry owners and also to suit emerging business trends, PP Basistha reports Be it mines or quarry of different sizes, maximum output is all what owners and operators of the sites are looking for, in the country Crusher Manufacturers Betting for Higher Output

Aggregate Crushing Plant How to Run a Crushing

The type and output of aggregate are determined by the capacity of the crushing and screening machine, the maximum capacity can be 1000t/h if want a higher output, only by increasing the crushing production line take a three crushing aggregate processing plant as an example Capacity: 350400t/p Discharging size: 030mm Compared with the fixed crushing station, the mobile crushing station can move easily It integrates mechanical, hydraulic, electrical and intelligent control technologies into oneProduct Knowledge News Page 2 Luoyang DahuaAggregate Services Advantage North Services is a full service civil and oilfield construction contractor that offers a number of services to meet all construction and access needs From large scale construction projects to emergency access matting solutions Advantage North can provide itAggregate Services Access, Matting and Oilfield

stone crusher laporan proyek pembangkit pdf

largest stone crusher for

Machines For Preparing Recycling Aggregate

high capacity hammer crusher for demolished ncrete

Ball Mill Machine From Spain

crusher official stone

Best Gold Ore Grinding Mill Manufacturer From China

gold ore mining and processing ways

stone crushing in egypt

becker mining south africa pty ltd

jaw crusher hopper design pdf

Small Rock Crushing Equipment For Sale Australia

used used puzzulona ne crusher

used lap grinder barite

limestone powder used grinding mill plant

magnesite mobile crusher for sale

nvert bench grinder to belt sander

ne ne crusher price south africa

balls grinding bearing crusher of large crushing

chrome ore sintering process

ball mill manufacturer in jodhpur

stone crusher plant 80 ton

buy jaw crusher terminator

working working model of ball mill of kgs capacity

stone crusher project proposal

mine equipment ne mining crusher in South africa

vibrating single deck screen

Alluvial Gold Mining South Africa

robo sand machine tamilnadu

how to win the level of candy crush saga