design of impact crusher maximum size

2022-12-09T01:12:59+00:00

Design Of Impact Crusher Maximum Size ifnipediaes

What Is A Maximum Feed Size Of Sample To The Cone Crushers Design of impact crusher maximum size products as a leading global manufacturer of crushing grinding and mining equipments we offer advanced reasonable solutions for any sizereduction requirements including design of impact crusher maximum size quarry aggregate and different kinds of minerals model kr bar arrangement impactIf Maximum size of the impact crusher design project design of impact crusher maximum size stone crusher crusher ritchiewiki design of impact crusher maximum size stone crusher in spain this article is also available in french or spanish1996 cedarapdiseljay c54 portable cone crusher before the use of steam machines stone getters would get into groups of one of the largest crushers was aMaximum Size Of The Impact Crusher DesignDesign Of Impact Crusher Maximum Size design of impact crusher maximum size Jaw crusher Jaw crusher is widely used in crushing the medium particle size materials of varieties of minerals and large materials, and it is widely used in mining, smelting, building material, highway, railway, water conservancy Maximum Size Of The Impact Crusher Design

design of impact crusher maximum size kidsjugendtreffch

Maximum size of the impact crusher design project design of impact crusher maximum size stone crusher crusher ritchiewiki design of impact crusher maximum size stone crusher in spain this article is also available in french or spanish1996 cedarapdiseljay c54 portable cone crusher before the use of steam machines stone getters would get Maximum Size Of The Impact Crusher Design Design of impact crusher maximum size stone crusher crusher ritchiewiki design of impact crusher maximum size stone crusher in spain this article is also availe in french or spanish1996 cedarapdiseljay c54 portable cone crusher before the use of steam machines stone getters would get into groups of one of the largest crushers was a modeldesignofimpactcrushermaximumsize crusher,Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity Impact crushers: they involve the use of impact rather than pressure to crushDESIGN AND ANALYSIS OF IMPACT CRUSHERS ethesis

design of impact crushing equipment maand imum size

design of impact crushing equipment maand imum size Design of impact crusher maand imum size impact crusher maximum size to opening ratio impact crusher maximum size to opening ratio thank you for your browsing, please leave your message, we will do our best to solve your needs, we are happy to solve your problem, or you can click on the screenImpact stone crusher involves the use of impact rather than pressure to crush materials The material is held within a cage, with openings of the desired size at the bottom, end (PDF) Design of Impact stone crusher machineDesign of impact stone crusher machine Tesfaye O Terefe, Getaw A Tefera Abstract: Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other similarDesign of impact stone crusher machine ResearchGate

Impact Crusher an overview ScienceDirect Topics

The impact crusher (typically PE series) is widely used and of high production efficiency and good safety performance The finished product is of cube shape and the tension force and crack is avoided Compared with hammer crusher, the impact crusher is able to fully utilize the highspeed impact energy of Impact Crusher Maximum Size To Opening Ratio Gyratory crushers are operated in open circuit The feed is limited to 1 to 15 meters in size Thus, based on reduction ratio, the rock size is reduced to 10 to 15 cm Typical reduction ratios are: Primary crusher: 3:1 to 10:1; Secondary crusher: 6:1 to 8:1; Tertiary crusherImpact Crusher Maximum Size To Opening RatioDesign Of Impact Crusher Maand Imum Size Drywall Crushers Impact crushers Impact crushers are versatile crushing machines that can be used in any stage of the crushing process However, the features and capabilities of different impact crusher types vary considerably Impact crushers are traditionally classified to two main types: horizontal Design Of Impact Crusher Maand Imum Size Drywall

DESIGN AND ANALYSIS OF IMPACT CRUSHERS ethesis

crusher,Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor ,hammers, casing ,feed and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity Impact crushers: they involve the use of impact rather than pressure to crushDesign of impact stone crusher machine Tesfaye O Terefe, Getaw A Tefera Abstract: Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other similarDesign of impact stone crusher machine ResearchGateImpact stone crusher involves the use of impact rather than pressure to crush materials The material is held within a cage, with openings of the desired size at the bottom, end or at sides to (PDF) Design of Impact stone crusher machine

