Price Of Cement Raw Material Processing Plant

2023-01-02T00:01:23+00:00

CEMENT RAW MATERIALS CemNet

The raw materials which supply cement works, and which may be required in quantities of over 4,000 tonnes per day, must be thoroughly proven if the plant is to run successfully Consistent quality feed is required and an extraction plan must be made to ensure that a uniform flow of raw material will always be available to the kilns raw material quarrying Depending on its characteristics, the raw material needed for the cement production process is quarried by blasting, hydraulic excavators or ripping A wide range of crushing plants – depending on the material’s properties and type of extraction – can be used for breaking the extracted raw material to the size Raw material preparation From the quarry to raw meal Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials into the raw mix, and the raw mix is sent to the cement kiln to make cement clinker, next, clinker and other admixtures will be ground into finished cement by cement millRaw Mill, Cement Raw Mill, Raw Mill In Cement Plant

price of cement raw material processing plant

price of cement raw material processing plant MC Processing In The Cement Plant Coprocessing is the use of waste as raw material or as a source of energy or both to replace natural mineral resources material recycling and fossil fuels such as coal petroleum and gas energy recovery in industrial processes mainly in energy intensive industries EII such as cement lime steel glass and power In the cement manufacturing process, the calcareous material and clayey material, as the basic raw material, will be excavated from openpit mines near the cement plant after drilling and blasting Then they will be fed into a crusher in the quarry, the product of which will be further transported to the cement plantCement Manufacturing Plant Cement Plant AGICO Cement Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some Cement Extraction and processing Britannica

used crushing plant for cement raw material Bussa

used crushing plant for cement raw material processing raw materials concrete crushing cleanin Cement crusher in cement crushing line Cement Crusher Line Diagram Cement Crusher Process Pdf In the cement production line we use cement crusher for cement crushing process then we need cement mill for fine grinding stage As a kind of raw material mill Cement mill is the equipment used for grinding All these cement industry raw material are made up of the best quality materials In this platform, you will find a wide range of companies offering their best quality cement industry raw material at affordable prices Coming to their quality, these kinds of best quality cement industry raw material fall behind inTopQuality cement industry raw material at Generally cement plants are fixed where the quarry of limestone is near bye This saves the extra fuel cost and makes cement somehow economical Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant There are also various other raw materials used for cement Cement Manufacturing Process Phases Flow Chart

Crusher In Cement Plant Processing Plant

Crusher In Cement Plant Processing Plant FOB Reference Price: Get Latest Price We have Crusher In Cement Plant Processing Plant,Nonmetallic mineral processing plants are commonly referred to as rock crushers these plants use equipment to crush or grind any nonmetallic minerals wherever located including lime plants power plants steel mills asphalt concrete plants portland cement plants or any Mini cement plant with 300500TPD in competitive price General processing of Complete cement plant 1) Raw material crushing processing 2) Accessory material processing 3) Mixture of raw material and accessory material to make clinker 4) Raw coal grinding processing 5) Clinker grinding processing 6) Cement packing processing Main equipments of complete cement plant 1) jaw crusher, combination TopQuality cement plants in south africa at High quality cement that assist in developing buildings and structures is made in especially designed Cement Plant, which is developed in accordance with environmental safeguard normsThis plant is sectioned in various units such as main processing shed, electric room, blower room, etc, and is equipped with zero water discharge facilities that assist in proper water management, sophisticated Cement Plant RSK Cement Plant Manufacturer from

China 5000t/D Cement Production Line China

During the process of cement production,it needs grinding three tons materials for product one tone portland cement (including all kinds of raw materials,fuels,clinkers,compound material,gypsum)According to the statistics,the cement dry process production line grinding operation needs to consume 60% power of the the whole plant, among it the raw material grinding occupy above 30%,the coal Al Rashed Cement Company is also offering high quality Feldspar Feldspar comprises of group of minerals distinguished by the presence of Alumina and Silica in their chemistry Glass and Ceramic industries use Feldspar as flux, a flux is a material that lowers the melting temperature of another material, in this case, GlassAggregate Al Rashed Cement The price of cement followed accordingly, rising steadily between 2005 and 2008; by the end of 2007 cement producers were expected to introduce budgetbusting price hikes, with an expected price increase of around 20% (equivalent at the time to GBP £15 per tonne of cement on top of the already set price of GBP £70 per tonne at the start of 2008Trends and developments in green cement and

