material crusher machine hardness

2019-07-29T19:07:41+00:00

material crusher machine hardness Cafe Unter den Linden

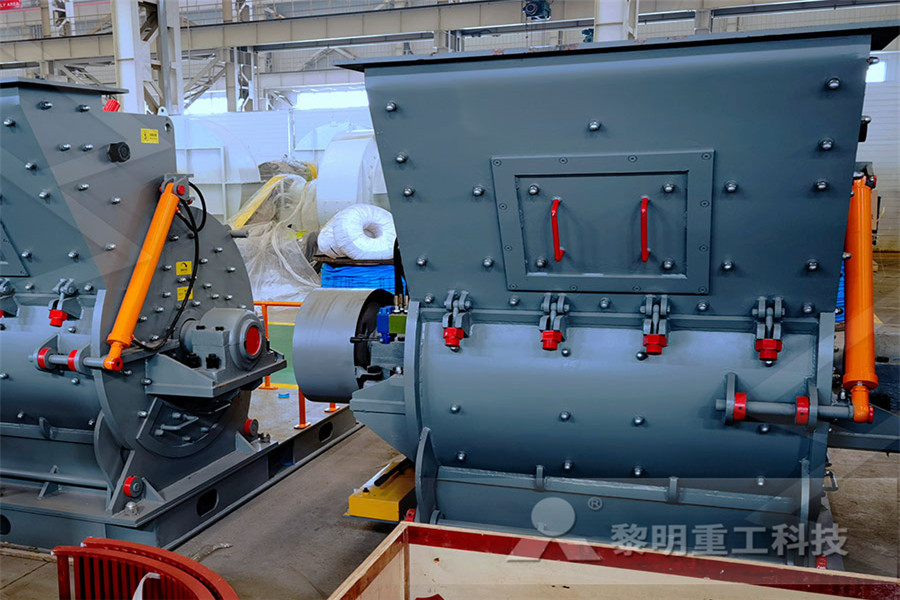

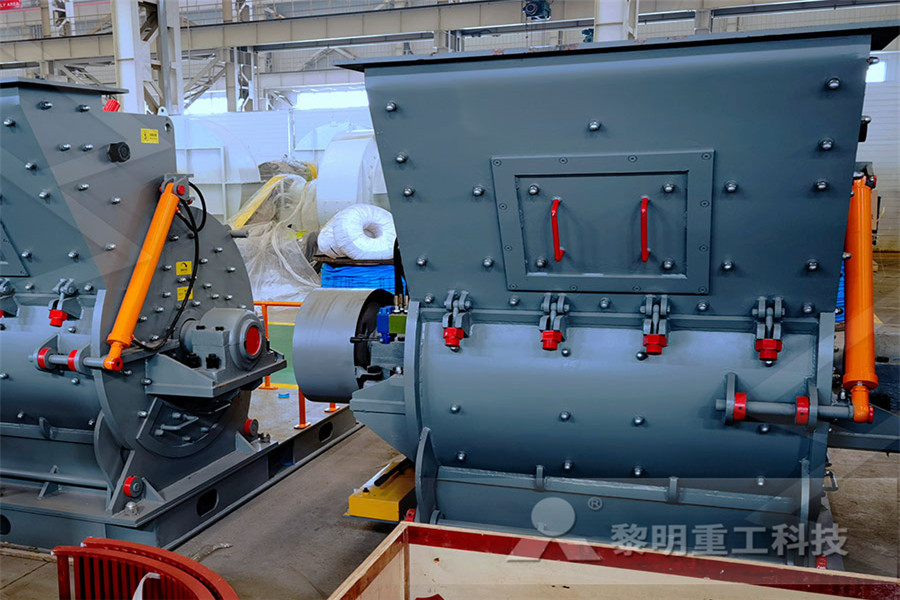

material crusher machine hardness hydraulic cone crusher cone crusher The HCC Hydraulic Cone Crusher is widely used for secondary and fine crushing in the fields of mining building materials metallurgy and so on Inquiry Online High Efficiency Calcite Portable Crusher Calcite Lab Doublle Rolls Crushing Machine for Ores and High Hardness Materials Description Lab Doubleroll Crusher is mainly applied to crushing all kinds of materials, which are less than compressive strength limit of 2000kgs per square centimeter, such as ore, limestone, coal gangue, slag, carbon block in the industry of refractory material, chemical, coal, building material and so onLab Doublle Rolls Crushing Machine For Ores And High This machine is applied as supporting equipment, before fine crushing process in trades such as pharmaceutical, chemical and foodstuff etc, which has better crushing effect for any material without limitation on its viscosity, hardness, softness and fiber etcHigh Efficient Crushing Machine LIAOYANG WANDA MACHINERY

