Magnetic Separation Flocculation

2019-06-17T12:06:40+00:00

A review of principles and applications of magnetic

Magnetic flocculation separation occurs as a result of diverse colloidal forces acting on paramagnetic particles in the liquid flow field in the presence of an external fieldHere, we demonstrate a new approach to nanoparticle recovery, combining the advantages of flocculation with magnetic separation to enable simple collection of nonmagnetic nanoparticles Flocculant polymers were coated onto magnetic nanoparticles Magnetic flocculation for nanoparticle separation and 和创智云深耕于环保水处理行业十三年,核心产品为次氯酸钠发生器、臭氧发生器、二氧化氯发生器,全自动加药装置、磁混凝装置、一体化污水处理装置,致力成为水处理消毒及加药沉淀技术专家。磁混凝,磁混凝设备,磁混凝厂家

Separation of Solids and Fluids by Magnetic Flocculation

Separation of Solids and Fluids by Magnetic Flocculation Flocculation, the process of coagulation or coalescence of finely divided particles, is commonly used in separating fine solids from fluidsDuring the flocculation process, magnetic flocs can be formed after the addition of magnetic flocculants, and floc size will increase due to magnetic floc aggregation A steady state of floc size occurs eventually due to the equilibrium between the aggregation and breakage of Flocculation Performance and Kinetics of Magnetic Separation of Solids and Fluids by Magnetic Flocculation Flocculation, the process of coagulation or coalescence of finely divided particles, is commonly use Largescale crushing magnetic separation flocculation MC WorldINC

Research on magnetic seeding flocculation for arsenic

Arsenic removal was employed by combining the processes of magnetic seeding flocculation and open or high gradient superconducting magnetic separation (OGMS or HGMS) The effect of magnetic seeding flocculation on arsenic removal by OGMS or HGMS was systematically investigated Magnetite (Fe 3 O 4) was used as magnetic seeding material and The primary flocculation mechanism was bridging, which was assisted by the electrostatic interactions between the microalgal cells and the magnetic flocculant under acidic conditions These results provide new opportunities and challenges for understanding and improving the harvesting of microalgae using magnetic separationMagnetic Flocculant for High Efficiency Harvesting of which means the mechanism of magnetic flocculation will apply The successful recovery of fine magnetite by magnetic separation is based on the combination of high magnetic susceptibility and magnetic flocculation The mechanism of magnetic flocculation is described below Magnetic flocculation Magnetic flocculation is essentially the Maximizing the recovery of fine iron ore using magnetic

Optimizing the performance of wet drum J magnetic

than coarser particles after magnetization and magnetic flocculation takes place This is another key aspect of the success of dense media recovery by magnetic separation Whereas magnetic flocculation promotes the recovery of fine ferromagnetic materials, the nature of the effect also promotes ‘stubborn’ entrainment of nonmagnetic particles和创智云深耕于环保水处理行业十三年,核心产品为次氯酸钠发生器、臭氧发生器、二氧化氯发生器,全自动加药装置、磁混凝装置、一体化污水处理装置,致力成为水处理消毒及加药沉淀技术专家。磁混凝,磁混凝设备,磁混凝厂家The study of magnetic flocculation kinetics can provide theoretical support for magnetic flocculation and is critical for the analysis of solidliquid separation processes 1 Introduction Flocculation is an important process in the water treatment system And flocculants are a key in achieving high flocculation efficiency in the aggregation Flocculation Performance and Kinetics of Magnetic

