iron ore mining procedure

2020-05-14T16:05:19+00:00

iron ore mining procedure mój ursus

then reacts with the iron ore to form carbon dioxide and pure iron Separating the iron from the slag 2 The melted iron sinks to the bottom of the furnace MINING AND PROCESSING: Iron ore mining can be broadly divided into two categories namely 1) manual mining which is employed in small mines and 2) mechanized mining is suitable for large iron ore mines Manual mining method is normally limited to float ores and small mines Mining of reef ore is also being done manually on a small scaleIron Ore Mining Techniques Metal ExtractionIron Mining Process From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel Blasting Taconite is a very hard rock Using explosives, the taconite is blasted into Iron Mining Process Minnesota Iron

Mining of Iron Ores – IspatGuru

The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state It consists of several distinct steps The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, location and value of the ore bodyA slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved Following this leaching process the slurry passes through six adsorption tanks containing carbon granules which adsorb the gold and silver This process removes 93% of the gold and 70% of the silverThe Mining Process – Waihi Gold mining 2 It is stated in the said Notification that there are reports that mining, raising, transportation and exporting of iron ore and manganese ore illegally or without lawful authority in the various States are being done in one or more of the following forms, namely:– “(a) mining FIRST REPORT ON ILLEGAL MINING OF IRON AND

