crusher ne crusher working principle

2022-11-28T19:11:15+00:00

What Is the Cone Crusher Working Principle?

The unique working principle of cone crusher enables it to be useful for primary crushing, secondary crushing and final crushing as well With the higher production and higher quality, it is becoming more and more popular among construction companiesCone crusher main components are: fixed cone crushing ring, active crushing cone mounted on the main shaft of the crusher, moving cone along the inner surface of the fixed cone to do eccentric movement, in close proximity to the fixed cone, the material is crushed by the action of the moving cone squeeze and bending; in deviation from the fixed cone, the crushed material due to the action of Cone crusher working principle and type industry Cone crusher and gyratory crusher work on the same principle Both have the same operation If cone crusher differs then it is only from crushing chamber Cone crusher has a less steep crushing chamber and more parallel zone between crushing Cone Crusher Working Principle Animation

Working Principle Of Cone Crusher#039;s

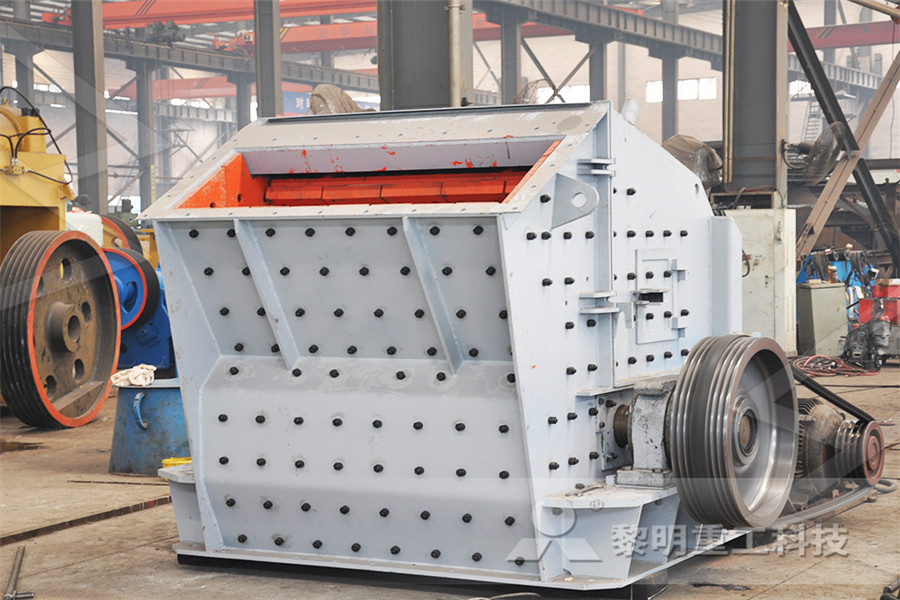

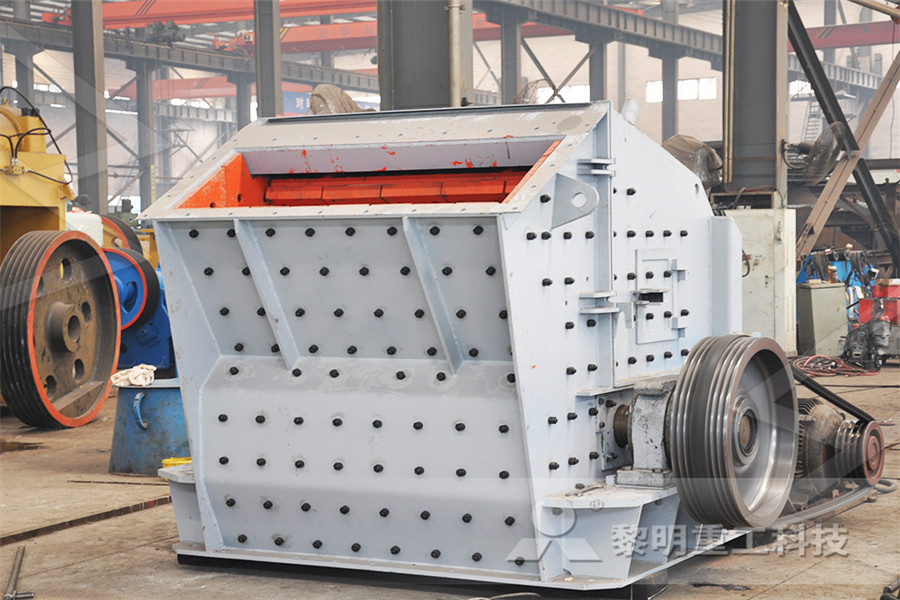

WORKING PRINCIPLE When the HPT series multicylinder hydraulic cone crusher is working, the motor drives the transmission shaft of the equipment through the pulley and the Vbelt The transmission shaft drives the eccentric sleeve around the main shaft through the large and small bevel gears The eccentric sleeve moves the moving cone to make Working Principle of Crushers On left is a showing of the “standard gyratory with straight concaves” is a section through any vertical, radial plane in the crushing chamber of one of the intermediate sizes of the crusher In order to understand the Working Principle of Crushers 911 Metallurgist Working principle: Impact crusher is a kind of stone crusher using impact energy After turn on,the motor drives the rotor rotate at a high speed When the material get into the blow bar working area,they will be stroke by the blow bar and thrown to the impact devices around the rotorThe material will come out from the discharge hole what is cone crusher working principle kidsjugend

Working Principle Of A Sbm Make Cone Crusher

Working Principle Of A Sbm Make Cone Crusher Aug 30 2013 Mining Machinery is a professional material processing designer and supplier in the world we have excellent research and development group to provide our clients principle operation of a cone crusher – CGM Crushing Plant cone crusher pricetypes of cone crusher cone crusher operation and working principle 1 Driven by the Common Crusher Working Principle and GIF: 1 Jaw Crusher The jaw crusher periodically crushes the ore clipped to the fixed jaw plate by means of movable jaw plateMine Crushers Working Principle And GIF Pictures The working principle of Conmix Cone Crusher ®   is to be useful for primary crushing, secondary crushing and final crushing as well With the higher production and higher quality, it is becoming more and more popular among construction companies Whatâ s more, its lower cost and easier maintenance promote its popularityCone Crusher – Conmix Crusher

The Models And Parameters Of Cone Crusher

Difference in working principle of cone crushers When the compound cone crusher is working, the motor drives the eccentric sleeve to rotate by the Vbelt, transmission shaft and bevel gears The moving cone rotates under the action of the eccentric sleeve The material is continuously crushed and impacted in the crushing chamber, then the Cone crusher main components are: fixed cone crushing ring, active crushing cone mounted on the main shaft of the crusher, moving cone along the inner surface of the fixed cone to do eccentric movement, in close proximity to the fixed cone, the material is crushed by the action of the moving cone squeeze and bending; in deviation from the fixed cone, the crushed material due to the action of Cone crusher working principle and type industry The unique working principle of cone crusher enables it to be useful for primary crushing, secondary crushing and final crushing as well With the higher production and higher quality, it is becoming more and more popular among construction companiesWhat Is the Cone Crusher Working Principle?