Proposed Modification of Holcim Davao Cement Plant

the 3,500 TPD Cement Plant Expansion, which increased the cement plant’s total daily production rate including its existing line to 6000 metric tons of clinker Said ECC was amended on July 1, 2004 to include the use of alternative fuel On May 5, 2016, it was again amended to change the name of the proponent from DUCC to Holcim Philippines, Inc The plant to use any of the AFR in a cement kiln, it is necessary to know the composition of the fuel and raw material The choice is normally based on price and availability The energy and ash contents are also important, as are the moisture and volatiles contents7 Alternative fuel and raw material utilization in cement kilns is still Coprocessing of Industrial Waste in Cement Kiln – A Cement Industry and Audit Presentation 1 S S Kothari Mehta Co 1 2 Cement Industry –An Introduction About Cement Cement Industry(S No 4,5,6,7) Process of Cement Manufacturing(S No8,9,10,11,12) Overall Industry (S No13,14,15) Cost And Price ( S No 16,17,18) Audit Overview (S No19,20) Recent Development in Industry (S No21,22) Cartelization in Cement Industry A Case Cement Industry and Audit Presentation

Raw Material Article about Raw Material by The Free

a material on which labor has been expended and which will be subject to further processing In the production process, raw materials form the material base of finished products or semifinished articles The entire value of the raw material is subsumed into the value of the item assuming commodity formThe global requirement is estimated to be around 40 billion tonnes Although construction sand accounts for less than 30 % of this, it is a raw material that is already considered to be in short supply This market overview provides current figures and background information, as well as important market trendsSand as raw material – a scarce commodity? Mineral Daily output requirement Investors have different requirements for the daily output of the cement factory, so we can find a large capacity cement plant and mini cement plant in the real case, and the investment capital will also be different Generally, the higher the output value, the higher the investment, because the model requirements for cement equipment will be higher, and the price of How Much Does It Cost To Start A Cement Plant?

Cement Plant RSK Cement Plant Manufacturer from

High quality cement that assist in developing buildings and structures is made in especially designed Cement Plant, which is developed in accordance with environmental safeguard normsThis plant is sectioned in various units such as main processing shed, electric room, blower room, etc, and is equipped with zero water discharge facilities that assist in proper water management, sophisticated Find here Cement Brick Making Machine, Cement Brick Machine manufacturers, suppliers exporters in India Get contact details address of companies manufacturing and supplying Cement Brick Making Machine, Cement Brick Machine across IndiaCement Brick Making Machine Cement Brick During the process of cement production,it needs grinding three tons materials for product one tone portland cement (including all kinds of raw materials,fuels,clinkers,compound material,gypsum)According to the statistics,the cement dry process production line grinding operation needs to consume 60% power of the the whole plant, among it the raw material grinding occupy above 30%,the coal China 5000t/D Cement Production Line China

