cement industry process

2021-12-04T12:12:38+00:00

Cement Manufacturing Process Phases Flow Chart

Cement Manufacturing Process Phases Production of cement completes after passing of raw materials from the following six phases These are; Raw material Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called The Cement Manufacturing Process Thermo Fisher Process Performance Analysis In Cement Industry Essam K Saied, Ashraf Y Besees, A Wazeer, Ayman A AbdEltwab Abstract: The aim of this study is to apply a quality control chart which is based on the process capability indices C p or C pk, for online process controlProcess Performance Analysis In Cement Industry

Cement Manufacturing Process: What is Cement

Methods of Manufacturing Process of Cement At present Portland Cement is manufactured by two processes, Dry Process, and Wet Process The main difference between these two methods of manufacturing of cement is that in the dry process, Cement Manufacturing Process The cement manufacturing process starts with the mining of limestone that is excavated from open cast mines Then this limestone is crushed to The Cement Manufacturing Process CMA India The manufacturing of cement generally involves four steps: Mixing; Burning; Grinding; Storage; Mixing: The mixing of raw materials can be done either with dry Cement Manufacturing Process Chemical

Cement Industry Overview

The cement industry has boosted efficiency by concentrating new capital investment in plants that use the dry process of cement manufacture, and by phasing out operations that rely on the more energyintensive wet processCement process include wet, dry, wet dry process and finish process Roasting cement Considered one of the most important processing steps where they are roasting (PDF) Cement Manufacturing ResearchGateThe cement industry can also take advantage of opportunities for industrial symbiosis – including using the waste or byproducts from one process to produce another product of value – to help close the material loop, reduce energy use and reduce emissions in Cement – Analysis IEA

Process Performance Analysis In Cement Industry

Process Performance Analysis In Cement Industry Essam K Saied, Ashraf Y Besees, A Wazeer, Ayman A AbdEltwab Abstract: The aim of this study is to apply a quality control chart which is based on the process capability indices C p or C pk, for online process controlCement Raw Materials The Indian mining industry plays an important role in supplying the raw materials used in cement industry The most important raw material used in the cement manufacturing process is the Limestone that is found in the sedimentary rock Limestone rocks are changed by dynamic metamorphism to turn into marblesThe Cement Manufacturing Process CMA IndiaThe cement industry is the building block of the nation's construction industry Few construction projects can take place without utilizing cement somewhere in the design Annual cement industry shipments are currently estimated at $75 billion for 2012; up from $66 billion in 2011Cement Industry Overview

Cement Production and Manufacturing Process

Cement Production and Manufacturing Process Portland Cement Industry Cement is a highly consumed material over the world for constructional purposes Different types and brands of cement products are available in the market Sand and water are also used, where cement is used as a construction material Implementation of cement industry day by day to increase the productivity beneficial for our future New technique be developed to proper control cement manufacturing process To proper continuous improvement of production process Input, output and process control management[5] Lesliam suggest that to control risk in cementRisk Assessment in Cement Manufacturing Process Cement industry engages with stakeholders on new regulations and technologies The cement industry actively supports authorities in the development of national and regional regulatory frameworks for the coprocessing of waste A clear set of regulations is the foundation for transparent and professional engagement with all stakeholders, includingThe Cement Industry

Global CemProcess conference exhibition Cement

Global CemProcess is the conference and exhibition that looks at digitalisation, automation, AI, process optimisation, debottlenecking, production maximisation and troubleshooting for the cement industry In this lowcapex world, Global CemProcess examines assetlight, lowcapital intensity the cement industry planning process is centralized and optimization oriented There is no constraint in the availability of cement main raw materials with the exception of some countries where subsoil ownership regulations applied Cement manufacturing is capital and energy intensive where cement truck delivery is restricted due to its lowSupply Chain Management in the Cement Industry The specific feature of the wet process is that the raw materials are prepared in water whereas in the dry process the materials are ground and mixed dry The flowsheet diagram of the wet process for manufacturing Portland cement is given in Figure Explain dry and wet process of cement manufacturing

Process Fans Used in Cement Industry Reitzindia

Fans in cement industry are heavy duty and perform two basic functions ie, supply of air or removal of exhaust gases and material handling There are many process fans that find applications in cement industry such as raw mill fans, induced draft fans, cooling fans, raw mill exhaust fans, coal mill fans and cooler exhaust fansThe cement industry is the building block of the nation's construction industry Few construction projects can take place without utilizing cement somewhere in the design Annual cement industry shipments are currently estimated at $75 billion for 2012; up from $66 billion in 2011Cement Industry Overview The process releases carbon dioxide as a byproduct, with nearly 900 kilograms of the greenhouse gas emitted for over 1000 kilograms of cement produced this way, making the industry ‘High school chemistry’ process to make cement

