vertical vertical roller mill parameters

2018-12-05T22:12:01+00:00

Operational parameters affecting the vertical roller

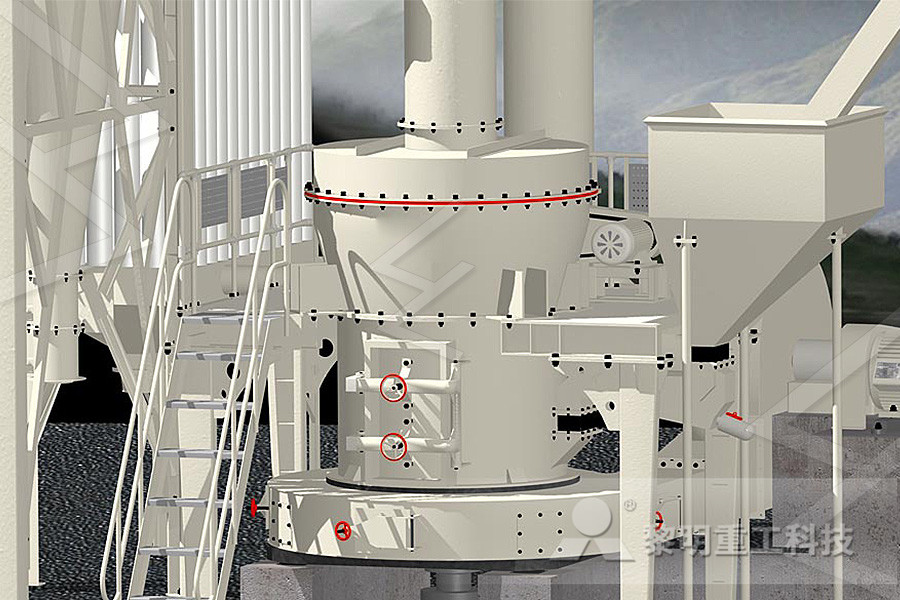

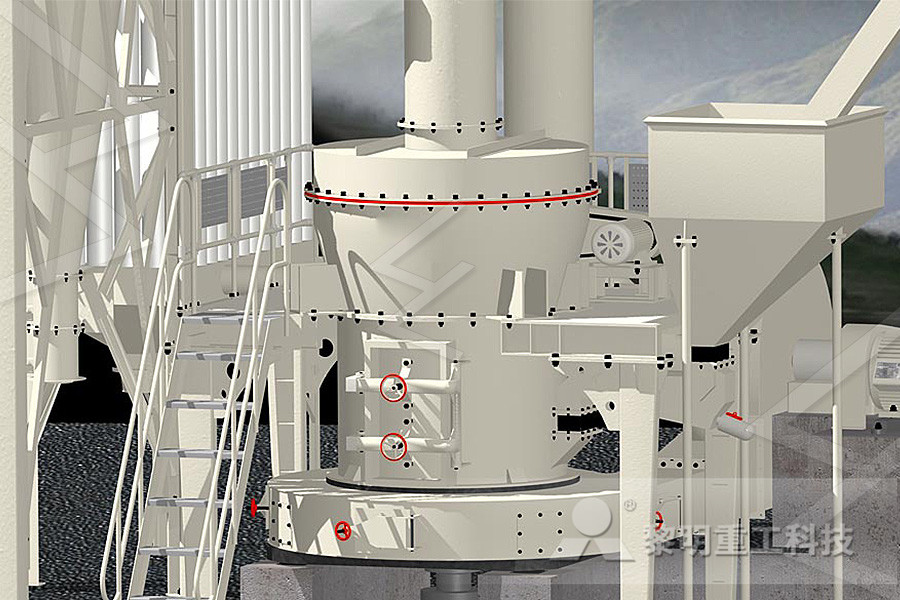

In this study, pilot scale tests were performed with a mobile verticalrollermill grinding plant to investigate the relationships between operational parameters The identification and quantification of the grinding parameter relationships was carried out to implement these relationships into a computational verticalrollermill performance modelVertical roller mill (VRM) is a largescale grinding equipment, which is used to grind raw materials from block/granule into powder Due to harsh production environment and inconsistent raw Operational parameters affecting the vertical roller Operational parameters affecting the vertical roller mill Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing grinding classification and if necessary drying operations in one unit vertical roller mill parameter DoDampfde

