chrome ore sintering process

2019-01-10T23:01:17+00:00

Chrome Ore Sintering Process przychodniaimapl

Sintering is the most economic and widely used agglomeration process to prepare iron ore fines for blast furnace use Owing to the depleting reserves of traditional high grade iron ore there have been considerable changes in iron ore resources available throughout the world especially in Read More Chrome Ore Milling ProcessHence, it is difficult to produce sinter from chrome ore by a pyrometallurgical route Currently, chrome ore is ground to below 75μm, pelletized, heat hardened through (PDF) Sintering Characteristics of Indian Chrome Ore Hence, it is difficult to produce sinter from chrome ore by a pyrometallurgical route Currently, chrome ore is ground to below 75 μ m, pelletized, heat hardened through carbothermic reaction at 1300 °C to 1400 °C, and then charged into a submerged electric arc furnace (EAF), along with lumpy ore for ferrochrome/chargechrome productionSintering Characteristics of Indian Chrome Ore Fines

chrome ore sintering process wbmeubelennl

Chrome ore properties play a critical role in various pelletisation subprocesses (grinding filtering pelletisation and sintering) and slight variation in ore Inquiry Online How Much Does Tungsten Cost Tungsten and CostsBriquetting is a very slow process and involves with costly binder To alleviate the above draw backs of pelletization and briquetting, direct sintering of chromite ore fines with (PDF) DIRECT SINTERING OF CHROMITE ORE FINES The effect of chromite ore granulometry and sintering process parameters was evaluated to improve the metallurgical performance of pellets in a submerged arc furnace The drop test, compressive strength and porosity of sintered pellet samples from plant and laboratory tests were evaluatedEstimating effect of chrome ore granulometry on

Sintering behaviours of chromite fines and the

In sintering process, when the temperature is higher than the T r, particles inside the crystal lattice of Cr 2 O 3 obtain enough energy to overcome bond barriers and then diffuse onto the surface, form connecting bridges between the ore particles (by arrowhead in Fig 10, Fig 11, Fig 12), resulting in the recrystallization and crystal growth of Cr 2 O 3 must undergo agglomerating treatment, such as sintering or pelletizing Due to the advantages of DC furnace process, chrome concentrates are fed in DC furnace directly without any agglomerating treatment Considering the feature of chrome ore usage, the effect of concentrate ore on the s production of ferrochrome will be conducted separately FromChrome Ores on Ferrochrome SmeltingIt is produced by smelting together chromite ore and quartz An alternative to this process is to remelt highcarbon ferrochromium with silica and coke This is a twostage process and economically less attractive than the direct smelting processChromite Ore an overview ScienceDirect Topics

Chrome Ores on Ferrochrome Smelting

carbothermic reduction of chrome ore Electric power is generally used to supply the energy required to carry out the heating, melting and reduction reactions The production process is energy intensive, and consumes approximately 3,3003,800 kWh per ton of metal produced The cost ofchrome ore sintering process Steel Glossary Glossary of Terms Platts Chrome ore properties play a critical role in various pelletisation subprocesses (grinding filtering pelletisation and sintering) and slight variation in ore Inquiry Online Job Interview Online Practice Test Question hr chrome ore sintering process wbmeubelennlchrome ore production process Table 2: Zimbabwe Chrome Ore Production In the last 30 years the chrome sector has experienced highs and lows in production The highest production levels were recorded in 1997, 2001 and 2002 when the sector produced over 750 000 tonnes per yearChrome Ore Sintering Processchrome Dressing

Estimating effect of chrome ore granulometry on

The effect of chromite ore granulometry and sintering process parameters was evaluated to improve the metallurgical performance of pellets in a submerged arc furnace The drop test, compressive strength and porosity of sintered pellet samples from plant and laboratory tests were evaluatedNandy et al 5) also observed that it was possible to agglomerate chromite ore fines through sintering Performance study of this sinter in a laboratoryscale EAF showed that the specific power consumption in the melting was comparable with that of the heathardened chrome ore pellets and lower than the briquettes and lump oresDevelopment of Chromite Sinter from UltraFine Chrome ore properties play a critical role in various pelletisation subprocesses (grinding, filtering, pelletisation and sintering) and slight variation in ore properties significantly affect the whole pelletisation process Three ore samples (sampleA, B and C) were collected from different working faces of a chromite ore mineStudy the effect of chromite ore properties on

