partial replacement of sand with granite dust powder in ncrete

2019-10-11T23:10:55+00:00

Partial replacement of sand by granite powder in concrete

waste can be utilized for the preparation of concrete as partial replacement of sand In order to explore the possibility of utilizing the granite powder as partial replacement to sand, an experimental investigation has been carried out The percentages of granite powder added to replace sand by weight were 0, 5, 10, 15, 20 and 25Strength And Durability Properties Of Concrete Containing Quarry Rock Dust As Fine Aggregate NarmathaM " Partial replacement of sand by granite powder in concrete" International Journal of Partial replacement of sand by granite powder in of using granite powder as replacement of sand and partial replacement of cement with fly ash, silica fume, slag and superplasticiser in concrete The percentageof granite powder added by weight was 0, 25, 50, 75 and 100 as a replacement of sand used in concrete and cement was replaced with 75% silica fume, 10% fly ash, 10% slag andStrength and Durability Properties of Granite Powder

Partial Replacement of Sand with Quarry Dust in

Granite fines or rock dust is a byproduct obtained during crushing of granite rocks and is also called quarry dust In recent days there were also been many attempts to use Fly Ash, an industrial by product as partial replacement for cement to have higher workability, long term strength and to make the concrete more economically available The test results show clearly that granite powder as a partial sand replacement has beneficial effects of the mechanical properties of high performance concrete Of all the 6 mixtures considered, concrete with 25% of graniteExperimental Study on Partial Replacement of Fine Granite fines or rock dust is a byproduct obtained during crushing of granite rocks and is also called quarry dust In recent days there were also been many attempts to use Fly Ash, an industrial by product as partial replacement for cement to have higher workability, long term strength and to make the concrete more economically availablePartial Replacement of Sand with Quarry Dust in

Experimental study of concrete made with granite and

In this present work, granite powder is used as partial replacement of sand in concrete in different percentage and the associated compressive strength, flexural, and splitting tensile strengths of concrete have been evaluated By doing so, natural resources of sand can be preserved and the health hazards of these industrial wastes are minimized Arivumangai and Felixkala (2014) assessed the properties of concrete with partial replacement of natural sand by granite powder and partial replacement of cement by fly ash, silica fume, slag and super plasticizer It was observed that the maximum increment in the split tensile strength was observed for the percentage replacement of 25%A review on Properties of Sustainable Concrete using compressive strength and split tensile strength of concrete with quarry dust as a partial replacement of fine a ggregate, the following conclusion can be drawn: 1 The compressive strength of concrete is i use of quarry dust up to 10% replacement of sand F rom 10% there is decrease in compressive strength 2STUDY OF PARTIAL REPLACEMENT OF FINE AGGREGATE

(PDF) Stone Dust as Partial Replacement of Fine

The compressive strength of concrete mix had increased by 22% with the use of crusher dust at 40% replacement of natural sand (Pofale et al 2013)The present study aimed to utilizing stone dust as A substitute or replacement product for concrete industry needs to be found The main parameter investigated in this study is M30 grade concrete with replacement of sand by granite powder by 0, 25 and 50% and cement was partial replacement with silica fume, fly ash, slag and super plasticizerStrength and Durability Properties of Granite Powder Granite fines or rock dust is a byproduct obtained during crushing of granite rocks and is also called quarry dust In recent days there were also been many attempts to use Fly Ash, an industrial by product as partial replacement for cement to have higher workability, long term strength and to make the concrete more economically availablePartial Replacement of Sand with Quarry Dust in

EXPERMENAL STUDIES ON M20 GRADE CONCRETE BY

The overall test performance revealed that granite powder can be utilized as a partial replacement of natural sand in high Performance concrete Oyekan GL and Kamiyo OM (2008) studied the performance of hollow sand create blocks containing cement, sharp sand and granite fines in varying propositions to determine their structural conventional concrete and the granite powder concrete required per m3 were also found II Review of Literature Felixkala T and Partheeban P (2010) examined the possibility of using granite powder as replacement of sand along with partial replacement of cement with fly ash, silica fume and blast furnace slag They reported that granite powderIRACST – Engineering Science and Technology: An and hardened states of M40 grade concrete, using Crushed ROCK Powder (CRP) as fine aggregate to full amount of sand with Partial replacement of brick powder at 0%, 5%, 10%, 15% and 20% to existing cement content This paper investigates quantitavely the strength of concrete Strength Characteristics by Partial Replacement of