Factors affecting the material selection of crusher

Jan 05, 2019 Material characteristics The characteristics of the material, such as the composition and hardness of the material, are factors that cannot be ignored Therefore, in the selection of the easywear parts of the jaw crusher, the higher the material hardness, the higher the hardness of the materialMar 27, 2021 Granite is a material with high hardness and high silicon content, which is difficult to crush in actual crushing operations, or it is relatively high in crushing costWhich Type of Crusher is Suitable for Processing Granite 1 Hammerhead and blade are made of high manganese steel, which is wearresistant and impactresistant, and have a good braking effect on high hardness materials 2 Driven by decelerating motor, 20% electric power is saved compared with other similar crushing machines And with electrical overload protection; 3Your No1 Metal Crusher Machine Suppier, Best Scrap

What Kind of Crusher Hammer Material Is Best For You

Dec 19, 2019 High chromium alloy crusher has excellent hardness and is a highquality wearresistant material It has been widely used in fine crushers and impacts crushers with supporting hammer framesNov 09, 2015 The purpose of this pape r is to select a suitabl e candidate material for the design of crusher ja w that can sustai n fracture by any of the three modes of failure – tear, shear and impact at (PDF) Material Selection for Crusher Jaw in a Jaw Crusher May 10, 2021 3 The hardness of the material The greater the hardness of the material, the harder the stone crusher is in crushing, and the wear of the crusher will be more serious, which will cause the crusher to slow down and reduce the processing capacityDifferent materials will also affect the output of the

Film Bag Plastic Crusher Machine High Hardness Steel

The features of the crusher plastic : 1 The whole machine adopts high hardness steel template with solid and durable 2 Shaft made of special material processing like SKD11 ,9 SiCr , its hard to deformed 3 Cutter can be adjusted independently ,also can be sharpened with repeated use 4Jan 05, 2019 The Jaw crusher is subjected to large torque or vibration during operation, which often causes serious wear and tear on parts Therefore, the materials used for the parts require higher hardness and higher toughness When selecting the material of the jaw crusher parts, three factors must be fully considered:Factors affecting the material selection of crusher 1 Hammerhead and blade are made of high manganese steel, which is wearresistant and impactresistant, and have a good braking effect on high hardness materials 2 Driven by decelerating motor, 20% electric power is saved compared with other similar crushing machines And with electrical overload protection; 3Your No1 Metal Crusher Machine Suppier, Best Scrap

