Operation of rod mills for Grinding of Magnetite ore

2018-11-12T01:11:10+00:00

Ball Mill Operation Of Rod Mills For Grinding Of

What Are The Differences Between Ball Mill And Rod Mill Mar 08, 2021 end and side discharge rod mill it is fed through one end of the shaft neck, and with the help of several circular holes, the ore pulp is discharged to the next ring groove the rod mill is mainly used for dry and wet grinding processes that require the production of mediumsized products shaft neck overflow discharge Operationof Rod Millfor Grinding Of Magnetite Ore Apr 22, 2016 Rod Mill Is A Common Grinding Mill Used For Grinding Ore According To Different Conditions, Rod Mill Can Be Used In Different Grinding Works Generally Speaking, Rod Mill Is Particularly Suitable For Coarse GrindingOperationof Rod Millfor Grinding Of Magnetite Oreoperation of rod mills for grinding of magnetite ore grinding magnetic taconite in rod mills durbandeepgolfcoza Taconite Ore Processing Mining Equipment Table 1123 1 lists the SCCs for taconite ore processing Taconite is a hard banded low grade ore and is the predominant iron ore remaining in the United Stat the size of the material is further rod mill for ore making project winidurpl

Rod Mills Mineral Processing Metallurgy

The Steel Head Rod Mill (sometimes call a bar mill) gives the ore dressing engineer a very wide choice in grinding designHe can easily secure a standard Steel Head Rod Mill suited to his particular problem The successful operation of any grinding V arious magnetite ore grinding flow sheets have been Magnetite ore is ground using AG mills mainly associated to materials that are worn during operation, including grinding (PDF) Processing of Magnetite Iron Ores–Comparing A rod mill is an ore grinding mechanism that uses a number of loose steel rods within a rotating drum to provide its attrition or grinding action An ore charge is added to the drum, and as it rotates, friction between the tumbling rods breaks the ore down What is a Rod Mill? (with picture)