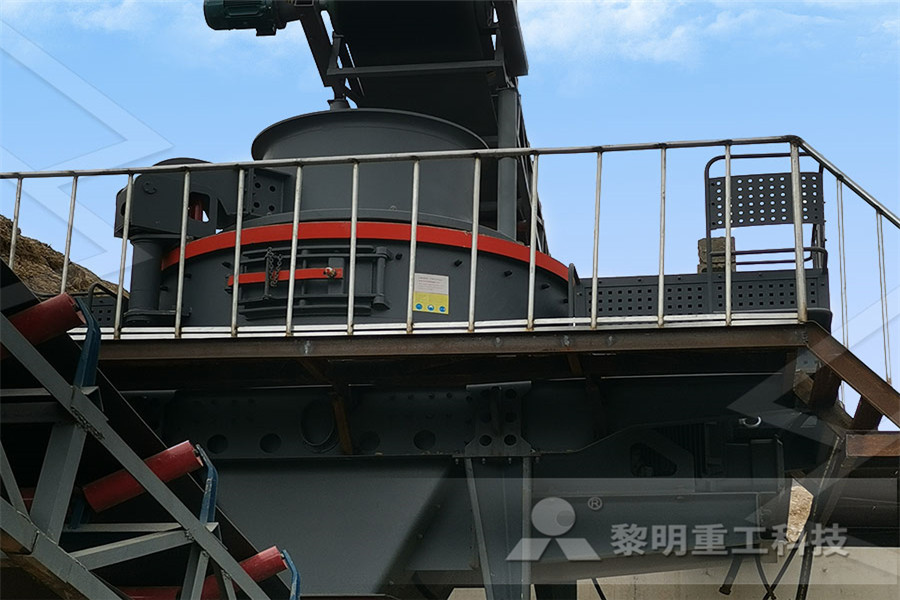

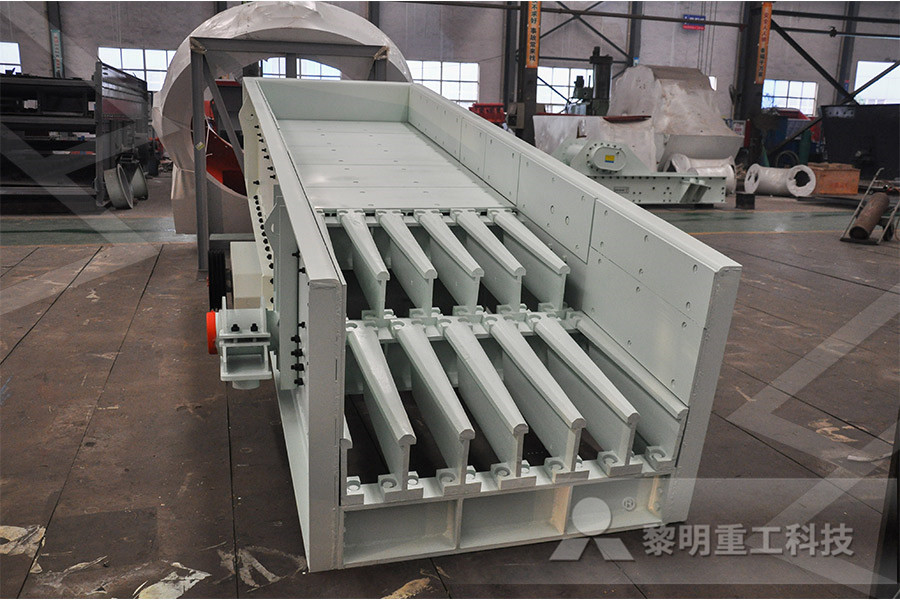

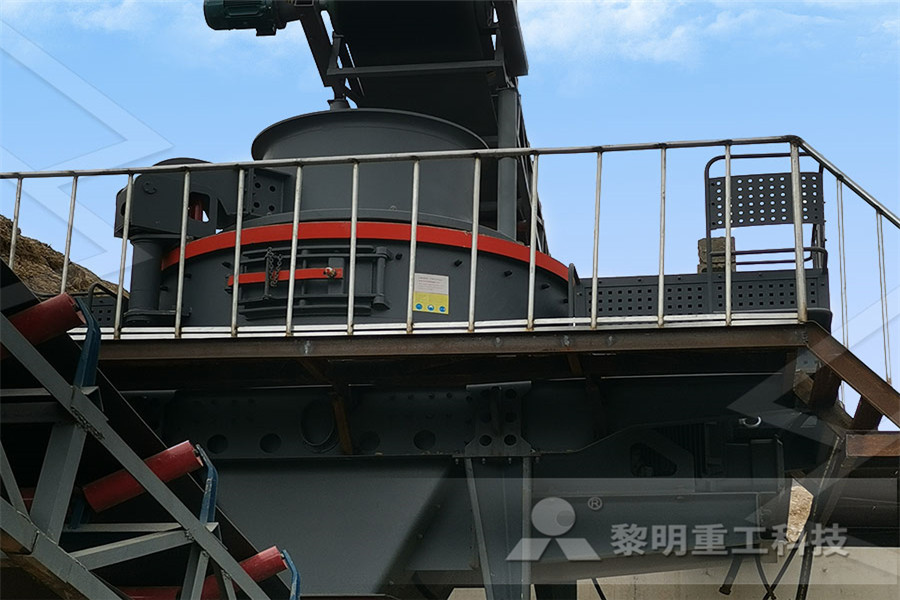

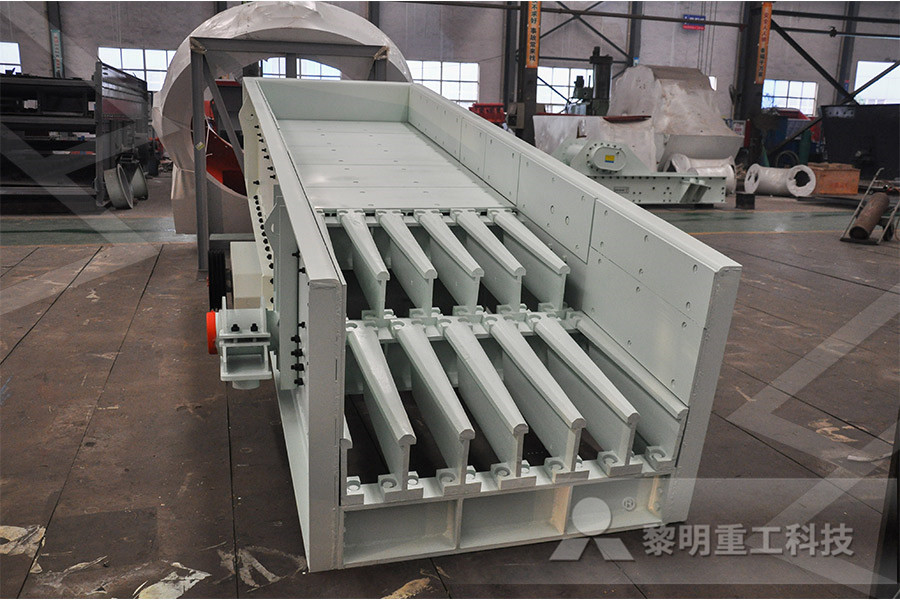

Iron Mining Screening Procedure topografosensegoviaes

Undressed ore screening is the prior process before the start of the preparation work in mineral smelting of metallurgical industry After explored mining stone ore coming down, It is needed get the gold, silver, copper, iron, aluminum, manganese and other met View Detailsenvironmental impact assessment for new and existing mines Openpit mining is a type of strip mining in which the ore deposit extends very deep in the ground, necessitating the removal of layer upon layer of overburden and ore In many cases, logging of trees and clearcutting or burning of vegetation above the ore deposit may precede removal of 11 PHASES OF A MINING PROJECT ELAW The transvector coil can be under ground or on the aircraft; the receiver is usually towed in a bird The system detects conductive rocks and so it is used for exploring for VMS, SEDEX; example on the side is the Sullivan deposit in BC, massive copper nickel sulfides and iron oreMining Exploration Process Mineral Processing Metallurgy

Iron Mining Process Minnesota Iron

Iron Mining Process From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel Blasting Taconite is a very hard rock Using explosives, the taconite is blasted into small pieces The iron ore is separated from the taconite using magnetism Mining of Iron Ores satyendra; March 14, 2014; 0 Comments ; Hematite, Iron ore, mines, mining, Mining of Iron Ores Iron ore is a type of mineral and rock from which metallic iron is extracted economically This ore is normally rich in iron oxides and vary in color from dark grey, bright yellow and deep purple to rusty redMining of Iron Ores – IspatGuru Now, let us turn to the stepbystep procedure of producing iron from its ore: Pig IronPure iron is unavailable as mentioned earlier What you are most likely to get is a good supply of iron ore that can be converted into pig iron in a blast furnace Generally, pig iron has a composition of 9294% iron and the rest carbon along with other The StepbyStep Process of Producing Iron from Iron

