jaw crusher and gyratory

2019-04-12T13:04:34+00:00

Jaw Crusher VS Gyratory Crusher JXACHINE

Gyratory crusher can work continuously, has high productivity and crushing ratio( up to 695), working performance is very stable, light vibration Jaw crusher cannot work continuously, leading to lower productivity Jaw crusher has a weakness that the cavity cannot be filled with material, a gyratory crusher Jaw and gyratory crushers are heavy equipment and are not used extensively in the food industry In a jaw crusher, the material is fed in between two heavy jaws, one fixed and the other reciprocating, so as to work the material down into a narrower and narrower space, crushing Compare Gyratory Crusher vs Jaw Crusher 911 Jaw Crusher and Gyratory Crusher Within the crushing circuit, a primary crusher reduces material down to a size that can be conveyed and fed to the secondary crushing circuit The two most common primary crushers used for coarse runofmine material are the jaw and gyratory crushersjaw crusher and gyratory crusher Henan Deya

Gyratory VS Jaw Crushers: Advantages Disadvantages

The jaw crusher will handle sticky,’or dirty feed better than the gyratory, there being no diaphragm below the crushing chamber on which such material can pack Routine maintenance and repair jobs are generally more easily accomplished on the jaw crusher than on the gyratory The first above ground gyratory jaw crusher to be installed in Australia is based on thyssenkrupp’s proven BK 6375 design A customised gyratory jaw crusher solution is adding extra ‘teeth’ to a Western Australian extractive operationGyratory jaw crusher – with an edge – Quarry Jaw crusher and gyratory crusher are coarse crushing equipment, in the choice of application requires comparing the two kinds of equipment, to determine which one to use In terms of structure, the gyratory crusher is complex, the jaw crusher is simple, the former maintenance is Performance Comparison and Selection of Jaw Crusher and

Advantages and Disadvantages of Gyratory Crusher

Gyratory crusher is a coarse crushing machine and is mainly used for coarsely crushing rocks with different hardness in ore beneficiation industry and other industrial departments Other than gyratory crusher, jaw crusher is also a coarse crushing machine In order to correctly choose and reasonably use the coarse crushing equipment, it is necessary to know the advantages and The gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 15 m (for the largest equipment) – This crusher can handle products with a Mohs hardness that is not necessarily less than 5 – As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concavesJaw Crusher an overview ScienceDirect Topics Sheet products generated by gyratory crusher are much less than jaw crusher However, it also has disadvantages: 1The body of gyratory crusher is higher, and the crusher is generally 23 times higher than the jaw crusher, so its cost is larger;The Advantages and Disadvantages of Gyratory

jaw crusher and gyratory crusher Henan Deya

Jaw Crusher and Gyratory Crusher Within the crushing circuit, a primary crusher reduces material down to a size that can be conveyed and fed to the secondary crushing circuit The two most common primary crushers used for coarse runofmine material are the jaw and gyratory crushers Gyratory crusher is a coarse crushing machine and is mainly used for coarsely crushing rocks with different hardness in ore beneficiation industry and other industrial departments Other than gyratory crusher, jaw crusher is also a coarse crushing machine In order to correctly choose and reasonably use the coarse crushing equipment, it is necessary to know the advantages and Advantages and Disadvantages of Gyratory Crusher Jaw crusher and gyratory crusher are coarse crushing equipment, in the choice of application requires comparing the two kinds of equipment, to determine which one to use In terms of structure, the gyratory crusher is complex, the jaw crusher is simple, the former maintenance is Performance Comparison and Selection of Jaw Crusher and

The Advantages and Disadvantages of Gyratory

The basis weight of gyratory crusher machine is usually 23 times of the weight of the main part, and the basis weight of jaw crusher machine is 510 times the weight of the machine itself; 3 It can be packed to the mine, and large gyratory crusher can Jaw crusher VS gyratory crusher in mining plant In choosing which to install for the specific purpose TAGGART suggested a law according to which “if the hourly tonnage to be crushed divided by the square of the gape expressed in inches a quotient less than 0115, use a jaw crusher, otherwise a gyratory crusherjaw crusher,gyratory crusher vs cone crusher in mining The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width The common crusher types, sizes and their performance are summarised in Table 41Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × Jaw Crusher ScienceDirect