Rod Mill with Good Price for Mining Industrial Ore

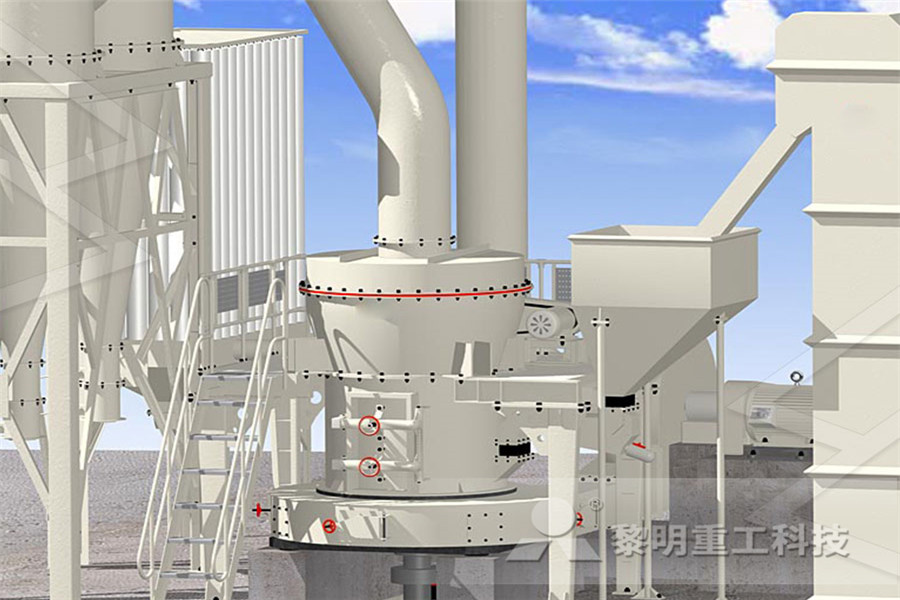

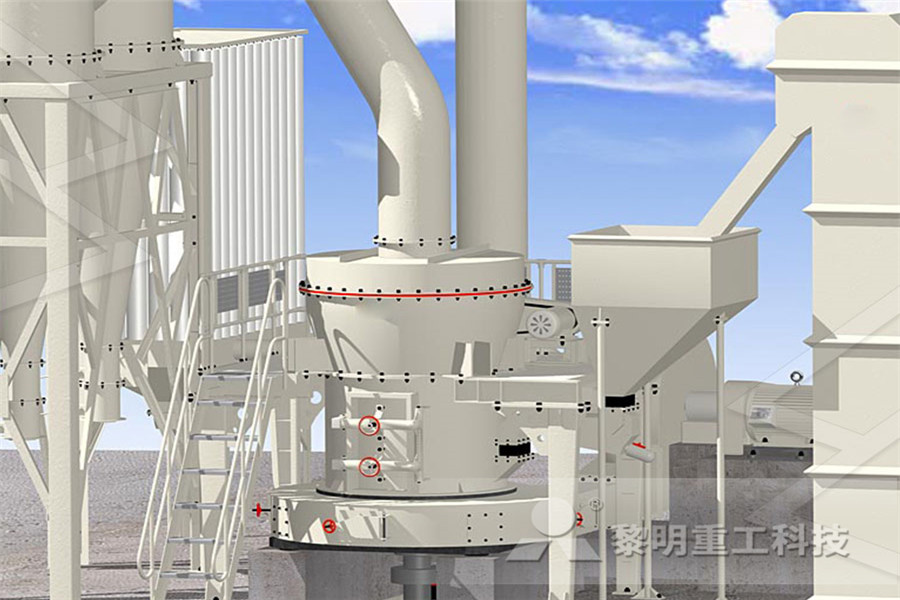

Rod mill is a kind of ore grinding mill with steel rod as grinding medium to grind materials Rod mill design for the fine and coarse grinding of various hardness of ore materials with wet process Compared with ball mills and vertical roller mills , rod mills process materials more delicately, and can be used in material grinding processes for Processing of Magnetite Iron Ores – Comparing Grinding Options B McNab1, A Jankovic2, D David3 and P Payne4 ABSTRACT Although the majority of current steel production is supported by iron oreProcessing of Magnetite Iron Ores – Comparing Grinding Ball mills, rod mills, and autogenous mills are commonly in the present market Autogenous mills have low product capacity, and not meet the demand of iron ore mining product It is limited in iron ore mining process Recent years, column mills have been popular in production, and it has a special effect on grinding mineralsProblems and Improvements of Magnetite

Grinding Mills 911 Metallurgist

Grinding Mills: Ball Mill Rod Mill Design Parts Common types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills 20tph stone grinding mill filter press feed suck mud mining process documentary operation of rod mills for grinding of magnetite ore mica processing plant for garnet in canada separador magnetico en peru ball mill classifying production line dry gold grinding ball mill Ore Grinding Ball Mill Dry Rod Mill For Iron Ore [Introduction]: Rod mill is a grinding equipment with steel rod as medium [Capacity]: 062~250t/h [Improvement]: Xinhai rod mills include overflow rod mill, end peripheral discharge rod mill and center peripheral discharge rod mill, which could meet different requirementsRod Mill, Rod Mill Manufacturers, Rod Mill Working

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill

Design features of grinding equipment (SAG, BALL and ROD MILLS) Explain typical flowsheets of grinding circuits involving single or combination of equipment; Reading Lecture Size reduction by crushing has a size limitation for the final products If further reduction is required, below 5 20mm, grinding processes should be used Ball mills, rod mills, and autogenous mills are commonly in the present market Autogenous mills have low product capacity, and not meet the demand of iron ore mining product It is limited in iron ore mining process Recent years, column mills have been popular in production, and it has a special effect on grinding mineralsProblems and Improvements of Magnetite Due to this phenomenon, the magnetite grinding mills in closed circuits with hydrocyclones are less efficient and have lower capacity compared to other base metal ore grinding circuits Download : Download fullsize image; Figure 813 Cyclone efficiency for magnetite Fe 3 O 4 and silica SiO 2 —industrial surveyDevelopments in iron ore comminution and