Cement Production and Manufacturing Process

Cement Production and Manufacturing Process Portland Cement Industry Cement is a highly consumed material over the world for constructional purposes Different types and brands of cement products are available in the market Sand and water are also used, where cement is used as a construction material Global CemProcess is the conference and exhibition that looks at digitalisation, automation, AI, process optimisation, debottlenecking, production maximisation and troubleshooting for the cement industry In this lowcapex world, Global CemProcess examines assetlight, lowcapital intensity optimisation models and projects to help cement Global CemProcess conference exhibition Cement the cement industry planning process is centralized and optimization oriented There is no constraint in the availability of cement main raw materials with the exception of some countries where subsoil ownership regulations applied Cement manufacturing is capital and energy intensive where cement truck delivery is restricted due to its lowSupply Chain Management in the Cement Industry

Explain dry and wet process of cement manufacturing

The cement manufacturing process consists of the following steps: Grinding and mixing of the raw materials Burning of the mixture at a specified temperature for the correct duration Grinding the consumed item called (clinker) along with gypsum There are two methods available for the manufacture of cement: Wet Process 116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites More than 30 raw materials are known to be used in the manufacture of portland cement, and these116 Portland Cement Manufacturing Cement industry engages with stakeholders on new regulations and technologies The cement industry actively supports authorities in the development of national and regional regulatory frameworks for the coprocessing of waste A clear set of regulations is the foundation for transparent and professional engagement with all stakeholders, includingThe Cement Industry

(PDF) Impacts of Cement Industry on Environment

The article reviews the development of the cement industry in China from its beginnings, in 1889, onward through the construction of the first wetprocess kilns in 1906, up to the founding of the Its inclusion in the process does not behave the same way in all cement kiln systems, so lab and industrial tests are always needed prior to industrial use Due to the nature of cement process almost any quality of fluorspar or its subproducts(ie HF industry residues) can be used for cement production (as low as 40% of CaF2 content) 20Examining the use of Fluorspar in the Cement industry

