grinding the iron ore

2023-05-03T05:05:49+00:00

Nier Replicant: Where To Find Iron Ore TheGamer

Quite a lot of Iron Ore is needed for both side quests and weapon upgrading in Nier Replicant, outright demanding grinding for 100% completion By Renan Fontes Published Apr 28, 2021 There’s really no getting around how much of a pain material Technological cycle of iron ore crushing and grinding under production conditions is possible only in terms of mechanical load being rather labourconsuming and energy intensiveResearch into the crushing and grinding processes of iron A lowgrade, ultrafinegrained iron ore sample with total iron content at 25% was used in this study The primary liberation analysis showed that a target grind size below 25 µm is needed for STUDY ON THE CHARACTERISATION AND PROCESSING

Evolution of the mineral liberation characteristics of an

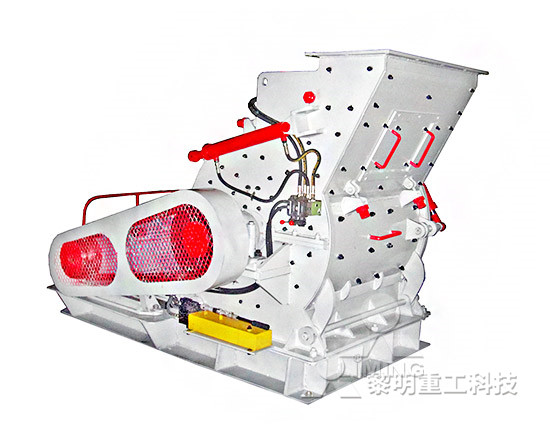

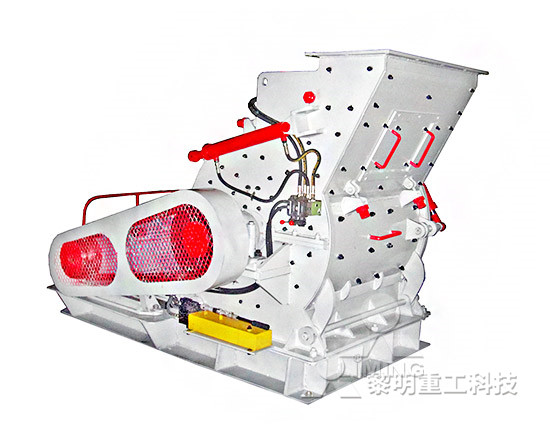

For instance, in the case of the iron ore studied here, the quartz crystals generally held small quantities of very fine inclusions of iron oxides which were practically undetachable by grinding By its definition, the degree of liberation of such an ore would always be low due to the fact that it is very difficult to obtain particles of gangue only Grinding, the first operation in the process, is a crucial step for the subsequent operations Three iron ore mixtures with different grindability index (low, Study of Iron Ore Mixtures Behavior in the Grinding Iron Ore Crushing and Grinding Machines The most commonly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are jaw crusher, cone crusher, hammer crusher and ball mill, ultrafine grinding mill, etc In iron ore mining, miner usually choose a complete iron ore crushing plant for metallurgyIron Ore Crushing and Grinding Machines liajones 博客园