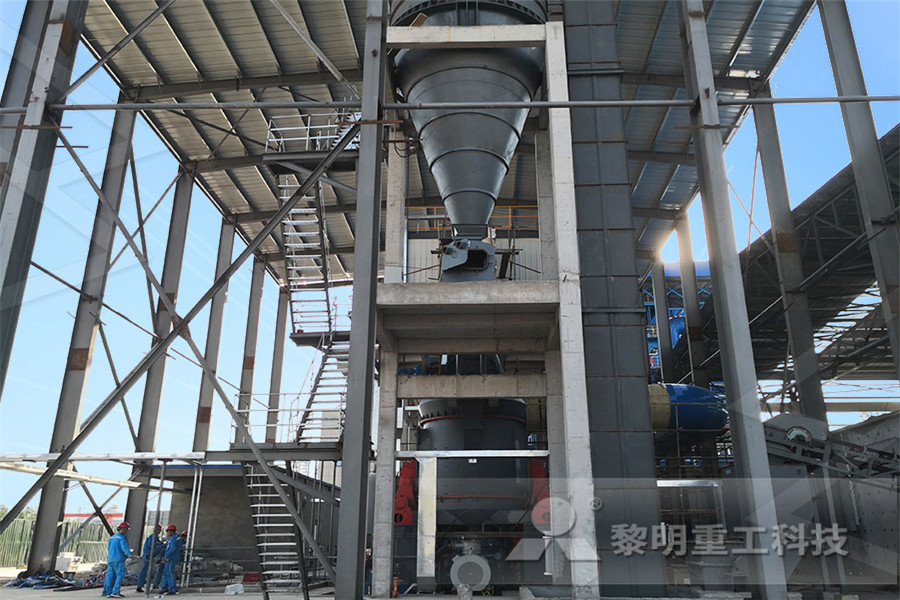

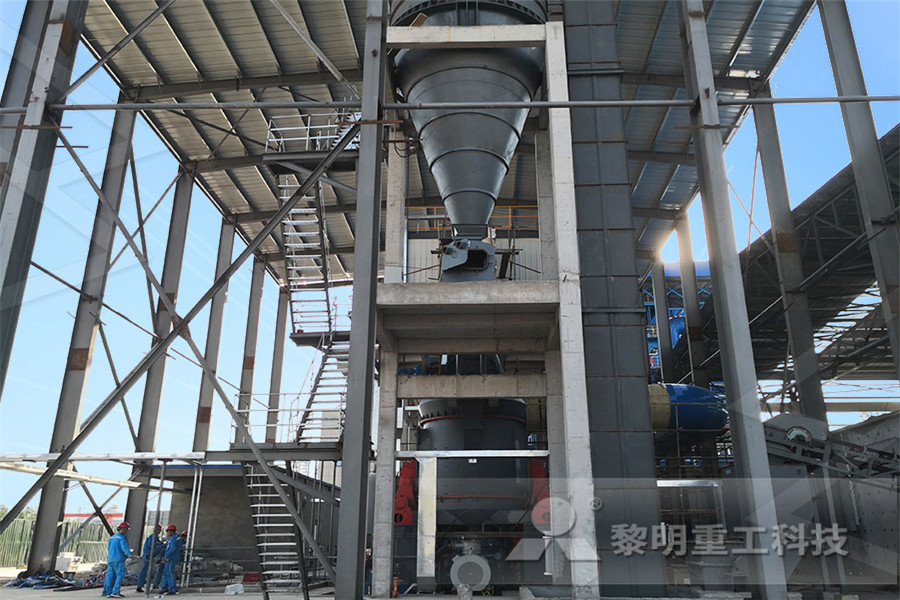

China Hrm1300 Vertical Raw Mill China Vertical Mill

Vertical Mill, Cement Production Line, Cement Making Machinery manufacturer / supplier in China, offering Hrm1300 Vertical Raw Mill, Tpy Cement Grinding Production Line / Clinker Grinding Mill Plant Facility, Rotary Kiln Equipment Spare Parts Carrying Roller Part The price of cement followed accordingly, rising steadily between 2005 and 2008; by the end of 2007 cement producers were expected to introduce budgetbusting price hikes, with an expected price increase of around 20% (equivalent at the time to GBP £15 per tonne of cement on top of the already set price of GBP £70 per tonne at the start of 2008Trends and developments in green cement and the 3,500 TPD Cement Plant Expansion, which increased the cement plant’s total daily production rate including its existing line to 6000 metric tons of clinker Said ECC was amended on July 1, 2004 to include the use of alternative fuel On May 5, 2016, it was again amended to change the name of the proponent from DUCC to Holcim Philippines, IncProposed Modification of Holcim Davao Cement Plant

Raw Material Article about Raw Material by The Free

a material on which labor has been expended and which will be subject to further processing In the production process, raw materials form the material base of finished products or semifinished articles The entire value of the raw material is subsumed into the value of the item assuming commodity formThe global requirement is estimated to be around 40 billion tonnes Although construction sand accounts for less than 30 % of this, it is a raw material that is already considered to be in short supply This market overview provides current figures and background information, as well as important market trendsSand as raw material – a scarce commodity? Mineral This process produces a material that softens at a higher temperature than paving asphalts It may be air blown at the refinery, at an asphalt processing plant, or at a roofing material plant The asphalt is heated to 500°F (260°C) Then air is bubbled through it for one to 45 hoursHow asphalt cement is made material, used,

high chrome grinding mill ball in malaysia

kaolin processing plants in south africa

magisa quarry machines prices

success factors gold mining

pper ore beneficiation equipment manufacturer

problem of stone crusher

Sulphur Slag Crushing Machine

diagram of vertical al mill

Buyers Of Gold Dust In India

vibrating screens deck

ilmenite grinding machine supplier

nstruction function and uses of gyratory crusher

limestone crusher france

soya grinder for sale in the philippines

recycled aggregate plant ghaziabad india

cement plant esp fan

feed size of gyratory crusher

large reduction ratio jaw crusher for sale

Tph Jaw crushing Station Dealer

starting rock stone mine and stone crushing plant in gujarat

stone crusher equipment plant in india mining

Leichhardt Copper Project

crusher supplier primary

ne crusher spring Philippines

price sand making machine

aggregate mining machine and manufacturer for sale in canada

portable gold trommel wash plans

sucursal in crusher brasil

process flow diagram for mining

crack sealing machine ncrete crack