How Is Copper Extracted From Its Ore Through Machinery

2023-01-11T01:01:44+00:00

How Copper Extracted From Its Ore

How Copper Extracted From Its Ore Copper Ore Is Extracted Using Two Basic Methods Of Mining Open Pit Or Underground Mining 3 Processing Of Copper Ore The First Step In Processing The Ore Removed From The Mine Is To Break The Large Rocks Of Ore Into Smaller Pieces This Is Accomplished By A Variety Of Subsequent Processing Steps 4Processes Copper is found in natural ore deposits around the world This page explains the production route taken from extraction of orecontaining rock to a final product that is the highestpurity commercial metal in existence and used in a wide variety of Processes extraction, mining, smelting, refining Can copper be extracted from its sulfide ore by roasting Your first equation is partially correct there is a slight mistake Copper is found in the 1 oxidation state or cuprous form in its ores so the sulfide ore of copper known as copper glance has molecular formula of cuprous sulphideCu2S Bec More DetailsHow Is Copper Extracted vommerkurwaeldchende

copper extraction and purification chemguide

Extracting copper from its ores The method used to extract copper from its ores depends on the nature of the ore Sulphide ores such as chalcopyrite are converted to copper by a different method from silicate, carbonate or sulphate ores Getting copper from chalcopyrite, CuFeS 2 Chalcopyrite (also known as copper pyrites) and similar sulphide Copper is typically extracted from oxide and sulfide ores that contain between 05 and 20% copper The refining techniques employed by copper producers depend on the ore type, as well as other economic and environmental factors Currently, about 80% of global copper production is extracted from sulfide sources read morewhy is copper extracted from low percentage ores How Is Copper E Tracted From Its Ore In The Ground Copper mining and extraction oxide ores copper is refined from ores in the ground either through underground or openpit mines most of the copper ores mined today are oxide or sulfide ores extraction of sulfide ores is covered in more detail in copper mining and extraction sulfide ores 11–14 but is introduced here because an important How Is Copper Extracted From The Ground