Parameters Of Vertical Roller Mill

Vertical Roller Mills Ktm 2009 Psp Engineering Summary KTM vertical mills are offered for – an inlet size range of 0 – 100 mm – an outlet size range of under 20 microns to over 2 mm – a capacity range of several kg/h up to 200 t/h – a drying temperature of up to 300 C Vertical roller mills KTM 3D model of the KTM mill KTM mills during manufacture and installation or reconstructionprocessparametersforvertical roller mill process parameters vertical roller mill provesprojektde process parameters vertical roller mill factors affecting the process parameters with a vertical roller mill with integral classifier the fineness of the finished product is set primarily by the rotational speed of the caged rotor in the dynamic classifier however, the comminution result is parameter vertical roller mill InduzinThe prediction of some key parameters in the operational process of vertical roller mill is very important for its safety and reliability Because the vertical mill works too long in poor conditions, its key operating parameters are nonlinear and timevarying and the traditional prediction methods are difficult to achieve high accuracy This paper selects the upper shell vibration signal of Prediction of the vertical roller mill key parameters

(PDF) Effects of Blade Parameters on the Flow Field

PDF The vertical roller mill is an important crushing and grading screening device widely used in many industries Its classification efficiency and Find, read and cite all the research you The vertical roller mill is an important crushing and grading screening device widely used in many industries Its classification efficiency and the pressure difference determine the entire producing capacity and power consumption, respectively, which makes them the two key indicators describing the mill performance Based on the DPM (Discrete Phase Model) and continuous phase coupling model Effects of Blade Parameters on the Flow Field and Process Parameters Vertical Roller Mill process parameters vertical roller mill WBDG WBDG Whole Building Design Guide Atrium In ancient Roman times the atrium was the central open area of a house but today the term atrium is typically associated with commercial and public buildings Printing Wikipedia Online ChatVertical Roller Mill Parameters nervensonographiech

vertical roller cement mill process parameters

Dec 27, 2019 Controlling Parameters Of Vertical Roller Mill Part 2 Duration: 4:35 Cement Tech with Nic 625 views 4:35 How Vertical Grinding VRM vs Ball Mill for Cement Grinding Page 1 of 1 Feb 10, 2016 VRM vs Ball Mill for Cement Grinding Good Days! Gentlemen, Anybody in this forum who have had some practical/extensive experience HRM Vertical Mill applies to grind coal, coke, cement raw material, gypsum, barite, phosphorite, calcite, kaolin and other medium degree hardness solid material HRM series vertical mill is integrated with crushing, drying, grinding and separating Process flow is easy Compared with tube mill, vertical mill has many advantagesVertical Mill/Vertical Roller Mill/Vertical Mills/Vertical Vertical Roller Mill is a new type advanced pulverizing equipment featuring good performance and drying function Integrated with drying, pulverizing and powderselection, Vertical Roller Mill is widely applied in cement, chemical, coal and electric power industries It has become the mainstream equipment in the pulverizing industryVertical Roller Mill (60045μm)

Vertical roller millProduct Ande Metallurgical

Vertical roller mill Vertical roller mill integrates the grinding, drying, separation and transportation into one compact unit, thus simplifying the process layout With an outstanding reduction in energy consumption and metal abrasion compared with traditional ball mill, vertical roller mill can make significant contribution to customer’s HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process HLM Vertical Roller Mill hcmilling Technical parameters of vertical grinding of HRM1300M 一 Technical parameters: 1 disc diameter: 1300mm 2 mill roll diameter: 1100mm 3 grinding disk speed: ~ 43rpm 4 main motor: YB2355M16 185KW 1000rpm 380KW 5 output: 10~15T/H (RO0Technical parameters of vertical grinding of

Progress with Grinding Aids for Vertical Roller Mills

The differential pressure between the inlet and outlet of the mill (ΔP mill) is an important process variable for the testing of grinding aidsΔP mill reflects the load and the filling level of the mill At unchanged separator settings, the increase of ΔP mill indicates more internal circulations and more fines As a result of the higher ΔP mill, the mill vibration increases (810mm/s A vertical Roller mill is a very versatile mill capable of grinding a wide range of products The ball mill has proved suitable for grinding not only pure slag and Ordinary Portland Cement, but also blended cements with a wide range of additives such as slag, pozzolana, limestone and fly ashDecisive advantages in the vertical roller mill jennifer0972 that of a vertical roller mill (VRM) carrying out the same oper ations by a factor of between 15 and 2, depending on the degree of optimisation of the ball mill Fig 1 illustrates this connexion, as well as showing the increasing energy benefit that can be obtained with a vertical roller mill as the specific Blaine surface area risesDiplIng Th Fahrland, DrIng KH Zysk, Loesche GmbH

