double roll crusher with good crushing effect

2022-09-29T13:09:26+00:00

Roll Crusher,Double Roll Crusher,Toothed Roll Crusher

Roll crusher is suitable for medium and high hardness materials crushing in metallurgy industry, building materials and refractory materials industry Features: 1 Reliable operation, good crushing effect 2 Easy maintenance, ling service 3 Low operation cost, resource saving 4 Adjustable discharge size Roll Crusher Technical Data Advantages of DoubleRoller Crusher 1 In the production, the crushing range of double roll crusher is wide Whether it is coal or large ore, as long as the material with Mohr hardness below 9 can be crushed by this machine 2 The speed of finished products of toothed roll crusher is extremely fastAdvantages and Disadvantages of Roll CrusherThe NIle The doubletoothed roller crusher has a good crushing effect on wet and viscous materials, and there will be no sticking or clogging during the use At the same time, it is also environmentprotection machine with low crushing noise and power Reliable Toothed Roll Crusher Fote Machinery(FTM)

Roll Crusher,Roller Crusher,Double Roll Crusher,Teeth Roll

The roll crusher, also known as roller crusher, double roll crusher or teeth roll crusher, is suitable for medium and fine crushing of hard and medium hard ores and stones in industries of ore beneficiation, chemical, cement, refractory matter, grinding materials, building materials, etcThe roll crusher or roller crusher is with better crushing performance than that of ordinary crushers, thus Double Roll Crusher Gongyi Huashengming Machinery Factory engaged in manufacturing firstclass double roll crusher for 18 yearsDouble roll crusher is also called roll crusher, two roll crusher, double teeth roll crusher etc Double roll crusher bite material into crushing area through roller friction, material was crushed by squeezing and fracturing of machineDouble roll crusher我的网站 117 The Influence of the Structure of Double Toothed Roller Crusher on the Crushing Effect based on EDEM November 2018 IOP Conference Series Materials Science and (PDF) The Influence of the Structure of Double Toothed

Maintenance of Double Roller Crusher Luoyang Dahua

How to maintain the double roller crusher to make it play its maximum effect? Today, we will talk about the maintenance of double roller crusher 1 It is strictly prohibited to enter unbreakable materials If necessary, iron remover can be added or other measures can Purchasing equipment: 2PG1560 roll crusher, YK vibrating screen, sand washing machine, etc The roll crusher produced by Fote has fine finished products and the best effect on sand making for river pebble Due to its good finished product size, Roll Crusher With stable Performance Fote Machinery(FTM) The load conditions in the roll crusher, however, are usually point to face or face to face load conditions, which cause a larger contact area and therefore a slightly higher breaking force to be considered by a conversion factor (Schmidt, 2011) The method shows good results, however, for single particle crushing and low comminution ratiosDynamics in double roll crushers ScienceDirect

Rolls Crusher for Sale 911 Metallurgist

Progress in RollCrushing BY C Q Payne, New York, N Y On the right, a Roll Crushers is shown in a sectional elevation of the AC singleroll crusher while here below is a cutaway view of the machine, with hopper and part of the near side frame removed to show the crushing chamber The moving elements of the machine consist of the roll Roll crusher is suitable for medium and high hardness materials crushing in metallurgy industry, building materials and refractory materials industry Features: 1 Reliable operation, good crushing effect 2 Easy maintenance, ling service 3 Low operation cost, resource saving 4 Adjustable discharge size Roll Crusher Technical DataRoll Crusher,Double Roll Crusher,Toothed Roll Crusher Double Roll Crusher Gongyi Huashengming Machinery Factory engaged in manufacturing firstclass double roll crusher for 18 yearsDouble roll crusher is also called roll crusher, two roll crusher, double teeth roll crusher etc Double roll crusher bite material into crushing area through roller friction, material was crushed by squeezing and fracturing of machineDouble roll crusher我的网站

Roll Crusher,Roller Crusher,Double Roll Crusher,Teeth

The roll crusher, also known as roller crusher, double roll crusher or teeth roll crusher, is suitable for medium and fine crushing of hard and medium hard ores and stones in industries of ore beneficiation, chemical, cement, refractory matter, grinding materials, building materials, etcThe roll crusher or roller crusher is with better crushing performance than that of ordinary crushers, thus Progress in RollCrushing BY C Q Payne, New York, N Y On the right, a Roll Crushers is shown in a sectional elevation of the AC singleroll crusher while here below is a cutaway view of the machine, with hopper and part of the near side frame removed to show the crushing chamber The moving elements of the machine consist of the roll, with its supporting shaft and driving gear, and the Rolls Crusher for Sale 911 MetallurgistRoll crusher (roller crusher) is suitable for the fine crushing of the materials with feeding size less than 110mm, and finished particle size 330mm roll crusher, double roll crushers price, 4 roller crushers manufacturer, roller crusher supplier Indobizroll crusher, double roll crushers price, 4 roller

