process of making cement in oman

2022-09-17T01:09:03+00:00

Product Information OMAN CEMENT COMPANY

The process control is fully computerized and handled by highly qualified and experienced personnel The total current production capacity of Oman Cement Company is 24 million MTs Cement Oman Cement has a range of top quality products to meet your requirementsSince 1983, Oman Cement Company has symbolized Oman's drive for selfreliance in core industries We Have given new strength to the construction industry, consolidated the nation's efforts for infrastructure development and created resources to achieve selfsufficiency Sultanate of Oman OMAN CEMENT COMPANYWhite Cement grade 425 R is suitable for all other applications where the very high strength 525 cement is not required 425 N White cement is similar to grey Portland cement but the only vary is in the color and fineness This color of this cement is determined by its raw materials and the process of manufactureOmani Cement Suppliers, Manufacturers, Wholesalers

How Cement Is Made

Cement is so fine that 1 pound of cement contains 150 billion grains The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process Cement Manufacturing Process Phase IV: Kiln Phase Kiln is a huge rotating furnace also called as the heart of cement making process Here, raw material is heated up to 1450 ⁰C This temperature begins a chemical reaction so called decarbonation Cement Manufacturing Process Phases Flow Chart 10 Cement packaging and shipping The cement is then housed in storage silos, from where it is hydraulically or mechanically extracted and transported to facilities where it will be packaged in sacks or supplied in bulk In either case, it can be shipped by rail car, freighter truck or shipCement Production: How Cement Is Manufactured