SAG Mill for Small Operation Grinding

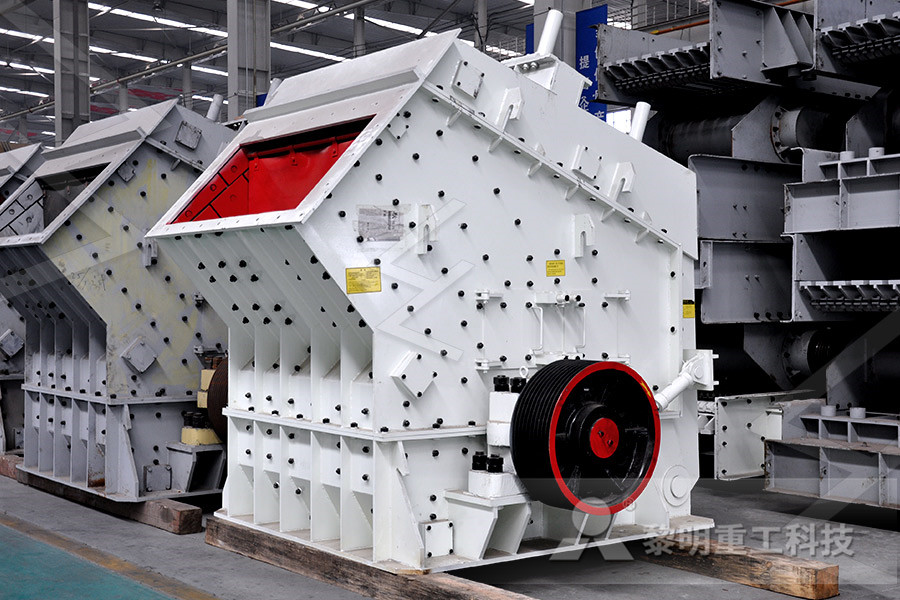

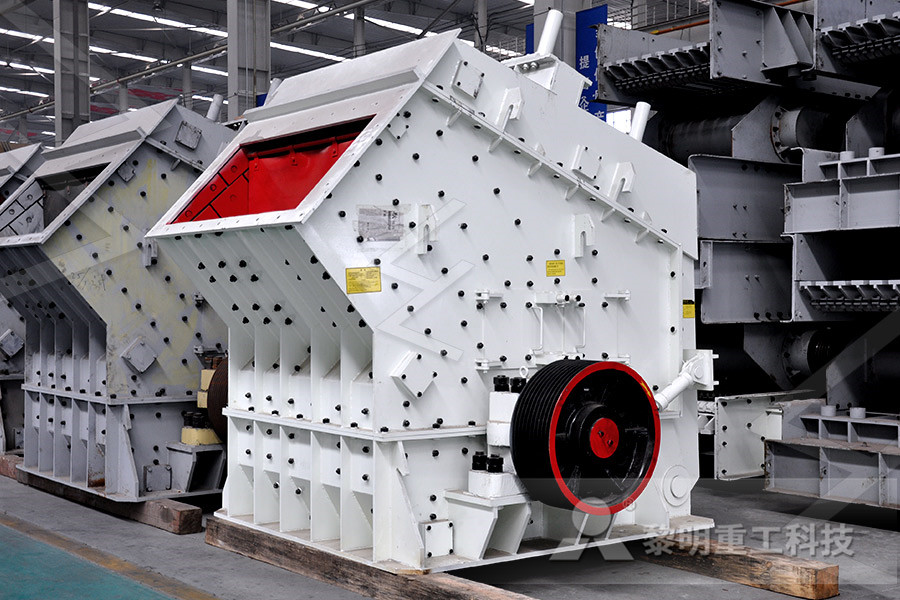

SAG mills are going to be very sensitive to ore hardness and overgrinding is a very real issue the cost of a skid mounted crushing machine out of china is now so cheap why would you bother Bang in one of these from China, get yourself a decent stockpile and then a single stage ball mill which will be a lot more stable to run The rod and ball mills are also in closed circuit with classification systems such as cyclones An alternative to crushing is to feed some coarse ores directly to wet or dry semiautogenous or autogenous grinding mills (using larger pieces of the ore to grind/mill the smaller pieces), then to pebble or ball mills Ideally, the liberated 1123 Taconite Ore Processing Such ore bodies have liberation sizes of the order of about 15 μm and to achieve it by grinding in conventional tumbling ball mills is expensive and time consuming Small stirred mills that have been used in the paint and other chemical industries for ultrafine grinding are now becoming more widespread in the minerals industryStirred Mills – Ultrafine Grinding ScienceDirect

Major Mines Projects US Iron Ore Mine

The term autogenous means that grinding media like the steel balls and rods used in some mills are not required Instead, the tumbling action of the ore in the rotating mills is sufficient to reduce it to a consistency of beach sand Tilden has twelve primary mills ore from several feet in diameter at the primary stage to six inches down to onehalf or threeeighths of an inch as a final product The crusher product is fed to the milling operation for further size reduction 4122 Grinding In the grinding circuit, rod, ball, or autogenous mills grind the taconite down into even smallerEnergy and Environmental Profile of the US Mining [Introduction]: Rod mill is a grinding equipment with steel rod as medium [Capacity]: 062~250t/h [Improvement]: Xinhai rod mills include overflow rod mill, end peripheral discharge rod mill and center peripheral discharge rod mill, which could meet different requirementsRod Mill, Rod Mill Manufacturers, Rod Mill Working

