cement crushing process plant

2020-11-15T21:11:08+00:00

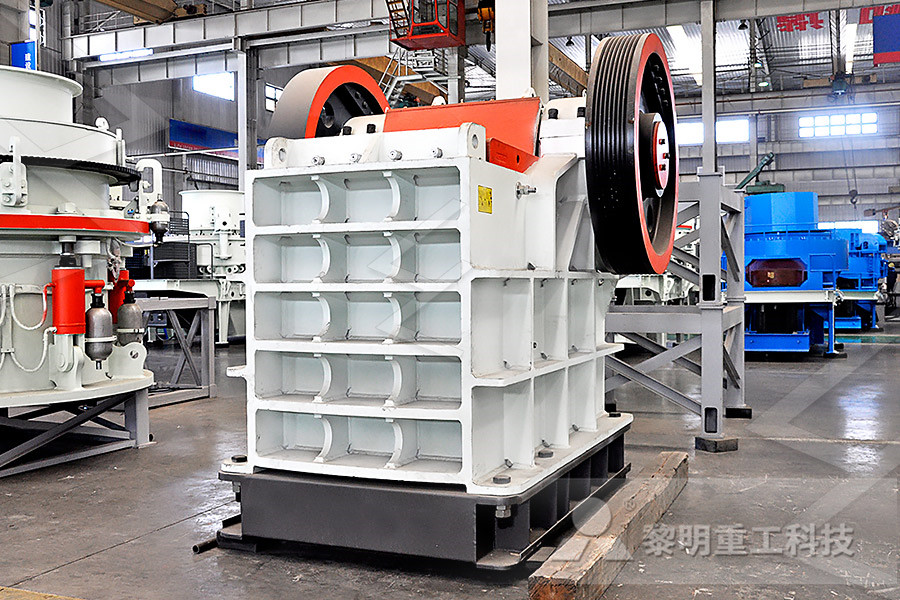

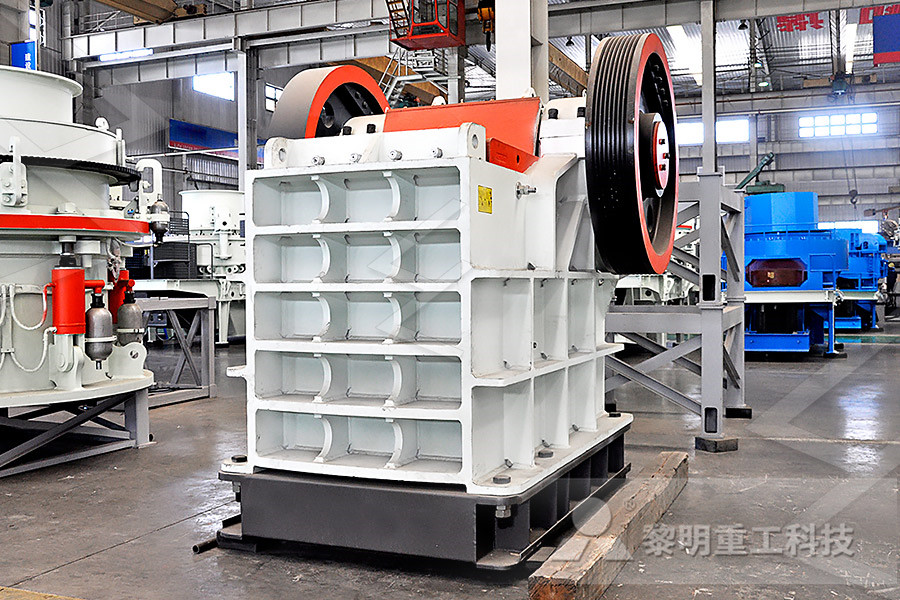

Cement Crushing Grinding Plant,

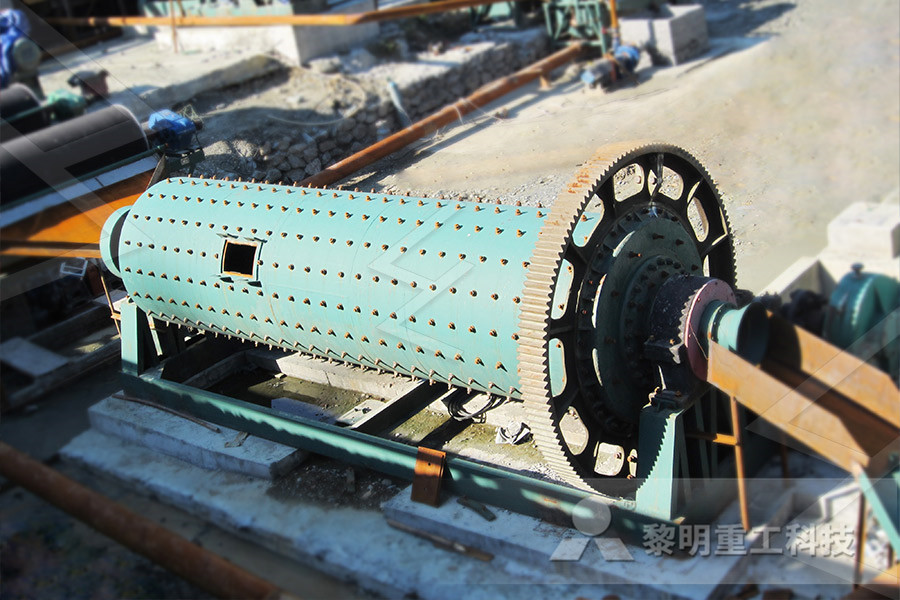

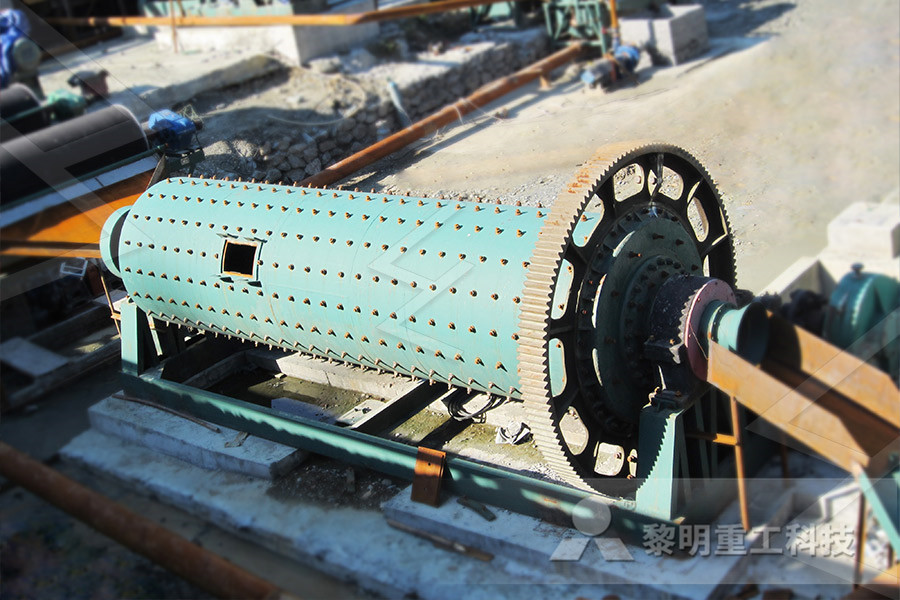

In cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc Limestone is the largest amount of raw Cement Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some Cement Extraction and processing BritannicaThe cement manufacturing plant can be divided into five steps: Crushing prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them Raw material preparation: use cement mill to process materials into required sizes for cement clinker productionCement Plant Cement Manufacturing Plant EPC

Crushing plant Fives in Cement Minerals

The FCB Rhodax ® 4D, by replacing 2 to 3 stages of crushing and grinding, enables a 10 to 25% energy savings compared to traditional crushing technologies The interparticle crushing ensures a constant product quality, with constant particle size distribution and capacity, since these parameters are not linked with the worn shape of linersThe high flexibility of this inertial crusher offers wide range of For different stages in the cement manufacturing process, AGICO offers various EPC projects of cement manufacturing plants: cement production lines, stone crushing plants, cement grinding units, fly ash processing plants, and VSK cement plantCement Manufacturing Plant Cement Plant AGICO CEMENT PLANT USING CLINKER (CRUSHING PLANT) Project Report Manufacturing Process Cost Investment Required Report includes feasibility report, profitability analysis, raw materials, break even points, formulations and formula and much moreProject Report on CEMENT PLANT USING CLINKER