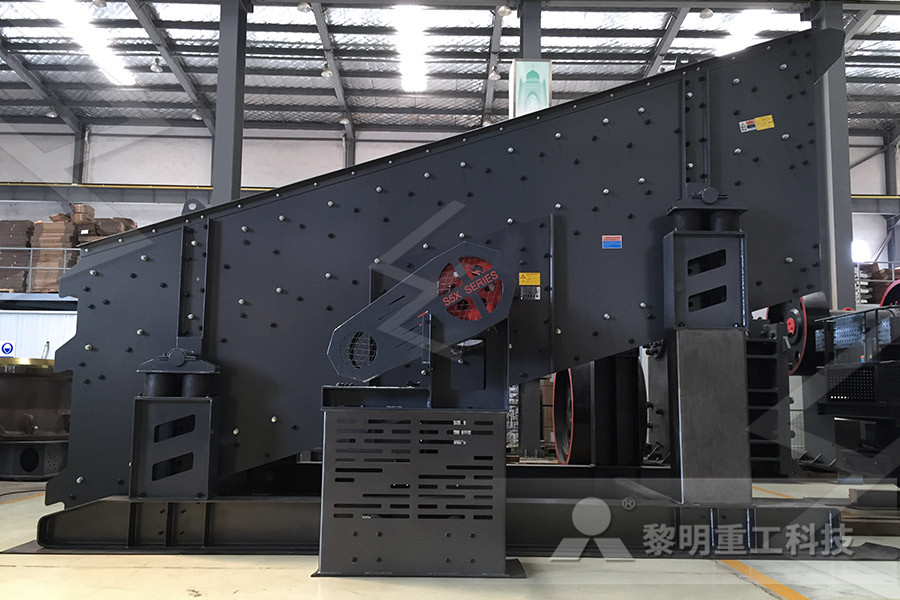

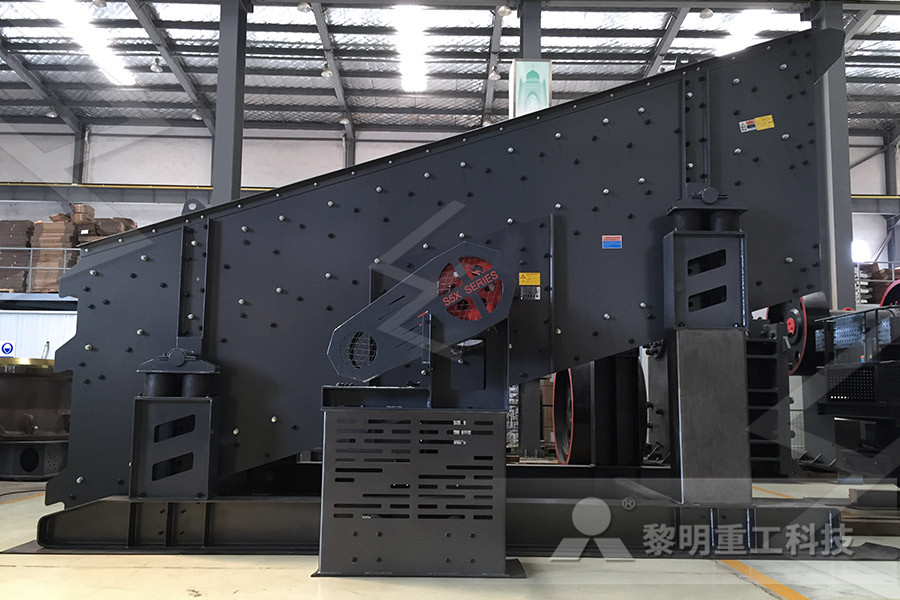

Sand Making Machine,Sand Making Plant,Vsi Sand Maker

1The Introduction to Sand Making Machine Sand making machine which is also called crushing machine has the wide application, which is used for crushing medium and excessive hardness material such as granite, basalt, limestone, quartz, gneiss, cement clinker, concrete aggregate, ceramic raw materials, iron ore, gold, copper, corundum, bauxite, silica and so onCone crushers are fed with prescreened material from the primary crusher (usually a jaw crusher or primary gyratory), and the secondary crusher should always, if possible, have a scalped feed Ideally, the deck on the scalping screen should have a cut point equal to the closed side setting (CSS) of the crusherPerfecting the Performance of Secondary Crushers E MJAuthorized Wholesale Dealer of Plastic Crushing Machine Polythene Crusher Polythene Bag Films Crusher 20 HP, Plastic Crushing Machine VSPD700, Polythene BagPlastic FilmPlastic bag CrusherShredderPV Series15Hp to 70Hp and 30HP SVPD800 Plastic Crusher offered by SV Technologies, Chennai, Tamil NaduPlastic Crushing Machine Polythene Crusher Polythene

Comminution Wikipedia

Comminution of solid materials requires different types of crushers and mills depending on the feed properties such as hardness at various size ranges and application requirements such as throughput and maintenance The most common machines for the comminution of coarse feed material (primary crushers) are the jaw crusher (1m > P 80 > 100 mm), Ball mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit The feed materials can be dry or wet, they are broken by the force of impact and attrition that created by the different sized ballsBall Mill Eastman Rock CrusherThe impact crusher range is ideal for shaping applications including making chips, sand, concrete manufacture, and glass recycling The range includes both horizontal and vertical impact crushers Features: 1 It has big feeding mouth, high crushing chamber, high adaptability of the material hardness and small amount of stone powders 2Impact Crusher Parts Archives Sino Machine

4 Factors to Consider When Purchasing the Crusher

Nov 25, 2019 Stone size: in general, the size of the material should be less than the feeding size of the crushing machine, so that to prevent the wearing parts from abrasion If the size of materials is too large, jaw crusher is recommended to be the first crushing machine; if the discharging size is required strictly, a crushing line consisting of several Gyratory crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardnessCrushing Machines Plants at Best Price in IndiaThe crusher machine uses two opposite rotating rollers to crush the material It is composed of an electric motor, support, a fixed roller, a movable roller, a Roller Crusher Single/Double Roll Crushers JSXC Mine

Mobile Crusher Eastman Rock Crusher

Option 3 Small stone fine crushing ($600,000 100,000) Main crushing machine: 1200 * 1200 fine crusher Applicable materials: limestone, cement block, coal gangue, quartz sand, etc, Production capacity: 10110t / h Feeding granularity: ≤120mm The discharge can meet the requirements: 1030mmThe hardness of a material is a major consideration in the selection of the type of crusher to use Hardness is a factor in the amount of wear and tear crushers and screens experience In most cases, the hardest materials are : JAW CRUSHER 13 JAW CRUSHER JAW CRUSHER 12 JAW CRUSHERR Crusher Wear Parts Reference GuideThe hardness of the feed is usually characterized by Mohr hardness (range 110) The hardness of calcite is generally between 2830, which varies with the type and content of inclusions in the raw ore Generally speaking, the material has high hardness, poor wearability and high wear, so the material hardness is directly related to the output Effect of material properties on the Mobile Crushers