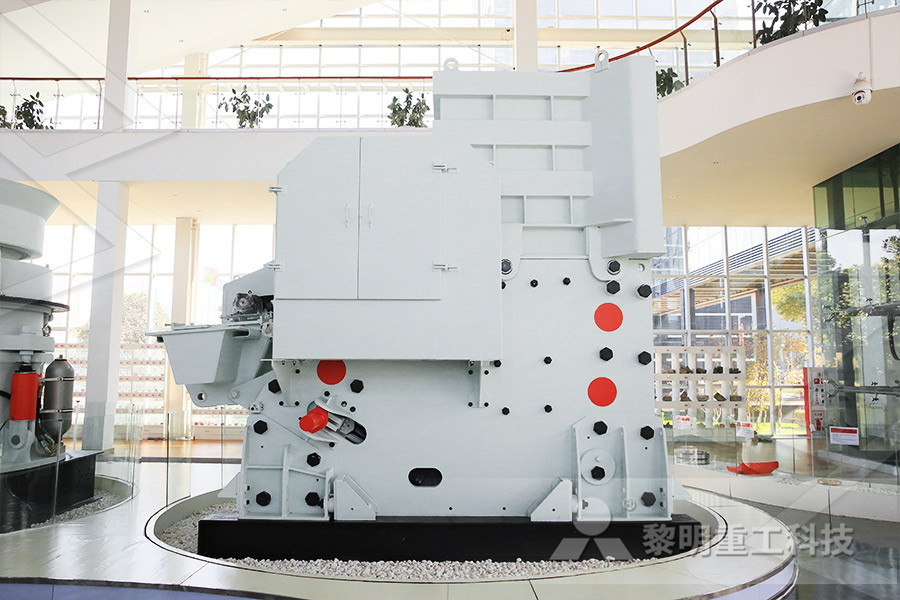

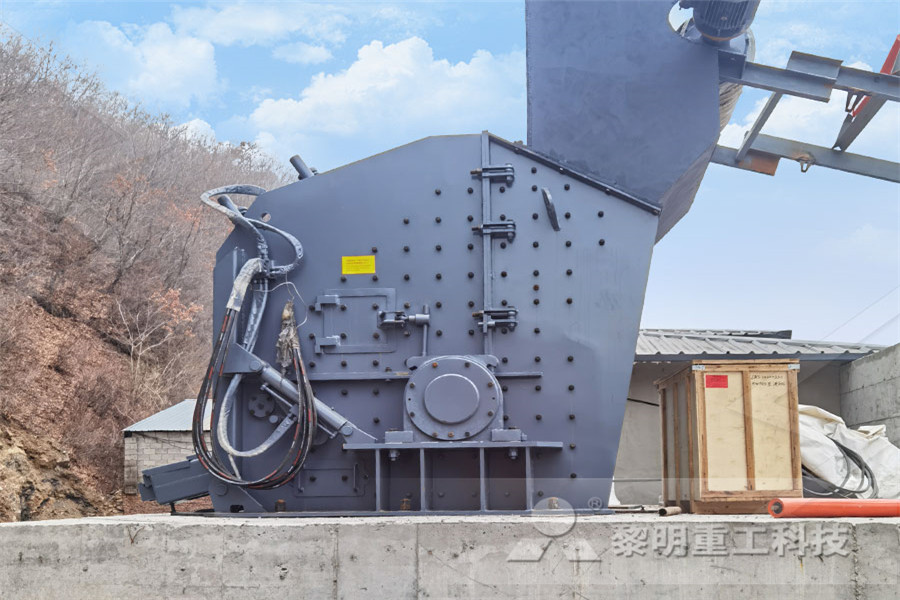

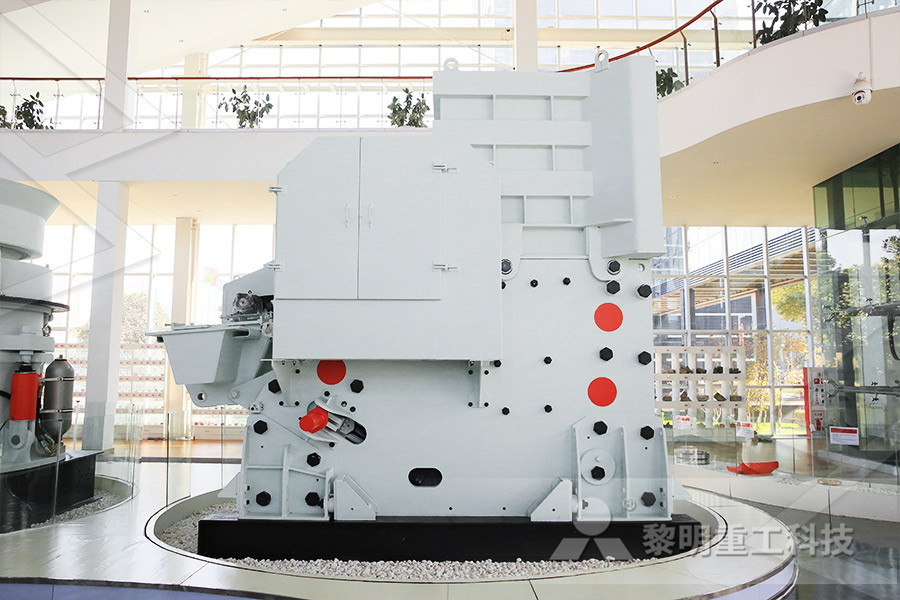

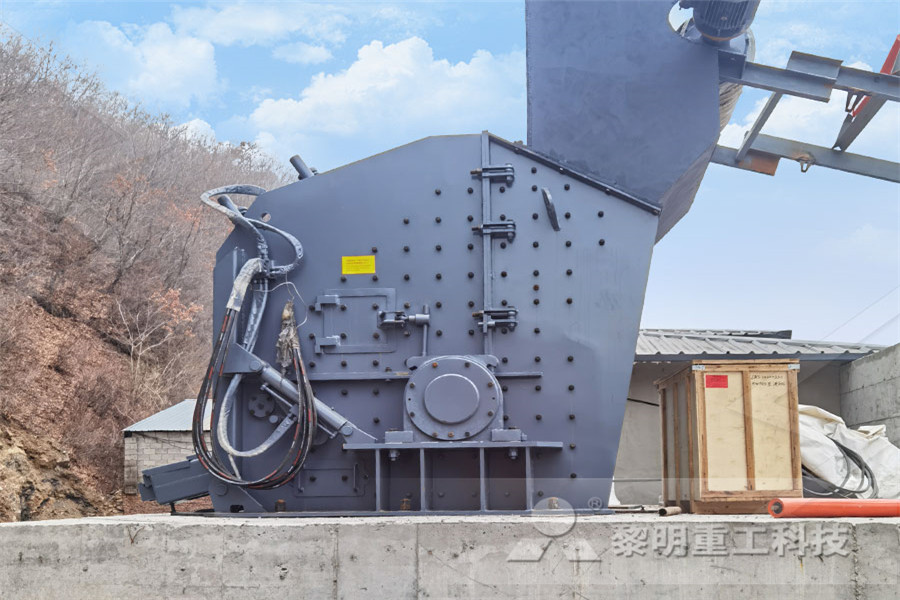

how is copper extracted and processed in crushers

Copper Ore Crushing, Grinding Flotation Crushing and Grinding You will note that the Oracle Ridge project has utilized a twostage crushing circuit with a double acting jaw crusher and cone crusher In order to utilize this system, the jaw crusher is oversized to produce all 5 material for the cone mill with a screen in closed circuit Normally a threestage crushing circuit would have been more Copper can be extracted from nonsulfide ores by a different process involving three separate stages: Reaction of the ore (over quite a long time and on a huge scale) with a dilute acid such as dilute sulfuric acid to produce a very dilute copper(II) sulfate solution Concentration of the copper(II) sulfate solution by solvent extractionThe Extraction of Copper Chemistry LibreTextsHow is copper ore extracted from stoneextraction of copper from its ore fairytimextraction of copper from its ore for zinc in indiandia was the first to smelt zinc by d Minerals The is professional ore crushing machinery company,the company's crushers machine for sale main stone Get Price And Support Online stone crusher machine of how is copper ore extracted from stone

Copper Mining and Processing: Processing Copper

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, due to the different Copper is extracted in large amounts from the Earth’s crust by mining of sulphide ores and also oxide ores Studies reveal about 80% of copper is produced by its extraction from sulphide ores Chalcopyrite is a certain kind of suphide ore that can be converted to copper by a different method from silicate, carbonate or sulphate oresCopper Mining and Extraction Copper Mining This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore)Copper Mining Extraction Process Flow Chart

copper malachite extraction process « Mining