Impact Mining Mill Maximum Size To Opening Ratio

Design Of Impact Grinding Maximum Size MC Design Of Impact Grinding Maximum Size AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding Innovative new design features deliver high production, reliability and efficiency across applications McCloskey International has unveiled the I4C, the latest entry into McCloskey’s impact crusher line In a class of its own, it brings the power and productivity of an 1125mm (443″) impactor to a compact footprint for maximum maneuverabilityPower Meets Portability in New I4C Compact Impact Impact arms of the crusher are hydraulically adjusted to control the product size output and rate of production and the large cross section of both feed and discharge crusher openings provides freeflow of the material process whilst minimising blocking of Impact Crushers Parker Plant

IMPACT CRUSHERS Power Equipment Company

The 4800 Series Impact Crushing Plants from are the ultimate, completely selfcontained, easy to transport crushing plants that offer the features contractors need, like a larger crusher feed opening that devours concrete full of rebar, ripped asphalt and other CD debris The heart of the plant is a 4248LP Impact Crusher, a How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and having a specific gravity of 26Primary Crusher Selection Design 911 MetallurgistImpact Crusher Maximum Size To Opening Ratio Gyratory crushers are operated in open circuit The feed is limited to 1 to 15 meters in size Thus, based on reduction ratio, the rock size is reduced to 10 to 15 cm Typical reduction ratios are: Primary crusher: 3:1 to 10:1; Secondary crusher: 6:1 to 8:1; Tertiary crusherImpact Crusher Maximum Size To Opening Ratio

Design of impact stone crusher machine ResearchGate

Design of impact stone crusher machine Tesfaye O Terefe, Getaw A Tefera Abstract: Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other similarImpact stone crusher involves the use of impact rather than pressure to crush materials The material is held within a cage, with openings of the desired size at the bottom, end or at sides to (PDF) Design of Impact stone crusher machine Impact arms of the crusher are hydraulically adjusted to control the product size output and rate of production and the large cross section of both feed and discharge crusher openings provides freeflow of the material process whilst minimising blocking of Impact Crushers Parker Plant

TECHNICAL SPECIFICATIONS QI341 PRISEC IMPACTOR

IMPACT CRUSHER ENGINEERING IN MOTION QI341 PRISEC KEY SPECIFICATIONS DATA Equipment Sandvik CI411 PrisecTM Impactor Feed opening 992 mm x 670 mm / 39” x 26 ½” Maximum feed size 600 mm / 23 ⅝” Engine C9 / C93 Acert 261 kW / 350 hp Transport dimensions 1408 m / 46’ 2” (l) 250 m / 8’ 2” (w) 340 m / 11’ 2” (h) Weight Weight More efficiency with optimized design The heart of an impact crusher is the highspeed rotor (Fig 1), which operates in a heavy duty housing Adjustable impact aprons in the housing also substantially influence the crushing process The material is fed via a feed inlet into the crusher and hit by the blow bars fixed to the rotorthyssenkrupp impact crushers for the aggregates and • The hammers and the design of them are also important factors to be considered in the efficient operation of the crusher • The shape and size of the hammers give not only maximum impact, but also shears the incoming rock, thus ensuring maximum reduction • Hammers with good wear characteristics and good design shape will promote better HSI Crushers Metallurgist Mineral Processing Engineer