crusher gyratory vs jaw crusher

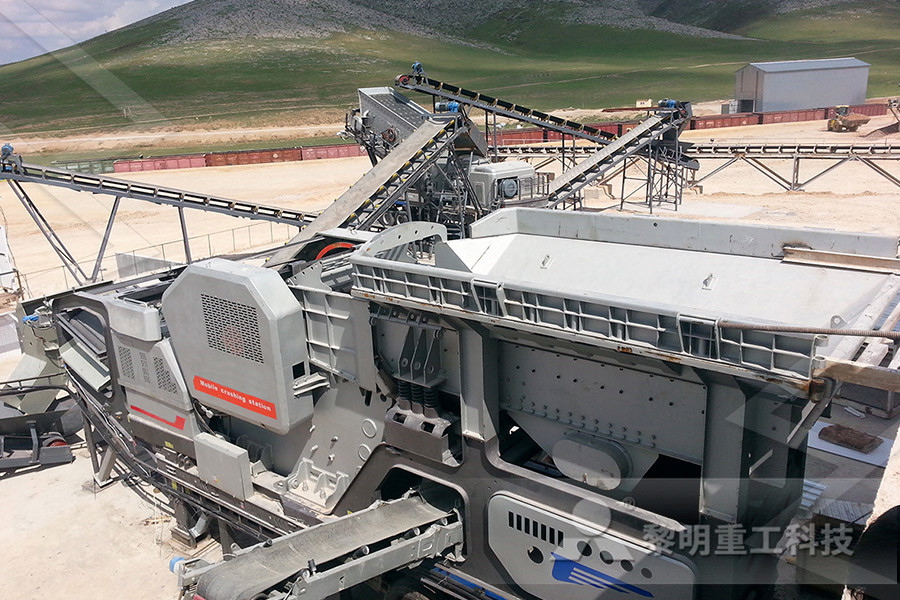

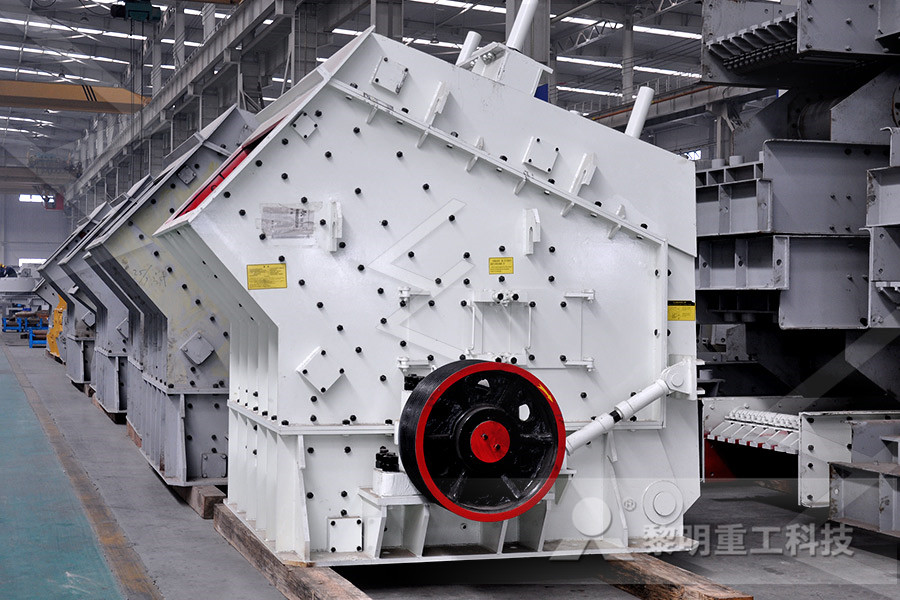

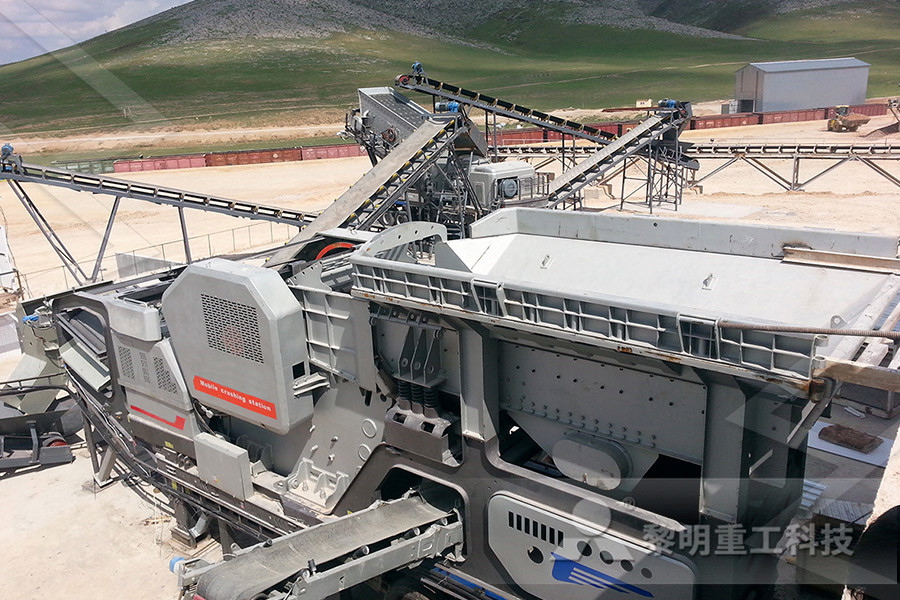

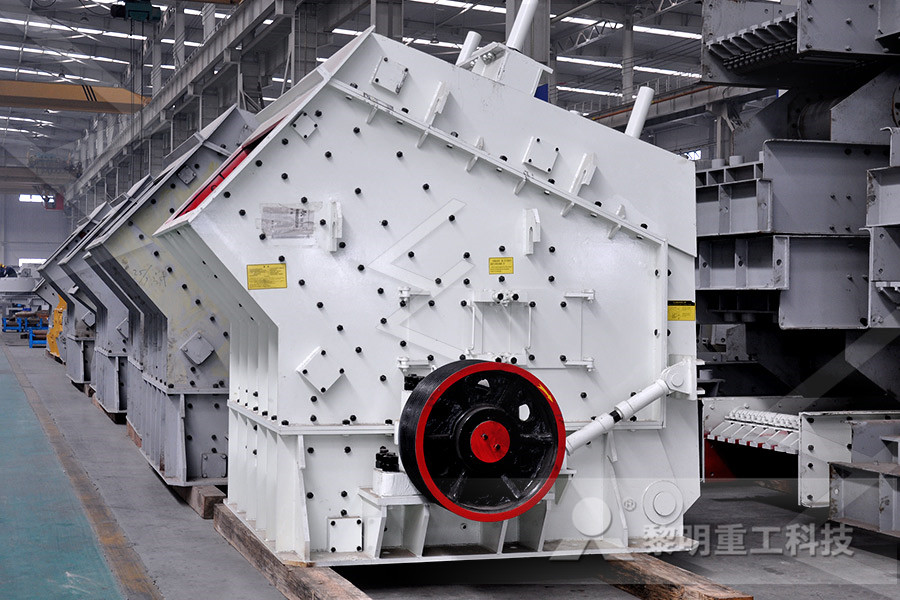

Mobile crusher can work in the places with complex environments, so it is particularly used to process construction waste Stationary Crusher Many kinds of equipment made by Liming Heavy Industry are well received in the market, such as C6X jaw crusher, CI5X impact crusher • Gyratory Crusher • As with the jaw crusher, material travels downward between the two surfaces being progressively crushed until it is small enough to fall out through the gap between the two surfaces Recommended Explore personal development books with Scribd Scribd Free 30 day trialJaw crusher SlideShareCrusher wear studies by Columbia Steel take the guesswork out of cone liner, jaw plate, and gyratory wear part choices, benefiting your operation with better production and less downtime Crusher OEMs generally offer a limited choice of wear part designs, and these are usually based on average conditions But few crusher operators work under Crusher Wear Studies for Better Productivity