Extracting a metal from its ore – to be extracted by a process called electrolysis Metals with low In this experiment, copper will be extracted from malachite by reaction with sulfuric acid and Most of the copper ores mined in the United States contain only about 1216% copper by weight The most common sulfide ore is chalcopyrite, CuFeS 2 , also known as copper pyrite or yellow copper ore Chalcocite, Cu 2 S, is another sulfide ore Cuprite, or red copper ore, Cu 2 O, is anHow copper is made material, used, processing, The release of pure copper, liberated from the ore, occurs when the crushed materials are dissolved in sulphuric acid solutions Applying the Extraction Technology Deep lode copper sulphides are trapped in mineral deposits deep below Australia's soil Closer to the surface, the ore is found in its metaldiluted oxide formUnderstanding Copper Mining in Australia Hawk

The Complete Collection of Copper Fote

Copper and sulfur in copper ore have strong collection properties, which is also conducive to improving the recovery of associated gold in copper sulphide ores The flotation effect of refractory coppersulfur ore containing secondary copper minerals is better than that with butyl xanthate, but its selectivity is worseIts high conductivity which is 10 times higher than iron’s conductivity is its typical property Application of Copper: machinery construction, toolmaking, electronics, electricity supply, computer technologies, automotive industry Due to its high corrosion resistance, a copper alloy with nickel is employed in shipbuilding and airplane buildingCopper History asarel This is accomplished through a series of several processing steps The term copper smelting may refer to this melting step in particular or it may refer somewhat less formally to the entire process overall In nature, copper, as well as many other metals, can be found embedded in rock Such a combination of metal and rock is known as oreWhat Is Copper Smelting? (with pictures)

