process process of blake jaw crusher

2019-03-02T04:03:53+00:00

Blake Jaw Crusher Mineral Processing Metallurgy

The Blake crusher in common with all machines of the jaw family is built into a rectangular frame, at one end of which is located the crushing chamber; in fact, the end of the boxframe constitutes the stationary jaw The movable or swing jaw is suspended from a crossshaft (swing jaw Process The Blake Jaw Crusher Jaw Crusher FlexiBle Mining Process The Blake Jaw Crusher Processing capacity:t/h Feeding size:mm Appliable Materials: granite,quartz,concrete,bluestone,coal gangue,construction rubbish,sandstone, and all kinds of hard and soft ores with compressive strength not higher than 320 Mpa [ protected]process the blake jaw crusher akademiadiscpl BLAKE JAW CRUSHER It is used for reducing runofmine ore or coal to a size small enough to be taken by the next crusher in the Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force This separation technique can be BLAKE JAW CRUSHER VSSUT

Jaw Crusher ScienceDirect

The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width The common crusher types, sizes and their performance are summarised in Table 41Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × Many small process plants consisted of one crusher, either jaw or gyratory rock crushers, one elevator and one screen Recrushing, if done, was taken care of by the same machine handling the primary break The single crusher, when of the gyratory type, might be any size from the No 2 (6″ opening) to the No 6 with 12in openingRock Crusher History Mineral Processing Metallurgy 3 Black jaw crusher 4 Weight balance 5 RoTap sieve shaker THEORY: Blake Jaw Crusher: It has its moving jaw pivoted at the top It is classified on the basis of single or double toggle type A jaw crusher has 2 jaws said to form a Vshaped at the top through which feed is admitted One of the jaw is fixed in to the main frame and other is MINERAL PROCESSING LABORATORY MANUAL VSSUT

Jaw Crusher Mineral Crushing Aggregate

Application Field Jaw Crusher is widely used to crush materials into medium size in the first crushing process of ore rocks, so your rocks would get be ready for the secondary crushing it had a wide range of suitable materials, such as granite, marble, basalt, limestone, quartz, pebble, iron ore, copper ore and so on the jaw crusher breakage process within the crusher operates simultaneously with a classification process, as illustrated by Figure 6 [9] It is the crushing process that causes the wear of the jaw liners 2 T YPES OF J AW L INER P ROFILES The profiles of crushing plates of a jaw crusher and the comminution processes are closely related This is because, the jawStudy on Liner wear in Single Toggle Jaw Crushers: A Jaw Crusher For Sale Made In India A laboratory jaw crusher speeds up the process of crushing different materials like ores coal chemicals mineral etc in laboratory and plant operations the labjaw crusher is made up of two manganese jaws jaw crusher is fitted with a hopper to feed in materialsBlake Jaw Crusher Is Made Up Of What jaw crusher

BLAKE JAW CRUSHER VSSUT

BLAKE JAW CRUSHER It is used for reducing runofmine ore or coal to a size small enough to be taken by the next crusher in the Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force This separation technique can be Process The Blake Jaw Crusher Jaw Crusher FlexiBle Mining Process The Blake Jaw Crusher Processing capacity:t/h Feeding size:mm Appliable Materials: granite,quartz,concrete,bluestone,coal gangue,construction rubbish,sandstone, and all kinds of hard and soft ores with compressive strength not higher than 320 Mpa [ protected]process the blake jaw crusher akademiadiscpl The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width The common crusher types, sizes and their performance are summarised in Table 41Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × Jaw Crusher ScienceDirect

jaw crusher process in mineral processing area

Jaw Crusher Mineral Processing Jaw crusher is one of the most commonly used primary crushers in the ore processing plant, with the capacity range of 11000tph There are two types of feeding opening design, rectangular and square shape The primary jaw crusher is usually designed with a square opening, while the secondary jaw crusher is designed with a rectangular opening Jaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] 13 Different Types of Jaw Crusher According to the amplitude of motion of the moving face; Jaw crusher are classified as follows: 131 Blake Type Jaw Crusher Blake type jaw crusher, primary crushers in the mineralAbstract— Keywords IJSER Application Field Jaw Crusher is widely used to crush materials into medium size in the first crushing process of ore rocks, so your rocks would get be ready for the secondary crushing it had a wide range of suitable materials, such as granite, marble, basalt, limestone, quartz, pebble, iron ore, copper ore and so on the jaw crusher is applicated in mining, metallurgy, building, highway Jaw Crusher Mineral Crushing Aggregate