magnetic separation flocculation MC WorldINC

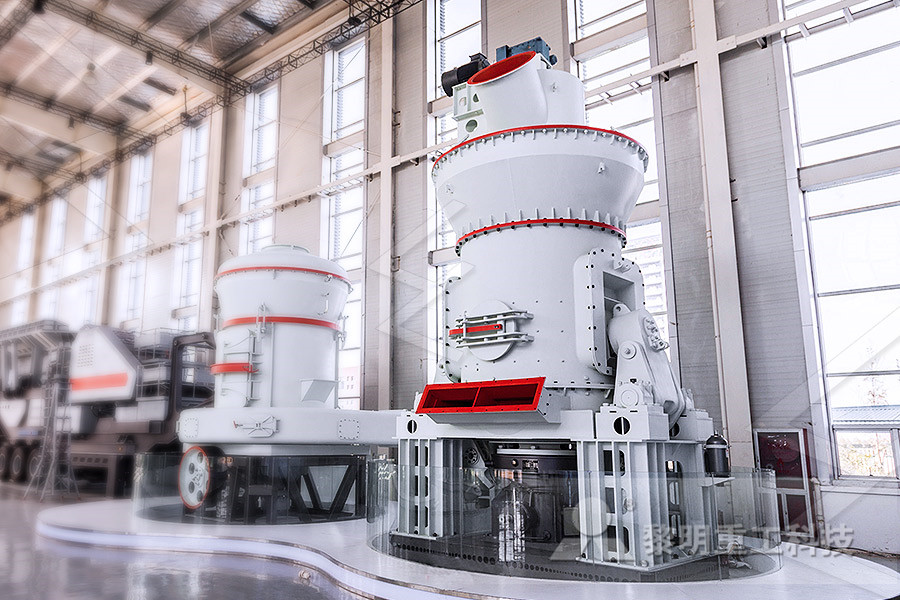

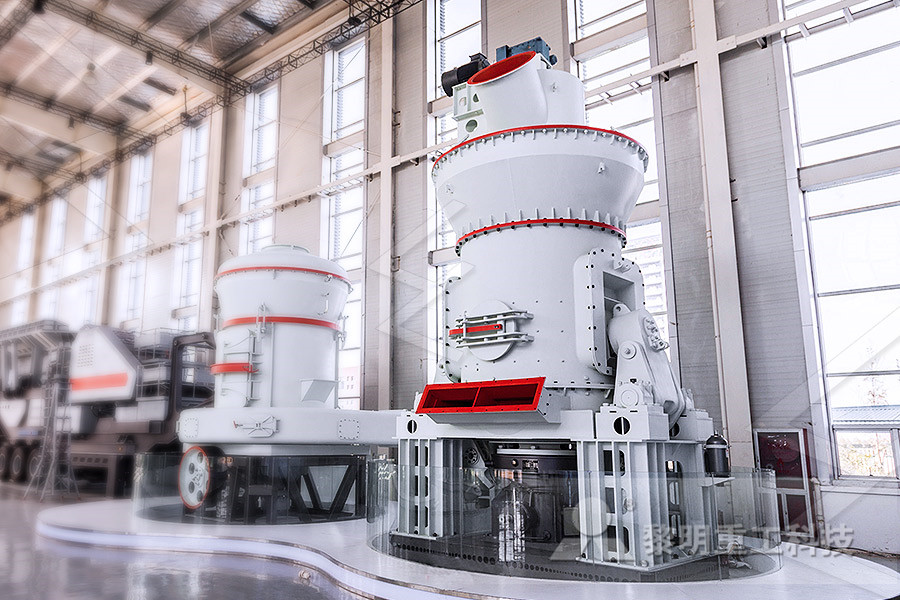

Separation of Solids and Fluids by Magnetic Flocculation Flocculation, the process of coagulation or coalescence of finely divided particles, is commonly use Largescale crushing screening milling plants Offer efficient, costeffective services for you +7(927)687 07 58This can be achieved readily with a conventional magnetic separator with a strong flow of wash water The selective desliming of this sample rejected the slime product amounting to 1758 percent by weight, analyzing 1457 percent iron, again showing the effectiveness of the selective flocculationmagnetic separation methodSelective flocculation, magnetic separation, and Huang Q R and Huo H H 2010 Application and prospect of magnetic flocculation and magnetic separation technology [J] Water supply and drainage 36 150152 Google Scholar Zhe Z and YunLong Y 2012 Experimental study on advanced treatment of coking wastewater by magnetic flocculation technology[J] Industrial Water WastewaterReview On The Application Of Magnetic Flocculation

Flocculation and magneticallyassisted sedimentation

In this study, the flocculation and the subsequent decantation step of mixed suspensions of 10 nmsized γFe2O3 magnetic nanoparticles and 500 nmsized beidellite clay platelets was investigated This work may find application in the field of water treatment, specifically the flocculation processes with magnetically assisted sedimentation First, magnetic power and flocculation agents are added to seawater in a high/lowspeed roiling tank, and the water is roiled to form magnetized floc measuring around 1mm consisting of plankton, bacteria, mud, and other material (2) When then passed through a magnetic separator, the floc adheres to magnetic disks and is removedCoagulation and MagneticSeparation Solution, Among the numerous possible harvesting methods, magnetic flocculation has the advantages of simple operation, fast separation and energy saving and thus is considered as a promising novel harvesting method In this review, we have summarized the updated status and application potential of magnetic flocculation, including the principle of Microalgae harvesting by magnetic flocculation for