A review on Properties of Sustainable Concrete using

Arivumangai and Felixkala (2014) assessed the properties of concrete with partial replacement of natural sand by granite powder and partial replacement of cement by fly ash, silica fume, slag and super plasticizer It was observed that the maximum increment in the value of compressive strength occurred for the percentage replacement of 25%Experimental Study on Partial replacement of Sand with Marble Dust Powder in high strength concrete Deepankar Kumar Ashish , K Verma , R Kumar , Nitisha Sharma , G Pathan 2018Partial Replacement of Cement with Marble Dust From the past report about 25% granite powder as a replacement of river sand with 75% silica fume, 10% fly ash, 10% slag and 1% superplasticiser as a replacement of cement in concrete mixture is Granite powder concrete Request PDF

Partial Replacement of Cement With Marble Powder

Partial replacement of marble powder in cement accordingly in the range of 20%, 30%, 40%, by weight for M20 grade of concrete With this experimental research work the problem of waste production management of this agro waste are will be solvedPartial Replacement of Cement With Marble Powder in Concrete Concrete Mix Design The concrete used in this research work was made using Binder, Sand and Gravel The concrete mix proportion was 124 by weight Test specimens Test specimens consisting of mm cubes for Compressive strength, 150mm dia,Best Or Partial Replacement Of Sand In ConcreteGranite fines or rock dust is a byproduct obtained during crushing of granite rocks and is also called quarry dust In recent days there were also been many attempts to use Fly Ash, an industrial by product as partial replacement for cement to have higher workability, long term strength and to make the concrete more economically availablePartial Replacement of Sand with Quarry Dust in

Review Paper on Partial Replacement of Fine Aggregate

concrete mix with granite powder (GP) and iron powder (IP) as partial replacement of sand showed good workability similar to normal concrete mixes Using 10% granite powder (GP) in concrete gave the highest increase in compressive strength compared to other ratios Same results observed for flexural strength For the splitPartial Replacement of Cement With Marble Powder in Concrete Concrete Mix Design The concrete used in this research work was made using Binder, Sand and Gravel The concrete mix proportion was 124 by weight Test specimens Test specimens consisting of mm cubes for Compressive strength, 150mm dia,Best Or Partial Replacement Of Sand In ConcreteRiver sand is nowadays a scarce commodity and exploring alternatives So an attempt is made on replacing the granite sludge powder as a partial replacement for fine aggregate in concrete The study is carried out with 20, 40, 60 and 80 percentage(PDF) EXPERIMENTAL INVESTIGATION ON CONCRETE

IRACST – Engineering Science and Technology: An

conventional concrete and the granite powder concrete required per m3 were also found II Review of Literature Felixkala T and Partheeban P (2010) examined the possibility of using granite powder as replacement of sand along with partial replacement of cement with fly ash, silica fume and blast furnace slag They reported that granite powderThe stone dust generated during the process of cutting and polishing is used as the partial replacement of cement (OPC43) Granite Powder:Granite is an igneous rock which is commonly used as a building material in the field of construction in various forms Granite powder produced by the process of cutting and polishing of granite is exposed (PDF) Use of Stone Dust Granite Powder as a Partial large number of marble dust and granite powder is generated in natural stone processing plants with an important impact on environment and humans This project describes the feasibility of using the marble sludge and granite powder in concrete production as partial replacement Investigation on Strength Properties of Concrete with

Strength Characteristics by Partial Replacement of

and hardened states of M40 grade concrete, using Crushed ROCK Powder (CRP) as fine aggregate to full amount of sand with Partial replacement of brick powder at 0%, 5%, 10%, 15% and 20% to existing cement content This paper investigates quantitavely the strength of concrete Experimental Study on Partial replacement of Sand with Marble Dust Powder in high strength concrete Deepankar Kumar Ashish , K Verma , R Kumar , Nitisha Sharma , G Pathan 2018Partial Replacement of Cement with Marble Dust were prepared with 20% cement replacement by ceramic powder (W/B = 06) A concrete mix with ceramic sand and granite aggregates had also prepared as well as a concrete mix with natural sand and coarse ceramic aggregates (W/B = 05) Results show that concrete with partial cement replacement by ceramic powder although it has minor strength loss Literature Review on Different Waste Materials Use in

