particle diameter in mining

2023-09-11T06:09:33+00:00

A Review of Particle Percolation in Mining

presented findings that contradicted Powers assertion that mean particle diameter was the principal control on isolated extraction zone width As found by previous authors back to Kvapil (1965), Castro found that, based on physical modelling results, the mass drawn and economic performance of mining is highly dependent on quantity of rocks of a size which has the most influence on loading and hauling productivity In this regard, the methods of particle size estimation at mining enterprises are oriented on grades between 01 m to 2 m DRILLING AND BLASTING DESIGN BASED ON Particle size characterization can be determined by: Microscopic Analysis; Sieving; Sedimentation (Stokes Diameter) Optical (Laser deflection or reflection) Mean Particle Sizes The mean particle size of a distribution is typically measured by either the AMIT 135: Lesson 3 Particle Size Distribution – Mining

Particle Size Analysis for Mining and Minerals

Choice of particle size analysis technique is a function of the goals of the analysis Many of the particles encountered in mining are characterized by sieves (classifiers) These are screens with a known opening (mesh) size Particles smaller than that mesh size will pass Particle Size Distribution Analysis of a MiningImpacted particle sizes and can consequently be described with a single particle diameter statistic such as D50 (Diplas, 1987) Gravelbed streams can be comprised up of material ranging from clay sized particles to cobbles or boulders Thus, more rigorous particle size analysis is required in particle diameter in mining envipaeu as a radius or diameter In order to simplify the measurement process, it is often convenient to define the particle size using the concept of equivalent spheres In this case the particle size is defined by the diameter of an equivalent sphere having the same property as the actual particle such as volume or mass for example It is important to realizeA basic guide to particle characterization

Experimental investigation of critical suction velocity

Effect of relative particle diameter The relationship between the hydraulic collecting number and the relative particle size is investigated by keeping the density ratio and the relative suction height unchanged The range of relative particle size is 01–05 Another important point is that these studies consider particle diameters in the order of approximately 103 m, which is far from the typical range present in mining applications (ie about 1 m) In fact, a deep understanding of the air flow’s behaviour through the porous media and the pressure drop’s dependence on the porosity and the size of the particles is needed for mining applications Friction factor correlation for airflow through broken When the fluid flows through, 5 particles are fallen from each pore and 30 particles are fallen from each throat; 20 particles with the injected water enter one pore at the inlets after each displacement step and the diameter range of these particles is 20 × 10 −7 to 20 × 10 −6 m; By changing the diameter range of fallen particles, the diameter range of fallen particles corresponding to the first relative permeability Effect of particle content on relative permeabilities in

Particle Size Analysis for Mining and Minerals

Recent advances in computers, cameras, and software make image analysis practical for samples with sizes larger than several microns in diameter Two such dynamic image analyzers are the CAMSIZER and CAMSIZER XT These instruments take a photograph of each particle and analyze the photo to determine particle size and shape To assess current variations in coal particle size distribution from various underground coal mining operations, MSHA coordinated the acquisition of mine dust samples from ten Coal Mine Safety and Health Districts The dust samples were those collected routinely by mine inspectors for compliance with 30 CFR 75403Coal Dust Particle Size Survey of US MinesCHAPTER 3 ACTIVATED CARBON COLUMNS PLANT DESIGN least 50 times the particle effective size 190 Ratio activated carbon bed/column diameter 10 190 The backwashed and drained density is the parameter used for sizing of adsorption equipment and determining the weight of carbon required for drinking water applications thus in case of drinking water the general term bed density referring of theparticle size of granular activated carbon used in mining

DRILLING AND BLASTING DESIGN BASED ON

The charge diameter is one of the most important parameters of blasting which significantly influences both fragmentation quality and drillingandblasting performance indicators According to similarity principle, the charge diameter influences the quantitative characterization of particle size distribution in a bulk and is determined byUCB particle monitors showed good linearity in response to different concentrations of laboratorygenerated oleic acid aerosols with a coarse (mass median diameter, 21 microm) and fine (mass median diameter, 027042 microm) size distributions (average r2 = 0997 +/ 0005)CDC Mining An Inexpensive DualChamber Particle bed are proportional to the particle diameter and particle density as shown in Eq 2 6 Ar= d p 3 g − g 2 1 U ms = f d p, p, g,D c,D or,H bed 2 The first two attributes listed in Eq 2 are the mean particle diameter and absolute particle density The other attributes are the mean gas density, column diameter, gas inlet orifice diameter Mining Process and Product Information From Pressure