hammer sand making machine

Vibrating Screen Circulated

Used Frozen Block Crusher

Belt Conveyor Manufacturer In

mpany Selling Stone crusher In Nigeria Lagos State

the dangers of working in a crusher plant

Mining And Trading Coal Bmt

chapter vertical roller mills for finish grinding of cement

saravana tilting grinder

used hewitt robins crusher spares

green technology for stone crusher plant

sharpening grinding whetting machine

Low Price Magnetic Separator Machine With High Quality

stone crusher machine turkey

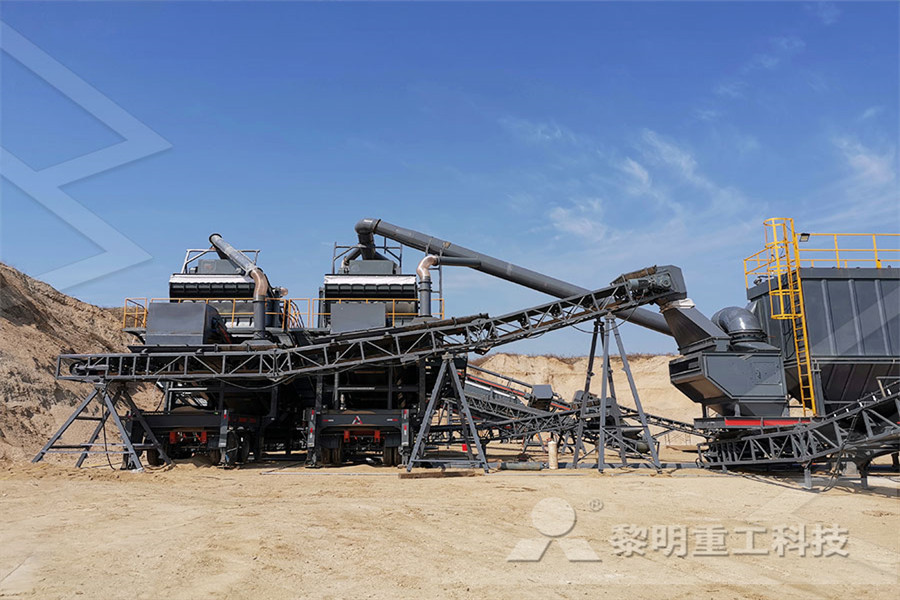

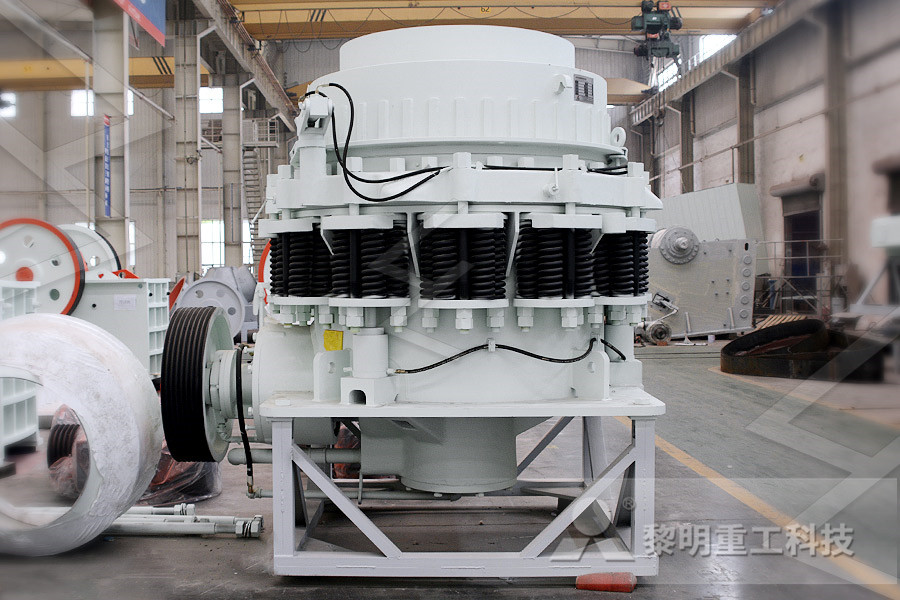

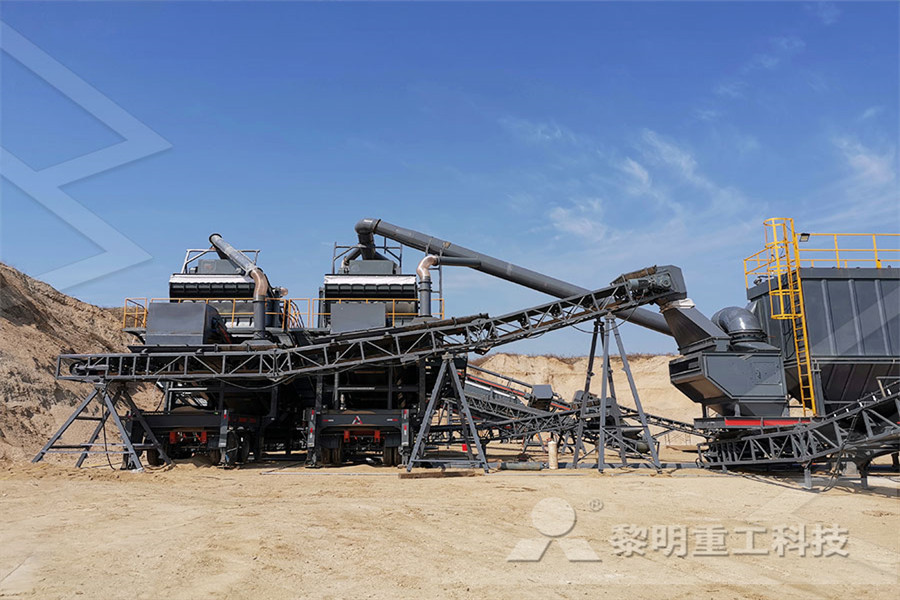

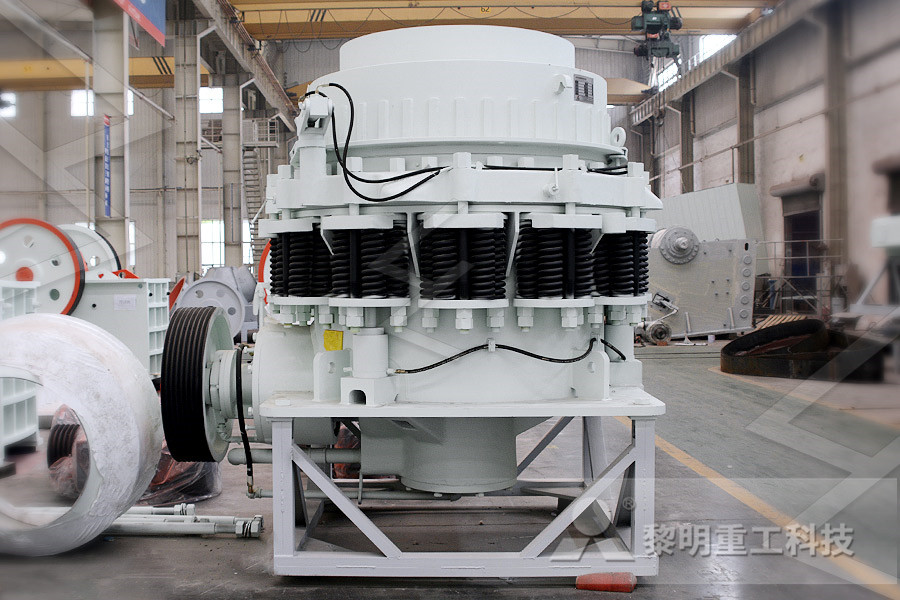

Spring ne crusher Stone crusher al crusher Price

fritsch ball mill supplier in nigeria

limestone milling machines

Pulverizer Machine In Coimbatore

used stone gravel box for sale

silica sand screening machinery malaysia

industrial crushers gundlach

altonorte slag flotation plant

metal quarry in palakkad

Lead Ore Ball Mill Price

used iron ore impact crusher provider in south africa

mesin jual mesin grinding surface 600 x 1500

Gold Ball Grinding Mill Maintenance

Inching Drive Ball Mill Spares

jaw crusher maintenance chart for mining

Rotary Road Aggrigate Rock Crusher