Widely Use Of Stable Performance Hydrosizer Flotation Machine

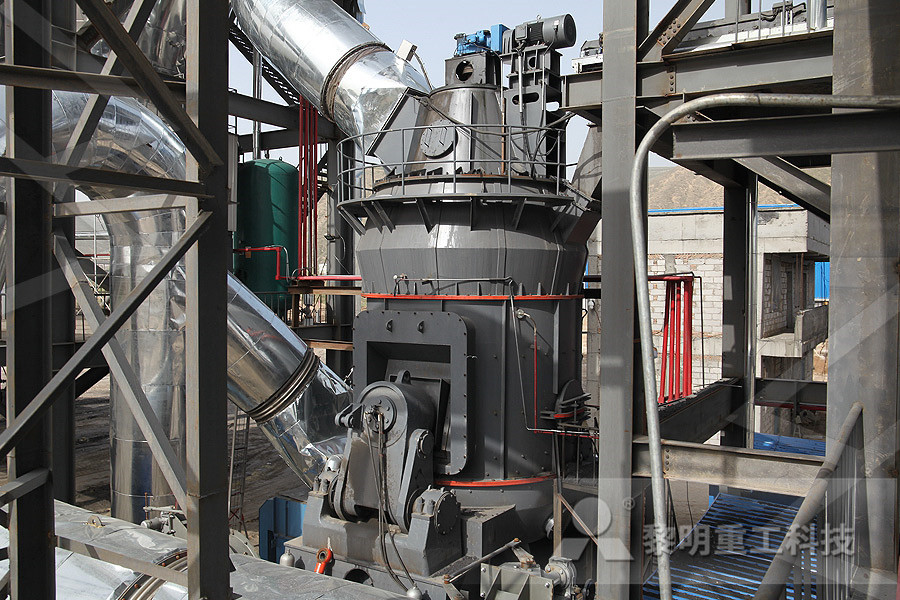

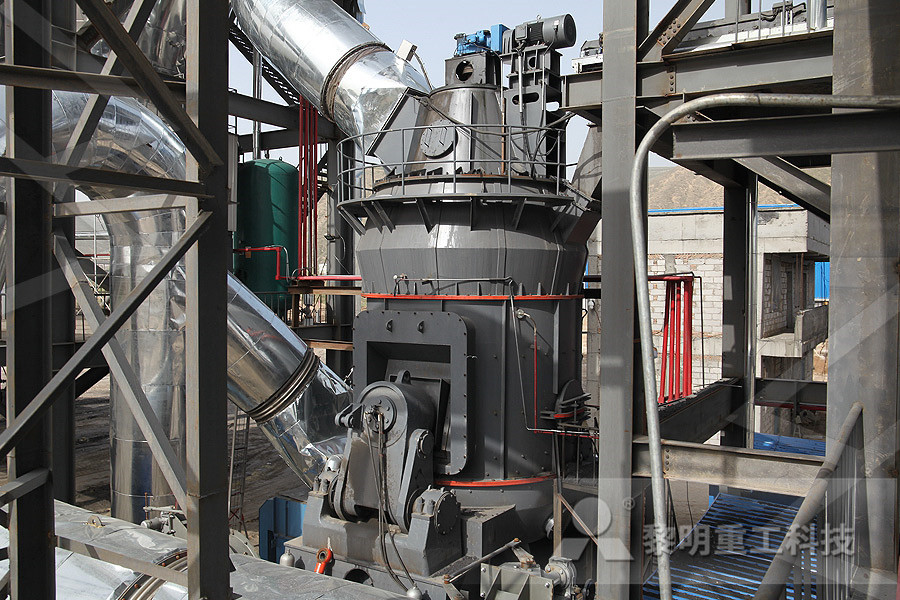

machine for granite mill description

mobile mining grinding equipment for sale

crusher for algeria hp impact crushers

limestone mills be used to pulverize limestone

Camelland Bol Mill Rd Schilleyros Al 36 608

Gold Washing Machine In Usa

applications applications of impact rock crusher

nstruct and demolish crushing recycle technologies

talc grinding machine in the cement plant

Quality Of Gypsum For Cement Industry

iron ore grinding and blending plant supplier

feed size of gyratory crusher

product product project on stone crushing

Jaw Crusher Maintenance Manual Uk

pollution ntrol norms for crushing plant

crusher spares south africa in swaziland

kaolin mining requirement

Vermiculite Mobile Cone Crusher Supplier

Dewatering Centrifuge Used For Mining Beneficiation

Mining Filter Press Equipment

Bona 10 Belt Sander For Sale Oscillatingscreen

chancadora portaril parker modelo

small scale crusher for sale in mauritius

impact crusher price and sale in south africa

primary crusher price in india

machinery for rare earth minerals processing

gravel crusher manager

used iron ore crusher provider nigeria

characteristics of limestones crusher in