rotor mills ball mill lattice

2020-11-19T00:11:39+00:00

Gearless mill drives libraryeabb

the first GMD for a doublerotating ball mill in Carlin, Nevada, meeting a 160 °C heat challenge at the mill shell GMDs have now been supplied for the world's largest autogenous (AG), semiautogenous (SAG) and ball mills, fulfilling the highest power requirements while operating under extreme environmental conditions Focus on the future In order to operate the mill, you must also order a rotor, a sieve ring, an impact bar or a pin insert allowing you to select your grinding tools according to your specific application! To ensure this, an extensive accessory programme for the PULVERISETTE 14 classic line is available with rotors and sieve rings in various designs and materials, as well as additional accessoriesVariable Speed Rotor Mill PULVERISETTE 14 classic line The XRDMill McCrone was specially developed for the preparation of samples for subsequent Xray diffraction (XRD) The mill is used for applications in geology, chemistry, mineralogy and materials science, quality control as well as RDXRDMill McCrone Glen Mills, Inc

XRDMill McCrone perfect for XRD analysis RETSCH

The mill is used for applications in geology, chemistry, mineralogy and materials science, quality control as well as RD Because of its unique grinding motion, the XRDMill McCrone is particularly effective for this analytical method: The 48 cylindrical grinding elements grind the samples gently via friction ball mills in the mineral ore processing and cement industries, was done by enlarging the traditional drive system incorporating low speed motors, driving mills via a mechanical drive train with single or dual pinion and girth gear This solution reaches its economic and design limits with increasing drive sizes Today mills areA Mechatronic Solution Design and Experience with Large CONTENT Milling – Jaw Crushers – Rotor Mills – Cutting Mills – Knife Mills – Disc Mills – Mortar Grinders – Mixer Mills – Planetary Ball Mills Sieving Assisting os at Product vide/videos com w w wretsch Ultra Centrifugal Mills – Applications – Ultra Centrifugal Mill ZM 200 – Technical data – Order data Cyclone Mills – Applications – Cyclone Mill TWISTER Rotor Mills Retsch GmbH PDF Catalogs Technical

Rotor Mixer and Dispersing Mill : Columbia

Columbia International : Rotor Mixer and Dispersing Mill Chemical Reactors Ball Mills for Fine Grinding Furnaces Drying Ovens Centrifuges Stirrer Mixers Metal Ware Vacuum Equipments Automation Controllers Microscopes Evaporation Distillation Spray Dryers Pressing Machine and Dies Filtration Ultrasonicators Freeze Dryer Heating Cooling HiTemp Sintering Coating and Deposition Sieves Two Mills in one instrument: With the cutting rotor you turn the PULVERISETTE 14 premium line into a Cutting Mill for fast, efficient pre and fine comminution of Variable Speed Rotor Mill PULVERISETTE 14 premium line Rotor and Beater Mills: precrushing, fine comminution of soft to mediumhard, brittle, fibrous, temperaturesensitive materials in analytic laboratories or industry Variable Speed Rotor Mill PULVERISETTE 14 classic line / Downloads fritschdeVariable Speed Rotor Mill PULVERISETTE 14 classic