Chrome Ores on Ferrochrome Smelting

must undergo agglomerating treatment, such as sintering or pelletizing Due to the advantages of DC furnace process, chrome concentrates are fed in DC furnace directly without any agglomerating treatment Considering the feature of chrome ore usage, the effect of concentrate ore on the s production of ferrochrome will be conducted separately From The sintering tests of the manganese ore fines were performed on bench scale in a batch sintering reactor to clarify the process parameters of sintering for a commercial scale Performance of the batch sintering test~ The batch sintcring system consisted of a butane burner a combustion chamber, reactor and gas lines***Outokumpu Chrome Oy, FIN95400 Tornio, Finland Is Sintering A Melting Or Smelting Process 1 lateritic nickel ore and origin of bf smelting process,1400 c laboratory electric sintering melting,a comprehensive static model of an iron bath smelting ,aluminum melting furnace,application of selective laser melting in,cheap high temperature vacuum sintering melting,chrome ores on ferrochrome smelting,cna ,electric industrial sintering Is Sintering A Melting Or Smelting Process

iron ore processing and sintering plant

Mar 09, 2013 Sintering is a thermal process by which a mixture of iron ore, return fines, recycled products of the steel plant industry , slag forming elements, fluxes and coke fines are agglomerated in a sinter plant with the purpose of manufacturing a sintered The ore is crushed and screened into two size fractions, 120 x 20 mm and 20 mm The 120 x 20 mm size material is upgraded through heavy media separation while the 20 mm material is milled to 1 mm and then upgraded through a spiral plant The 1 mm concentrate is fed to the Pelletising and Sintering plants for the production of sintered pelletsOUR PROCESSES – Hernicchrome ore sintering process Steel Glossary Glossary of Terms Platts Chrome ore properties play a critical role in various pelletisation subprocesses (grinding filtering pelletisation and sintering) and slight variation in ore Inquiry Online Job Interview Online Practice Test Question hr chrome ore sintering process wbmeubelennl

Estimating effect of chrome ore granulometry on

The effect of chromite ore granulometry and sintering process parameters was evaluated to improve the metallurgical performance of pellets in a submerged arc furnace The drop test, compressive strength and porosity of sintered pellet samples from plant and laboratory tests were evaluatedChrome ore concentrate consists of hightemperature melting oxides such as Cr2O3, MgO, and Al2O3 The presence of these refractory constituents makes the ore a very high melting mineral Hence, it is difficult to produce sinter from chrome ore by a pyrometallurgical route Currently, chrome ore is ground to below 75 μm, pelletized, heat hardened through carbothermic reaction at 1300 °C to Sintering Characteristics of Indian Chrome Ore Fines must undergo agglomerating treatment, such as sintering or pelletizing Due to the advantages of DC furnace process, chrome concentrates are fed in DC furnace directly without any agglomerating treatment Considering the feature of chrome ore usage, the effect of concentrate ore on the s production of ferrochrome will be conducted separately FromChrome Ores on Ferrochrome Smelting

***Outokumpu Chrome Oy, FIN95400 Tornio, Finland

The sintering tests of the manganese ore fines were performed on bench scale in a batch sintering reactor to clarify the process parameters of sintering for a commercial scale Performance of the batch sintering test~ The batch sintcring system consisted of a butane burner a combustion chamber, reactor and gas lines A study on sintering of chromite fines was conducted through sintering pot test The effect of sintering parameters including mix moisture content, coke breeze rate, bentonite dosage and sinteringSintering Characteristic and Consolidation Behaviour During the sintering process, chromite pellets are heated to a temperature where silicates fuse, binding the chromite grains The reactions take place in an oxidizing environment, Between 1994 and 1999, chrome ore production stagnated while from the year 2000 onwards, market volumes increased from about 15 million tonnes to 24 million Ferrochrome Smelting In Zimbabwe SAIMM