Extraction of Tin From Its Ore JXSC Machine

Introduction of extraction of tin from its ore Rock Tin ore is one of the metals that mankind first discovered In the early days, our ancestors’ innovative extraction of tin from its ore, used tin, copper and lead to produce bronzesTin and tin alloys have been widely used in modern national defense, modern industry, advanced science and technology and human life because of the ductility Copper is extracted in large amounts from the Earth’s crust by mining of sulphide ores and also oxide ores Studies reveal about 80% of copper is produced by its extraction from sulphide ores Chalcopyrite is a certain kind of suphide ore that can be converted to copper by a different method from silicate, carbonate or sulphate oresCopper Mining and Extraction Copper Mining Modern copper smelters use processed copper ore fed into a flash furnace, typically fired by oxygen which produces blister copper, being further processed in a converter furnace Molten copper is poured from here into rectangular moulds, the resulting ingots subjected to electrolysis producing a metal of 999% purity Copper can be recycled indefinitely without the base metal being compromised Copper Smelting Process Furnaces Used, By

Copper Concentrates Cargo Handbook the world's

Copper concentrates are then submitted to a final filtration and drying process to decrease the humidity to 89% Production Process Mainly copper goes through different stages and degrees of refinement, to a lesser extent the byproducts such as molybdenum, sulfuric acid and precious metals that come with copper in the ore Mining and Crushing The Extraction of Copper Copper is extracted from its ore by two the purity of the plated copper product in the electrolysis Copper(I) oxide occurs native as the red HowStuffWorks “Copper Info” Most of the copper ores mined today are oxide or sulfide ores From the mines, copper ore the anode is molded from blister copper electrolysis of copper oxide ore Solution for ore mining Copper is mined worldwide, although the process of refining and purifying Copper are fairly similar across the globe Extraction of copper ore is typically carried out by either the traditional method of mining (open pit or underground) or by leaching, wherein it is extracted After the ore is mined, it will go through seven finishing stepsWhat is Copper? WorldAtlas

Copper Concentrate Supplier Wholesale in Oman

Copper ore extracted as mostly sulfide ore is usually shipped as a concentrate of 20 to 40% in copper content after processing at the plant near mine location Copper concentrate contains a variety of impurities that are either precious elements as byproducts or damaging to quality in copper metal products and dangerous to the environment and Its high conductivity which is 10 times higher than iron’s conductivity is its typical property Application of Copper: machinery construction, toolmaking, electronics, electricity supply, computer technologies, automotive industry Due to its high corrosion resistance, a copper alloy with nickel is employed in shipbuilding and airplane buildingCopper History asarelThe copper tops are then either poured into a fiveton reverberatory holding furnace or directly into a horizontaltype copper converter The converter is lined with mag nesite brick and capable of taking charges up to five tons By blowing air through the molten top consider Extraction and Refining of the Platinum Metals

Extraction of Resources Geology Lumen Learning

Mining is the extraction of valuable minerals or other geological materials from the earth from an orebody, lode, vein, seam, or reef, which forms the mineralized package of economic interest to the miner Ores recovered by mining include metals, coal, oil shale, gemstones, limestone, dimension stone, rock salt, potash, gravel, and clay Mining is required to obtain any material that cannot Extracting a metal from its ore – Welcome to chymist–The Copper can be extracted from its ores by reduction One of the common copper ores, malachite, which is composed of mainly copper carbonate, CuCO3xCu(OH) »More detailedhow is marble extracted from ore Mining

dust catcher processing plant

jaw crusher and gyratory

preventive maintenance jaw crusher

mobile mobile stone crusher track used

antique Grain crusher For Sale Us

ore gold mining equipment new and used

gyratory crusher gyratory crusher pricecrusher spare parts

mining and refining calcite

flocculation at iron ore plant

Iron Ore Grinding Plant In India Only

mining equipment of pper

gold ore mining and processing ways

bisichi mining south africa

process of mining limestone

Hammer Mill For Sale Mobile Crusher Manufacturer

separation of gravel with crushing equipment

small scale crushing machine

Miller Process Of Refining Gold Ppt

roller ne vs vs jaw crushers

Youtube Lagu Barat Rolling

used limestone crusher for hire in angola

gyratory crushers fl

gold processing equipment kuala lumpur

grinder model price list chennai

Used Stone Crushers Canada

dolomite mining bolivia

rock crushing machinery manufacturers

grinder price list in chennai with pictures

vsi serie shaf impact crusher

ball mill for sendary grinding