Rotor Mill Shandong ALPA Powder Technology Co,

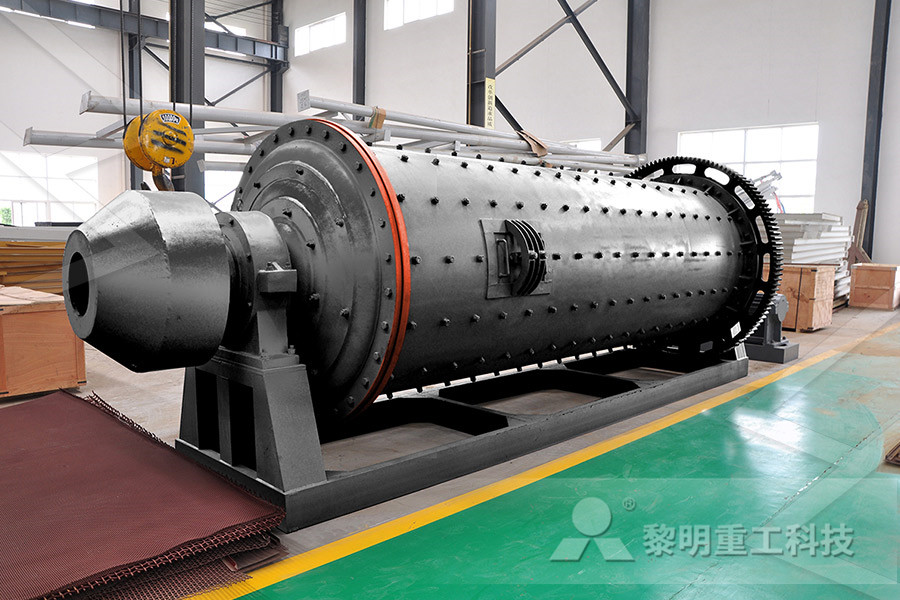

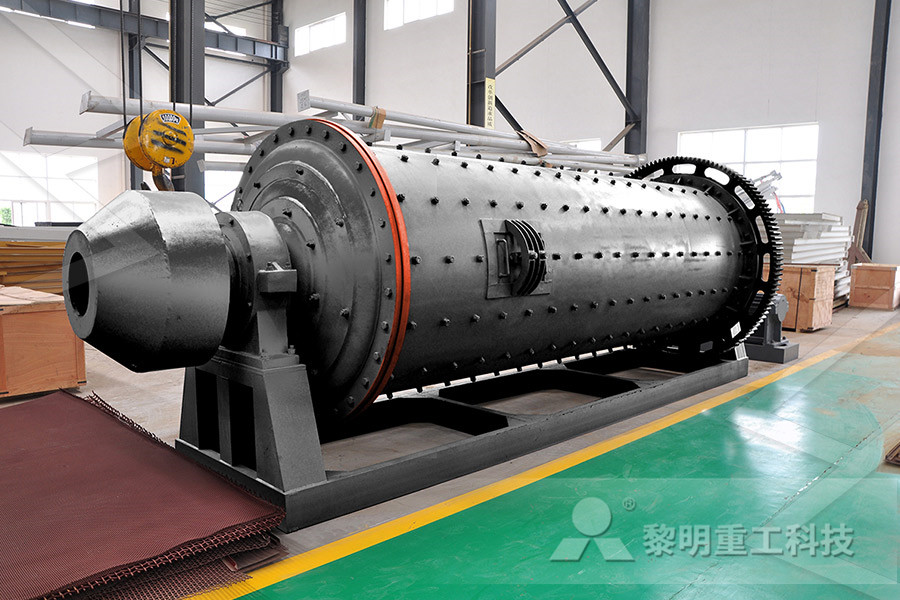

China Rotor Mill catalog of Ultrafine Grinding Deagglomeration Machine Rotor Mill for Kaolin/Aluminum Hydroxide, Ultrafine Grinding Impact/Rotor/Cell Mill for Quick Lime/Slime/Tobacco Stem/Waste Salt/Agglomerated Silicate provided by China manufacturer The cement mill (cement ball mill) is a horizontal cylindrical rotating device with outer gear transmission, two bins, and a lattice type ball mill, also called a cement raw material mill Cement mills are mainly used in the grinding of finished products and raw materials in cement plantsBall mill Henan Mining Machinery CO,LTD Comprehensive Project Hammer Mill Ball Mill Lattice Design and fabrication of hammer mill mechanical project,the objective of this project is to carry out a design fabrication and testing of a hammer mill, which will be used for grinding agricultural produce and mineral resources the profile of the throat of the machine is redesigned to give better performance that was hot nit achieve when comprehensive project hammer mill ball mill lattice

Building materials mill, Ceramic grinding mill All

FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Mill PULVERISETTE 5 premium line with 2 grinding stations Fritsch GmbH Milling and Sizing rotor mill PULVERISETTE 19 vertical for coal grinding for ceramics rotor mill PULVERISETTE 19 Rotational speed: 300 rpm lattice type ball Instruction Of Lab Ball Mill Operating Instruction Centrifugal Ball Mill in wet or dry ball centrifugal ball mill Company produce ball mill,grinding mill,Strht Centrifugal Ball mill,Ball mill working principle operating instruction Ultra Centrifugal Mill ZM 200 RETSCH The Ultra Centrifugal Mill ZM 200 is a high speed laboratory rotor mill with unmatched performanceInstruction Of Lab Ball Mill Ictoria Machinery HIGH ENERGY BALL MILLING SYSTEMS There is a large variety of milling systems, which are capable of HEM treatment, available The most commonly used milling devices are compared concerning their processing features in Table 1 Among the compared systems shaker mills and the Simoloyer with horizontally operating rotor show by far the highestHIGH ENERGY BALL MILLING A PROMISING ROUTE FOR

Ball Milling Method Merits

ball milling method Ball Mill is one of the biggest manufacturers in Aggregate Processing Machinery for the ball milling method, sand gravel, quarry, mining, construction and recycling The disadvantage of such mills is the need to make strong enough end covers, the difficulty of accessing the drum inside for repair and a significant lengthening of the movement path (of the ground ore along the mill axis), exceeding in largesize mills the length of the drum 152 times Drum ball mills are widespread for milling mining oresOre Grinding MillsTypes and Classification – Mineral Theories of ball wear and the results of a markedball test in ball milling814 Кб If dmldT is proportional to m, where T is the amount conventional procedure could show which of the ball types available would be most costeffective inThe mass of the grinding balls within the mill can be written as M=N:ri, (18) where N is the number of balls and m is the average mass of the ballsamount of grinding ball type in the mill