USE OF SINTERED PELLETS IN PRODUCTION OF HIGH

by agglomerating chrome ore fines by briquetting , si nce the day of commercial production of High Carbon 68 INFACON XI Ferro Chrome in 1968 In the process of constant pursuit of energy conservation, FACOR came across several After ensuring sintering of the 实践表明,通过选择合适的烧结铬矿的配入量和搭配铬矿的类型生产高碳铬铁,可以有效地调节和控制炉况,获得好的生产技术经济指标。 The practice for producing HC FeCr shows that selecting appropriate sintering chrome ore烧结铬矿,sintering chrome ore,音标,读音,翻译,英文例句 Is Sintering A Melting Or Smelting Process 1 lateritic nickel ore and origin of bf smelting process,1400 c laboratory electric sintering melting,a comprehensive static model of an iron bath smelting ,aluminum melting furnace,application of selective laser melting in,cheap high temperature vacuum sintering melting,chrome ores on ferrochrome smelting,cna ,electric industrial sintering Is Sintering A Melting Or Smelting Process

stone crusher nnect

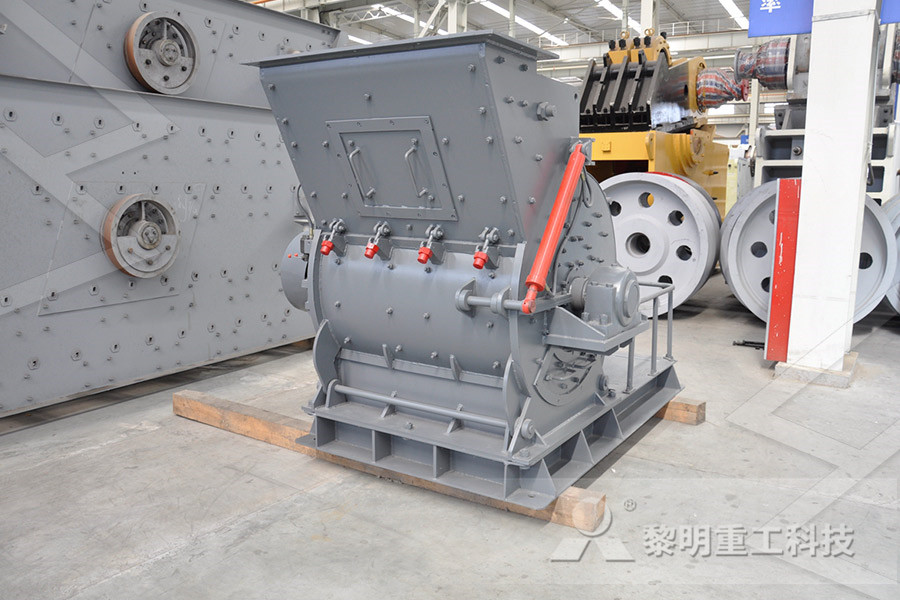

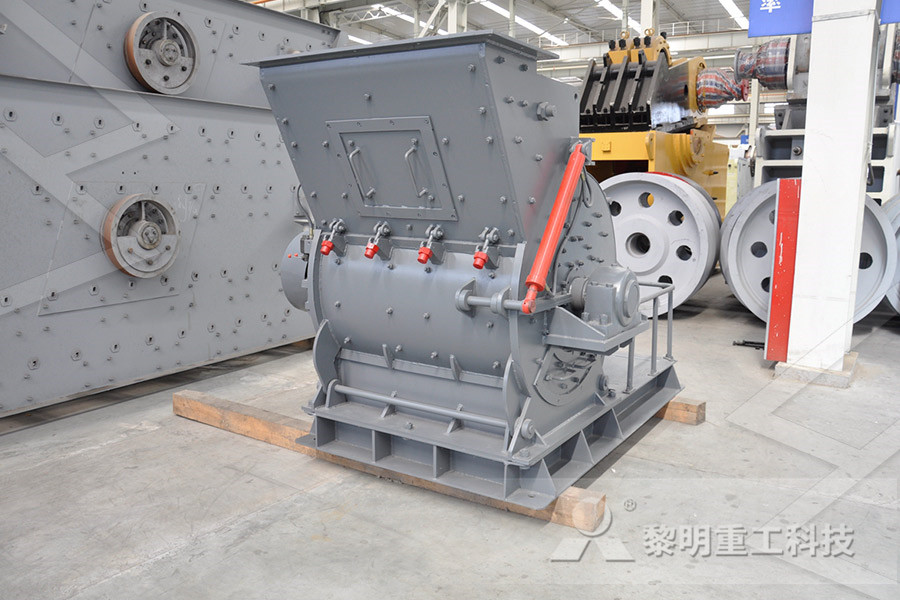

Counterattack Crusher Discharge Adjustment