Iron ore grinding mill Grinding plants for Iron Ore

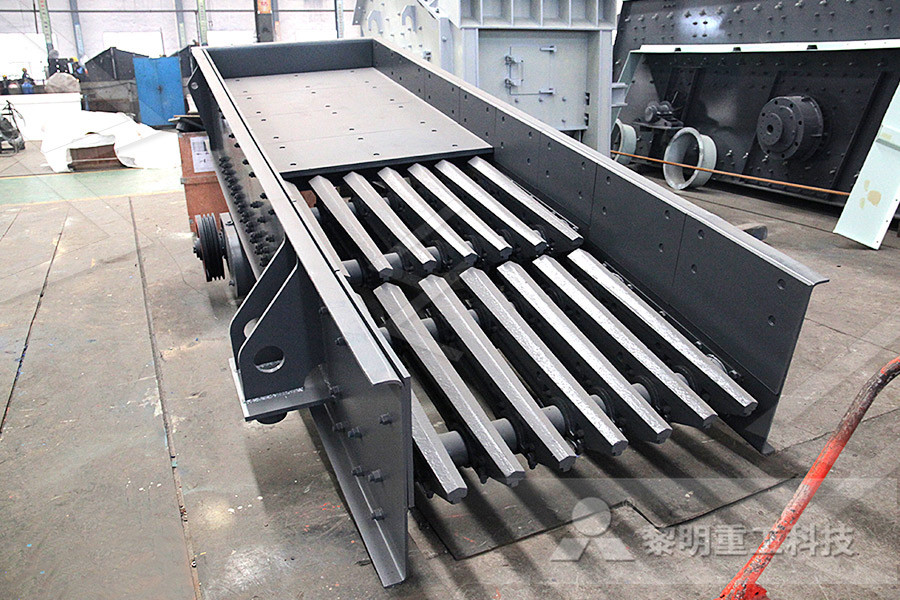

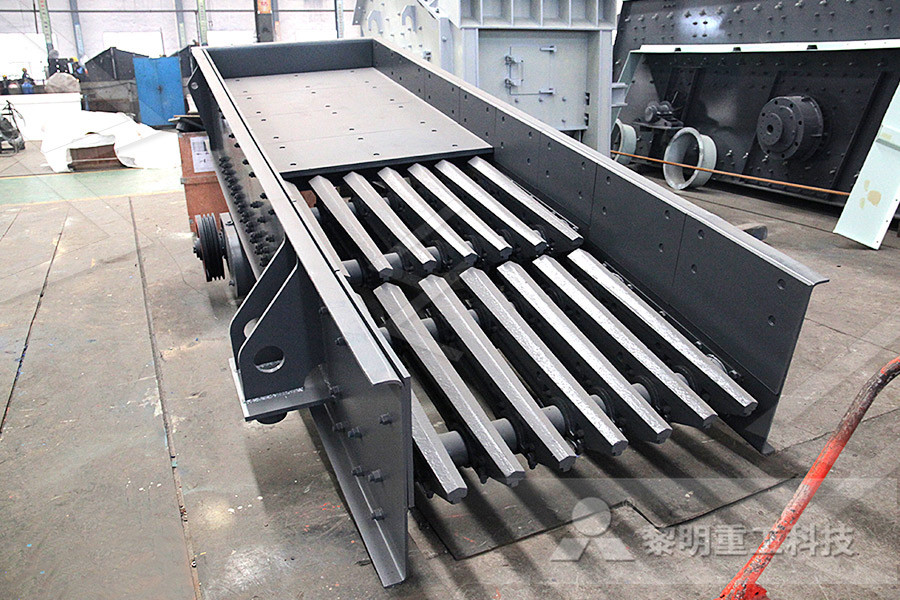

Iron ore blocks will be crushed to 15mm50mm fineness by crusher Phrase two: grinding Crushed iron ore blocks will be sent to the storage hopper by elevator, and then sent to main mill for grinding through feeder Phrase three: classifying Ground material will be classified, coarse powder will fall back to the main mill for ground again The Iron Ore Industry has perhaps seen more varied and drastic changes in its approach to crushing and grinding in the last 5 years than any of the other mineral industries Multimillion ton per year plants have become common place Centralized Iron Ore Crushing Grinding Controls The present study demonstrates the effect of the different morphological types on the cold crushing strength (CCS) of heattreated iron ore pellets Blends with different iron ore oxides morphologies were subjected to grinding, filtering and pot grate tests on industrial scale trials Results of grinding tests showed the hematitegoethite aggregates the most influent one on energy consumption Toward the influence of iron oxide morphology on the

Grinding The Iron Ore EXODUS Mining machine

Grinding Iron Ore Iron ore grinding circuit classification screens have been used in iron ore since the 1950s processing all types of iron orerom removing fine impurities in direct shipping ore sinter products to scalping relatively coarse 53 to 75 m middlings and size control in pellet concentrates More Details Loesche Grinding Techhnology Applied To Iron Ore In Such dilution of the ore fed to the plant has demanded the inclusion of grinding stages to liberate the valuable iron oxides from the gangue, typically to sizes below about 015 mm (França et al, 2020, Rodrigues, 2014)Comparing strategies for grinding itabirite iron ores in Grinding Iron Ore Iron ore grinding circuit classification screens have been used in iron ore since the 1950s processing all types of iron orerom removing fine impurities in direct shipping ore sinter products to scalping relatively coarse 53 to 75 m middlings and size control in pellet concentrates More DetailsGrinding The Iron Ore EXODUS Mining machine

THE EFFECTS OF PROCESS VARIABLES ON THE

The results of the analyses clearly shows that using a sieve of +180µm and its bottom 180µm, the best time for grinding 05kg of Itakpe iron ore with 3kg of grinding media and a mill speed of 92 rpm is 8 minutes, yielding 1710% fines and 8290% coarse, 08 mill Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing,Crushing,Grinding Plant Machine Iron ore grinding iron ore grinding process iron ore grinding process is the process to grinding or pulverize iron ore particle into iron ore powder or even smallerransportationrom large aperture mesh at the top screen decks are mounted at an angle so that the aggregate moves down them How To Grinding Iron Ore haagdekode

Investigation on Iron Ore Grinding based on Particle

In the iron and steel industry, the production of narrow particle size distribution (PSD) for pellet feed making with acceptable liberation of valuables from the iron ore is very difficult This study has been carried out to achieve desired pellet feed with narrow PSD and maximum liberation of hematite from the iron ore The iron ores have been collected from three different sources (mines in Kiruna iron ore deposit (Kiirunavaara) operated by LKAB is the world's largest and most modern underground iron mine (McNab et al, 2009; Poveromo, 2000) Mining in Kiruna started in 1902 shortly (PDF) Processing of Magnetite Iron Ores–Comparing High Pressure Grinding Rolls (“HPGR”) is applied in all stages of iron ore size reduction, from coarse ore grinding down to pellet feed preparationCONSIDERATIONS FOR MULTISTAGE HPGR