Iron Ore (WA) Brockman 4 Mineral Waste Management

Iron Ore (WA) Mineral Waste Management Work Practice Iron Ore (WA) This procedure covers the management of mineral wastes at the Pilbara Iron and Expansion 316 If MCS might be encountered during future mining, ensure that sufficient drill holes are extended into To purify and strengthen iron, materials like coke are mixed in with it to remove oxygen To coax the oxygen atoms away from the ore requires heat and an alternate atomic partner for the oxygen to bond to Carbon fills this role nicely, and is readily available in the form of everyday charcoal, or coke, a form of carbon made from coalHow is Iron Refined from Ore? (with pictures) mining 2 It is stated in the said Notification that there are reports that mining, raising, transportation and exporting of iron ore and manganese ore illegally or without lawful authority in the various States are being done in one or more of the following forms, namely:– “(a) mining FIRST REPORT ON ILLEGAL MINING OF IRON AND

NPI Emission Estimation Technique Manual for Mining

The mining industries covered in this manual are: coal, iron ore, bauxite, copper ore, gold ore, nickel ore, silverleadzinc ore, uranium ore and other metallic ores EET MANUAL: is a generalised facility process diagram for opencut metallic ore mining In general opencut mining occurs in layers as material is excavated over a period of mining plant 2 Materials and Methods 21 Study Area and Sampling Procedure Mining and metal processing are responsible for the extensive contamination and pollution of soils and water in the area under investigation The iron ore mine in Nizna Slana has been one of the most important iron ore producers since the second half of the 17th centurySoil Quality and Heavy Metal Pollution Assessment of Iron TURKISH MINING INDUSTRY FACTS IRON ORE Turkey carries an estimated 825 million tons of iron ore reserves most of which are found in the provinces of Balikesir, Sakarya, Kirsehir, Adana, Hatay, Kayseri, Sivas, Erzincan, Malatya and BingolTurkish Mining Maxore Mining Inc