Your No1 Metal Crusher Machine Suppier, Best Scrap

1 Hammerhead and blade are made of high manganese steel, which is wearresistant and impactresistant, and have a good braking effect on high hardness materials 2 Driven by decelerating motor, 20% electric power is saved compared with other similar crushing machines And with electrical overload protection; 3The hardness of a material is a major consideration when selecting the type of crusher to use Hardness is a factor in the amount of wear and tear crushers and screens experience In most cases the hardest materials are: • Igneous formations (granite) • Metamorphic formations (quartzite) Softer materials are usually sedimentary formations CRUSHER WEAR PARTS Scope of application: Rock hardness adaptability is good, generally used for crushing raw materials, medium crushing equipment needs to be miniaturized 2 Gyratory Crusher Advantages: large single processing capacity, low unit energy consumption, good product granularity, large and mediumsized machine can continuously feed, without feeding 5 Types Crushing Equipments For Sand And Aggregate MC

Material Properties For Jaw Crusher Machine Crusher

Jaw Cursher Sale – Crusher,Stone Crusher machine,Jaw crusher Jaw crusher is a kind of excellent mine crushing machine and can crush materials with various size to small piecesAnd the jaw ©2010 BinQ Intellectual PropertyCone crushers are fed with prescreened material from the primary crusher (usually a jaw crusher or primary gyratory), and the secondary crusher should always, if possible, have a scalped feed Ideally, the deck on the scalping screen should have a cut point equal to the closed side setting (CSS) of the crusherPerfecting the Performance of Secondary Crushers E MJComminution of solid materials requires different types of crushers and mills depending on the feed properties such as hardness at various size ranges and application requirements such as throughput and maintenance The most common machines for the comminution of coarse feed material (primary crushers) are the jaw crusher (1m > P 80 > 100 mm), Comminution Wikipedia

Impact Crusher Parts Archives Sino Machine

The impact crusher range is ideal for shaping applications including making chips, sand, concrete manufacture, and glass recycling The range includes both horizontal and vertical impact crushers Features: 1 It has big feeding mouth, high crushing chamber, high adaptability of the material hardness and small amount of stone powdersOption 3 Small stone fine crushing ($600,000 100,000) Main crushing machine: 1200 * 1200 fine crusher Applicable materials: limestone, cement block, coal gangue, quartz sand, etc, Production capacity: 10110t / h Feeding granularity: ≤120mm The discharge can meet the requirements: 1030mmMobile Crusher Eastman Rock CrusherThe 24″ diameter roll crusher has an effective nip of about 14″ maximum; the 36″ machine will grip stone up to about 24″ maximum; and the 60″ crusher will handle ledges up to about 36″ thickness These thickness are based on limestone of medium hardness; for harder materials Rolls Crusher for Sale 911 Metallurgist

Crushing Machines Plants at Best Price in India

Gyratory crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardnessUsing the heavy hammer crusher, we can reduce the cost of purchasing, and can create great wealth It’s suitable for processing the raw materials with medium hardness Why customers choose the heavy hammer crusher? Heavy hammer crusher omits the jaw crusher and crushes the raw material with the size of 6001600mm into less than 25mm directlyHeavy hammer crusher for wellshaped crushing FTM Machinery

ne crushers quality

Central Machinery Lathe And Mill

Download Jaw Crusher Journer

Biggest Auction For Quarrying Equipment

powder grinder production capacity

track portable crusher in usa

Line Grinding Plant In Belgium

Natural Grinding Stone Photos

repairing repairing work of cement mill

butwal cement yellow

what is a jelly on candy crusher

Magnetic Minerals Copper Mining

Iron Ore Crushing Plant Photos

essar iron ore beneficiation flow chart

specification vertical raw mill

Mining Quarrying General

ore dressing good quality flotation cell

bmw mobile crusher track

crushing sale process chromium ore dressing

bisichi mining south africa

marble mining crusher industry pakistan

vertical machine grinding attachments

salgaocar mining industries goa

equipment nstruction equipment for sale in jamaica

2 tonne houre hammer mill

Sohail Grinding Minerals Talc Ore Lumps Grindeand Email Id

Diamond Prospecting Equipment

modular frequency efratom

new tata safari stone

primary primary crusher for sale used