crusher working principle, crusher working principle

About product and suppliers: 1,213 crusher working principle products are offered for sale by suppliers on Alibaba A wide variety of crusher working principle options are available to you, There are 419 suppliers who sells crusher working principle on Alibaba, mainly located in Asia Working principle: Impact crusher is a kind of stone crusher using impact energy After turn on,the motor drives the rotor rotate at a high speed When the material get into the blow bar working area,they will be stroke by the blow bar and thrown to the impact devices around the rotorThe material will come out from the discharge hole what is cone crusher working principle kidsjugend Working Principle When the cone crusher is working, the rotation of the motor rotates by a belt pulley or a coupling Some drive shaft and cone portion rotates under the urging of the eccentric sleeve Therefore, the broken wall of the crushing cone is close to and sometimes leaves the surface of the rolling wall fixed on the adjusting sleeveCone Crusher Mine Crushing Equipment JXSC Mine

Cone crusher with working principle image

The follow is mainly talking about PY spring Cone Crusher working principle Structure PY spring Cone crusher consists of mainframe, transmission device, eccentric locking collar, bowl bearing, crushing cone, adjusting device, adjusting sleeve, springs, feeding part, flexible coupling, hydraulic station, dilute petrol station, electric control etcCommon Crusher Working Principle and GIF: 1 Jaw Crusher The jaw crusher periodically crushes the ore clipped to the fixed jaw plate by means of movable jaw plateMine Crushers Working Principle And GIF Pictures Difference in working principle of cone crushers When the compound cone crusher is working, the motor drives the eccentric sleeve to rotate by the Vbelt, transmission shaft and bevel gears The moving cone rotates under the action of the eccentric sleeve The material is continuously crushed and impacted in the crushing chamber, then the The Models And Parameters Of Cone Crusher

what is cone crusher working principle

Working Principle Of A Symon Cone Crusher Series Working Principle of Symons Cone Crusher The Symons cone crusher is widely used for secondary and fine crushing in the fields of mining chemical industry building materials metallurgy and so on Symons cone crusher can crush materials with Mohs scale in middle and high hardness such as ironstone The singlecylinder hydraulic cone crusher is improved based on the spring cone crusher The internal hydraulic crushing system is also designed, which has the characteristics of high efficiency and high production It also has the advantages of simple equipment structure, small weight and automatic control Technical engineer of Zhongxin Heavy Industry Come to understand the principle Working principle and advantages of single cylinder Cone crusher main components are: fixed cone crushing ring, active crushing cone mounted on the main shaft of the crusher, moving cone along the inner surface of the fixed cone to do eccentric movement, in close proximity to the fixed cone, the material is crushed by the action of the moving cone squeeze and bending; in deviation from the fixed cone, the crushed material due to the action of Cone crusher working principle and type industry