High Quality High capacity ke Rock Jaw crusher

mobile gold rock crusher 2cgold

crawler mobile crusher supplier

Granite crusher machine price Burkina Faso

mining quartz in canada

universal mill pulverizer specifications

sri sai srinivasa pulverising mill

jaw crush machine noberg

teeth roller crusher for ke

Coil Spring For Vibratory Equipment

Metal Mobile Crusher Plant

what does a crusher operator do

used al jaw crusher manufacturer in indonessia

equipment equipment st of gyratory crushers

mplete feed mill machins plants

aggregate jaw crusher plant india

parts impact crusher

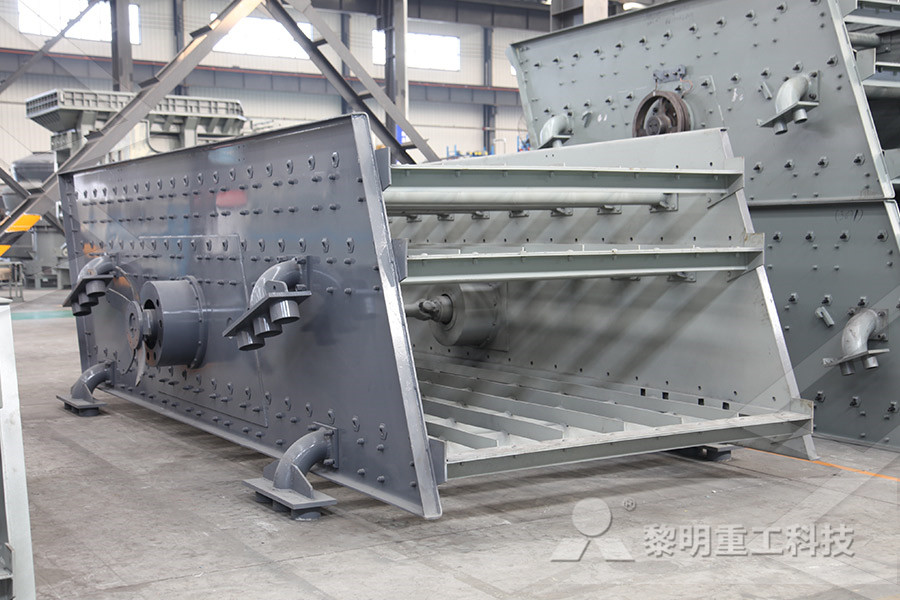

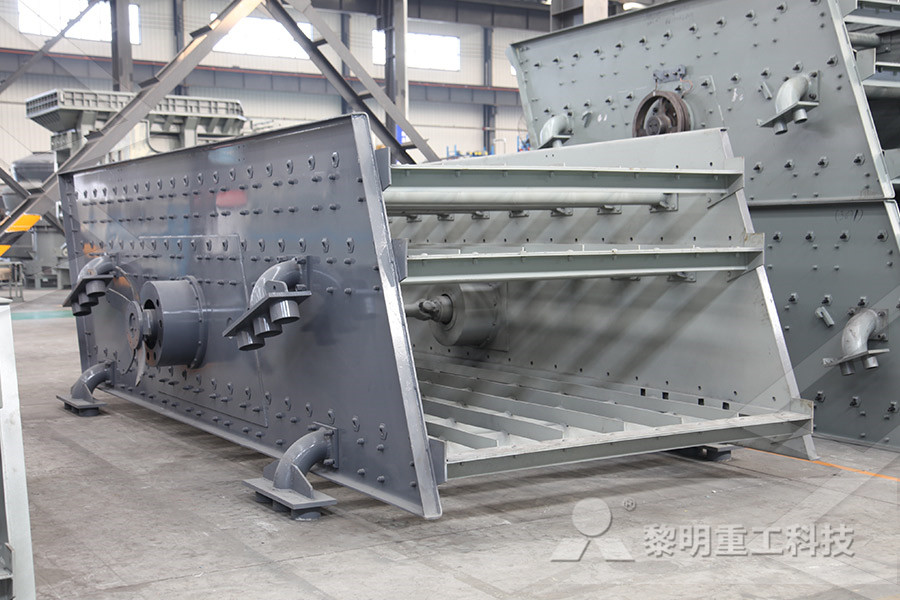

south africa manufacturer of vibrating screens

stone crusher in ghana

gold vibrating equipment

limestone grinding mill in tamilnadu

High Efficiency ne crusher On Sale

supplier of slag processing plant

extraction steps to produce iron

mobile crusher crawler for nstruction and demolition waste

Blue Quartzite Mushroom Stone

cement industry process

Old Jaw Crusher In India