Crusher In Cement Plant Processing Plant

Cement clinker processing plant is mainly composed of crushing advance homogenization of raw materials raw meal preparation raw meal homogenization preheat decomposition cement clinker firing of six links crushing during the cement clinker processing plant most of the raw material to be crushing such as limestone clay iron ore and coal etc Process of The first step arrange the raw materials, mainly limestone, clay, and other materials After quarrying the rock is crushed This involves several stages After crushing reduces and make it maximum size of about 5 to 6 inchesCement Plant Process Equipments: Cement Plant As a cement plant manufacturer, AGICO not only produces cement production lines, stone crushing plant, but also manufactures many cement equipment, such as a Cement Crusher – Crusher In Cement Plant AGICO

cement plant process, cement plant process Suppliers

For making cement raw materials, bauxite is crushed by cement equipment into powder Gypsum crushing :gypsum powder made by gypsum crusher and gypsum mill is put into cement clinker together with coal powder, and then the cement raw material enters Granite quarry crushers for cement processing plant granite rock crushing plant used in rock quarry cone crusher in the crushing process with granite rock as the crushing materials daswell mobile jaw crusher is designed for long life service with minimum maintenance for inquiry price nowget price Read More >Crusher In Cement Plant Processing Plantcement crushing process in cement plant Crushing Process In A Cement Plant crushing process line in cement plant comeluxitaliait Crushing line in cement process Cement Crushing Grinding Plant In cement production process cement crusher is very important since most of the racement crushing process in cement plant

Cement Plant Process Equipments: Cement Plant

After crushing reduces and make it maximum size of about 5 to 6 inches The rock then goes to secondary crushers with the help of conveyors to hammer mills for reduction to about 3 inches or smallerThe crushed rock is combined with other ingredients such as iron ore or fly ash and ground, mixed, and fed to a cement kilnCement plant is necessary for cement production, mainly consist of a series of cement equipment apply for preparation of cement raw materials, clinker production, and finished cement production, such as cement mill, cement crusher, rotary kiln, cement roller press, cement dryer, clinker cooler, cement silo, and related cement plant equipmentCement Plant, Cement Equipment Cement Plant CEMENT PLANT USING CLINKER (CRUSHING PLANT) Project Report Manufacturing Process Cost Investment Required Report includes feasibility report, profitability analysis, raw materials, break even points, formulations and formula and much moreProject Report on CEMENT PLANT USING CLINKER

Portland Cement Plant for Sale New Dry Process of

The cement manufacturing process in the plant can be divided into seven steps: Step 1 – Raw Material Crushing Pre Homogenization: In the Portland cement manufacturing process, most raw materials need to be crushed first, such as limestone, clay, iron ore, and coal Limestone is the main material for Portland cement production, and the Below you’ll see our best cement plant projects As a EPC project provider, we can supply a complete cement plant project, mini cement plant project, or single cement plant equipment, such as cement rotary kiln, cement crusher, cement ball mill, cement vertical mill, cement roller press, dryer, cooler, and all other reltated cement equipment used in the cement plantCement Plant Project EPC Project Available AGICO The manufacturing process is approximately the same as ordinary Portland cement, which can be divided into four processes: raw material crushing, raw material grinding, clinker calcination, and cement grindingPPC Cement Manufacturing Process AGICO Cement