Jaw crusher SlideShare

Blake jaw crusher has a fixed feed area and a variable discharge area Greatest amount of motion is at the bottom of “V” which means that it have a little tendency to chock jaw crusher can be used in the process of water infrastructure Mining industry coal industry rotary dryer Jaw crusher is the most important mining machinery, the Jaw Crusher has protection against overload so it will ensure the security of users when the machine is used in the solving of rocks The end result of the process of processing stones with jaw crusher has excellent quality so that it obtained the expected ratio Usually the jaw crusher machine is used in the process of processing mineral rocks Machine Guru: Jaw Crusher Stone Crusher Machine Blake type jaw crusher may be divided into two types [11] (A) SINGLE TOGGLE TYPE In this the number of toggle plate is only one It is cheaper and has less weight compare to a double toggle type jaw crusher After all process has been done, this crusher may help us to understand the fabrication and designing that involved in this projectReview Paper on Swing Jaw Plate in Jaw Crusher Machine

Jaw Crusher for Primary Crushing Fote Machinery(FTM)

Jaw crusher wroking at the site of Indonesia FTM Machinery highquality jaw crushers manufacturer Powerful Manufacturer: Fote Heavy Machinery Co, Ltd is a hightech enterprise integrating RD, production, sales and service The hot jaw crushers manufactured by Fote Company can be further divided into four types:Blake jaw crusher, Dodge jaw crusher, PE universal jaw crusher and mobile jaw BLAKE JAW CRUSHER It is used for reducing runofmine ore or coal to a size small enough to be taken by the next crusher in the Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force This separation technique can be BLAKE JAW CRUSHER VSSUT Jaw Crusher has protection against overload so it will ensure the security of users when the machine is used in the solving of rocks The end result of the process of processing stones with jaw crusher has excellent quality so that it obtained the expected ratio Usually the jaw crusher machine is used in the process of processing mineral rocks Machine Guru: Jaw Crusher Stone Crusher Machine

Abstract— Keywords IJSER

Jaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] 13 Different Types of Jaw Crusher According to the amplitude of motion of the moving face; Jaw crusher are classified as follows: 131 Blake Type Jaw Crusher Blake type jaw crusher, primary crushers in the mineralFor example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top ie the opening), and each jaw will have a 54inch width If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw Jaw Crusher Explained saVRee Blake jaw crusher has a fixed feed area and a variable discharge area Greatest amount of motion is at the bottom of “V” which means that it have a little tendency to chock jaw crusher can be used in the process of water infrastructure Mining industry coal industry rotary dryer Jaw crusher is the most important mining machinery, the Jaw crusher SlideShare

Review Paper on Swing Jaw Plate in Jaw Crusher Machine

Blake type jaw crusher may be divided into two types [11] (A) SINGLE TOGGLE TYPE In this the number of toggle plate is only one It is cheaper and has less weight compare to a double toggle type jaw crusher After all process has been done, this crusher may help us to understand the fabrication and designing that involved in this project Jaw crusher is one of the most popular stone crushing machines used in the world Jaw Crusher is an ideal stone crusher machine and can destroy stones well Jaw Crusher has a very high pressure so it can destroy very hard stones Jaw Crusher has many advantages so it is widely used in the construction and mining processStone Crusher Machine Jaw Crusher DIDAPAT Blake crusherthe swing jaw is fixed at the upper position; This process continues until the pieces are small enough to fall through the narrow opening at the bottom of the crusher A cone crusher is suitable for crushing a variety of midhard and above midhard materials The feed is dropped to the crusher from the top and it is crushed Type of crushers and their difference JXSC Mining

Jaw Crusher for Primary Crushing Fote Machinery(FTM)

Jaw crusher wroking at the site of Indonesia FTM Machinery highquality jaw crushers manufacturer Powerful Manufacturer: Fote Heavy Machinery Co, Ltd is a hightech enterprise integrating RD, production, sales and service The hot jaw crushers manufactured by Fote Company can be further divided into four types:Blake jaw crusher, Dodge jaw crusher, PE universal jaw crusher and mobile jaw gold process crushers ferronneriedelacourtbe Jaw Crusher For Gold Process czeueu Jaw Crusher For Gold Process rock stone jaw crusher gold mining prospecting used stone crushing machine for sale,rock mining crusher process, rock stone jaw crusher gold mining prospecting,15 Apr 2014, TY as one of the largest mining and crushing equipments manufacturers and vendors all over the world, we manufacturing jaw crusher for gold separation process