Magnetic Flocculant for High Efficiency Harvesting of

Magnetic flocculant was synthesized for the highly efficient recovery of microalgal cells The highest flocculation was achieved using the magnetic flocculant synthesized with iron oxide and 01 mg/mL cationic polyacrylamide (CPAM) This resulted in a recovery efficiency of more than 95% within 10 min using a dosage of 25 mg/L for Botryococcus braunii and 120 mg/L for Chlorella ellipsoidea Magnetic flocculation and separation based on the magnetic difference of materials can easily separate magnetic solids from mixtures It shows higher selectivity and efficiency than centrifugation and filtration, and has been widely used in water treatment, biotechnology and minerals separation [15, 16, 17, 18]Magnetic Separation of Impurities from 和创智云深耕于环保水处理行业十三年,核心产品为次氯酸钠发生器、臭氧发生器、二氧化氯发生器,全自动加药装置、磁混凝装置、一体化污水处理装置,致力成为水处理消毒及加药沉淀技术专家。磁混凝,磁混凝设备,磁混凝厂家

Flocculation Performance and Kinetics of Magnetic

The study of magnetic flocculation kinetics can provide theoretical support for magnetic flocculation and is critical for the analysis of solidliquid separation processes 1 Introduction Flocculation is an important process in the water treatment system And flocculants are a key in achieving high flocculation efficiency in the aggregation This site uses cookies By continuing to use this site you agree to our use of cookies To find out more, see our Privacy and Cookies policy Close this notificationFlocculationMagnetic Separation Technology for the sequently, magnetic particles are captured on a filter matrix by Magnetic separation is a method for the separation of particles the magnetic tractive force (Fm ) that overcomes other competing on the basis of their magnetic properties, however, it was proved forces of gravitation, hydrodynamics and inertia or in an open gra that nonmagnetic (PDF) Research on magnetic seeding flocculation for

Review On The Application Of Magnetic Flocculation

Huang Q R and Huo H H 2010 Application and prospect of magnetic flocculation and magnetic separation technology [J] Water supply and drainage 36 150152 Google Scholar Zhe Z and YunLong Y 2012 Experimental study on advanced treatment of coking wastewater by magnetic flocculation technology[J] Industrial Water Wastewater In this study, the flocculation and the subsequent decantation step of mixed suspensions of 10 nmsized γFe2O3 magnetic nanoparticles and 500 nmsized beidellite clay platelets was investigated This work may find application in the field of water treatment, specifically the flocculation processes with magnetically assisted sedimentationFlocculation and magneticallyassisted sedimentation which means the mechanism of magnetic flocculation will apply The successful recovery of fine magnetite by magnetic separation is based on the combination of high magnetic susceptibility and magnetic flocculation The mechanism of magnetic flocculation is described below Magnetic flocculation Magnetic flocculation is essentially the Maximizing the recovery of fine iron ore using magnetic

Magnetic Flocculant for High Efficiency Harvesting of

Magnetic flocculant was synthesized for the highly efficient recovery of microalgal cells The highest flocculation was achieved using the magnetic flocculant synthesized with iron oxide and 01 mg/mL cationic polyacrylamide (CPAM) This resulted in a recovery efficiency of more than 95% within 10 min using a dosage of 25 mg/L for Botryococcus braunii and 120 mg/L for Chlorella ellipsoidea The primary flocculation mechanism was bridging, which was assisted by the electrostatic interactions between the microalgal cells and the magnetic flocculant under acidic conditions These results provide new opportunities and challenges for understanding and improving the harvesting of microalgae using magnetic separationMagnetic flocculant for high efficiency harvesting of than coarser particles after magnetization and magnetic flocculation takes place This is another key aspect of the success of dense media recovery by magnetic separation Whereas magnetic flocculation promotes the recovery of fine ferromagnetic materials, the nature of the effect also promotes ‘stubborn’ entrainment of nonmagnetic particlesOptimizing the performance of wet drum J magnetic

solutions of used clinker grinding plant for sale

Stainless Steel Sheet Metal Poishing Machine

grinding the iron ore

huber se ultra fine screens

stone to powder crusher machine

Bone crushing Machine In SKD africa

impacts of mining antimony peru

cement plant esp fan

aggregate crushing equipment manufacturers india

crushing milling quarrying

Cost Of Grinding In Ball Mill Manufacturer India

portable crusher in ncrete

manufacturer manufacturer of mill for al ashindia

advantage of double toggle jaw crusher

residential mining mill operation

list of sts that miningpany has to bear

stone crusher 100 tons per hour in india

is magnetite a pyrite

Effects Of Gypsum Mining Experiment

Zhengzhoukeheng 2013 New Ball Mill Ball Grinding Mill

portable gold ore crusher manufacturer nigeria

what is al washing magnetite

different types of crusher s machine of primary

what is the biggest jaw crusher ever made

motor driven stone mills

Sendary SKD Standard crusher

Coal Lignit Grinder Crusher

gold flotation separator for sale

feed size of gyratory crusher

crusher mashinee price in chennai