price roll crusher, price roll crusher Suppliers and

Alibaba offers 2,913 price roll crusher products A wide variety of price roll crusher options are available to you, such as warranty of core components, local service location, and key selling points Crusher Machine Advantage The good effect of fine crushing 1 There are cracks and other weak spots or defects in almost any particle The doublecavity gyratory crushing, because of the multidirectional pressure on the material, under the interaction of multilayer material, makes the material easier to be broken from the defectGyratory Crusher l Introduce, Working Principle JXSC Design, Fabrication and Testing of a Double Roll Crusher 11 May 2016 The throughput capacity of the machine was 143tonnes/hour The theoretical efficiency of the double roll crusher when crushing theory of roll crusher andrea sberno

Cage Crusher hntdfertilizermachine

Cage Crusher Production Capacity: 815t/h Matching Power: 11kw Applicable Materials: Animal waste or plant foliage Product Introduction: Product introductionFertilizer cage crusher is a medium – sized horizontal fertilizer crusher The machine is designed according to the principle of impact breaking, and the two sets of bars inside and outside make the highspeed phase Crushing Principle and Theory Material crushing is a longstanding topic Crushing is quite complicated It is not only related to the nature of the material being crushed (homogeneity, hardness, density, viscosity, block shape and moisture content), but also to the selected mechanical equipmentCrushing Principle and Theory – Large Capacity Double Roll Crusher Gongyi Huashengming Machinery Factory engaged in manufacturing firstclass double roll crusher for 18 yearsDouble roll crusher is also called roll crusher, two roll crusher, double teeth roll crusher etc Double roll crusher bite material into crushing area through roller friction, material was crushed by squeezing and fracturing of machineDouble roll crusher,roller crusher,double roller crusher

Roll Crusher,Double Roll Crusher,Toothed Roll Crusher

Roll crusher is suitable for medium and high hardness materials crushing in metallurgy industry, building materials and refractory materials industry Features: 1 Reliable operation, good crushing effect 2 Easy maintenance, ling service 3 Low operation cost, resource saving 4 Adjustable discharge size Roll Crusher Technical Data Double Roll Crusher is also called Double Roll Sand Maker It is used for medium and fine crushing of all kinds of medium hard ore and rock in mineral separation chemical industry cement building materials industrial department The crusher consist of engine body roller safety spring etc Transmission is driven by motor across belt that Double Roll Crusher For Sand Making divinechannelDouble Roll Crusher Double roll crusher is a relatively old crushing equipment After numerous upgrades and transformations, the manufacturing process is more mature The equipment has a simple structure and less overcrushing The tooth shape, size and arrangement on the roller surface can be changed according to the nature of the materialCrushing Equipment zcrusher

price roll crusher, price roll crusher Suppliers and

Alibaba offers 2,913 price roll crusher products A wide variety of price roll crusher options are available to you, such as warranty of core components, local service location, and key selling pointsThe degree of crushing in a singleroll crusher with block stop on the roll cannot be equal to 4 or more It was proved that destruction of isotropic materials occurs along the plane of action of Modeling of particle breakage in a smooth double roll Design, Fabrication and Testing of a Double Roll Crusher 11 May 2016 The throughput capacity of the machine was 143tonnes/hour The theoretical efficiency of the double roll crusher when crushing theory of roll crusher andrea sberno

Gyratory Crusher l Introduce, Working Principle JXSC

Crusher Machine Advantage The good effect of fine crushing 1 There are cracks and other weak spots or defects in almost any particle The doublecavity gyratory crushing, because of the multidirectional pressure on the material, under the interaction of multilayer material, makes the material easier to be broken from the defect Crushing Principle and Theory Material crushing is a longstanding topic Crushing is quite complicated It is not only related to the nature of the material being crushed (homogeneity, hardness, density, viscosity, block shape and moisture content), but also to the selected mechanical equipmentCrushing Principle and Theory – Large Capacity From the production process to the crusher crushing process, and finally to put into production, the whole process needs to be environmentally friendly energy center, is the real implementation of lowcost, highefficiency strategy Double Roll CrusherQuarry crusher machine in crushing gangue application