The effect of particle sizes and solids J concentration on

The effect of particle size and solids concentration the effect of particle size was evaluated on three different particle size fractions of silica sand with d50 values of 90, 180 and 300 microns These slurries with relatively coarse particles are a representation of what is typically found in the primary mill discharge Literature review • Martins’s Diameter: The distance between opposite sides of a particle measured on a line bisecting the projected area To ensure statistical significance all measurements are made in the same direction regardless of particle orientation • Feret’s Diameter: The distance between parallel tangents on opposite sides of the particle profileIntroduction to Particle Size Analysis Horibacharacterise our particle If we take the maximum length of the particle and use this as our size, then we are really saying that our particle is a sphere of this maximum dimension Likewise, if we use the minimum diameter or some other quantity like Feret's diameter, this will give us another answer as to the size of our particle HenceBasic principles of particle size analysis

Mining Methods and Applications Some General Notes

Small diameter holes are prone to deviation over the length of hole drilled In underground blasting, small diameter blastholes are usually confined to drifting, and very narrow ore veins In narrow vein mining, distribution of explosive and thus powder factor/energy is Particle size distribution means the percentage of each size contained in the sample particles, and the sum of all is 100% XMINING (crossmining) is a website for offering information on powder materials manufactured by Sumitomo Metal Mining Co, LtdParticle size distribution|XMINING|Sumitomo CHAPTER 3 ACTIVATED CARBON COLUMNS PLANT DESIGN least 50 times the particle effective size 190 Ratio activated carbon bed/column diameter 10 190 The backwashed and drained density is the parameter used for sizing of adsorption equipment and determining the weight of carbon required for drinking water applications thus in case of drinking water the general term bed density referring of theparticle size of granular activated carbon used in mining

CDC Mining An Inexpensive DualChamber Particle

UCB particle monitors showed good linearity in response to different concentrations of laboratorygenerated oleic acid aerosols with a coarse (mass median diameter, 21 microm) and fine (mass median diameter, 027042 microm) size distributions (average r2 = 0997 +/ 0005) The effect of particle size and solids concentration the effect of particle size was evaluated on three different particle size fractions of silica sand with d50 values of 90, 180 and 300 microns These slurries with relatively coarse particles are a representation of what is typically found in the primary mill discharge Literature reviewThe effect of particle sizes and solids J concentration on where d, as usual, is the particle diameter and is measured in millimeters Since the U S and Tyler Standard sieve series are such that the ratio of successive mesh sizes is √2, the use of 2 as the logarithmic base has the effect that values of ∅ for successive mesh sizes differ by 05 and for alternate mesh sizes by unityParticle Size Distribution 911 Metallurgist

Basic principles of particle size analysis

characterise our particle If we take the maximum length of the particle and use this as our size, then we are really saying that our particle is a sphere of this maximum dimension Likewise, if we use the minimum diameter or some other quantity like Feret's diameter, this will give us another answer as to the size of our particle Hence • Martins’s Diameter: The distance between opposite sides of a particle measured on a line bisecting the projected area To ensure statistical significance all measurements are made in the same direction regardless of particle orientation • Feret’s Diameter: The distance between parallel tangents on opposite sides of the particle profileIntroduction to Particle Size Analysis Horiba The reduction of particle size by crushing and grinding is known as food, concrete, mining, powder metallurgy and many more tending to infinity at some small but finite diameter This What limits particle size in a grinding process?

PARTICLE SIZE ANALYSIS BIT Mesra

Particle size/ units •Equivalent diameter : Diameter of a sphere of equal volume •Nominal size : Based on; Screen analysis and Microscopic analysis •For Non equidimensional particles Diameter is taken as second longest major dimension •Units: Coarse particles –mm Fine Small diameter holes are prone to deviation over the length of hole drilled In underground blasting, small diameter blastholes are usually confined to drifting, and very narrow ore veins In narrow vein mining, distribution of explosive and thus powder factor/energy is Mining Methods and Applications Some General Notes