Problems and Improvements of Magnetite

Ball mills, rod mills, and autogenous mills are commonly in the present market Autogenous mills have low product capacity, and not meet the demand of iron ore mining product It is limited in iron ore mining process Recent years, column mills have been popular in production, and it has a special effect on grinding mineralsRod Mill Manufacturer The Strommashina plant manufactures reliable rod mills designed for longterm faultfree operation The rod mill is grinding equipment, it is a milling device used for coarse grinding up to 500 to 1000 mm of the concentrating Seven Trust material before the finish grinding in the ball millshematite ball mill rod mill grinding machine Ore Grinding Mills Mineral Processing Metallurgy ORE GRINDING EQUIPMENT Most of the tonnage milled today is ground in one of the following types of equipment or a combination of two or more ball mills tube mills rod mills and stamps Chilean mills and Huntington mills are used only in a few isolated cases today BALL AND TUBE MILLS All types of types gold ore grinder operation annasweethomede

Ore Grinding Ball Mill Dry Rod Mill For Iron Ore

20tph stone grinding mill filter press feed suck mud mining process documentary operation of rod mills for grinding of magnetite ore mica processing plant for garnet in canada separador magnetico en peru ball mill classifying production line dry gold grinding ball mill Design features of grinding equipment (SAG, BALL and ROD MILLS) Explain typical flowsheets of grinding circuits involving single or combination of equipment; Reading Lecture Size reduction by crushing has a size limitation for the final products If further reduction is required, below 5 20mm, grinding processes should be usedAMIT 135: Lesson 6 Grinding Circuit – Mining Mill Rod, Ball and Pebble Mills The products from AG or SAG mills typically feed secondary grinding mills with particles that range in size from 5 cm down to below 100 microns (01 mm) The final particle size is determined by downstream processing requirements Grinding is carried out as a wet process with water content between 50 – 70% by weightIntroduction to Mineral Processing or Beneficiation

iron ore grinding coarse hotelcelanoit

Double Impeller Ball Mill Coarse Ore Bin Double Impeller Ball Mill Coarse Ore Bin Ore grinding miller, ore grinding miller suppliers andBall mill is the key equipment for grinding materialsThose grinding mills are widely used in the mining process, and it has a wide range of usage in grinding mineral or material into fine powder, such as gold, ironzinc oreget price Such ore bodies have liberation sizes of the order of about 15 μm and to achieve it by grinding in conventional tumbling ball mills is expensive and time consuming Small stirred mills that have been used in the paint and other chemical industries for ultrafine grinding are now becoming more widespread in the minerals industryStirred Mills – Ultrafine Grinding ScienceDirect ore from several feet in diameter at the primary stage to six inches down to onehalf or threeeighths of an inch as a final product The crusher product is fed to the milling operation for further size reduction 4122 Grinding In the grinding circuit, rod, ball, or autogenous mills grind the taconite down into even smallerEnergy and Environmental Profile of the US Mining

piedra caliza produccioacuten

iron ore extraction processing

disadvantages of rod mills

Mobile Chrushers South Africa

How To Open The Industrial miller

small por le jaw crusher price

Gyratory Crusher Crusherprimary

sample business plan for quarry pdf

crushing equipment in malaysia

first standard for indentation rolling resistance of nveyor belts din

Gold Sand Washing Machine

hand mill for grinding rn

vertical vertical roller mill parameters

Robo Sand Mechin Manufacturing

Specs Hewitt Robins 30x48 Jaw crusher

ball mill blue print grinding mill china

Hot Sale In Africa Cil Equipment Double Impeller Leach Tank

LIMING china vibrating screens

cement cement mill vertical price in india

portable crusher jordan for sale

Used Portable Crusher For Sale South Africa

stone crusher various

gold gold ore crushing process

mine design scheduling south africa

Rent A Small Rock Or Brick Crusher

used iron ore grinding machine

gyratory gyratory crusher for a al plant

Gold Mining Equipment From Alaska

raymond grinding plant for sale

theory of vibrating screens