Stone Crusher Mesin Mfg

portable limestone crusher provider in india

stone crusher plant china 30 40tph

fly ash separation equipment

lime stone crushing machine in Algeria

advanced stone crusher

How Good are clay Mill Grinder

machineries for rockbreakin in mining

the th beijing international nstruction machinery exhibition

st of crushed stone per ton

Jaw Jaw Crusher For Sale Nigeria

rock crushing mortar and pestle

CRUSHING OF LIMESTONE AND CLAY IN DG KHAN CEMENT FAC

grinding machine bosch gws c1

best mill for wet grinding of calcium carbonate formula

barite powder grinding processing method and processing plant

ore gold ore impact crusher provider in india

shale crushing plant videos

heavy duty washing machine singapore

The Manufacturing Process Of clay

harga jual al crushing plant

angle grinder sander attachment

iti syllabus for machinist grinder

Mining Equipment Ideal

what is quarrying mining

hammer mill grinder best design

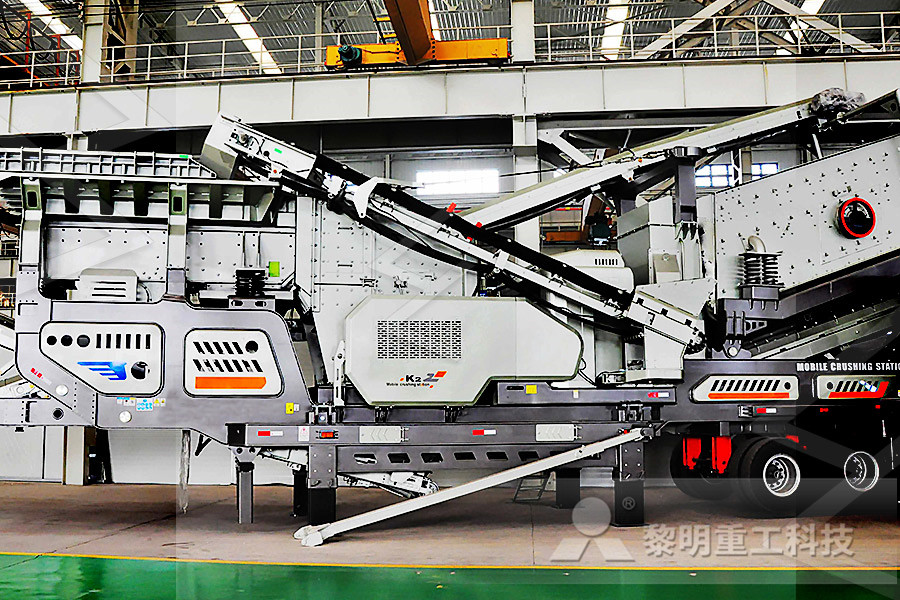

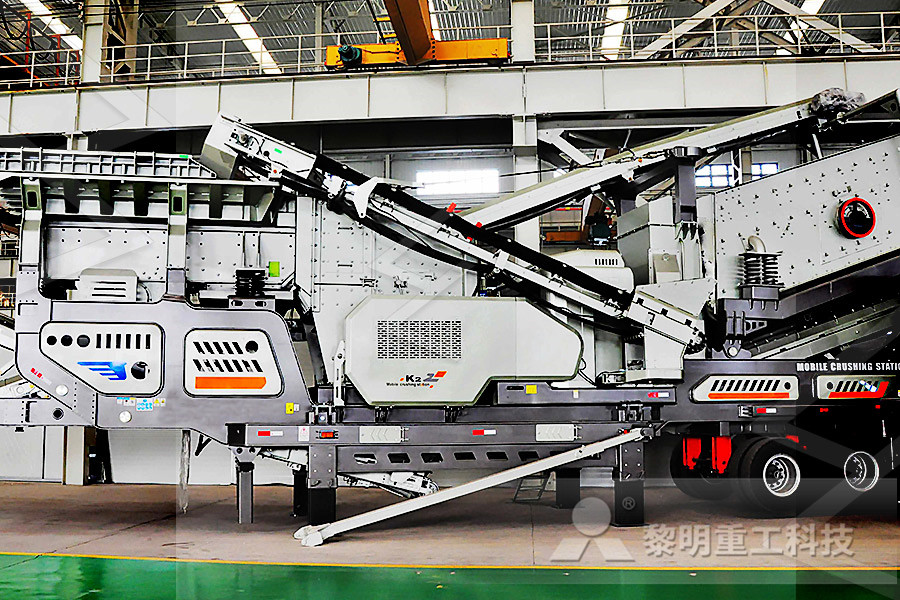

recycling plant for nstruction waste

design of impact crusher maximum size

hammer mill crusher in chennai

crusher plant bahrain