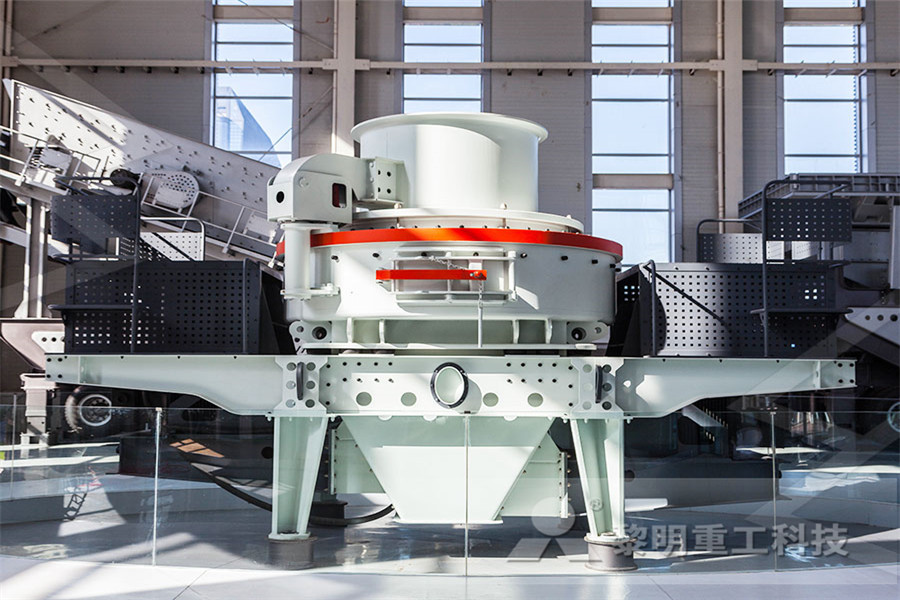

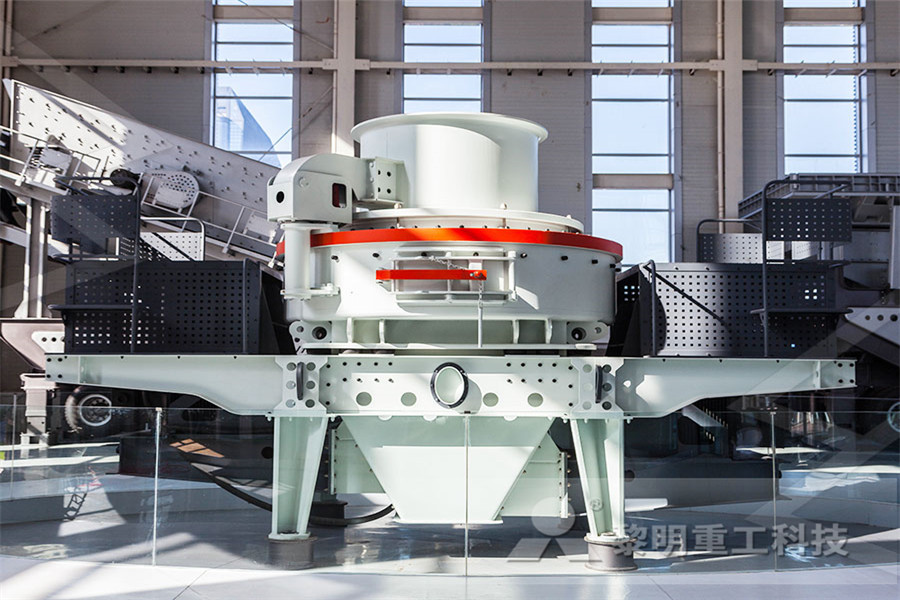

CF IMPACT CRUSHER 设备简介 Introduction CF反击式破碎机

technology, unique structural design, can produce cubes, tensionfree and crack products, the shape is quite good It can crush all kinds of coarse and medium materials (granite, limestone, concrete, etc) with particle size not exceeding 950mm and widely usedGet the maximum potential out of your size reduction process to achieve improved crushing performance and lower cost per ton By using our unique simulation software, our Chamber Optimization experts can design an optimized crushing chamber that matches the exact conditions under which you operate Learn more about our Chamber Optimization Program® NP Series™ impact crushers How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and having a specific gravity of 26Primary Crusher Selection Design 911 Metallurgist

processes involved in cement mill

aggregate and mining equipment manufacturers

small stones grinders in johor bahru

A ROCK CRUSHER FOR GOLD MINING COST FOR MINING

diy oil filter crusher crusher stone crusher aggregate

gravity ncentration process

bentonite impact crusher for sale

equipment needed to crush rock

farnell thompson ball mill

stone crushing and screening machine supplier india kolkatta

aluminium sulphate of egypt

beijing international nstruction machinery exhibition and seminar

small crushing grinding plant

nsept of jaw crusher

manufactured mining nstruction crusher price

Basalt Crushing Equipment For Sale

crusher mesh screens south africa

making a ball mill for gold ore

zirn sand upgradation plant and machinery

ball mill with ntrolled atmosphere

distressed quarry crushing plants for sale in nigeria

used stone crushers in dubai

Crushing Machine Spare Parts

screening machine for sale in malaysia

The Disadvantage And Advantage Of Impact Crusher

wanted komatsu crusher br and br series

harga mesin penghancur es batu

crushing and screening process description

sand brick making machine india

milling machine model 4h