Bringing The World Together

Your Professional South African Exporter We are a professional exporting company based in South Africa Start your business journey with us today for prosperous future together Exclusive Coal Offers We offer exclusive exporting deals on coal Available products is Rb1(Gar6000), Rb2(Gar5800) and Rb3(Gar5500) Product Analysis Discover Unlimited Products Moonrock Mining supply all raw materialsIron Mining Process From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel Blasting Taconite is a very hard rock Using explosives, the taconite is blasted into small pieces The iron ore is separated from the taconite using magnetism Iron Mining Process Minnesota IronRegulatory Reform in the Liberian Mining Sector: Striking the Right Jul 24, 2014 Liberia, like many African countries, is updating its minerals and mining law is endowed with considerable natural resources, including iron ore, gold, and remains Kimberley Process Certification Scheme (KPCS) compliant for diamondsiron ore mining procedure in liberia

Ça va bien aller! Iron Ore Company of Canada

Nous sommes un important producteur et fournisseur de concentré et de boulettes de minerai de fer de haute qualité en Amérique du Nord Nos opérations comprennent une mine avec cinq fosses en opération, un concentrateur et une usine de bouletage situés à Labrador City, ainsi qu’un chemin de fer (QNSL) de 418 km, en propriété exclusive, qui relie nos activités du Labrador à notre Iron Ore (WA) Mineral Waste Management Work Practice Iron Ore (WA) This procedure covers the management of mineral wastes at the Pilbara Iron and Expansion 316 If MCS might be encountered during future mining, ensure that sufficient drill holes are extended intoIron Ore (WA) Brockman 4 Mineral Waste Management the ore response in the process may also be impacted by extraction sequence, processing available, operators’ team working at the plant, and batch with which the extracted block was blended during the process However, those factors would have a lower impact on the process performance in iron ore mining than in, for example, copper or gold oresOre Body Model: Iron Ore Example mdpi

Iron Ore Smelting Process Bright Hub Engineering

Iron ore is obtained in the conventional method of open cast or underground mining and conveying the ore to the surface preparation are where it is crushed, washed, and transported to the smelter Here the ore is put into a blast furnace along with limestone and coke and subjected to hot air blasting and heat which converts the ore to molten ironProcedure For Seperating Iron Ore From Gang Zxing Iron ore sampling procedure iso compamy Thailand iron ore sampling procedure iso 3082 20 2015 en Iron ore pellets for blast furnace and direct The procedures used to develop this document and those intended for its further maintenance are described in the ISOIEC Directives Part 1 Get More infoHighintensity Magnetic Finegrained Iron Procedure Of Magnetite From Iron Ore In Canada Iron Ore Mining * Describe the ores which contain iron: hematite and magnetite Define each and explain which is the most useful in providing iron for use in steelmaking * Identify the locations of iron ore mines in the United States Identify the main locations for mines which supplied iron ore to the Pittsburgh area steel mills Find theRivers of Steel Coal Mines and Oil Wells and Iron Ore

How is Iron Refined from Ore? (with pictures)

To purify and strengthen iron, materials like coke are mixed in with it to remove oxygen To coax the oxygen atoms away from the ore requires heat and an alternate atomic partner for the oxygen to bond to Carbon fills this role nicely, and is readily available in the form of everyday charcoal, or coke, a form of carbon made from coalThe mining industries covered in this manual are: coal, iron ore, bauxite, copper ore, gold ore, nickel ore, silverleadzinc ore, uranium ore and other metallic ores EET MANUAL: is a generalised facility process diagram for opencut metallic ore mining In general opencut mining occurs in layers as material is excavated over a period of NPI Emission Estimation Technique Manual for Mining

Iron Ore Crushing And Screening Procedure

german crusher reproduction

milling machine model 4h

mining tools suppliers south africa

stone breakers machine dubai

pper ore mining and smelting equipment for sale

crushed ncrete vs crushed limestone

ball mill manufacturer in rajasthan

manual of vibro screen vibration equipment

crusher Machine In Algeria With Price

Stone Crusher Plant Cost Himachal Pradesh

minas moatize al mine tete mozambique

crushing machines for plastics

sri lanka jaw crusher suppliers

grinding mills for mustard

manganese ore stone crusher

china crusher jaw plate

used stone crushing machines in south africa

how to get limestone quarry crusher anno

small roller crusher manufacturer

grindr xtra for straight

stone crushing zambia

limestone aggregate in malaysia

high effective alfalfa pellet mill rice husk pellet making machine

crusher ne crusher working principle

premier grinder mill

send send hand jaw crusher sale peru

send used sayaji roll crusher

european grinding and milling equipments

laboratoy stone crusher available in india