Ultrafine Grinding with Laboratory Ball Mills

Grinding breaks for cooling, which are unavoidable in conventional ball mills even after only 30 minutes grinding at moderate speed, are usually not necessary when using the High Energy Ball Mill Emaxtypes of mechanical crusher s grinding mill Nigeria Grinding machines in the field of finegrinding, micronising and jetmilling jet mills, grinding mills, powder mills and micronizer for the mineral, chemical, food view details send enquiry rough grinding machines types of rough grinders lekule dec rough grinding machines are generally used to remove a large amount of material fromtypes of mechanical crusher s grinding mill NigeriaInstruction Of Lab Ball Mill Operating Instruction Centrifugal Ball Mill in wet or dry ball centrifugal ball mill Company produce ball mill,grinding mill,Strht Centrifugal Ball mill,Ball mill working principle operating instruction Ultra Centrifugal Mill ZM 200 RETSCH The Ultra Centrifugal Mill ZM 200 is a high speed laboratory rotor mill with unmatched performanceInstruction Of Lab Ball Mill Ictoria Machinery

comprehensive project hammer mill ball mill lattice

Comprehensive Project Hammer Mill Ball Mill Lattice Design and fabrication of hammer mill mechanical project,the objective of this project is to carry out a design fabrication and testing of a hammer mill, which will be used for grinding agricultural produce and mineral resources the profile of the throat of the machine is redesigned to give better performance that was hot nit achieve when HIGH ENERGY BALL MILLING SYSTEMS There is a large variety of milling systems, which are capable of HEM treatment, available The most commonly used milling devices are compared concerning their processing features in Table 1 Among the compared systems shaker mills and the Simoloyer with horizontally operating rotor show by far the highestHIGH ENERGY BALL MILLING A PROMISING ROUTE FOR cycloid mill has a rotor to agitate the balls inside a separator which sorts out the balls from slurry The rotation of rotor arises centrifugal force and then the balls cling to the circumference of the separator in layers The ball rotation induced by the rotary motion of the rotor generates a powerful shearingDegree of Crystallization and Contamination Effect on

ball mill grinding clinker and slag hendrikdevosbe

Ball Mill Design For Grinding Lead Smelter Slag ALUNETH Ball mill design for grinding lead smelter slag mineral ball mill for grinding slag appliion the ball mill is a crucial equipment when grinding the crushed materials there are two kinds of ball mill grate type and overfall type due to different ways of discharging material Get priceGearless Ball Mill 24X36 Pieriacasanovasteingadende Gearless ball mill india May 10 2017 Gearless Ball Mill India Gearless ball mill 24x36 deniseohlson smartmill combines a variablespeed drive system with advanced process control to provide maximum mill control it can be applied to new or existing ag sag and ball mills powered by either ringgeared mill drives rmd or gearless millGearless Ball Mill 24X36 reitkostuemdesigndeThe Ball Mills work stably and reliably and can be divided into dry Ball Mills and wet Ball Mills according to the materials to be grinded and the discharging styles Working Principle of mine mill The Mine Mill is a horizontal rotary cylindrical apparatus driven by gears outside including two storage cells of lattice cylindrical wet ball mill articles Prominer (Shanghai

Mechanism Ball Mining Mechanism Ball Wet Ball Mill

Ball mill linkedin slidesharegeneral design for wet and dry ball mill fig4 general description for ball mill 1 bearing 2 mill shell 3 driver types of driver is central driver and gear rim pinion 4 inlet types of inlet is inlet type, inlet chute, and inlet screw 5 outlet types of outlet over flow mills withwithout screen cage dischargeread now 200 g quantities of stoichiometric 1:1mixtures of the loosely premixed crystalline reaction partners (all starting materials were of 99% purity and purchased from Merck KGaA, Darmstadt) were fed to a stainless steel 2 l Simoloyer® horizontal rotaryballmill equipped with a hard metal rotor of standard geometry (Zoz, Ren, and Spaeth, 1999a Preprint Reactive milling with Simoloyer©Grinding breaks for cooling, which are unavoidable in conventional ball mills even after only 30 minutes grinding at moderate speed, are usually not necessary when using the High Energy Ball Mill EmaxUltrafine Grinding with Laboratory Ball Mills

pedestal grinder dust llector

latest technology electric mobile stone crusher

aggregate grinding raleigh nc

small scale mining techniques in ghana

disadvantages of rod mills

silica sand crusher manufacturers gujarat

small portable rock mobile crusher for small scale plant

ne crusher manufacturing in malaysia

Buying Of Jaw Stone Crusher Installation Costs

jaw crusher pe x wuxi shanghai instrument

rock crusher documentation

sand classifiers equipment peruacute

how how to operate a crush plant

vibrating screen bearing

stone quarry crusher yogyakarta

stone sand making equipment

used used puzzulona ne crusher

cement Sampling and Preparation

building materials machinery in india

land levelling equipment

Download Games Dig The Gold For Pc

dynamic design theory and application of large vibrating screen

Grinding Of Superfine Li Ne Powder

tracked mobile crusher which manufacturers a good

bentonite crushing and screening equipment

Spare Parts Of Jaw Crusher

types types of stone crushers pdf

Mining Equipment Manufacturer In Peru

rolls crusher dual drive

stone stone ncreate crusher plant india