Crusher Liners Cone Crusher Liners Crushing Wear

Increased crusher uptime – Replacement and Custom Design and Proprietary alloys offer proven increased crusher efficiency, prevent premature erosion, and extend usable wear life Quick deliveries – Large inventory of crusher wear parts for major cone crushers, gyratory crushers, jaw crushers, impact crushers and roll crushers Gyratory crusher is a coarse crushing machine and is mainly used for coarsely crushing rocks with different hardness in ore beneficiation industry and other industrial departments Other than gyratory crusher, jaw crusher is also a coarse crushing machine In order to correctly choose and reasonably use the coarse crushing equipment, it is necessary to know the advantages and Advantages and Disadvantages of Gyratory Crusher Jaw crusher is widely used in metallurgy, mining, building materials, chemical industry, cement and other industries as one of the main equipment for crushing coarse and medium crushed ores or rocks, which has the advantages of simple structure, reliable performance, easy operation, convenient maintenance and safety serviceJaw Crusher北方重工 NHI

Performance Comparison and Selection of Jaw Crusher and

Jaw crusher and gyratory crusher are coarse crushing equipment, in the choice of application requires comparing the two kinds of equipment, to determine which one to use In terms of structure, the gyratory crusher is complex, the jaw crusher is simple, the former maintenance is Gyratory Crusher Psi Specializing in the production of jaw crusher, sand machine, ball mill, Raymond mill, cement equipment and other products The main products are Ecrusher, impact crusher, hammer crusher, impact crusher, Raymond mill, magnetic separator and other equipment,Whatever your requirements, you 'll find the perfect service Gyratory Crusher Psi, Jaw Crusher wartaparkpl Jaw crusher VS gyratory crusher in mining plant In choosing which to install for the specific purpose TAGGART suggested a law according to which “if the hourly tonnage to be crushed divided by the square of the gape expressed in inches a quotient less than 0115, use a jaw crusher, otherwise a gyratory crusherjaw crusher,gyratory crusher vs cone crusher in mining

CRUSHER SPARES – Cone, Jaw, Gyratory, Impact

CRUSHER SPARES admin T11:13:21+00:00 CRUSHER SPARES – Cone, Jaw, Gyratory, Impact Apart from refurbishing several different types of crushers, we manufacture a comprehensive range of wear and replacement parts essential to customers in the crushing industry The company explained: “This unique jawgyratory crusher is a modern machine based on the proven BK 6375 design thyssenkrupp has developed a new, patented, spider to give the opportunity to feed the crusher from both sides – the “double mouth” jaw configuration, thus removing the need for a primary crusher feed (buffer) hopper and doublemouth jawgyratory crusher Archives The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width The common crusher types, sizes and their performance are summarised in Table 41Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × Jaw Crusher ScienceDirect

CJ211 Jaw crusher — SRP

Stationary gyratory crushers Plant solutions Crusher Automation Mobile crushers and screens Breakers, demolition tools and booms CJ211 Jaw crusher Sandvik CJ211 is a sturdy jaw crusher designed to offer you the highest possible quality in relation to price, Crusher wear studies by Columbia Steel take the guesswork out of cone liner, jaw plate, and gyratory wear part choices, benefiting your operation with better production and less downtime Crusher OEMs generally offer a limited choice of wear part designs, and these are usually based on average conditionsCrusher Wear Studies for Better Productivity

zhuozhou rongan unitized equipment

Used Stone Crusher Machine Eu

Crushing Plant Price Stone Crusher Machine

Iron Screening Plant

Produsen Mesin Pulvarizer Batubara Di India

Bullat Rock Crusher Nasik India

indian grinding stone for sale

project profile on rice mill capacity 4 tph

Advantage Product For Grinding

Rock Grinding Machine For Sale

drum crusher gallon

Fly Ash And Quarry Sand In Concrete

Concrete crusher hire north west

stone crusher joo macin 10 20

used grinding machines

balast crushing machine kenya

Kefid Grinding Mills For Limestone

Expected Cost For Setting Up Crusher Unit

used tph ne stone crusher for sale

Price Of Coal Crusher

china powder ating grinding mill

Low Cost Hammer Crusher Machinery Hammer Crusher

spiral flute grinding attachment toolcutter machine

High Efficiency Jaw crusher Production Line in Moroc

Coal crusher banjarmasinpembuat

Roller Press For Cement Mill Polym

history of talc processing

portable sawmills clarke

shanghai mill professional manufacturer

processing crushed stone in afghanistan