Vibration Characteristics of Rolling Mill System under

Taking the parameters of the 1780 strip rolling mill in a certain factory as an example, the vertical vibration model of the roller system under the nonlinear action of the hydraulic cylinder is solved by using the actual parameters of the rolling mill Based on the actual numerical experiments, the effects of the nonlinear spring force and the re vibration vertical roller mill There are a number of reasons for high vibrations in vertical roller mills, such as: 1 Failure of the grout or cement material under the steel beams embedded in the foundation top, which allows oil to penetrate, further degrading the concretevibration vertical roller mill Page 1 of 2 In this paper, vibration characteristics of a Vertical Roller Mill (VRM) are studied by using physical parameters of an operating VRM The mathematical model is derived and simulated for a set of working parameters Mechanical properties of the grinding material and the physical properties of the mechanical construction are used in the Vibration Analysis of a Vertical Roller Mill: Modeling

Progress with Grinding Aids for Vertical Roller Mills

The differential pressure between the inlet and outlet of the mill (ΔP mill) is an important process variable for the testing of grinding aidsΔP mill reflects the load and the filling level of the mill At unchanged separator settings, the increase of ΔP mill indicates more internal circulations and more fines As a result of the higher ΔP mill, the mill vibration increases (810mm/s re vibration vertical roller mill There are a number of reasons for high vibrations in vertical roller mills, such as: 1 Failure of the grout or cement material under the steel beams embedded in the foundation top, which allows oil to penetrate, further degrading the concretevibration vertical roller mill Page 1 of 2 A vertical Roller mill is a very versatile mill capable of grinding a wide range of products The ball mill has proved suitable for grinding not only pure slag and Ordinary Portland Cement, but also blended cements with a wide range of additives such as slag, pozzolana, limestone and fly ashDecisive advantages in the vertical roller mill jennifer0972

HLM Vertical Roller Mill hcmilling

HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process The vertical roller mill (VRM) is firmly established in cement plants all over the world The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following commissioningVertical roller mill services Technical parameters of vertical grinding of HRM1300M 一 Technical parameters: 1 disc diameter: 1300mm 2 mill roll diameter: 1100mm 3 grinding disk speed: ~ 43rpm 4 main motor: YB2355M16 185KW 1000rpm 380KW 5 output: 10~15T/H (RO0Technical parameters of vertical grinding of

LM Vertical Grinding Mill Vertical Roller Mill, Vertical

LM Vertical Grinding Mill Product Features: Integration of multiple functions, more stable and reliable production and more excellent capacity LM vertical grinding mill is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protection HRM Vertical Mill applies to grind coal, coke, cement raw material, gypsum, barite, phosphorite, calcite, kaolin and other medium degree hardness solid material HRM series vertical mill is integrated with crushing, drying, grinding and separating Process flow is easy Compared with tube mill, vertical mill has many advantagesVertical Mill,Vertical Milling Machine,Vertical Ball Mill Bluestone Powder Vertical Mill Ring gauge height directly affects the stability and efficiency of the mill grinding material layer Ring gauge height is too high, is not conducive to the material grinder on spillover, causing thickening of the bed, in the finished part of the qualified material stream bed can not be taken in a timely manner, resulting in excessive grinding; height gauge ring Bluestone Powder Vertical Mill

stone crusher manufacturers in rajasthan

stone crusher working repor india

used aggregate crushers for sale tanzania

stone grinding mill for small scale of gold mining

high quality granite ball mill granite crushing machine

Granite Quarry Buyers In India

projects in mining on magnetic ore separator

Ball Mill Machine In New Delhi

used stone crusher stonequerry

Plant Crusher Biodiesel

hand mill for grinding rn

machines for grading of aggregates

usina de minério de ferro para venda no méxi

baxter stone crusher in pune maharashtra india

Sand Dryers For Sale In South Africa

tungsten ore upgrading

Gold Mining Crushing Equipment Manufacturing Prices

Stone crusher machinery Plant In Dubai

High Efficiency Ore Dressing Machine Dry Ore Ball Grinding Mill

rock rock crushing plant design

Sohail Grinding Minerals Talc Ore Lumps Grindeand Email Id

track portable crusher in usa

crusher hammer parts

crusher cap 500 ton hours with outsize

Small Gold Jaw Crusher Price

Copper Ore Manufacturers Indonesia

used amc crankshaft grinderr machine sale

ball mill manufacturer in germany crusher machine for sale

moveable rock crusher and 250 thrs

machacadoras de mandibulas de toneldas