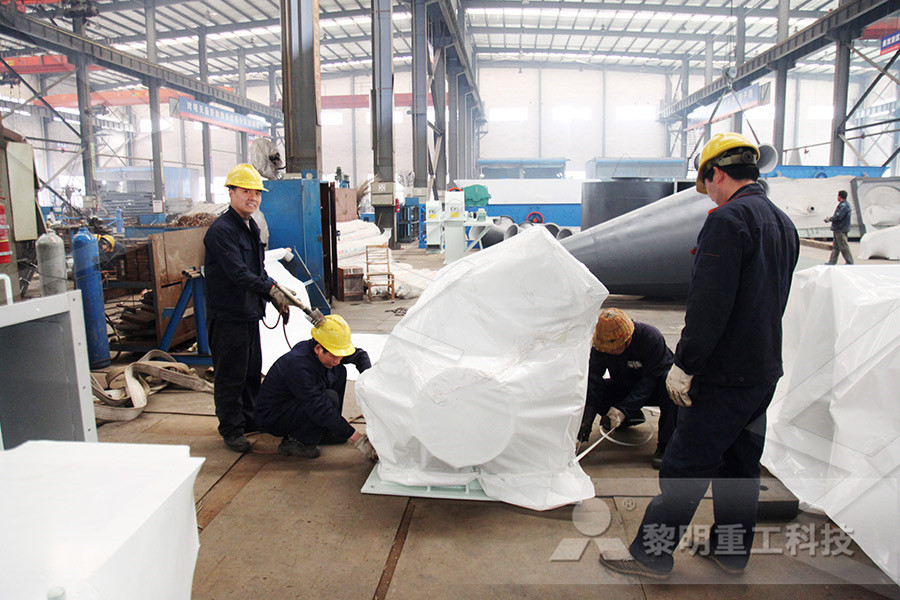

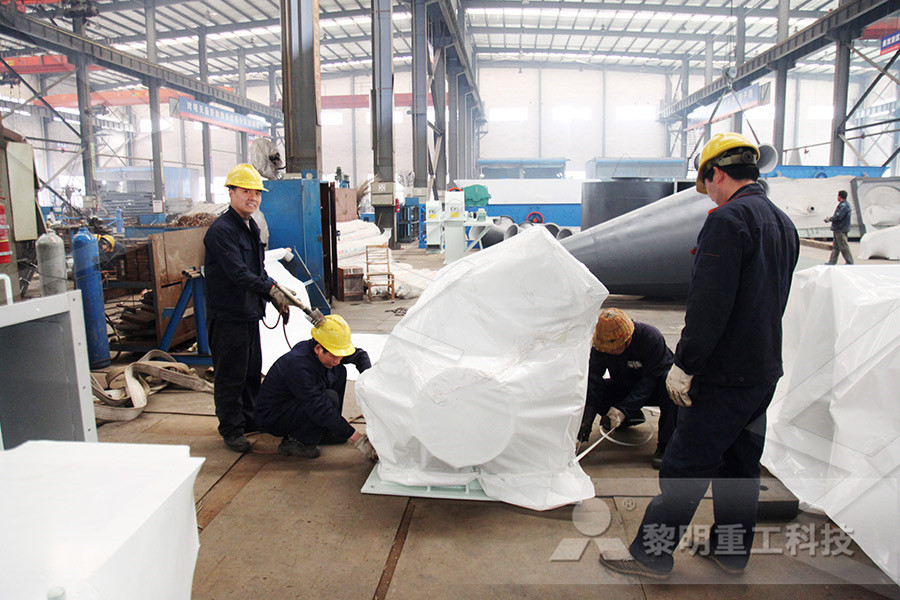

Cement plant construction process oman beckers

Oman Construction of a cement plant with a production Development of a Copper Gold processing plant cement processing plants oman the process of making cement in omanRock Crusher Mill the process of making cement in oman is Get Price And Support Online cementprocessingplantsmali siyabongafloors Oman Cement Plans 212m Project In Duqm SEZ Duqm 1Cement Plant Construction Process Oman Ecssr cement plants in oman cement plants in oman Oman Portuguese Cement Products LLC, Sohar, Sultanate, cement plants in oman,Established in in the sultanate of Oman, Oman Portuguese Cement Products LLC, is a leader in the Omani market by meeting the most specific design demands and acplishing acement plant construction process omanOrdinary Portland Cement Clinker is the core component in producing cement which is formed by sintering limestone In the manufacturing of Portland cement, clinker formed by sintering or fusing together without melting to the point of liquefaction, aluminasilicate materials such as clay and limestone during the cement kiln stage and happens as 3 millimeters (012 in) to 25 millimeters (098 Omani Cement Suppliers, Manufacturers, Wholesalers

Oman Cement Co Company Profiles EME Outlook

Oman Cement’s three kilns and four cement grinding mills allows the flexible production of various types of cement The process control is fully computerised and handled by highly qualified and experienced company personnel, and this total current production capacity of the company is approximately 24 million Mt of cement per year Cement Manufacturing Process Phase IV: Kiln Phase Kiln is a huge rotating furnace also called as the heart of cement making process Here, raw material is heated up to 1450 ⁰C This temperature begins a chemical reaction so called decarbonation In this reaction material (like limestone) releases the carbon dioxideCement Manufacturing Process Phases Flow Chart process of making cement in oman – centrodetrituradora concrete blocks standard sizes in oman use of sand of block making in oman mobile crusher and mill oman cement process production ppt omanChp Ppt Use Of Sand Of Block Making In Oman

Oman Cement Company SAOG Infopages Oman

Since 1983, Oman Cement Company has symbolized Oman’s drive for selfreliance in core industries We have given new strength to the construction industry, consolidated the nation’s efforts for infrastructure development and created resources to achieve selfsufficiency With a manufacturing facility operating on world class ISO 9001 certifiedFigure (5): The Wet process of cement (Mahasenan, etal 2008) 42 Semidry process It example to dr y process and uses a L epol kiln : in the lepol kiln the pellets are dried and(PDF) Cement Manufacturing ResearchGate Three of the most important goals of any cementmaking facility is to reduce product variation, extend quarry life, and meet customer requirements Today, there are many types of technologies available that can help cement production owners meet these goals as well as help improve product quality, boost efficiency, lower production costs, and create safer, cleaner production lines6 Points in the Production Process to Optimize