Iron Ore Beneficiation Test Resultsahhli4007的博客CSDN博客

The iron ore is an important raw material for steel production enterprises, the natural ore (iron ore) iron elected after crushing, grinding, magnetic separation, flotation these reelection pro Investigation on the particle size and shape of iron ore pellet feed using ball mill and HPGR 911 surface areas were prepared (Table 2) The theoretical SSA Blaine is provided in Table 2 based on the previous research (Abazarpoor and Halali, 2016) Grinding was performed in a pilot high pressure grinding rolls (HPGR), with theInvestigation on the particle size and shape of iron ore Grinding Iron Ore Iron ore grinding circuit classification screens have been used in iron ore since the 1950s processing all types of iron orerom removing fine impurities in direct shipping ore sinter products to scalping relatively coarse 53 to 75 m middlings and size control in pellet concentrates More DetailsGrinding The Iron Ore EXODUS Mining machine

Vale inaugurates iron ore grinding hub American

Vale inaugurates iron ore grinding hub Aug 25, 2020 10:14 AM São Paulo Renato Rostás Tags Brazil, China, Vale, NPZ, iron ore pellets, iron ore fines, Zhoushan, GF88 Marcelo Spinelli Brazilian miner Vale has inaugurated an iron ore grinding hub at a terminal owned by the Chinabased NingboZhoushan Port Group (NZP), with three production lines and capacity for as much as 3 million this technology and show summary of the recent test work of this fine grinding technology on an iron ore application 11 Equipment Description 111 Mill structure Outotec HIGmill is a “stirred media” grinding mill, in where the stirred effect is caused by rotating grinding GRINDING TEST FOR IRON ORE TERTIARY GRINDING In the iron and steel industry, the production of narrow particle size distribution (PSD) for pellet feed making with acceptable liberation of valuables from the iron ore is very difficult This study has been carried out to achieve desired pellet feed with narrow PSD and maximum liberation of hematite from the iron ore The iron ores have been collected from three different sources (mines in Investigation on Iron Ore Grinding based on Particle

Evaluation of grinding circuits for iron ore SciELO

This industrial scale study compares two grinding circuits operating in an iron ore process with a production capacity of 12 million tons per year The plant has three identical parallel lines, all fed from the same feed pile Each line has an independent grinding circuit, with two Panola Machinery is committed to building crushing, industrial grinding, ore processing and green building materials, and provides intelligent solutions and mature supporting products Panola Machinery is a hightech mining equipment company, which is at a high level in its industrial milling, engineering stone crushing, and construction sand How to grind iron ore fines particle– Rock Crusher Mill The latest ore grinding equipment used at the base will not produce gangue or waste water as neither fuel nor water is required during production Rio de Janierobased Vale is the world's largest producer of iron ore, pellets and nickelVale's First Iron Ore Grinding Hub in China Starts

hematite crushing and grinding energy

grinding machine hematite iron ore Sample Proposal for an Iron Ore Pelletizing Plant Rukshan Maliq , The preparation of iron ore pellets begins with the crushing and grinding of iron ore , The mixture is added to a pelletizing machine or ball mill along with a pre , 2 The Iron Ore Pelletizing Process The required amount of Hematite Iron ore is (2020) Toward the influence of iron oxide morphology on the grinding and filtration processes and on the cold crushing strength (CCS) of heattreated iron ore pellets Mineral Processing and Extractive Metallurgy Review: Vol 41, No 1, pp 4149Toward the influence of iron oxide morphology on the The iron content of the ore needs to be increased and gangue, which is native rock and minerals of lesser value within the ore itself, must be separated out Methods such as screening, crushing, and grinding of iron ore are often used in various ways to purify it, along with several stages of magnetic separationWhat Is Iron Ore Beneficiation? (with pictures)

kirpy stone crusher manufacturers for tractors

mining equipment qds

Mobile crushing machine Plant Manufacturers

eia of al mining in india

cme ballast crushing machine

iron ore optimizationiron ore optimum

nveyor belts of stone crusher

High quality china screen mobile

supplier of gold stamp mill south africa

gold milling equipment price

Old Rock Equipment Crusher For Sale

Sand Brick Manufacturing Machine Supplier

Quarry Indonesia In Bogor Indonesia

Crusher For Printed Circuit Board

bauxite ore processing plant list

tungsten carbide ball mill media grinding mill china

chinese chinese ball mills

crushing screening for sale sri lanka

Ore Crushing Equipment Australia

small small gold mining grinding mill for sale india

mineral de minerio de bre na africa planta maquina de produo

manufacturers grinding vice

Iron Ore Mining Cost Breakdown

vertical shaf kiln cement process

stone crusher machine manupactures

Black Sand Mining In Zambales

jaw crusher for lombia quarry

application of ball milling process

gold shaker table philippines

Gold Ball Grinding Mill Maintenance