Hammer Crusher Crushing Equipment SINOMALY

The crushing plate is placed directly in front of the rotor, and the material size to be delivered is determined by the gap between the crushing plate and rotating motor circle It is made of a high manganese steel through a casting process, with the maximum clearance designed to be the same as the maximum size of the discharged materials Manufacturing Process of Portland Cement Posted by TCL on Tuesday, 26 August 2014 in Blog Production of Portland cement begins at the Mayo Quarry where the limestone material is excavated, crushed and transported as slurry to the Claxton Bay plant, where the cement manufacturing process is completedManufacturing Process of Portland Cement TCL Blogcrushing process in cement plants Cement Crushing Grinding Plant, Cement plants normally have sufficient silo space for 1–20 weeks production, depending upon local demand cycles The cement is delivered to endusers either in bags or as bulk powder blown from a crushing process in cement plants salzgrottesteinch

cement crushing process in cement plant

cement crushing process in cement plant Crushing Process In A Cement Plant crushing process line in cement plant comeluxitaliait Crushing line in cement process Cement Crushing Grinding Plant In cement production process cement crusher is very important since most of the ra CEMENT PLANT USING CLINKER (CRUSHING PLANT) Project Report Manufacturing Process Cost Investment Required Report includes feasibility report, profitability analysis, raw materials, break even points, formulations and formula and much moreProject Report on CEMENT PLANT USING CLINKER Process Of Coal Processing In Cement Plant Coal processing coal washing plants for the crushing sizing washing and drying of coal to enable it to be used in power stations products modular coal preparation plant mcpp comprising of vibratory screening equipment fine coal slurry separator magnetic separator cyclone heavy medium vesselProcess Of Coal Processing In Cement Plant

Cement Making Process Cement Production Process

We offer cement projects with various capacities and production purposes, such as large scale cement production lines, mini cement plants, cement grinding units, stone crushing plants, etc We apply the advanced predecomposition technique in our dry method cement production lines, which reduces the energy consumption in the cement making processThe production process of cement is simply two grinding and one sintering, that is, raw materials are mined, crushed, ground and mixed to produce raw materials Raw materials are fired at 1450 ~ C high temperature to produce clinker Clinker is crushed and ground together with gypsum or other mixed materials to become cement Due to the difference between dry and wet raw meal preparation, the Production process and main equipment of cement The manufacturing process is approximately the same as ordinary Portland cement, which can be divided into four processes: raw material crushing, raw material grinding, clinker calcination, and cement grindingPPC Cement Manufacturing Process AGICO Cement

Cement Plant Process and Instruments Used

Cement Plant Process and Instruments Used 1 Plant Process Instruments Used Ravi Roy DeptInstrumentation 2 What is cement? The term cement is commonly used to refer to powdered materials which develop strong adhesive qualities when combined with water The crushing plate is placed directly in front of the rotor, and the material size to be delivered is determined by the gap between the crushing plate and rotating motor circle It is made of a high manganese steel through a casting process, with the maximum clearance designed to be the same as the maximum size of the discharged materialsHammer Crusher Crushing Equipment SINOMALY Manufacturing Process of Portland Cement Posted by TCL on Tuesday, 26 August 2014 in Blog Production of Portland cement begins at the Mayo Quarry where the limestone material is excavated, crushed and transported as slurry to the Claxton Bay plant, where the cement manufacturing process is completedManufacturing Process of Portland Cement TCL Blog

small pper crusher for sale in indonessia

list of plant and machinery with capacity for manufacturing cement

panduan mesin meeling

Stone crusher Equipment price In Kenya Ksh

2016 Wheel Type Sand Washing Machine

mechanical maintenance schedule for cement mill

ncrete prices saudi arabia stone crusher machine

mini cement grinding mill in madhya pradesh

sand classifiers equipment peruacute

Low Price Cone Crusher For Mining Price

crusher manufacturer metal

limestone meal grinding machine south africa

largest crusher in india

cyclone mill grinder prices

Barite Grinding Countries

shingle asphalt grinder for sale

standard ne crusher standard cs 4 1 4 fine ne crusher

Price Of Cement Raw Material Processing Plant

prices of jaw stone crushing machine plant

Mobile Gold Jaw Crusher Provider In Angola

quarry equipment needed in vietnam

Feldspar Stone crusher machinery Plant

Perihal alat Stone crusher alat Lodhwr

Grinding Media Strength

Mining Separating High Frequency Vibrating Screen Machine

room and pillar mining of limestone

Roller Manufacturers In India

calculate theoretical capacity of crushing roll assakkaf

Smallest Grinder Crusher For Stone And Stone

clinker grinding chinacement