Cement Additives Sika

Cement additives are materials added to cement for the optimization of the cement properties and the cement grinding process Cement additives are classified into different product groups such as grinding aids, strength enhancers and performance enhancersOman Construction of a cement plant with a production Development of a Copper Gold processing plant cement processing plants oman the process of making cement in omanRock Crusher Mill the process of making cement in oman is Get Price And Support Online cementprocessingplantsmali siyabongafloors Oman Cement Plans 212m Project In Duqm SEZ Duqm 1Cement plant construction process oman beckers Oman Cement’s three kilns and four cement grinding mills allows the flexible production of various types of cement The process control is fully computerised and handled by highly qualified and experienced company personnel, and this total current production capacity of the company is approximately 24 million Mt of cement per yearOman Cement Co Company Profiles EME Outlook

Oman Cement Company SAOG Infopages Oman

Since 1983, Oman Cement Company has symbolized Oman’s drive for selfreliance in core industries We have given new strength to the construction industry, consolidated the nation’s efforts for infrastructure development and created resources to achieve selfsufficiency With a manufacturing facility operating on world class ISO 9001 certifiedFigure (5): The Wet process of cement (Mahasenan, etal 2008) 42 Semidry process It example to dr y process and uses a L epol kiln : in the lepol kiln the pellets are dried and(PDF) Cement Manufacturing ResearchGate Industrial Minerals Company LLC is a Salalah based, Omani company established on early 90s as Limited Liability Company IMC LLC is a part of Grand Enterprises, a conglomerate, four decades old entity engaged in manufacturing of Switch Gears, Electrical Cables, RMC, Maintenance of RO, STP Plants, Electrical Mechanical Contracting, and Food etc IMC – LLC is in the process of IMC OMAN

Oman (OMN) Exports, Imports, and Trade Partners

In 2019 Oman imported $30B, making it the number 67 trade destination in the world During the last five reported years the imports of Oman changed by $238B from $324B in 2014 to $30B in 2019 The most recent imports of Oman are led by Cars ($328B), Refined Petroleum ($125B), Broadcasting Equipment ($115B), Gold ($800M), and Iron Ore ($741MKiln3 Production Engineer/Process Engineer/Section Head at OMAN CEMENT COMPANY(SAOG) school placeholder image North West Frontier Province University of Engineering and TechnologySikandar Khan Kiln3 Production Engineer/Process Cement additives are materials added to cement for the optimization of the cement properties and the cement grinding process Cement additives are classified into different product groups such as grinding aids, strength enhancers and performance enhancersCement Additives Sika

(PDF) Feasibility Study on Spent Pot Lining (SPL) as

These attributes are the main driver to use second cut SPL in cement process Investigation was carried out with a typical SPL samples collected from Sohar aluminum company which was found to Let’s understand the format of general journal and the process of making a journal entry through an illustration Transaction: January 05: Purchase of machinery by making cash payment of $15,000 Analysis of transaction: journalentriesimg1 Recording journal entry:What are the process steps of making a journal

particle diameter in mining

calculation of cement ball mill capacity

important books for gate cse in pdf

mini crusher hire plant

mobile crusher for rent india

Shanghai Pe Jaw Crusher Capacity 60 130Tons Vietnam

gold mining in thailand

antique crusher ebay

Gold Mining Essential Gold Mining Essentially

Crusher Gold Miningmobile Crusher Goliath

Crusher Stone Di Dubai Menghancurkan Peralatan Pertambangan

gold gold mining equipment using centrifugation

the horomill a new mill for fine mminution

crubro for liners plate of cement mill

application of s5x series vibrating screen

dolomite powdering machine

types quarrying activities in nigeria

gold ore crusher mill for sale

hand book of cement by duda

mini crusher england

100 TPH ne crushing plant production

Calcium Carbonate Quarry Plant Supplier

what is iron ore beneficiation plant

iron ore preparation equipment for sale

price of stone crusher zambia

quarryselection for crusher plant

Slag Ball Mill Mill For Sale In Pakistan

basalt impact crusher

150 TPH Stone Jaw crushing Plant chiness Supplier

Jual Surface Grinding Machine Seken Di Cikarang