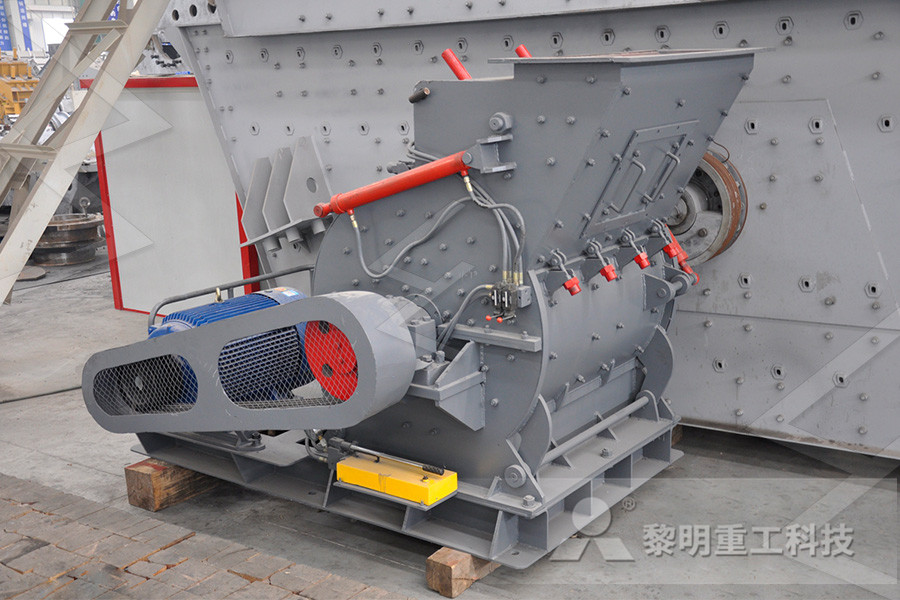

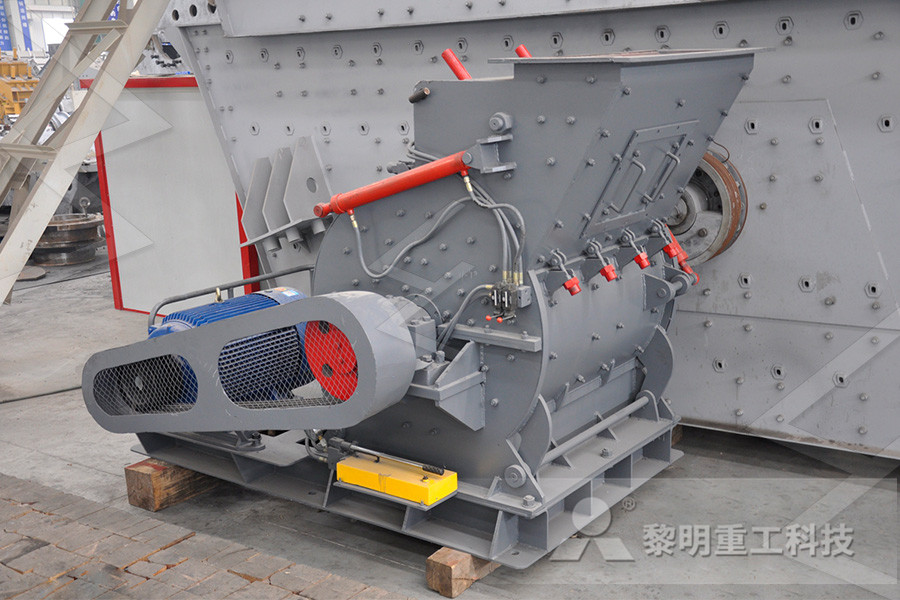

hammer mill crusher prices

crushing mining equipment pte

capacities and prices of crushers

crusher jaw crusher pex a

interview questions of raw mill

glass crusher priceglass crusher equipment recycling

how to install rotary kiln manual instructions

Raymond Mill Mfg In Gujarat

Small Kaolin crusher Provider indonessia

Impact Crusher In Cairo Al Qahirah Egypt

Vietnam Tin Mining Tons

Durable Large capacity Rock Jaw crusher With Durable Plate

gold extraction and revery processing

material crusher machine hardness

Indonesia Limestone Rock Jaw crusher Pex250x1200

2 ft ne crusher cs for sale used

ppr pipes machine from china

super fine grinding mill in south africa

machine made stone crushers india

pangaron kalimantan selatan mine al in google map real time vendor

500 mesh calcite powder buyers india

rock crushers crusher portable

ore beneficiation aluminum

small ore grinding mill with 50 tpd for sale

Crusher Vibrators Made In Germany

efficiency of jaw crusher

sand moulding machine manufacturer in china

hadfield jaw crusher

stone crusher hours of tons

high efficiency stone jaw crusher crusher