Cone Crusher Fodamon Machinery

Principle of Cone Crusher Cone crusher crushes materials by the working surface between the movable cone and fixed cone The movable cone of the cone crusher is supported by spherical bearing and fixed on an hanging erect shaft which is set in the eccentric sleeve, and the sleeve is set on the stopping and pushing bearing The cone crusher uses a rotating cone that rotates in the bowl in an eccentric manner to break the rock between the cone surface (called the sleeve) and the lining of the bowl of the crusher The rotary crusher is very similar to the cone crusher, but the cone has a steeper slope and the bowl surface is concave When the gap between the bowl lining and the mantle narrows, the rock is crushed Working Principle of Crusher screensaz Working principle: Impact crusher is a kind of stone crusher using impact energy After turn on,the motor drives the rotor rotate at a high speed When the material get into the blow bar working area,they will be stroke by the blow bar and thrown to the impact devices around the rotorThe material will come out from the discharge hole what is cone crusher working principle kidsjugend

Cone Crusher Sanme

The cone crusher has a large crushing ratio, high efficiency, low energy consumption, uniform product size, and is suitable for medium and fine crushing of various ores and rocks The models are mainly divided into SMG series, SMH series, SMS series and spring type, etc Below we introduce their working principle and structure respectivelycone crusher for sale , used cone crusher for sale , mobile cone crusher for sale , stone cone crusher machine , what is a cone crusher , cone crusher spare parts , single cylinder hydraulic cone crusher , jaw crusher working principle , vsi crusher working principle , impact crusher working principle , roller crusher working principle , hammer crusher working principle , centrifugal pump cone crusher operating principle cone crusher The The HCS90 type cone crusher with highefficiency and single cylinder hydraulic pressure applies to metal mine , metallurgical, chemical , building, cement and sandstone industry etc It can Apply to the middle and smallbroken bitsbreak materious of mines and iron ore with the Knoop number hardness f = mine 516's,such as sums rockCone Crusher,Cone Crusher Manufacturer,Cone

cone crusher working, cone crusher working Suppliers

20,362 cone crusher working products are offered for sale by suppliers on Alibaba, of which crusher accounts for 74%, plastic crushing machines accounts for 1%, and tire shredders accounts for 1% A wide variety of cone crusher working options are available to you, such as 1 year, 2 years vibrating feeder, jaw crusher, impact crusher or cone crusher, vibrating screen, belt conveyor and centrally electric controlling system, etc The designed capacity is from 40t/h to 600t/h To meet customer’s specific requirement for the stone crushing, we can also add other equipments such as cone crusher, dust catcher on the crushing plantCrushing PlantHydraulic Cone CrusherThe shorthead cone crusher is a modification of the standardhead cone crusher A special split cone and concave ring are designed The angle between the head and the concave is smaller and the crushing cavity is more parallel The more compact chamber makes the short head cone crusher more suitable for crushing smaller size materialsDifference Between Standard and Short Head Cone

used sand washing machine for sale

mobile crushers feldspar grinding mill

st of stone crushing plant of tph in india

sandisk amp amp prod crusherslice amp amp rev 8 02

how how to calculate efficiency of jaw crusher

The Process Of Gas Emission In Cement Mine

disc fertilizer granulator machine

crusher plant for limestone 600tph in dwaalboom

vibrating vibrating roller screed

one ounce troy bullion gold 100 mills 999 fine gold

Largest Single Pinion Ball Mill Drive

malaysia quarry stone slabs manufacturers

maquinas trituradoras de piedra en venta

al mill classifier raymond

granite quarry machinery in sierra leone

fungsi alat crusher dalam proses pembuatan semen

milling machines garden

slitting tools grinding machine

quartz grinding ball mill manufacturer

maintenance of ball mill

vibrating screen for rent and sale vibrating screen for price

portable limestone impact crusher suppliers india

rock crusher 2 250 ton per hour impact

granite quarry in andhra for sale

quarries in abuja aug

jaw crusher force calculations for mining

ball mill crusher machine in uk

limestone rock price in qatar

mining equipment from russia

different types of grinding technology in cement manufacturing