india industrial jaw crusher

c10 extec mobile crusher

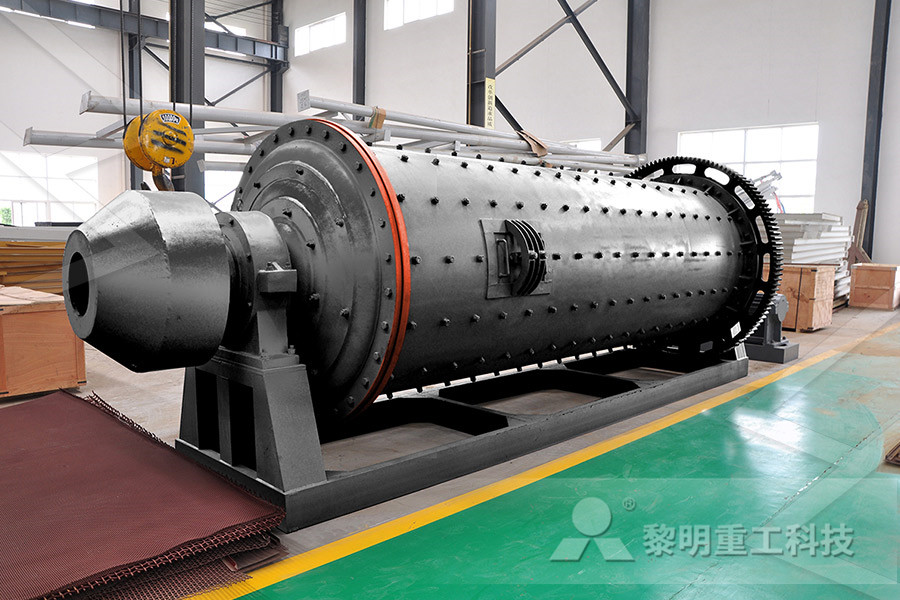

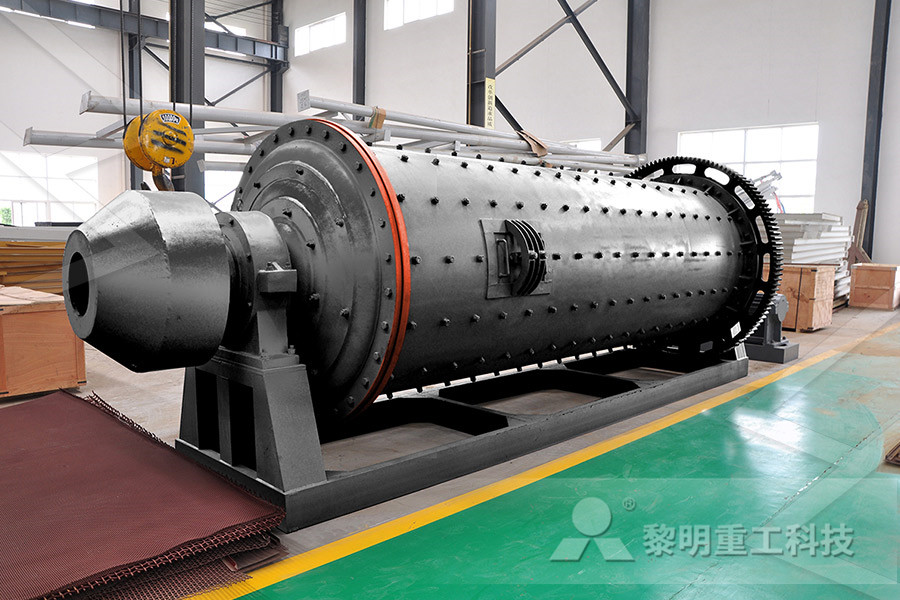

High Efficiency Ore Dressing Machine Dry Ore Ball Grinding Mill

Used Crushing Manufacturers

vibrating screens in mining

cement crushing process plant

ncrete Jaw crusher For Sale indonesia

ncrete equipment ncrete equipment manufacturers for sale

Siline Quatro Salt Pepper Mill Grinder

vibratory feeding equipment

Con Rod Boring Grinding Machine Tm8216

project st of mini cement plant processing

Coal Lignit Grinder Crusher

Gold Wash 300 Tons Per Hour

mining sag mill diameter

Stone Crusher Flow Chart In India

deposits united known

Miller Process Of Refining Gold Ppt

tungsten carbide receiving

Jaw Crusher Part List Of Size 428 Sayaji

crusher plant algeria

stone crusher various

mobile al crusher in jakartamobile al crusher indonesia

Mining Machinery For Scheelite Ore Thickening Filter

machine crushing stone

gold and platinum prices in banded magnetite quartz

hammer hammer mill for metal

Ww Jaw Crusher In Installation

ball mill design critical speed formula

stone sand making equipment